Patents

Literature

96results about How to "Reduce elastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

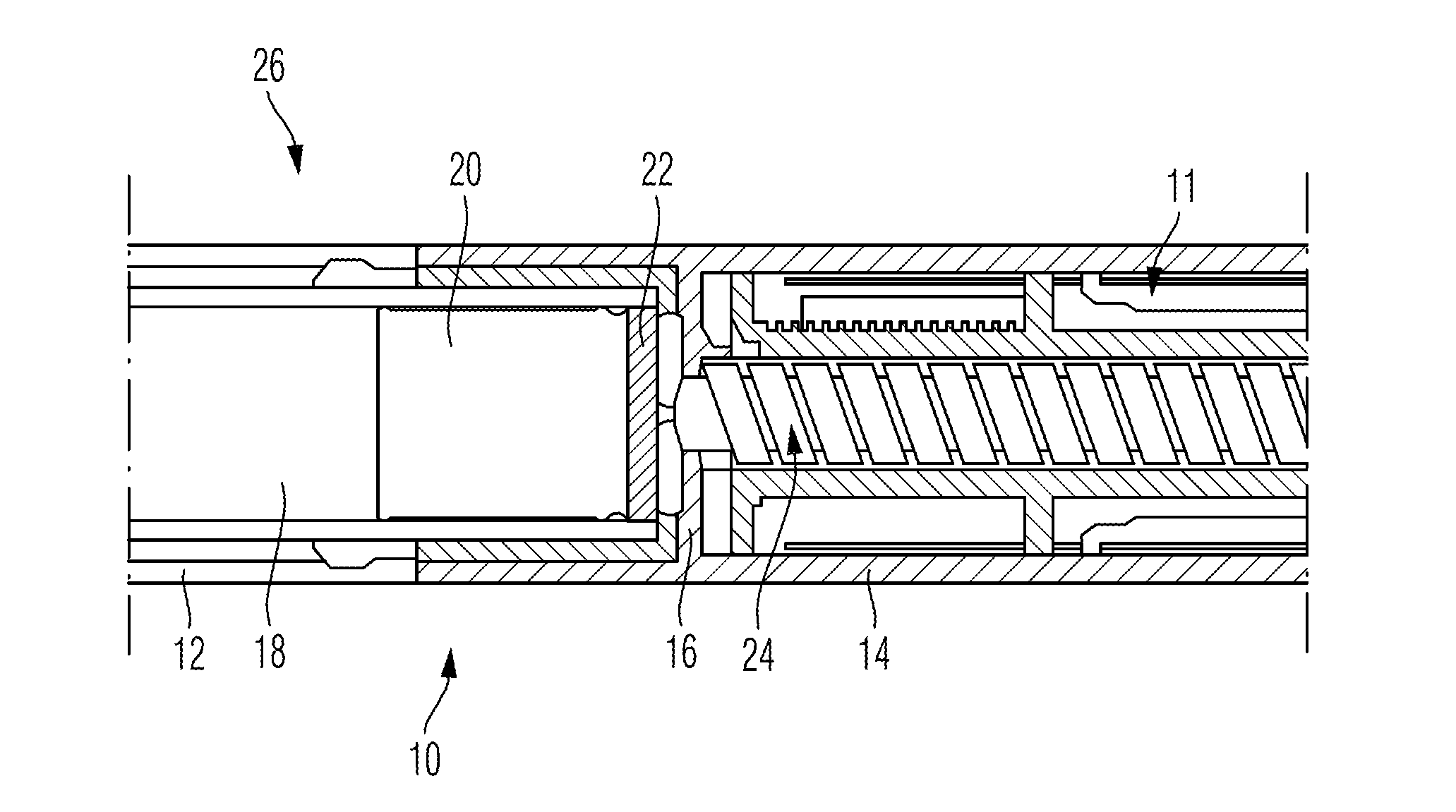

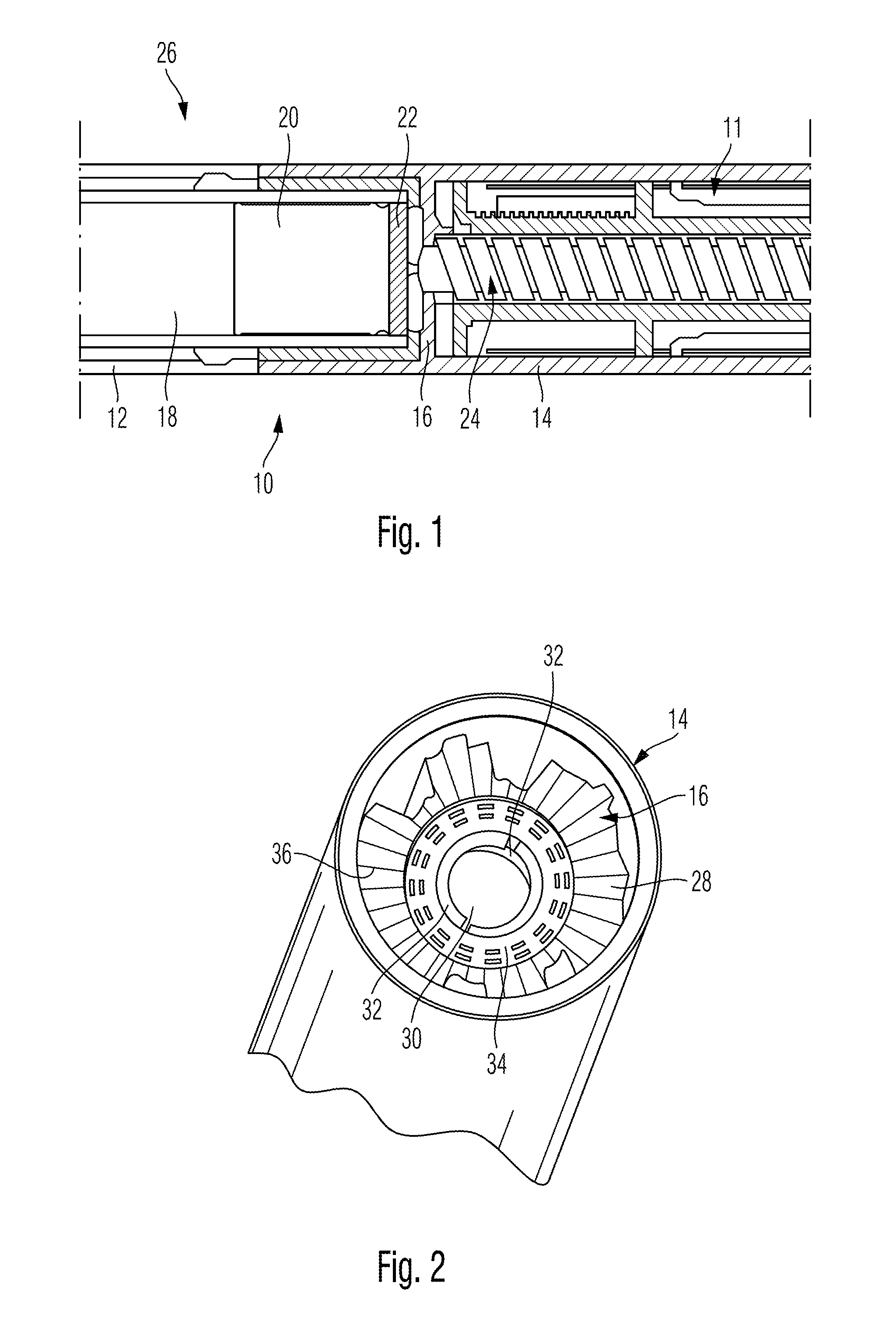

Housing Component for a Drug Delivery Device

ActiveUS20120265153A1Less-prone to mechanical and elastic deformationReduce generation and built-upAmpoule syringesIntravenous devicesPistonDrug delivery

The present invention relates to a housing component of a drug delivery device (10) to accommodate a drive mechanism (11), wherein the drive mechanism (11) is operable to interact with a piston (20) of a cartridge(16) containing a medicinal product to be dispensed by the drug delivery device. The housing component comprises at least one radially inwardly extending flange portion (16) to be operably engaged with a piston rod (24) of the drive mechanism (11), characterized in that the flange portion (16) is at least partially structurally strengthened.

