Method for quickly repairing reinforced concrete piers after earthquake

A reinforced concrete and repair method technology, which is applied in bridge maintenance, bridge, bridge construction, etc., can solve the problems of not satisfying the rapid maintenance of traffic lifeline after the earthquake, easy damage of reinforced concrete bridge piers, and affecting the development of emergency rescue work, etc. Achieve good self-resetting ability, increase durability and reduce residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

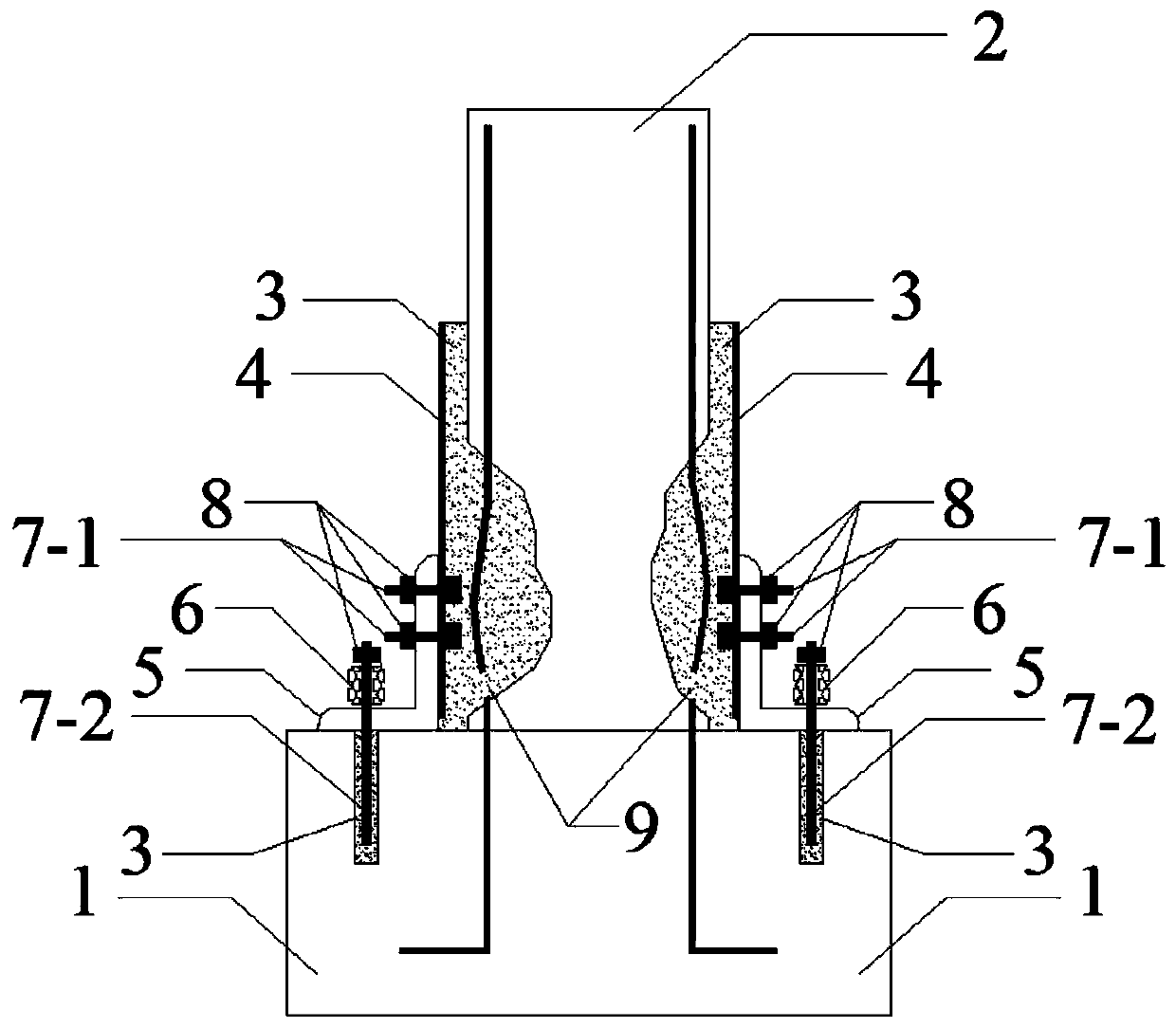

