Turning clamp and turning fixing method for thin-wall deforming part

A part and turning technology, which is applied in the field of aero-engine parts processing, can solve problems such as out-of-tolerance, inconsistency, and elastic deformation of the end face of the part, and achieve the effects of avoiding out-of-tolerance problems, preventing displacement, and reducing elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

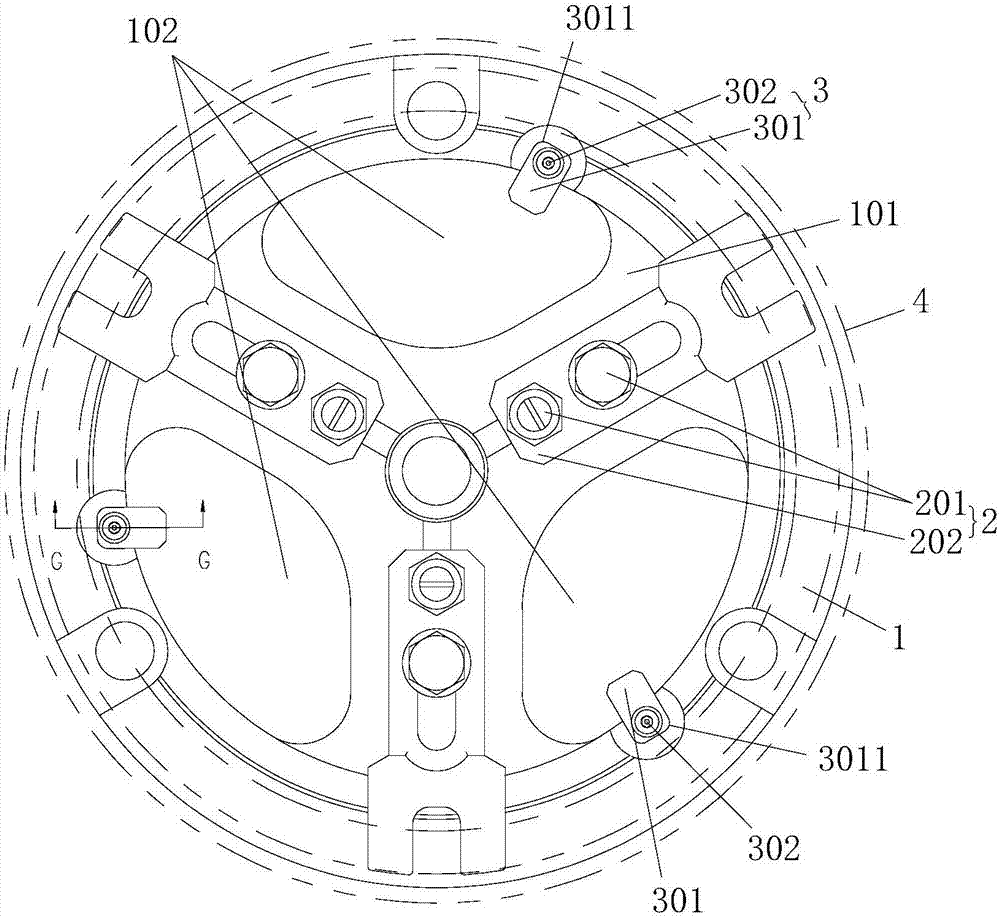

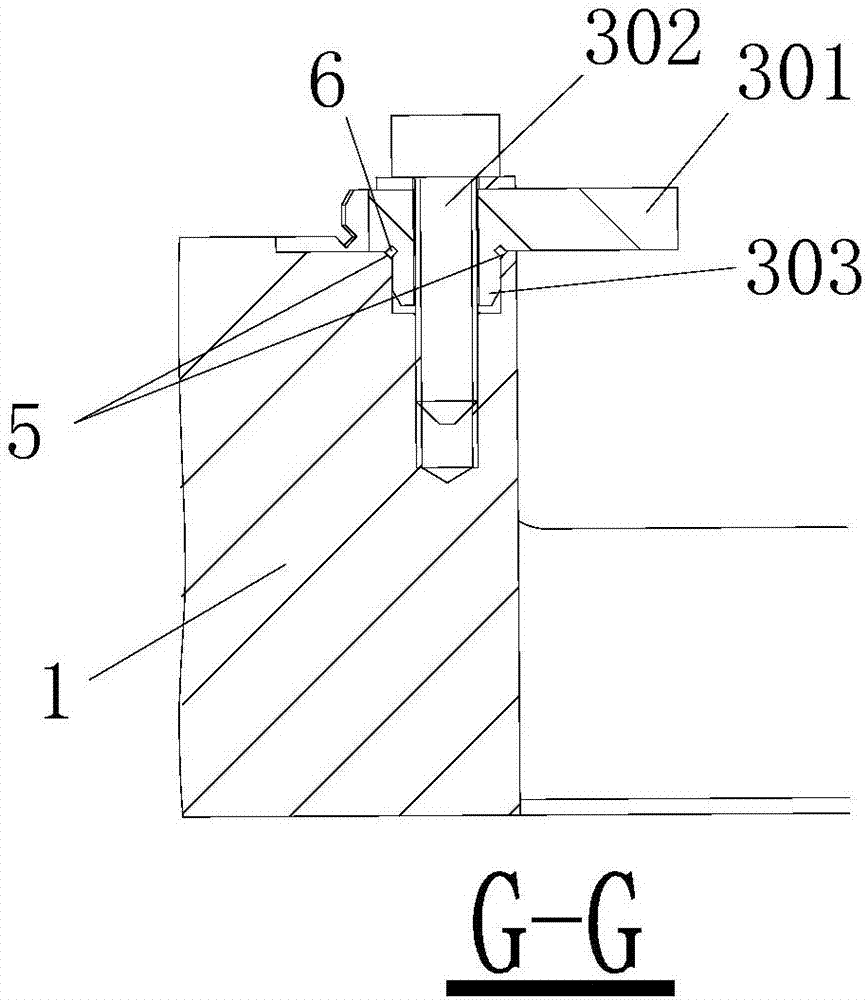

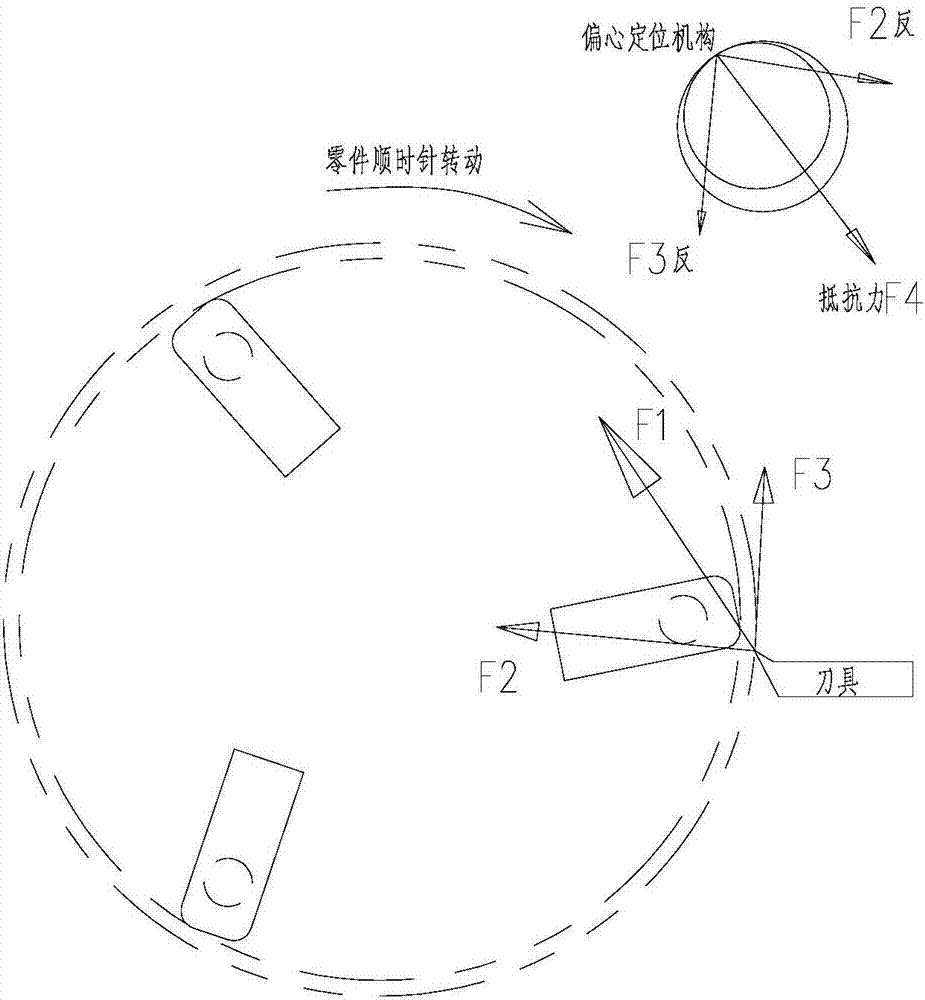

[0023] figure 1 It is a structural schematic diagram of the turning fixture of the thin-walled deformed parts in the preferred embodiment of the present invention; figure 2 yes figure 1 G-G sectional view of ; image 3 It is a force schematic diagram of the eccentric positioning mechanism of the preferred embodiment of the present invention.

[0024] Such as figure 1 As shown, the turning fixture of the thin-walled deformed part in this embodiment includes a base 1 for carrying the part 4 to be processed and assembled on the spindle of the machine tool to rotate with the spindle of the machine tool, and for pressing the part 4 to be processed on the base 1 The pressing mechanism 2, the base 1 is provided with multiple sets of eccentric assembly on the base 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com