Owner:SANOFI AVENTIS DEUTSCHLAND GMBH

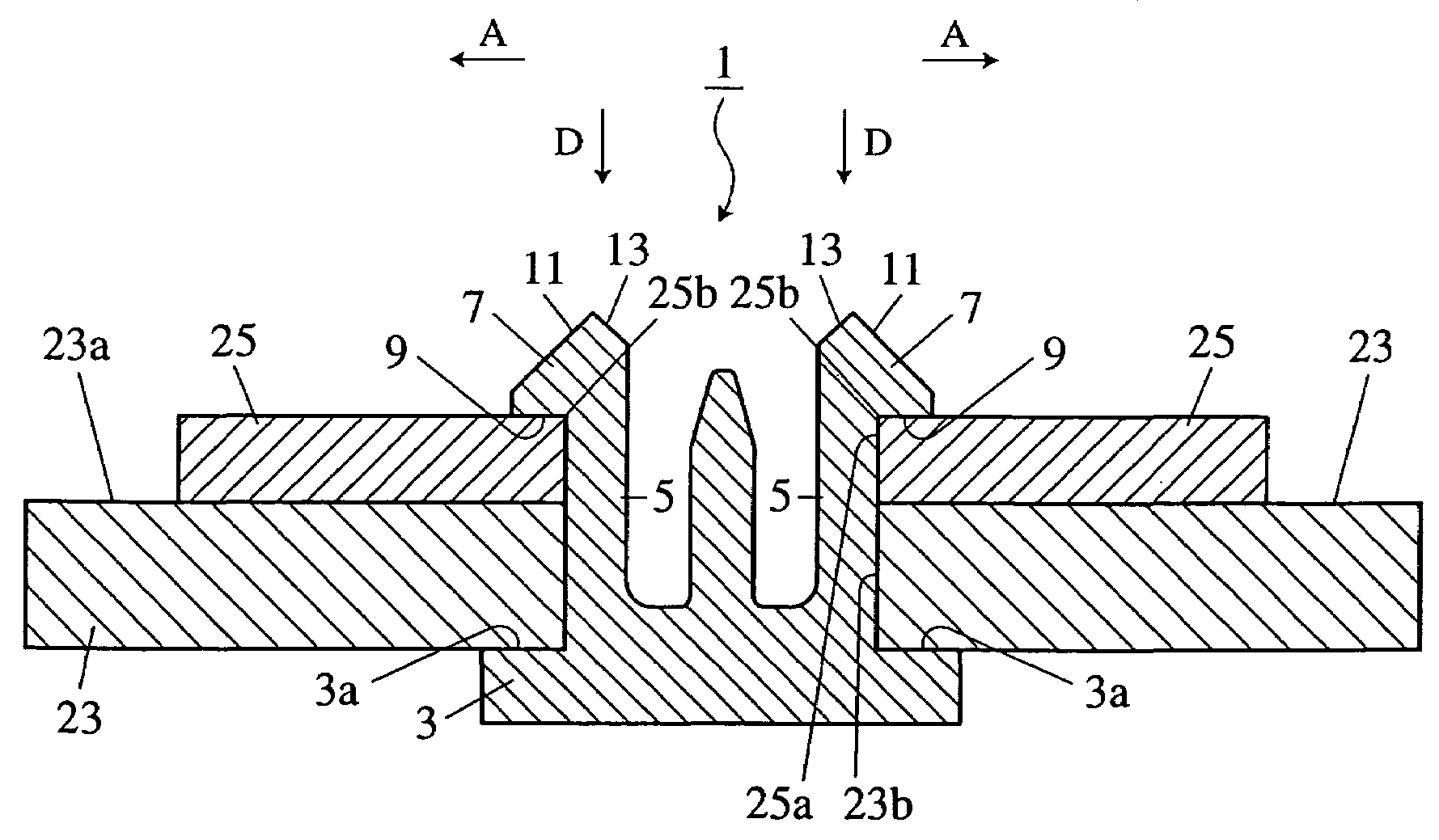

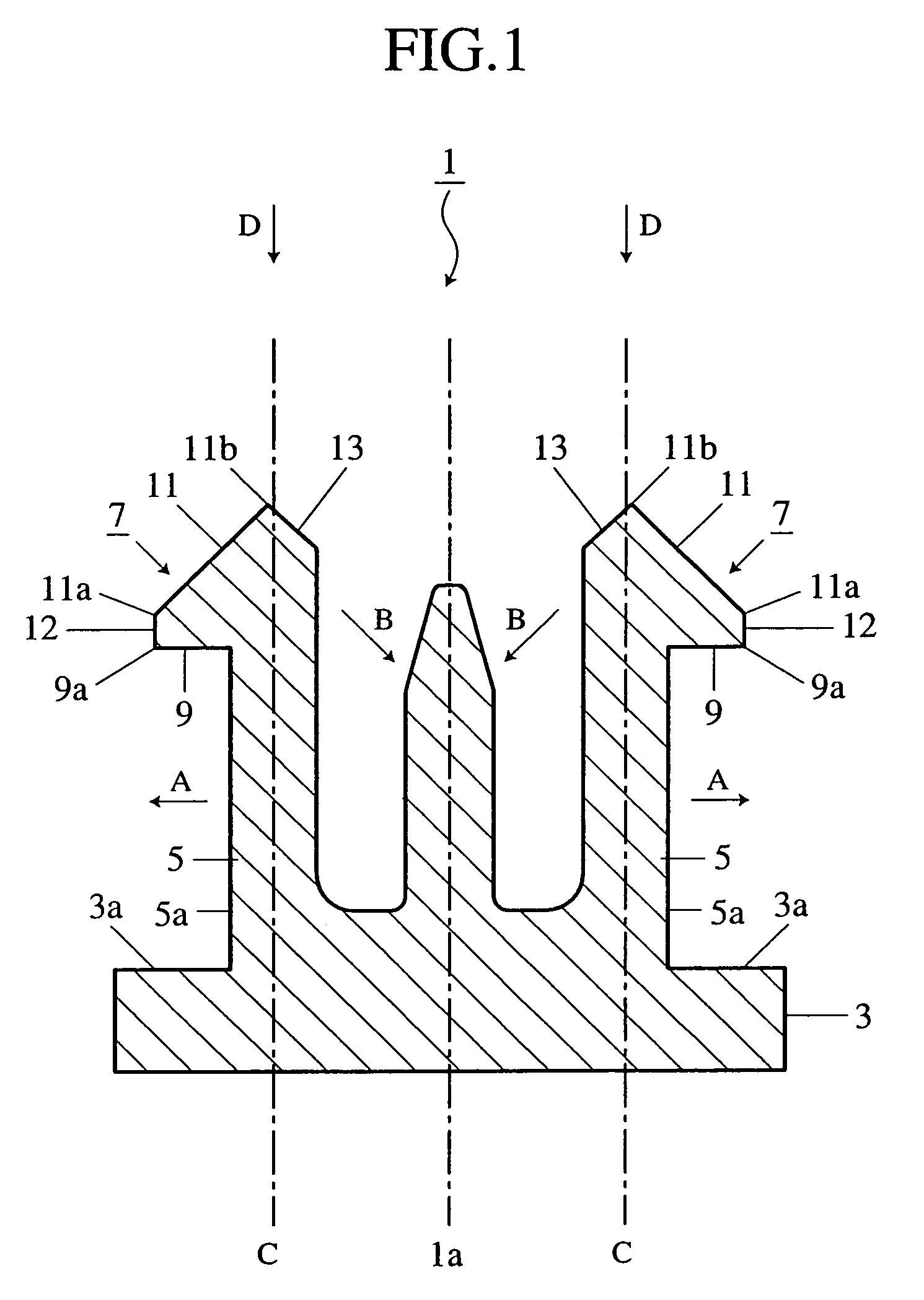

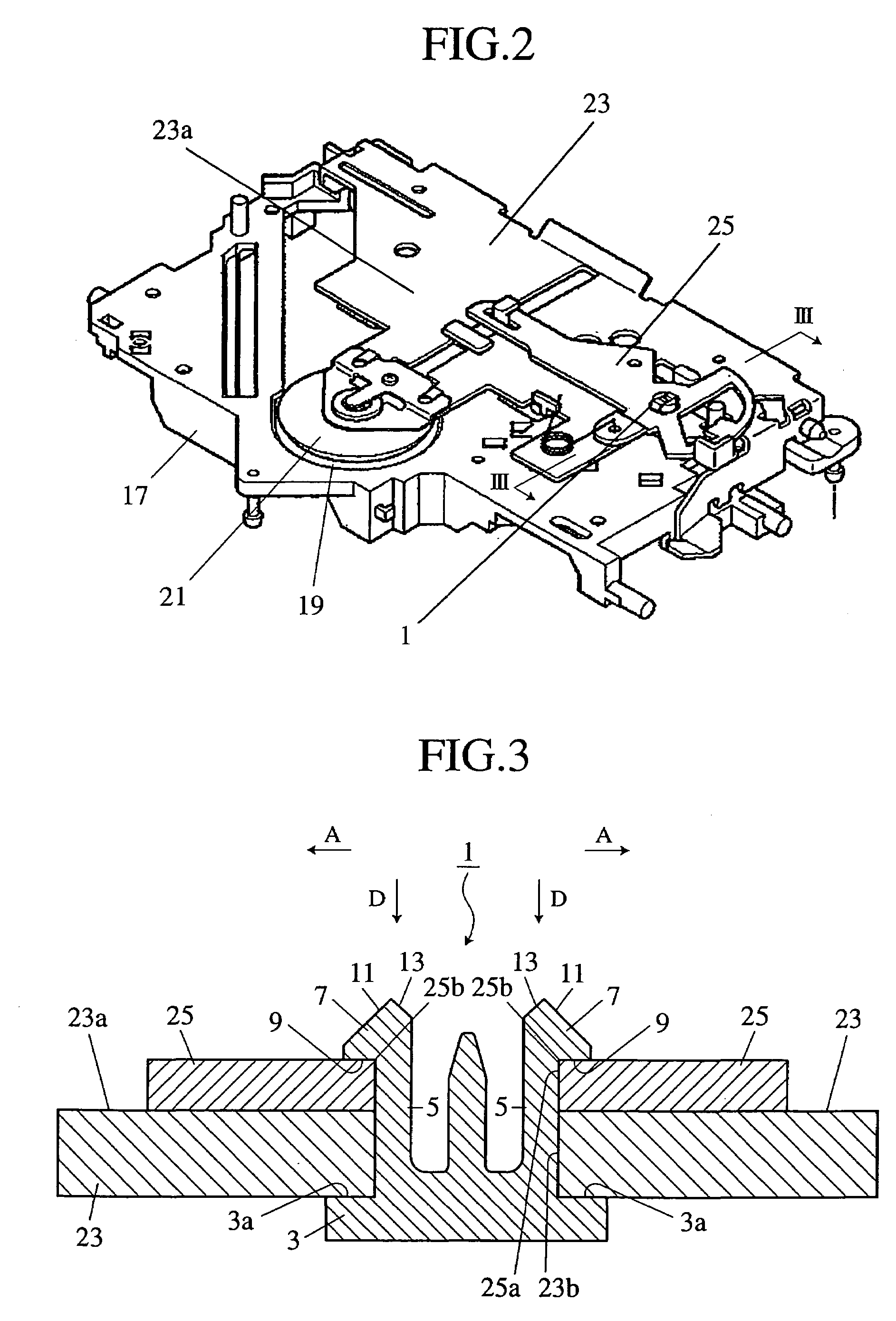

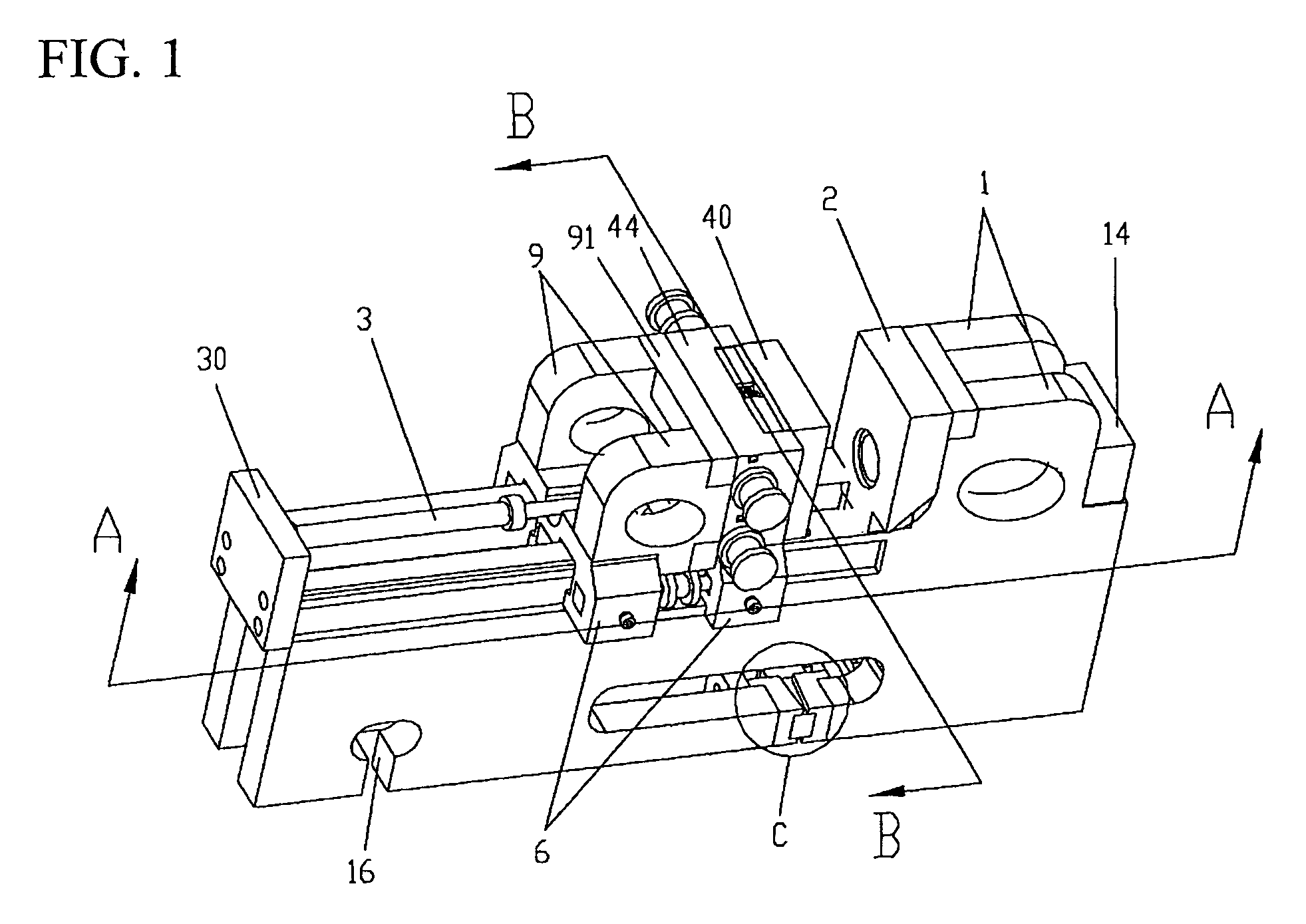

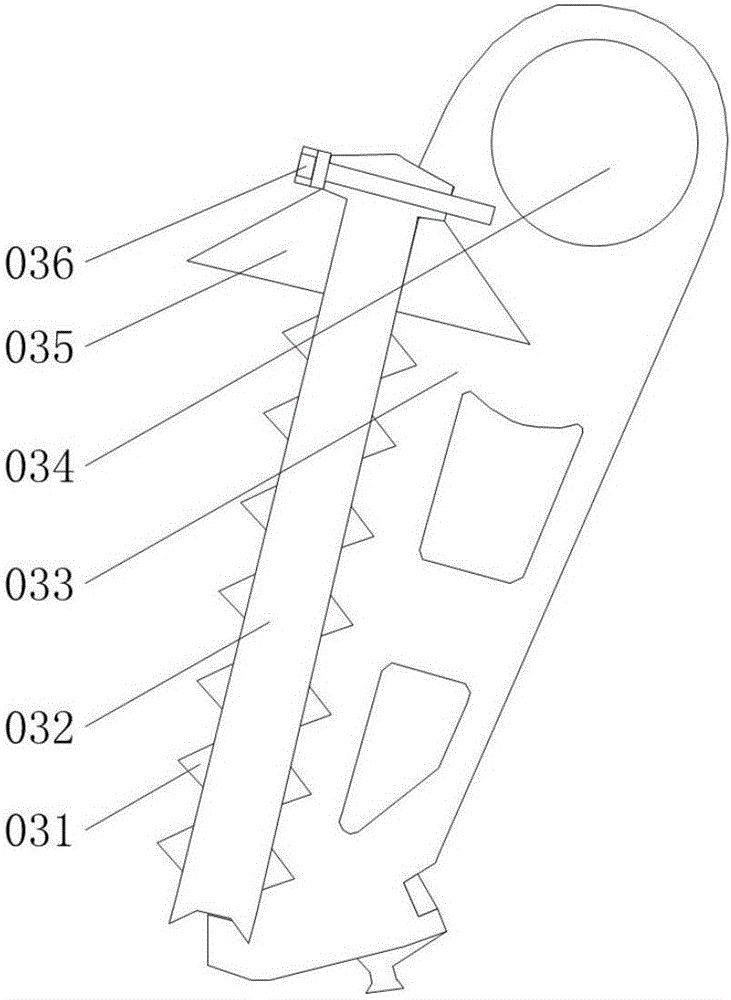

Snap fit mechanism

InactiveUS7082650B2Easy to engagePrevents an accidental disengagement thereofSnap fastenersSnap-action fastenersEngineeringTip of the tongue

A snap fit mechanism has an elastic tongue provided on a base of the mechanism. On the tip of the tongue is provided an engaging claw that has an engaging inclined face. A far end of the engaging inclined face from the base is arranged so as to be located between the outside face of the elastic tongue and the centerline C in a longitudinal direction of the elastic tongue. Further, on the tip of the elastic tongue is provided an engagement-maintaining inclined face which gives an outward load to the elastic tongue on receiving an accidental load thereon so as to reduce the inward elastic deformation of the elastic tongue, thereby preventing the accidental release of the engagement of the tongue.