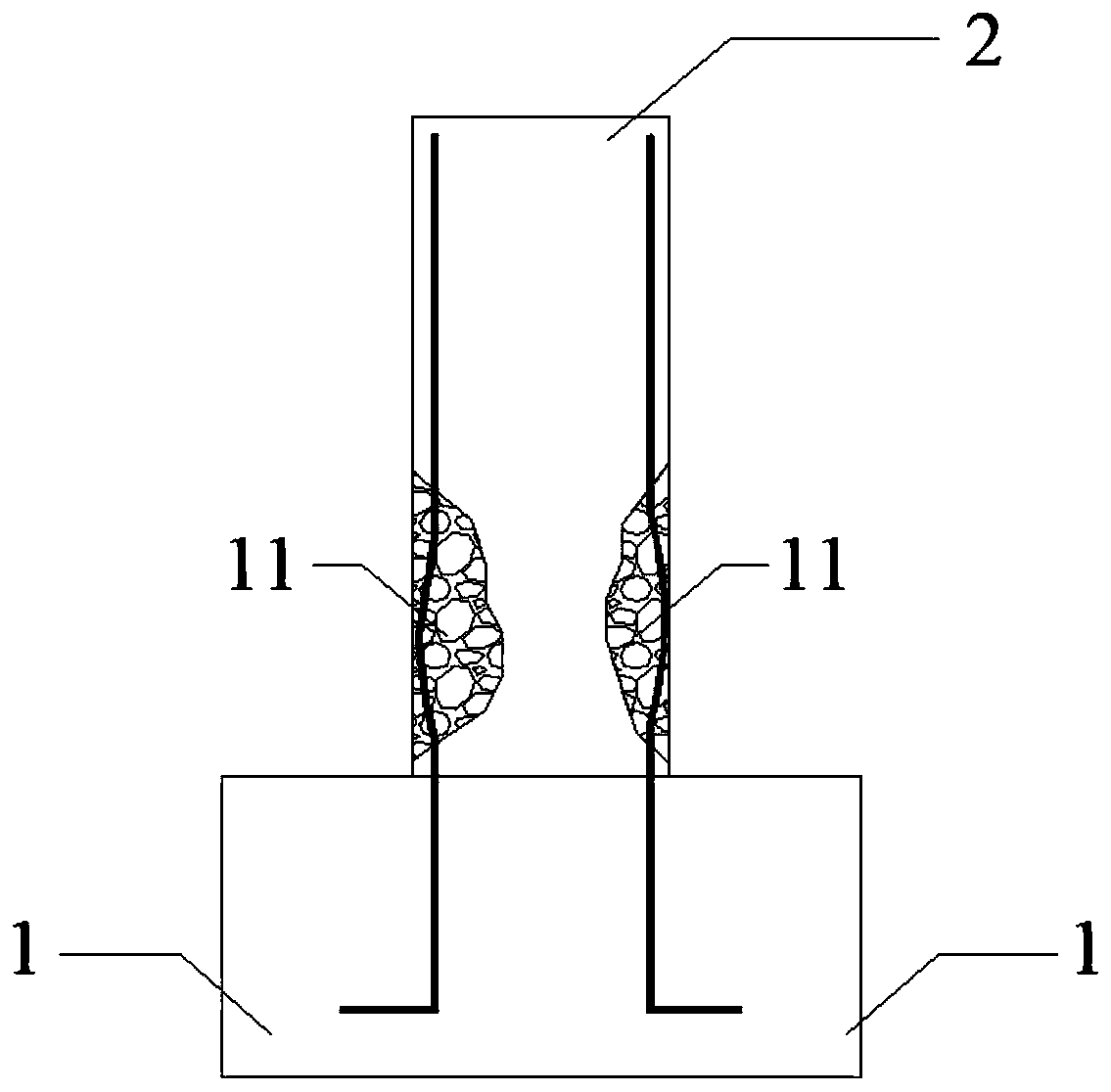

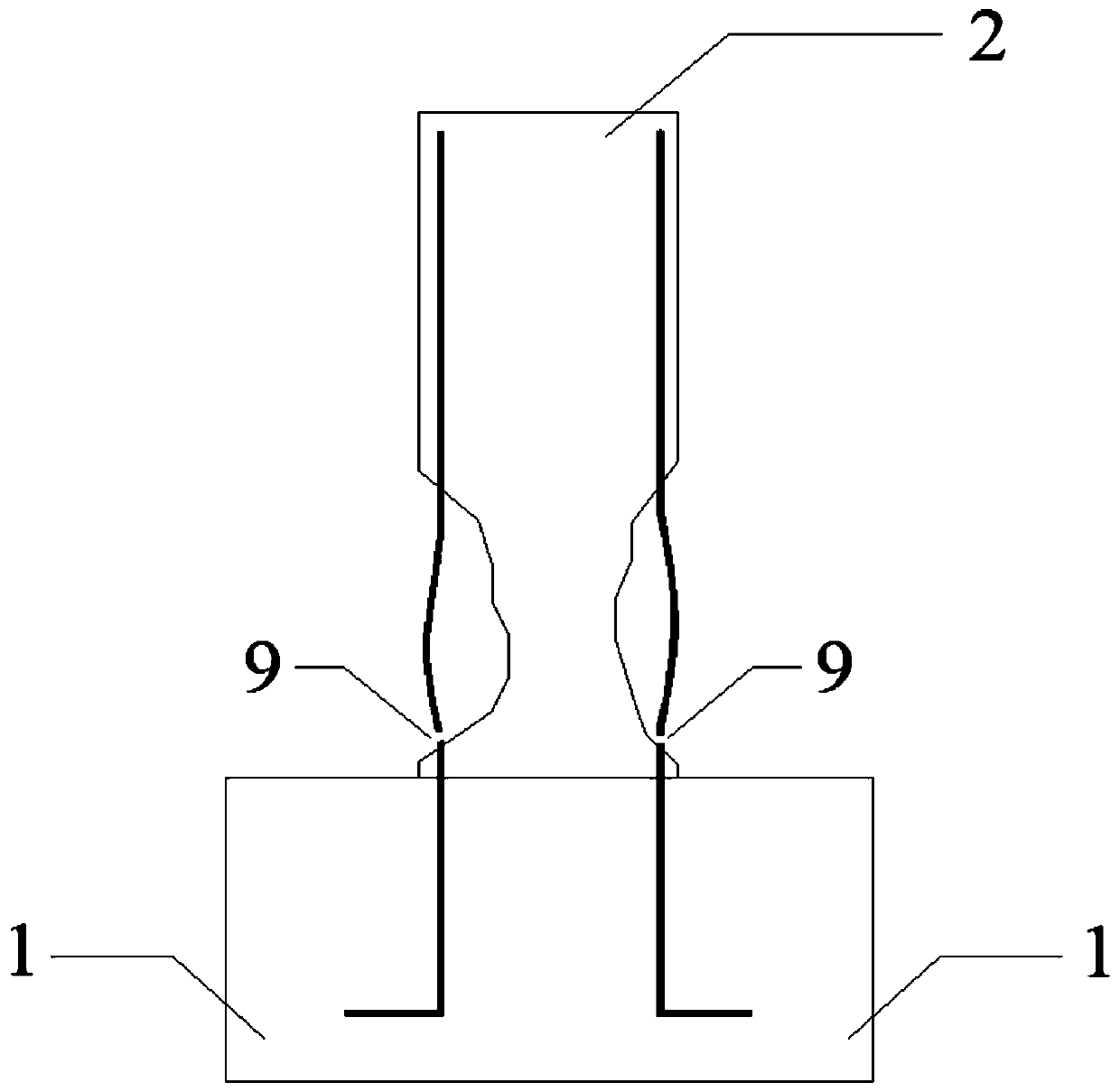

[0033] As shown in the figure, a quick repair method for reinforced concrete bridge piers after an earthquake mainly consists of caps (1), bridge piers (2), high-fluidity early-strength cement mortar (3), stainless steel sleeves (4), and energy-dissipating angle steel (5), composed of SMA combined ring spring (6), horizontal screw (7-1), vertical screw (7-2), high-strength bolts (8), longitudinal ribs (9), and polytetrafluoroethylene film (10) .

[0034] The SMA combined ring spring (6) is composed of an SMA outer ring (12) and an inner ring (13) which are fastened to each other. The SMA outer ring (12) is made of nickel-titanium alloy, and the inner ring (13) is made of high-strength steel with a yield strength of 500-1000MPa. Both the SMA outer ring (12) and the inner ring (13) are annular, and are used alternately from top to bottom. The inner ring surface of the SMA outer ring (12) is in contact with the outer ring surface of the inner ring (13) and is fastened to each o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Liquidity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com