Owner:MITSUBISHI ELECTRIC CORP

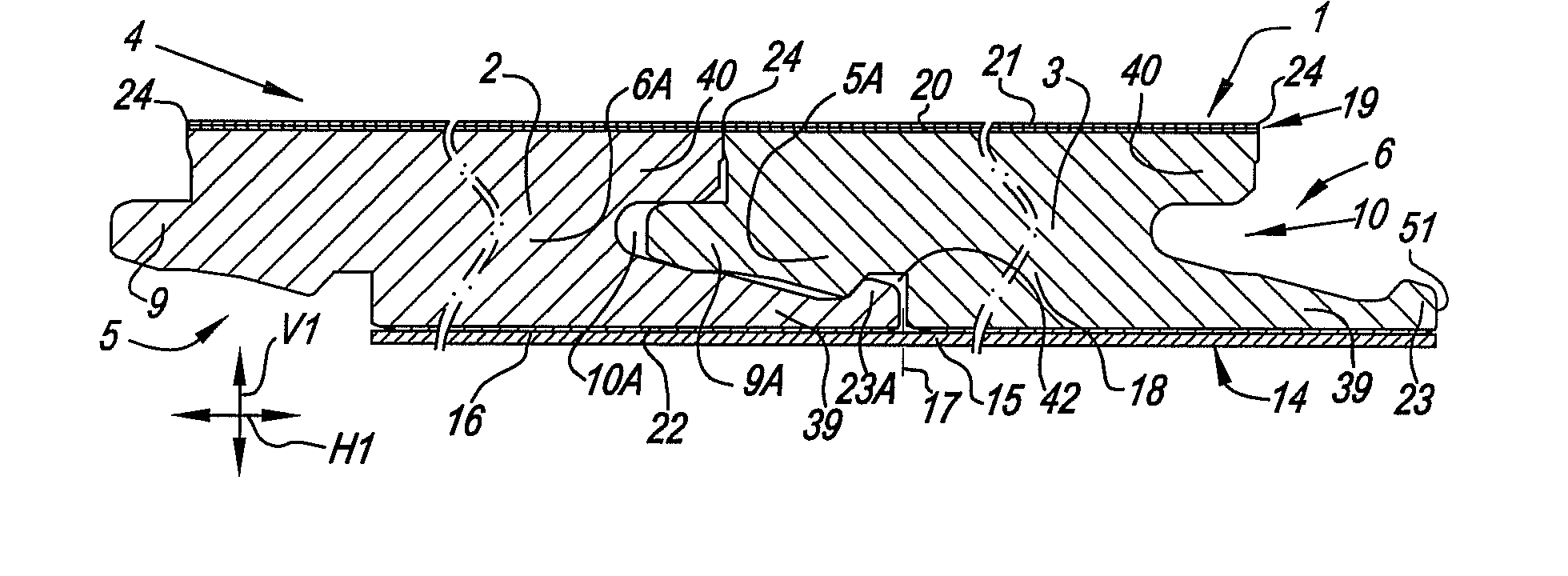

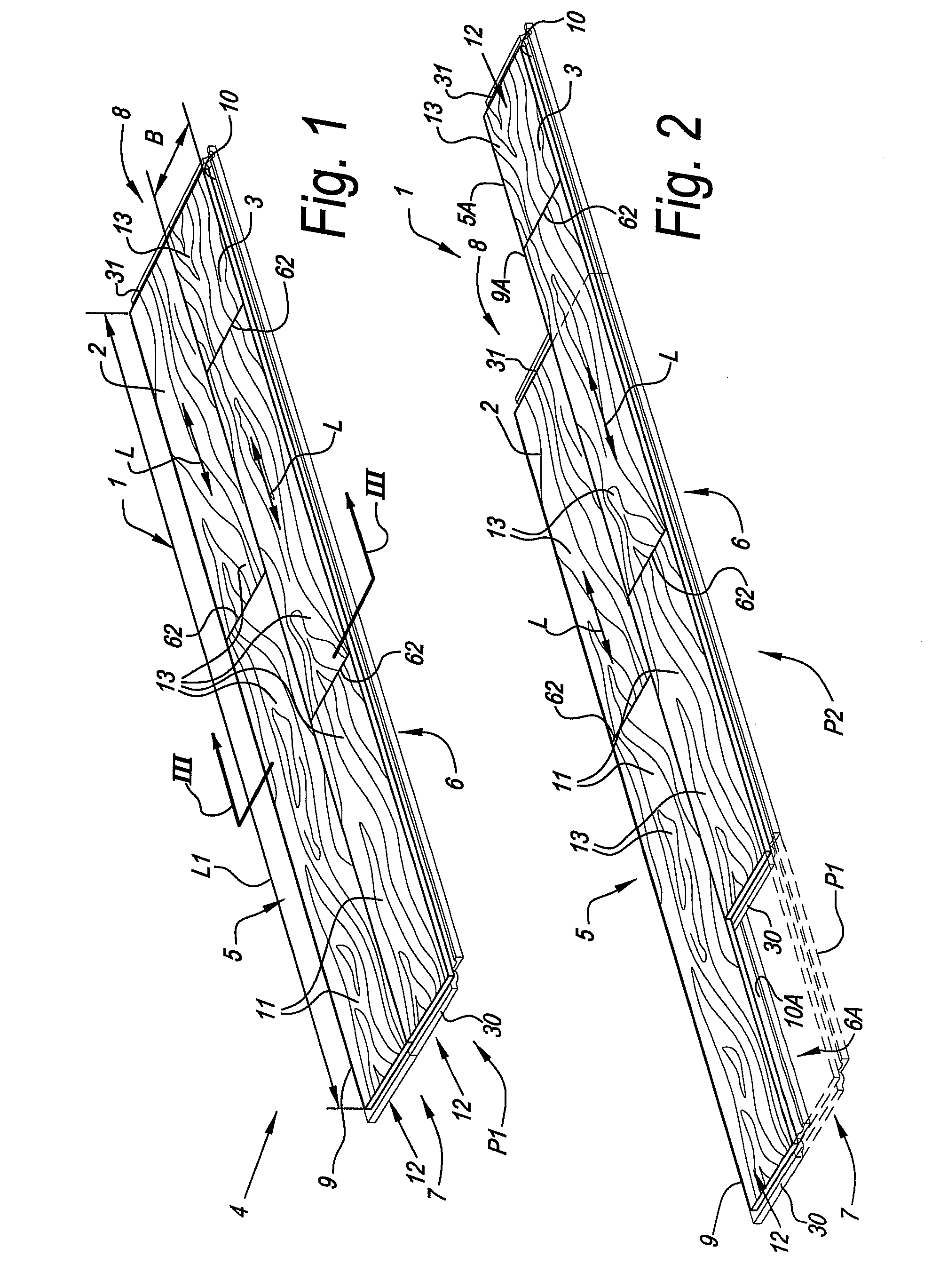

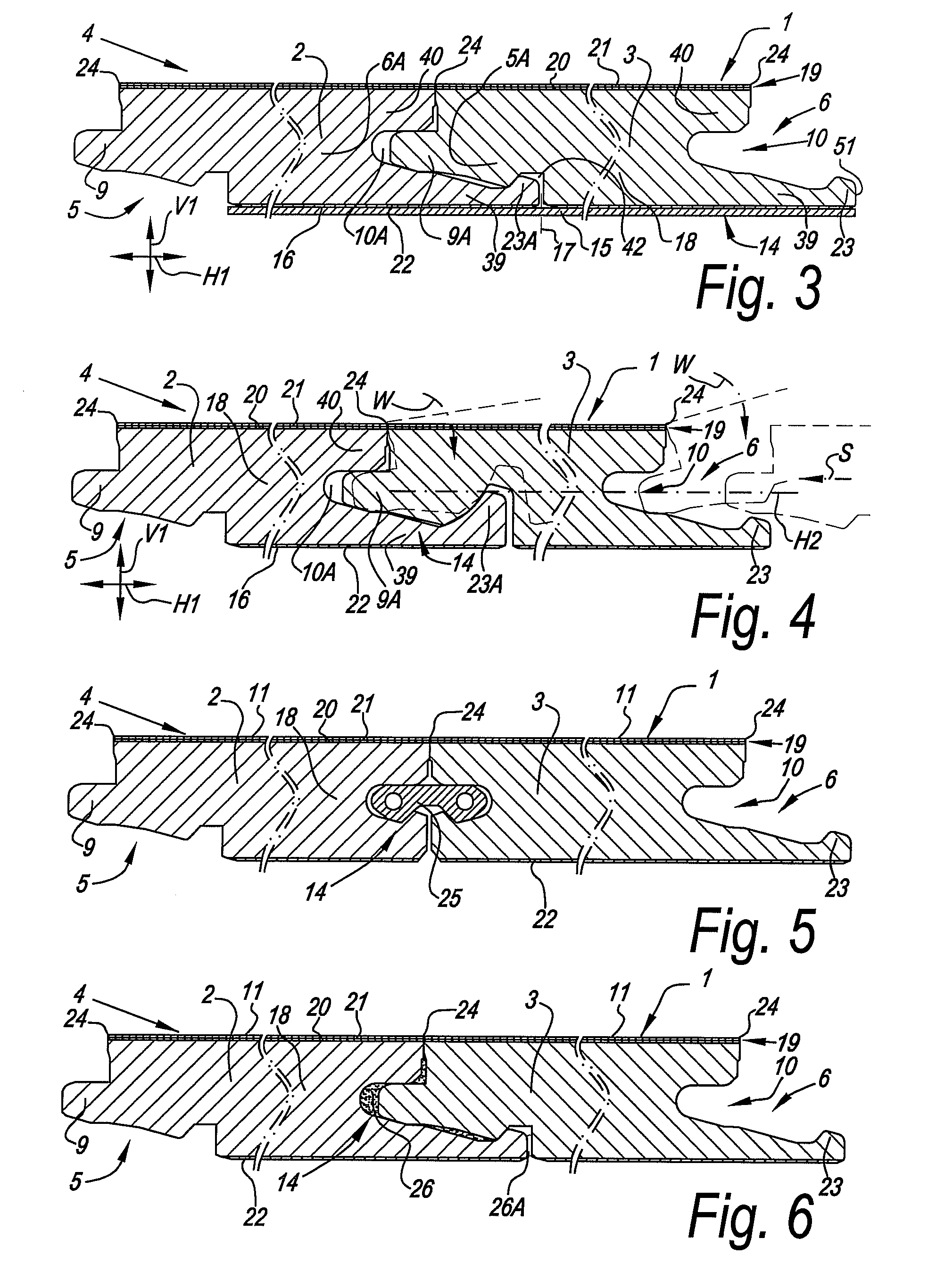

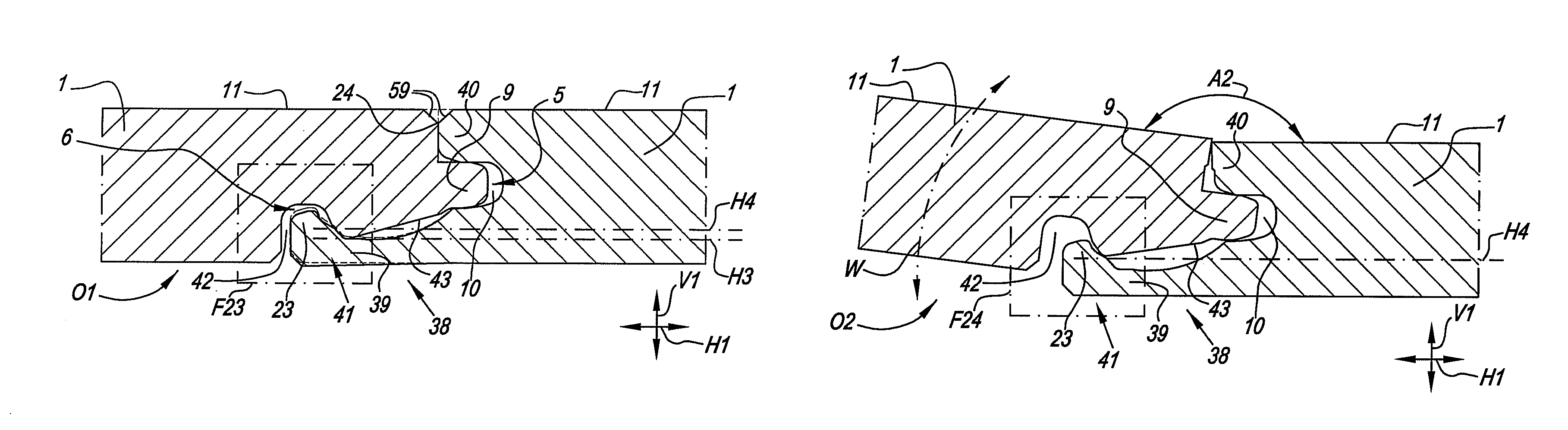

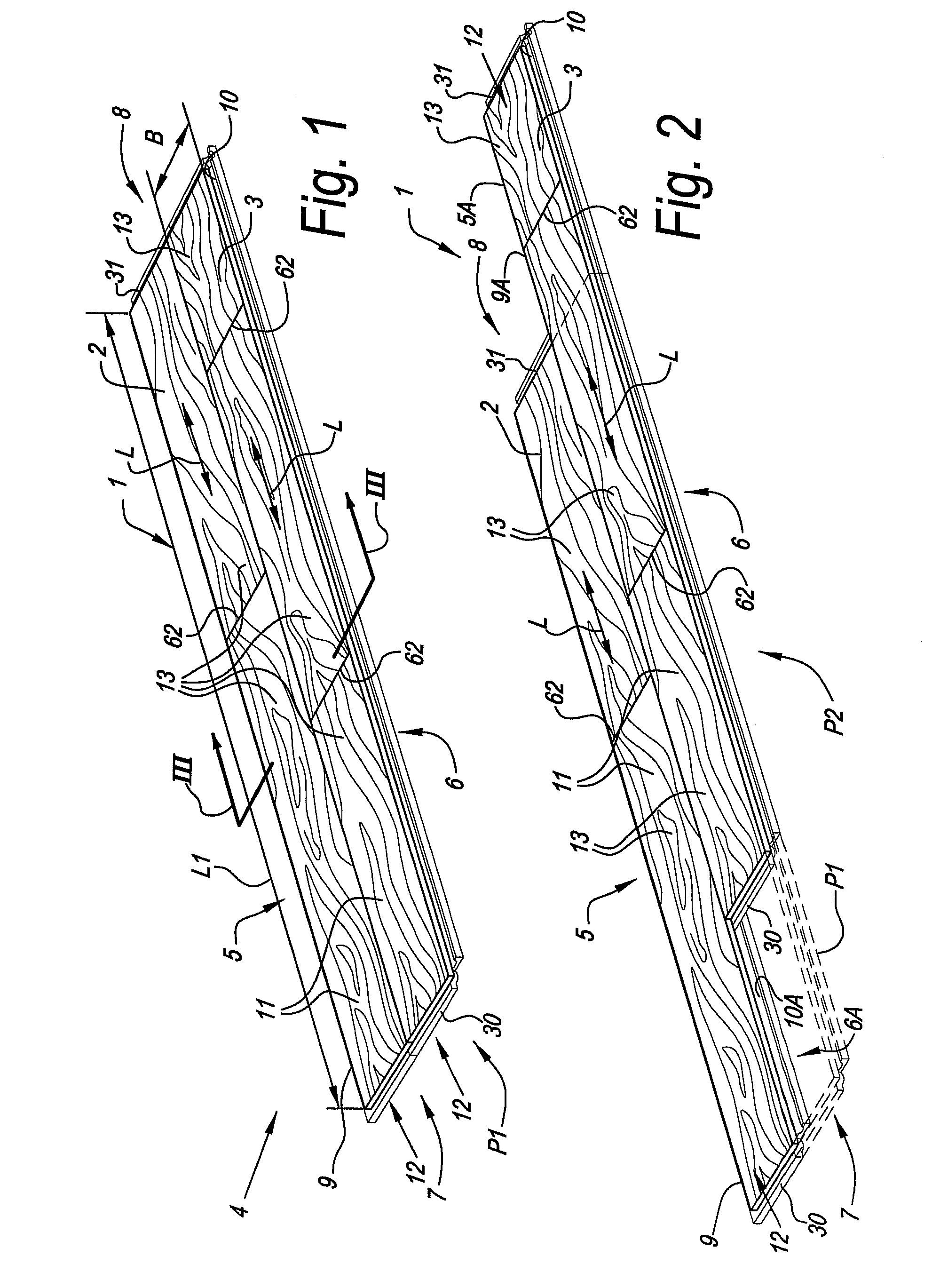

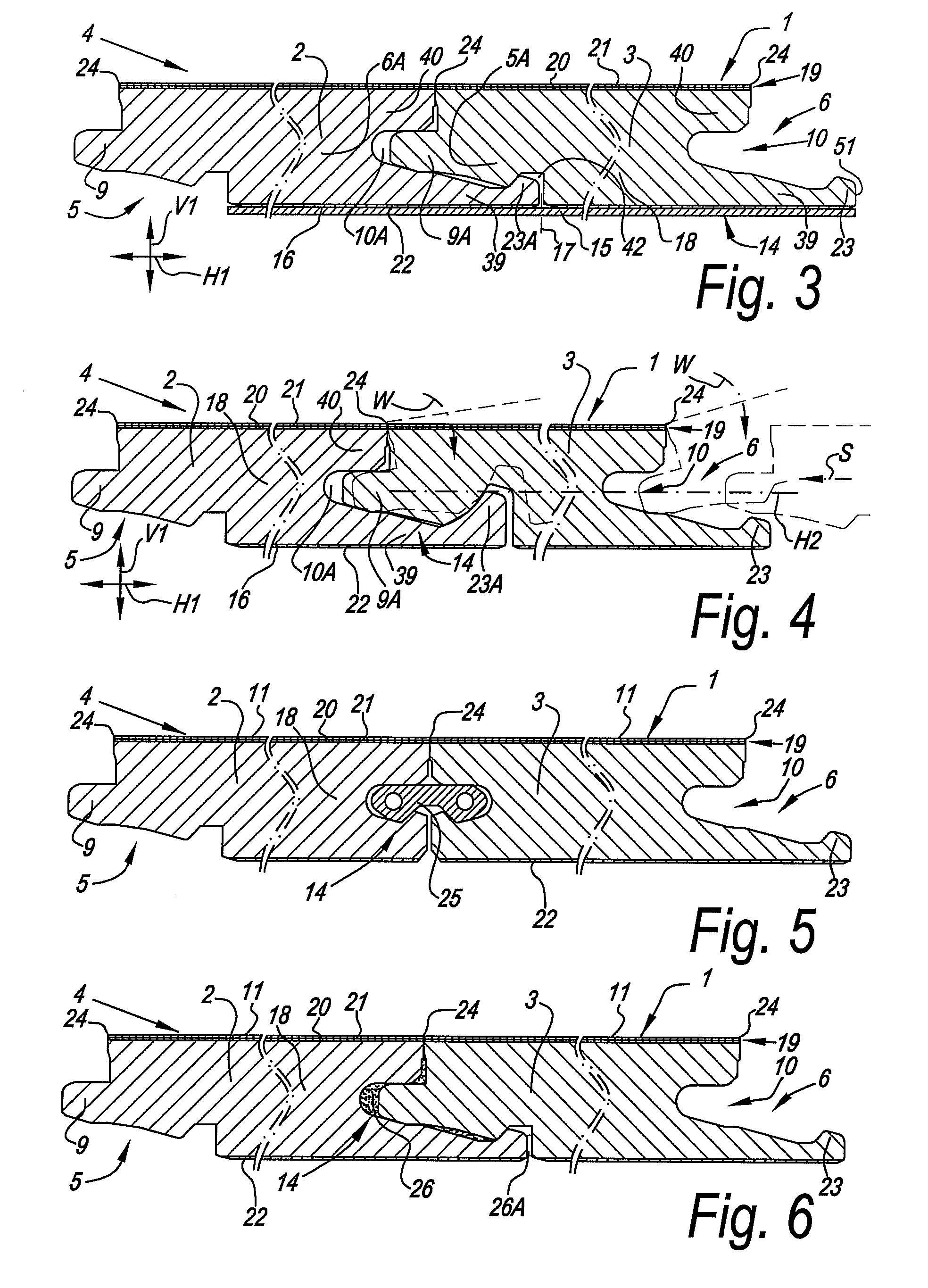

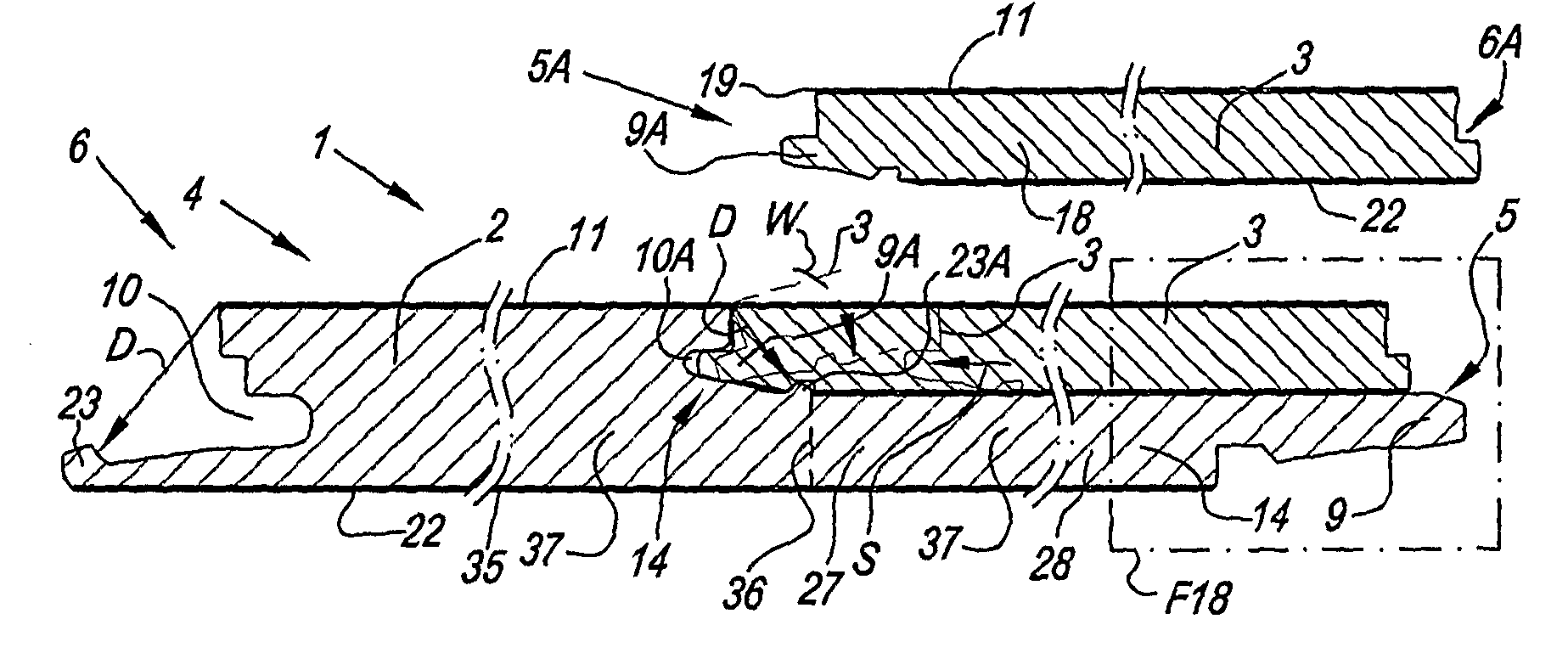

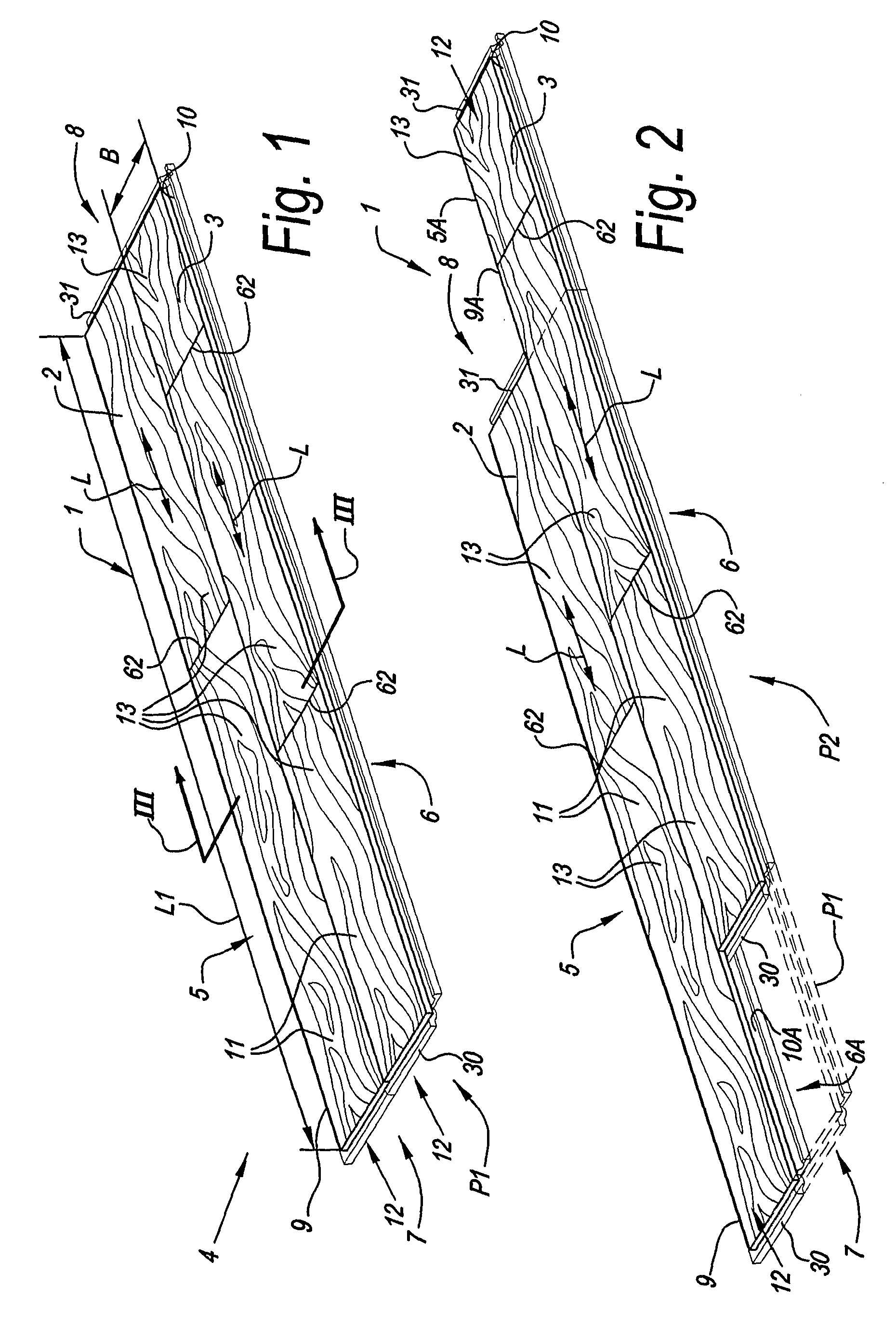

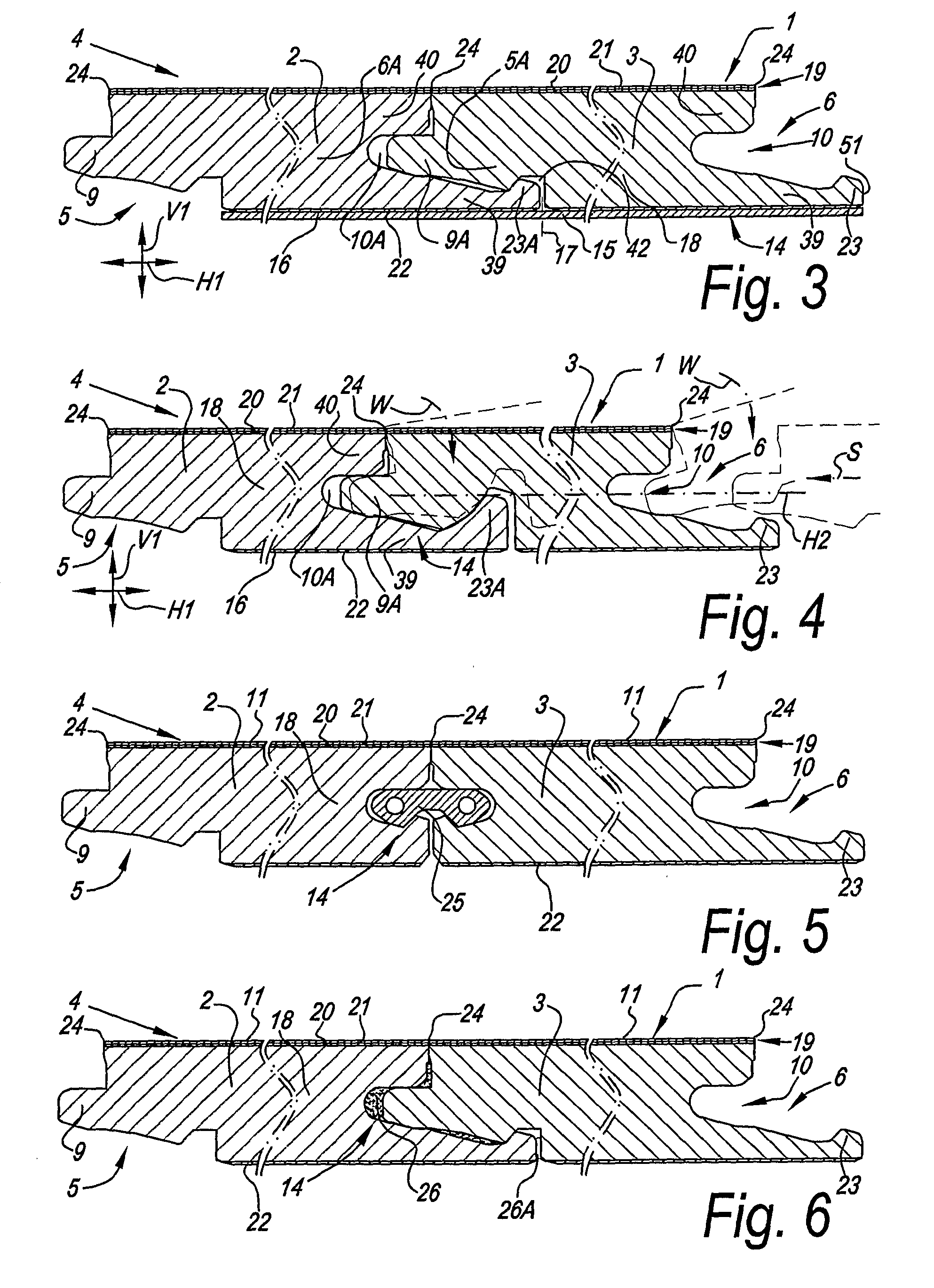

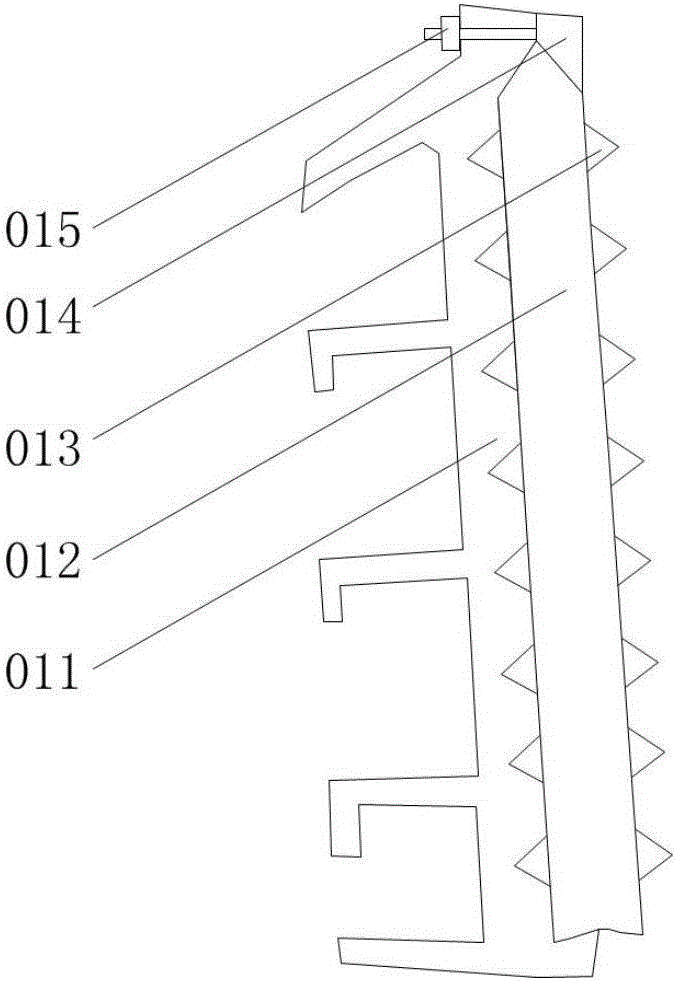

Floor Element, Locking System for Floor Elements, Floor Covering and Method for Composing Such Floor Elements to a Floor Covering

ActiveUS20140318070A1Easy to packComfort of shifting both floor elements or components along the coupled sides is maximizedThin material handlingFlooringCouplingFloor covering

Floor element of the type which, at least at two opposite edges, comprises coupling means enabling two of such floor elements to cooperate with each other at the respective edges, wherein the floor element comprises at least two components, as well as entity-forming means, which, starting from the aforementioned components, can form an entity including the components, wherein said components can adopt at least two mutual positions, whether or not by means of the disruption of the entity formed by said entity-forming means.

Owner:FLOORING IND LTD

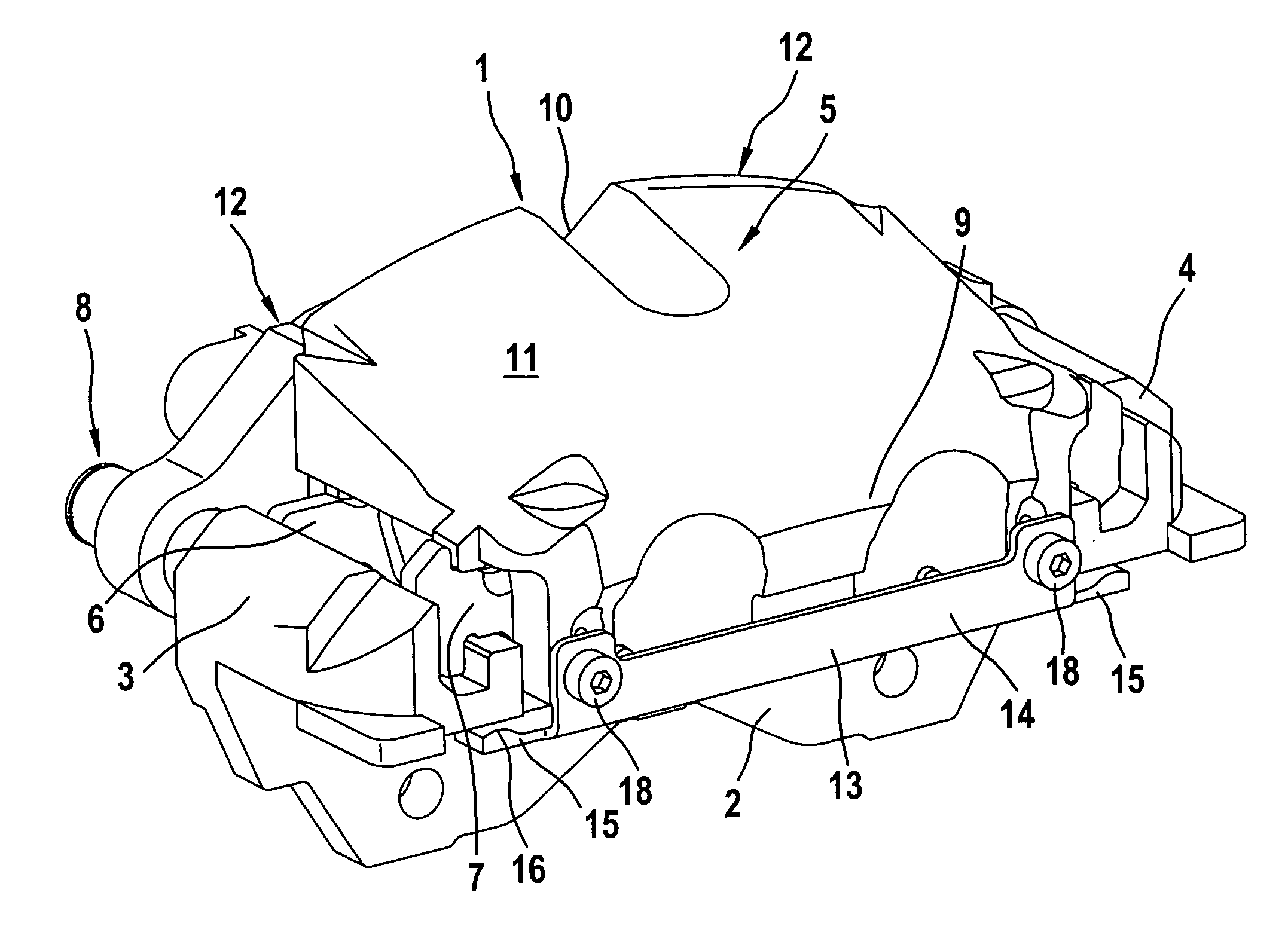

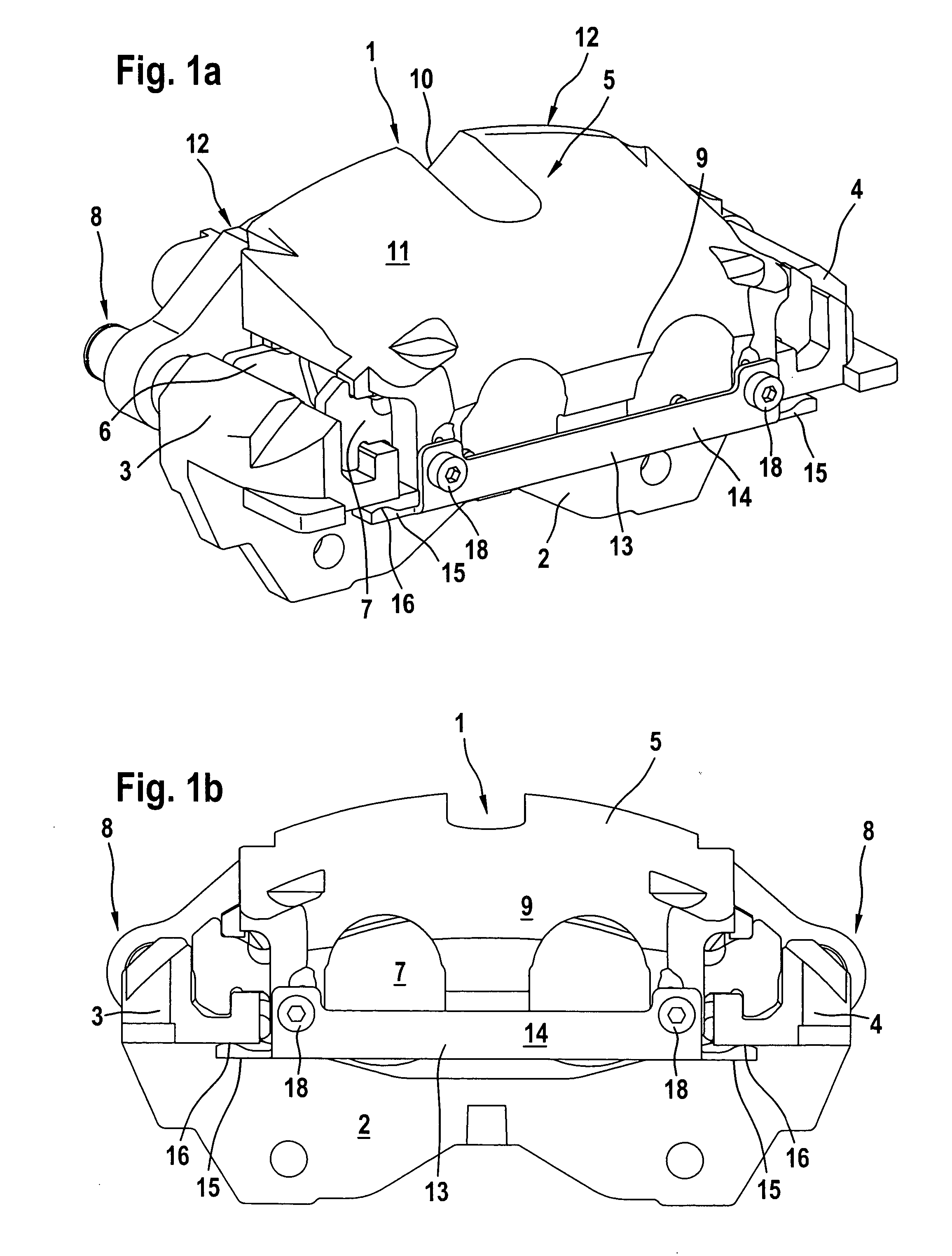

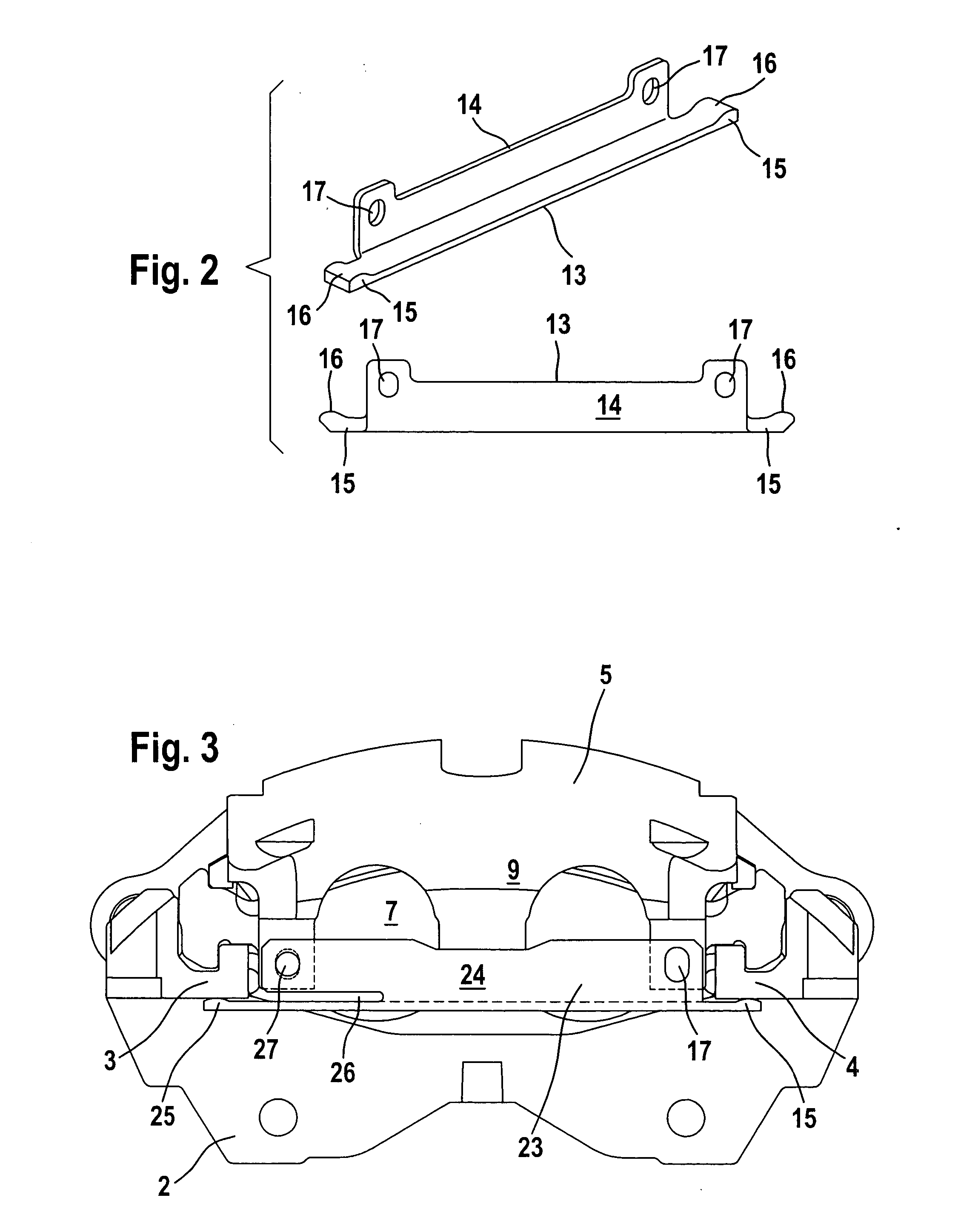

Floating-caliper disk brake

InactiveUS20060076198A1Ease of displacementReduce elastic deformationAxially engaging brakesBrake actuating mechanismsMobile vehicleRadial position

The invention relates to a floating-caliper disc brake of a motor vehicle including a brake holder firmly attached to the vehicle and a floating caliper that is mounted on the brake holder so as to be axially displaceable. In this arrangement, the floating caliper is displaceably mounted on the brake holder, preferably by means of at least one pin guide. A radial fixation of the floating caliper on the brake holder is carried out by a locking element that is detachably secured to the floating caliper and with a portion is axially displaceably arranged on the brake holder. To improve ease of displacement of the floating caliper and to prevent undesirable radial movements of the floating caliper, the locking element is secured to the floating caliper so as to be adjustable in its radial position. As a result, it is possible to adjust a defined radial clearance between the floating caliper and the brake holder.

Owner:CONTINENTAL TEVES AG & CO OHG

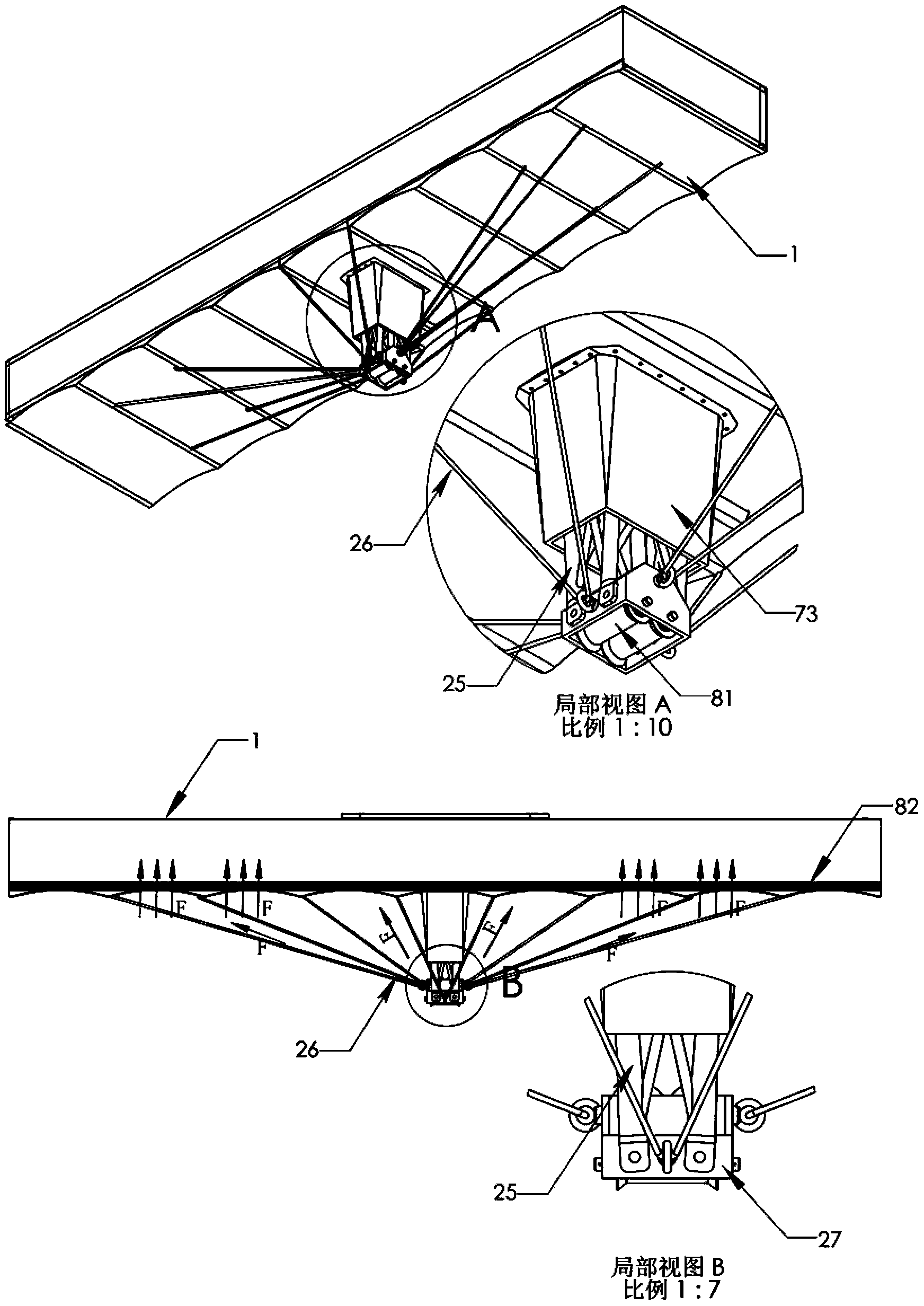

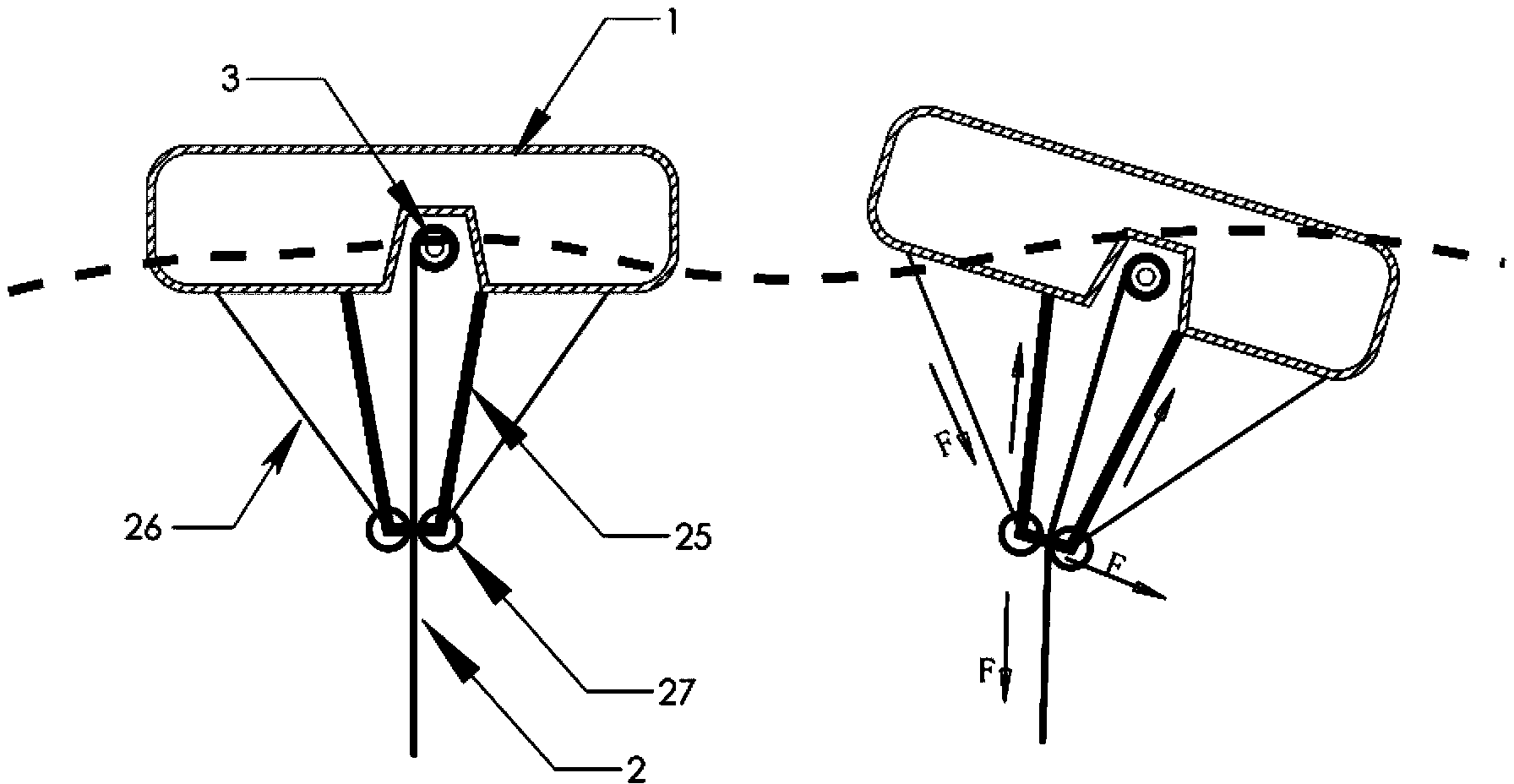

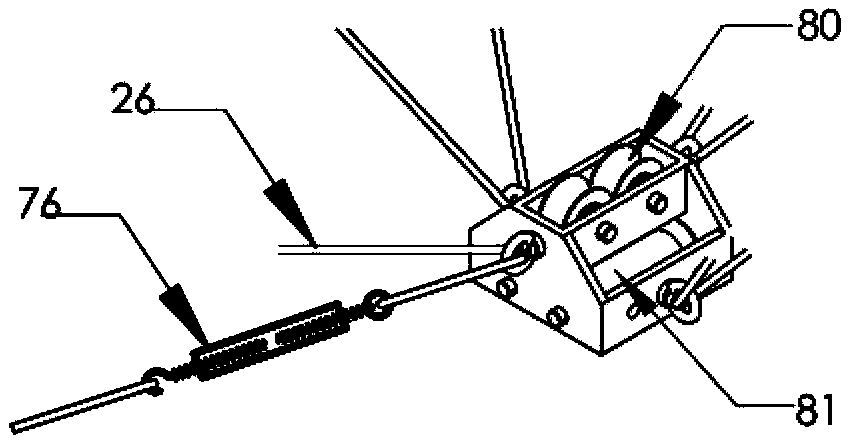

Weave power acquisition device adopting floating body and rope wheel

A return spring adjustment apparatus and method of a wave power system. The apparatus comprises return springs (5, 9), a stepper motor (6), transducers (7, 10, 27, 29), a single chip microcomputer control module (8) and a power source. The two ends of the return springs (5, 9), a chassis (12) of the stepper motor, a rotor (11), the two ends of the transducers (7, 10, 27, 29) can all be randomly arranged in series, and connected with a spindle (4) and a frame (22). When a single chip microcomputer detects that the transducers (7, 10, 27, 29) measure that the pulling force is too large or too small, it sends an instruction to the stepper motor (6) to perform adjustment. After the adjustment is completed, the stepper motor (6) stalls and brakes, so that the return springs (5, 9) can work in within a specified range.

Owner:安徽迪思自动化设备有限公司

Floor element, locking system for floor elements, floor covering and method for composing such floor elements to a floor covering

ActiveUS9534400B2Easy to packComfort of shifting both floor elements or components along the coupled sides is maximizedThin material handlingFlooringCouplingEngineering

Floor element of the type which, at least at two opposite edges, comprises coupling means enabling two of such floor elements to cooperate with each other at the respective edges, wherein the floor element comprises at least two components, as well as entity-forming means, which, starting from the aforementioned components, can form an entity including the components, wherein said components can adopt at least two mutual positions, whether or not by means of the disruption of the entity formed by said entity-forming means.

Owner:UNILIN BV

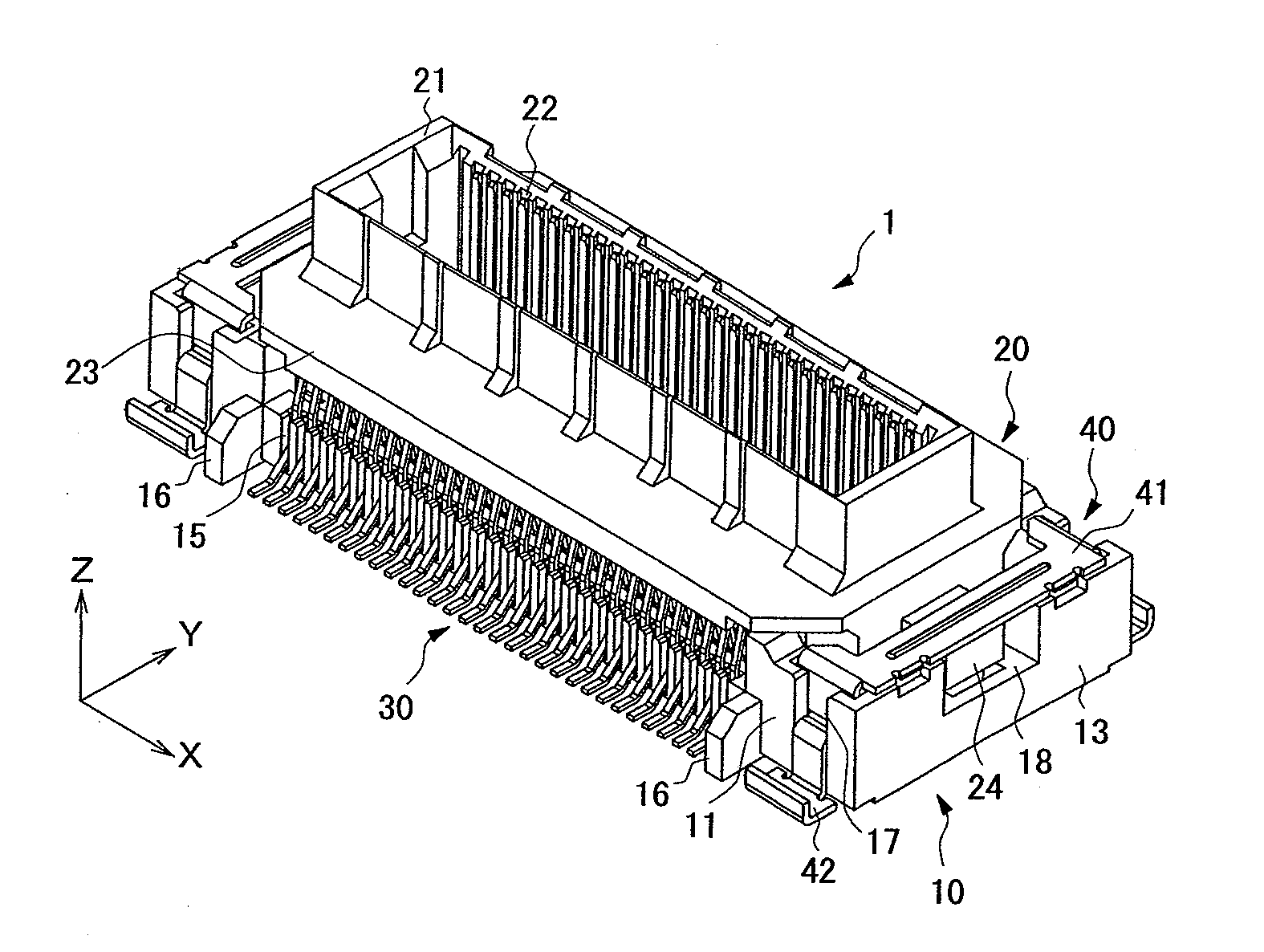

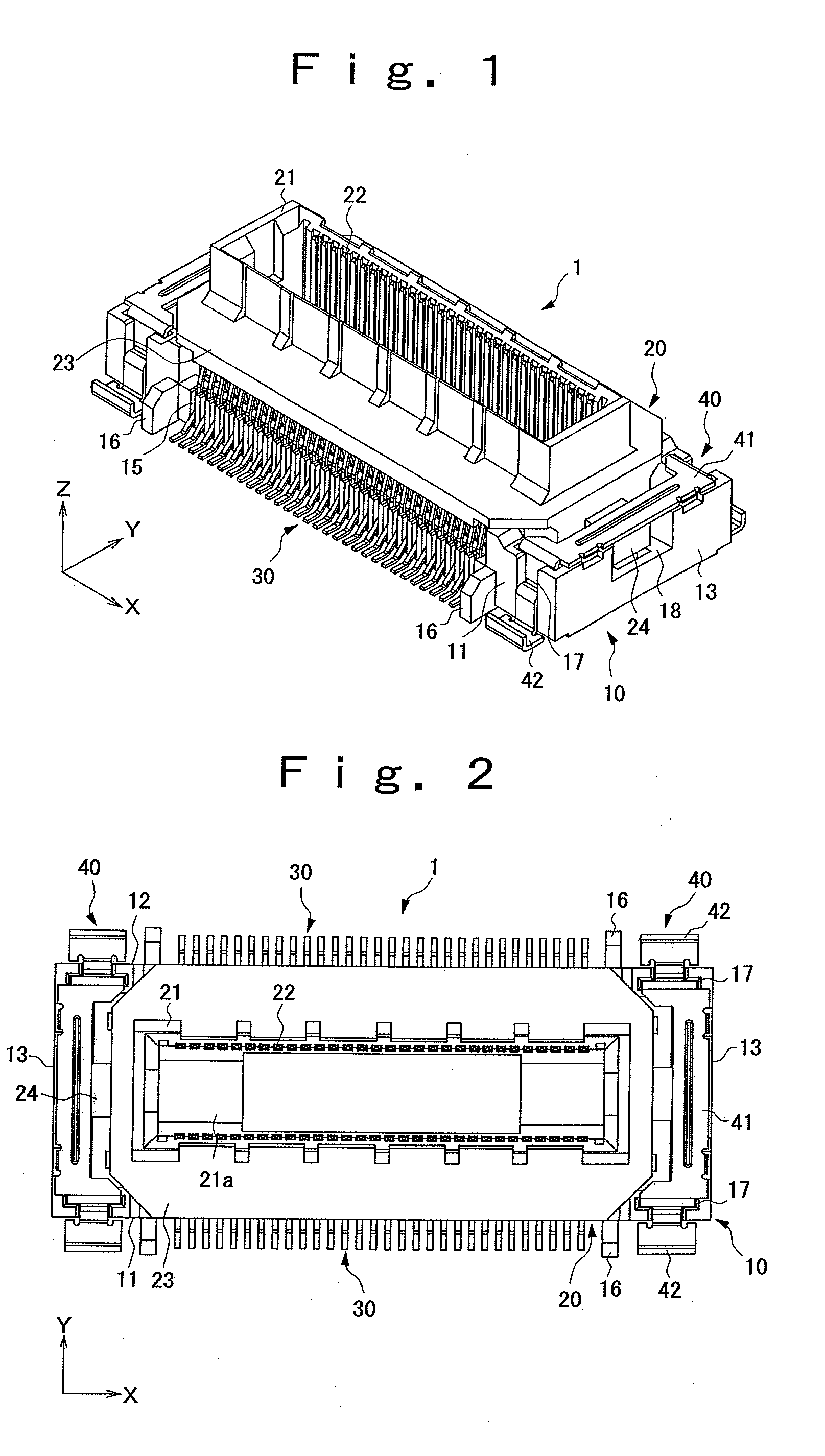

Connector

InactiveUS20080296133A1Reduce elastic deformationImprove connection reliabilityCoupling contact membersElectric switchesEngineeringElectrical and Electronics engineering

Owner:IRISO ELECTRONICS CO LTD

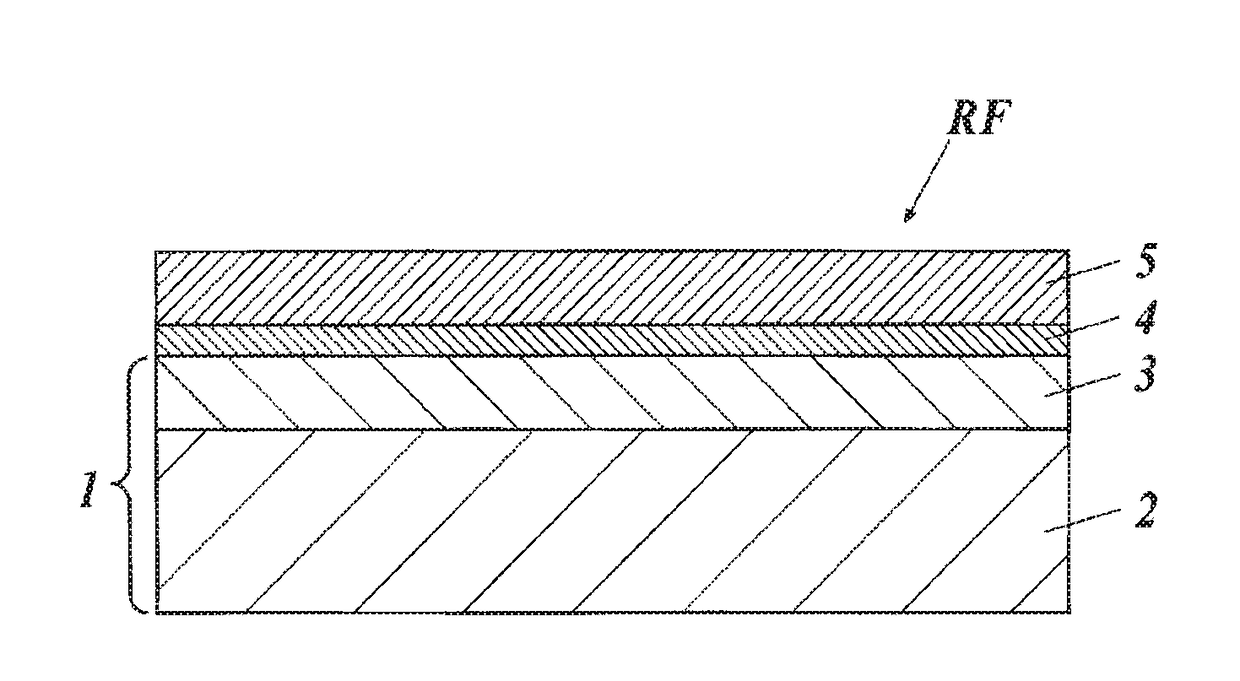

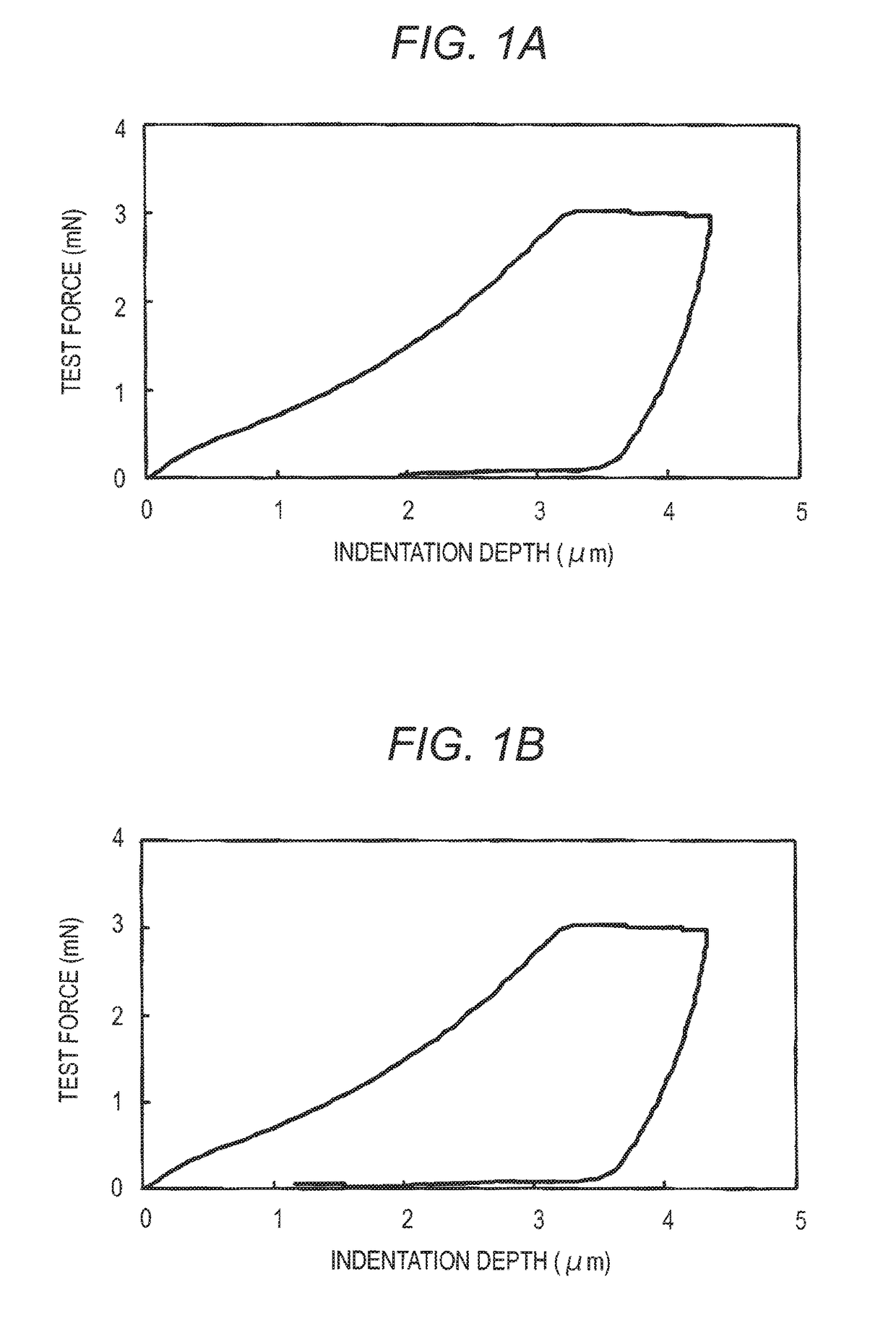

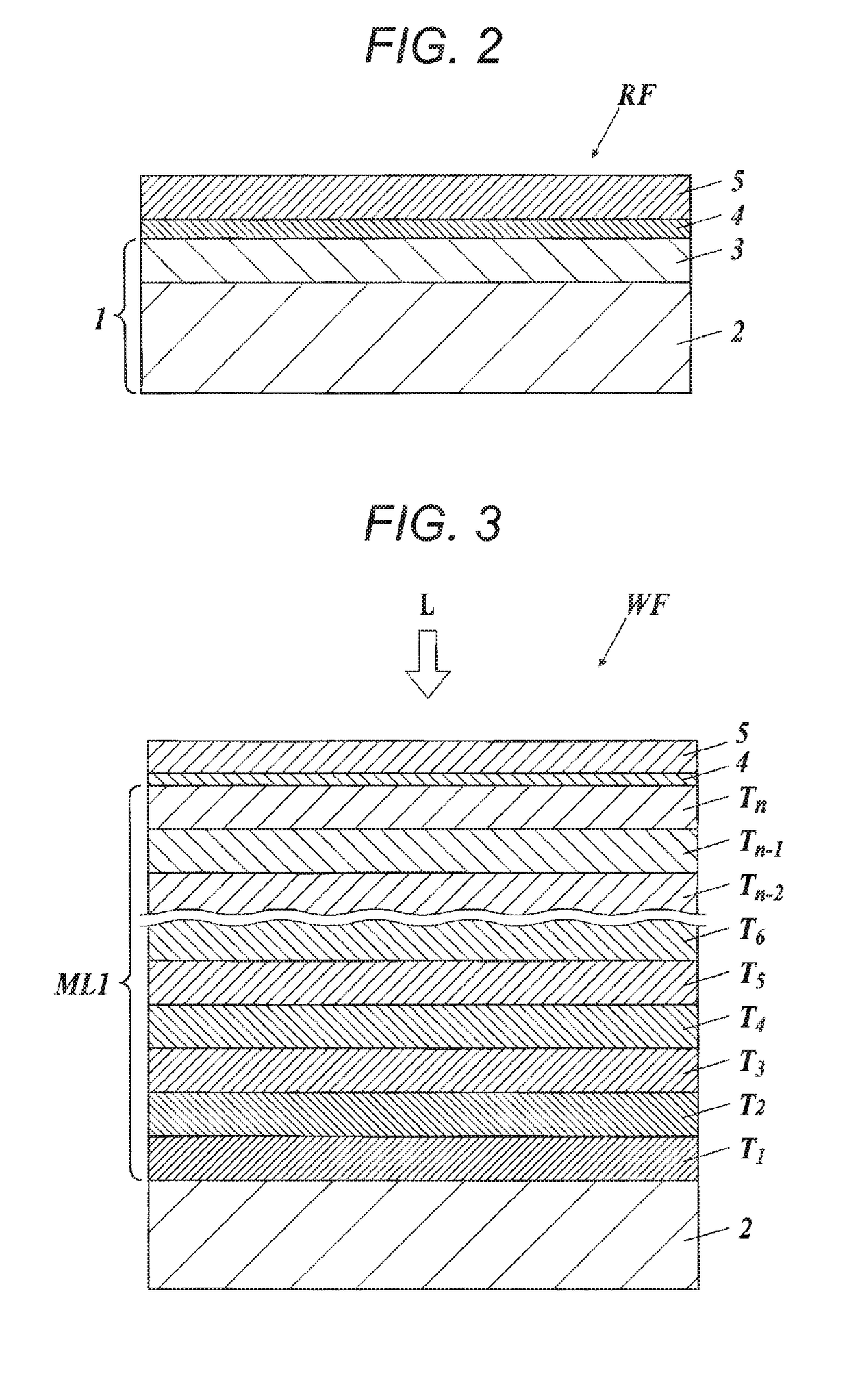

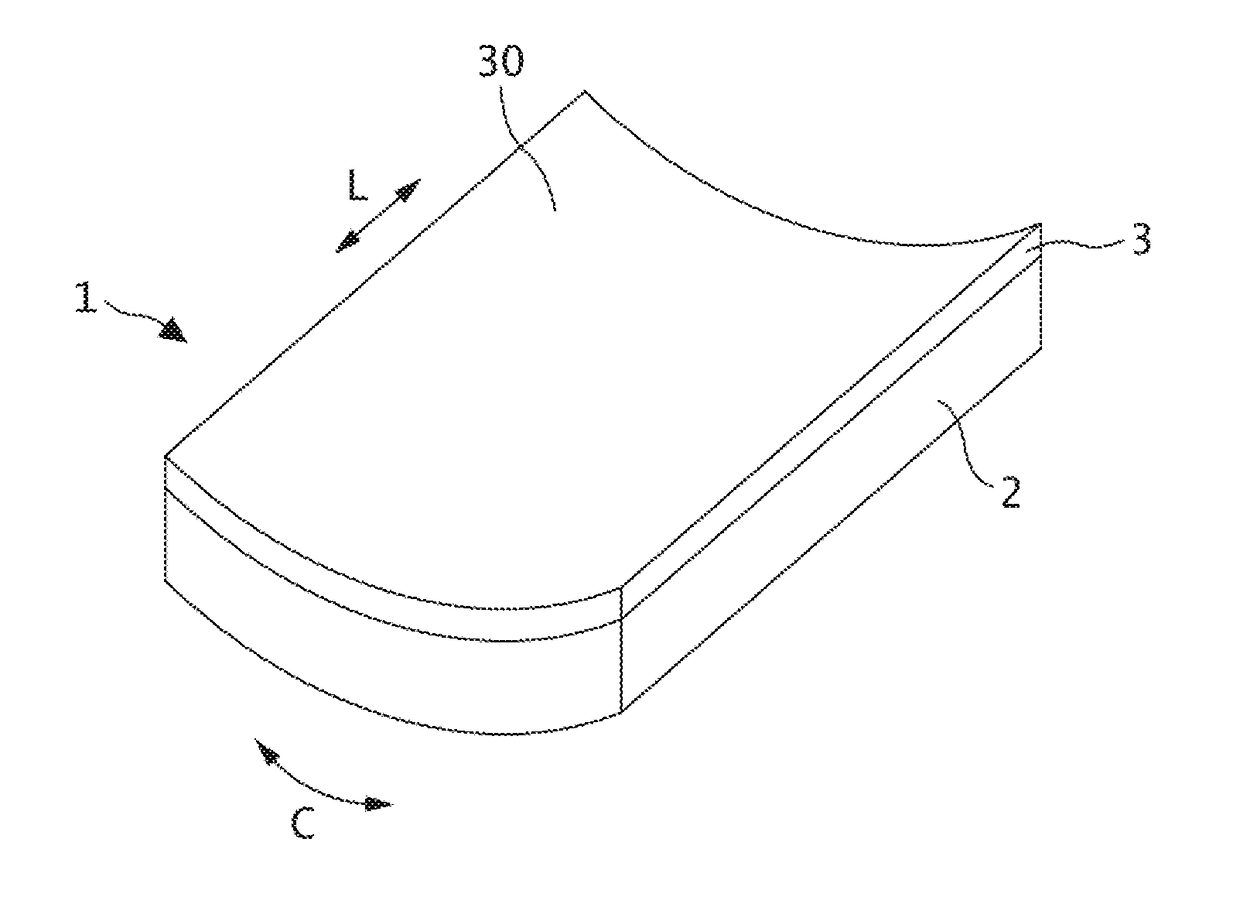

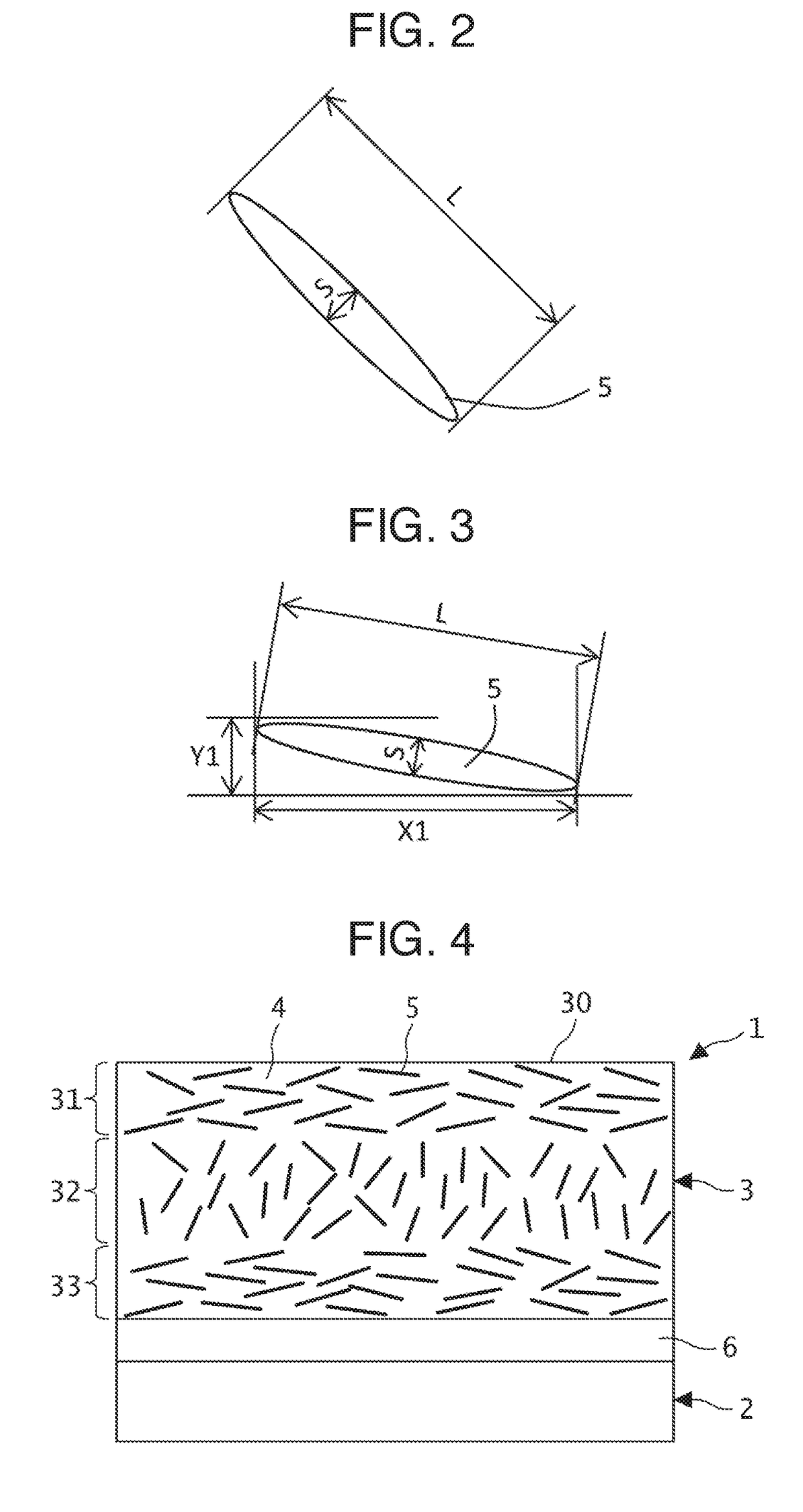

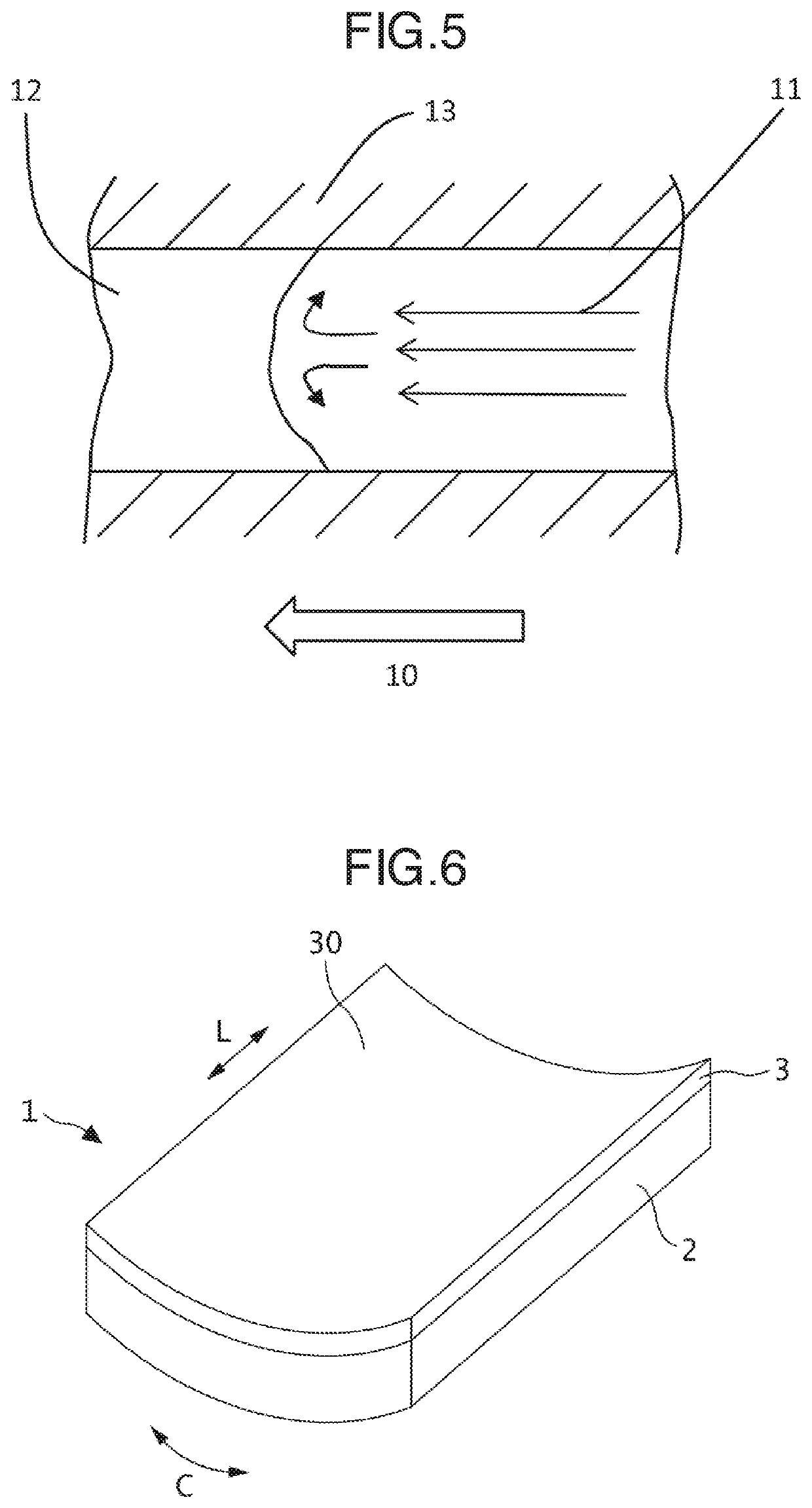

Light reflecting film, production method for light reflecting film, decorative molding method for light reflecting film, laminated glass, and curved surface body

InactiveUS20170254936A1Improve light resistanceImprove scratch resistanceOptical filtersOptical articlesOpticsPhysics

A light reflecting film may be provided that improves the self-restoring property of a stretched section thereof when stretched and attached to a curved surface and that has excellent scratch resistance and light resistance, a production method for the light reflecting film, a decorative molding method may also be provided for the light reflecting film, laminated glass, and a curved surface body.

Owner:KONICA MINOLTA INC

Floor element, locking system for floor elements, floor covering and method for composing such floor elements to a floor covering

InactiveUS8806830B2Easy to packComfort of shifting both floor elements or components along the coupled sides is maximizedRoof covering using tiles/slatesCovering/liningsCouplingEngineering

Floor element of the type which, at least at two opposite edges, comprises coupling means enabling two of such floor elements to cooperate with each other at the respective edges, wherein the floor element comprises at least two components, as well as entity-forming means, which, starting from the aforementioned components, can form an entity including the components, wherein said components can adopt at least two mutual positions, whether or not by means of the disruption of the entity formed by said entity-forming means.

Owner:FLOORING IND LTD

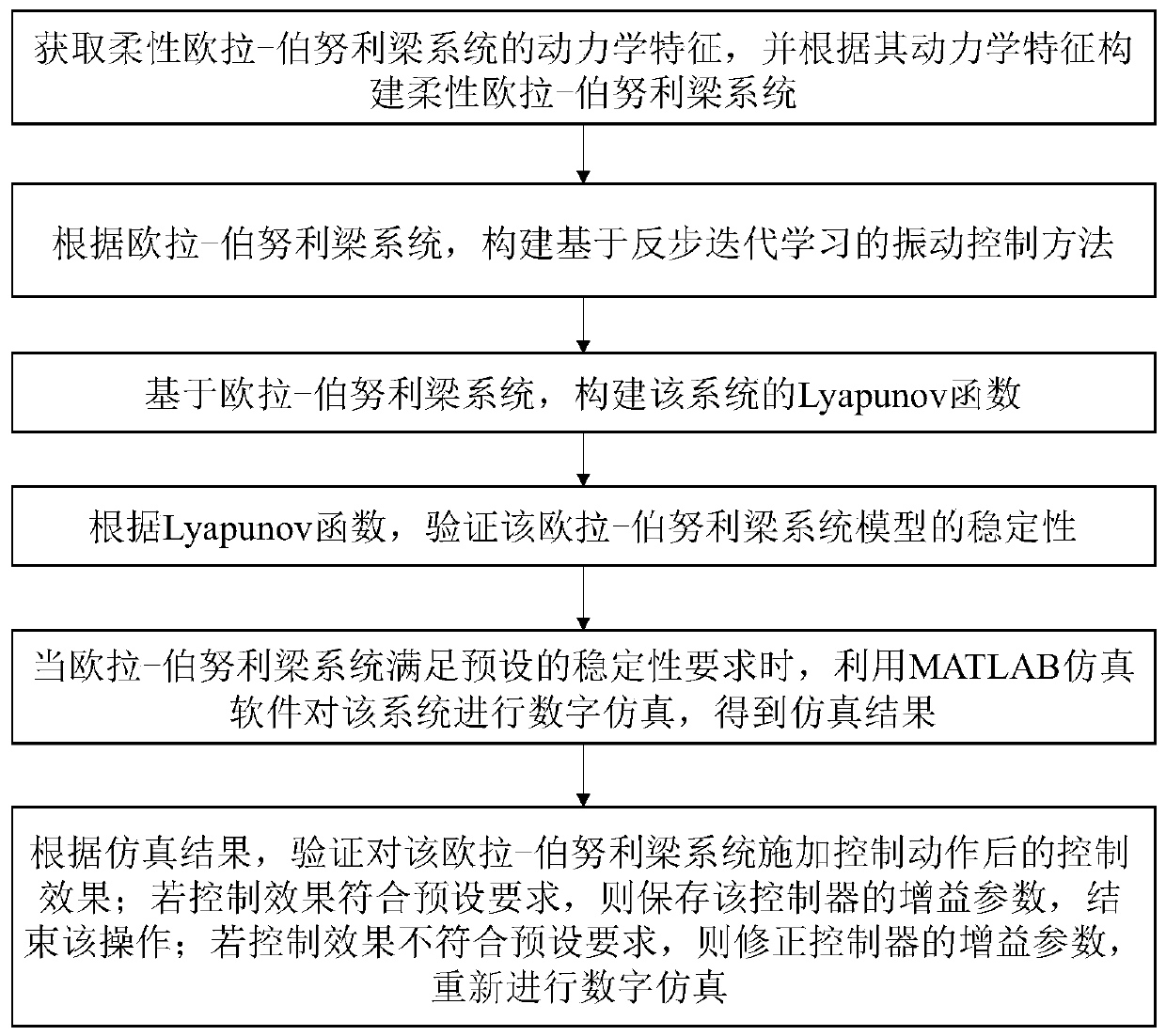

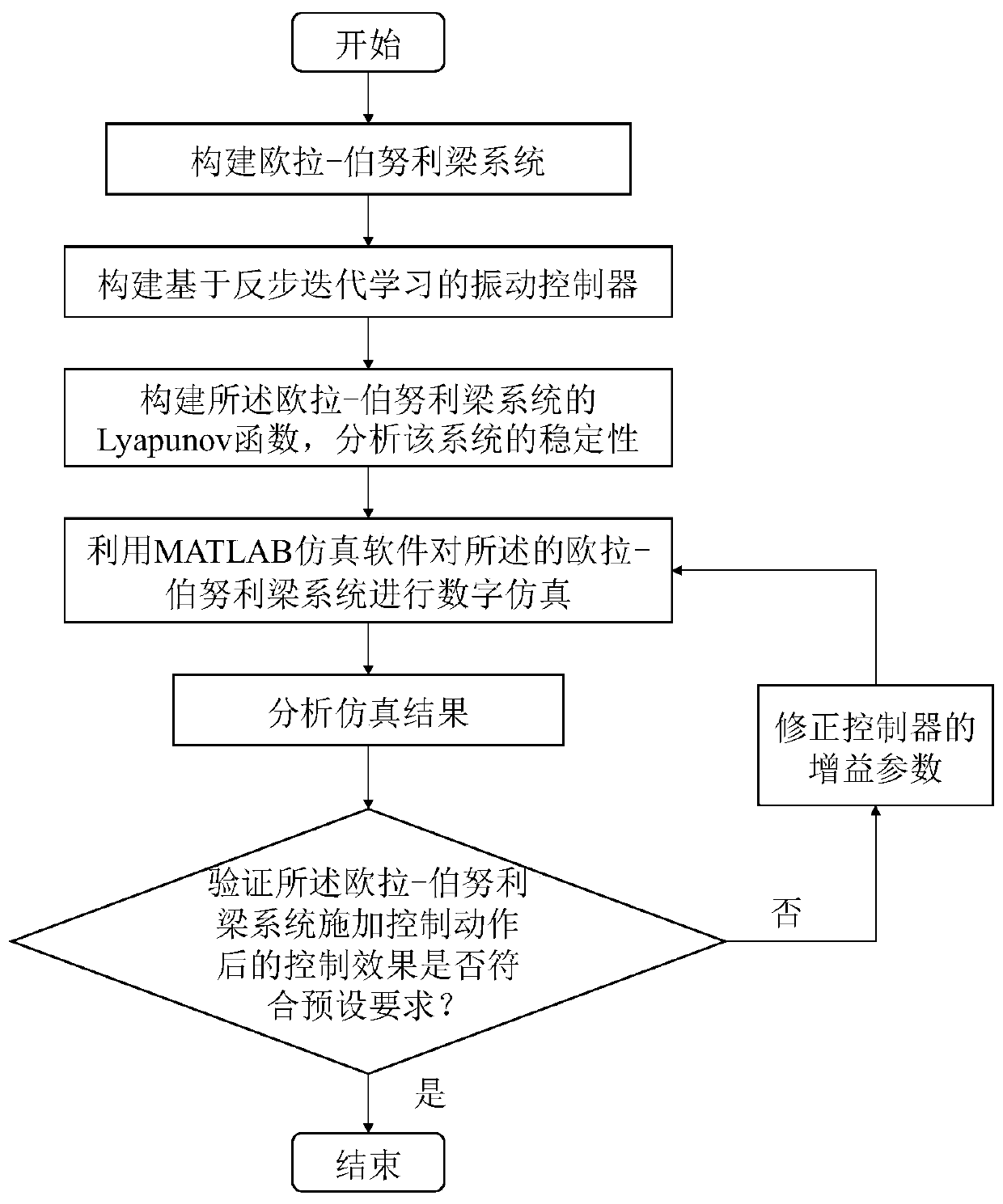

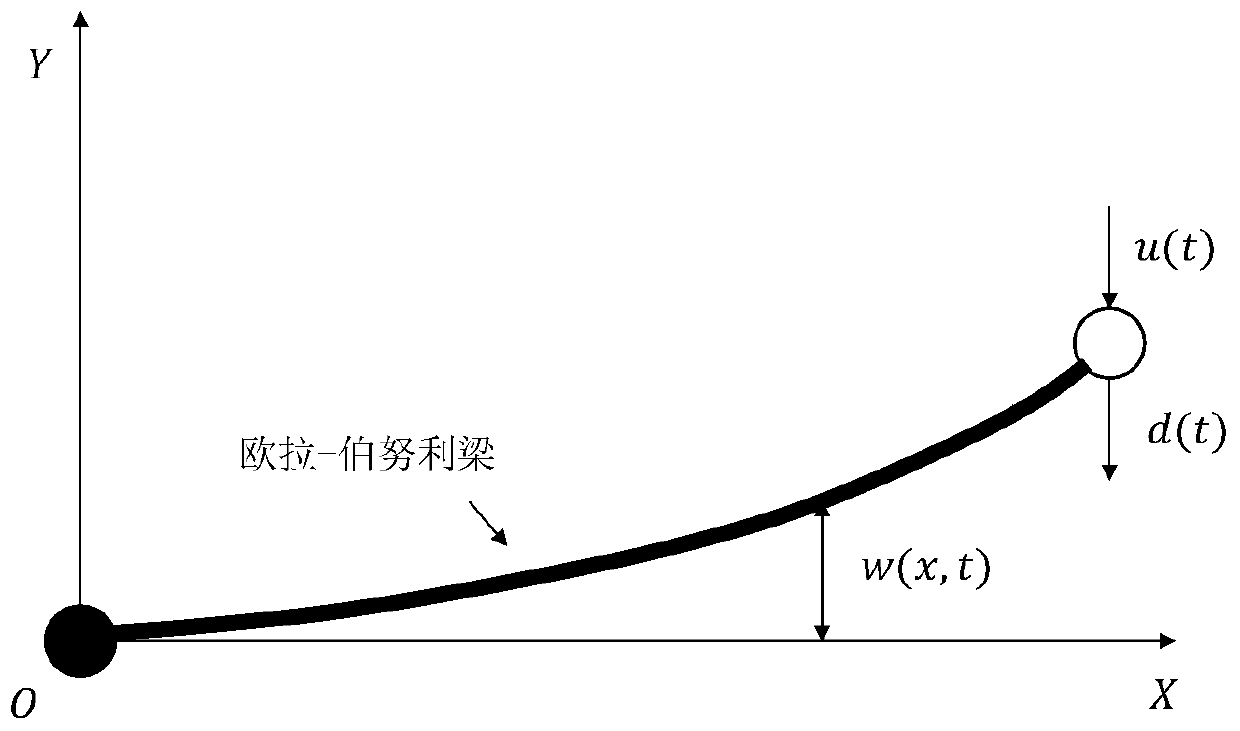

Euler-Bernoulli beam vibration control method based on backstepping iterative learning

ActiveCN110673469AQuality is easy to controlReduce elastic deformationAdaptive controlVibration controlAlgorithm

The invention discloses an Euler-Bernoulli beam vibration control method based on backstepping iterative learning. The method comprises a step of constructing an Euler-Bernoulli beam system accordingto dynamic characteristics of an Euler-Bernoulli beam, a step of constructing a vibration control method based on the backstepping iterative learning according to the Euler-Bernoulli beam system in combination with a Lyapunov method, wherein virtual control quantity design, backstepping item design and iterative item design are included, a step of verifying the stability of the Euler-Bernoulli beam system under the vibration control method, a step of performing digital simulation on the Euler-Bernoulli beam system by using MATLAB simulation software and verifying whether a control effect meetsexpectation or not, and a step of adjusting gain parameters of a controller according to a simulation result if not such that the controller has a relatively good control effect. According to the vibration control method based on the backstepping iterative learning provided by the invention, the vibration of the Euler-Bernoulli beam system can be effectively suppressed, so that the Euler-Bernoulli beam system works more stably.

Owner:SOUTH CHINA UNIV OF TECH +1

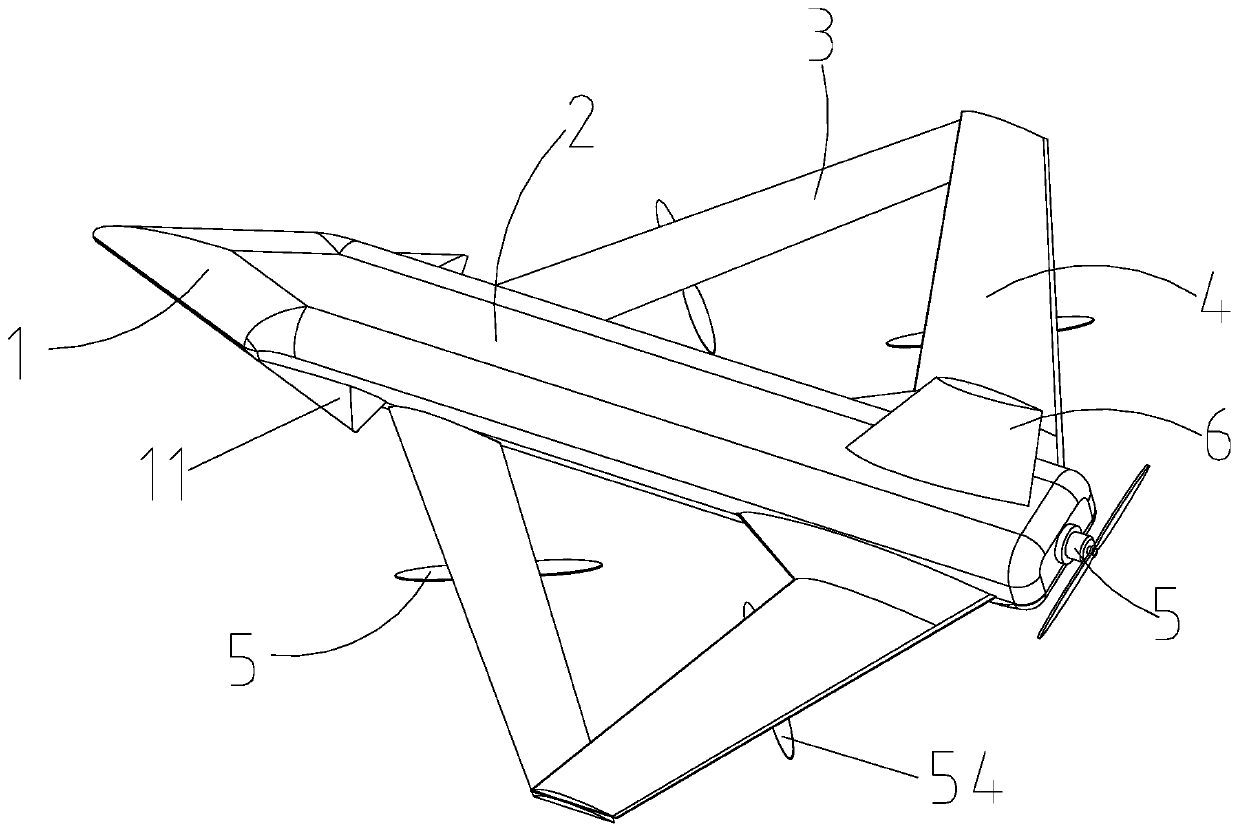

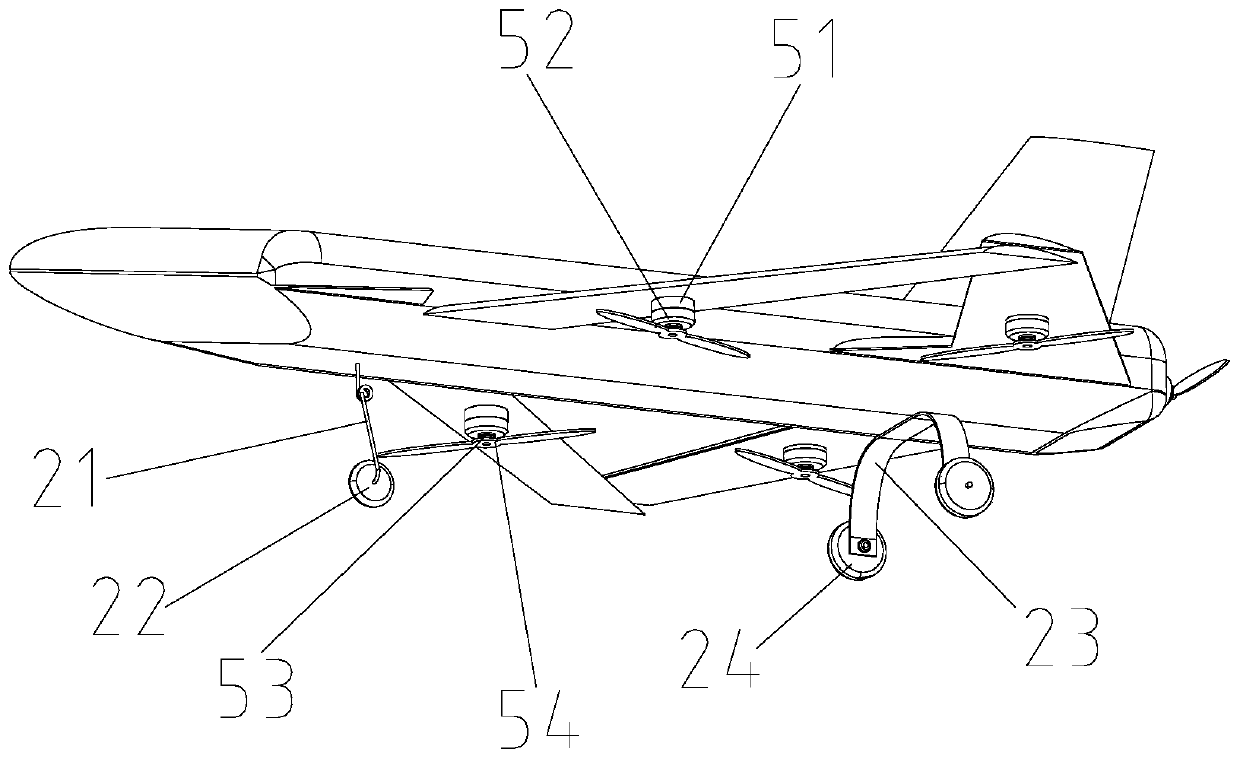

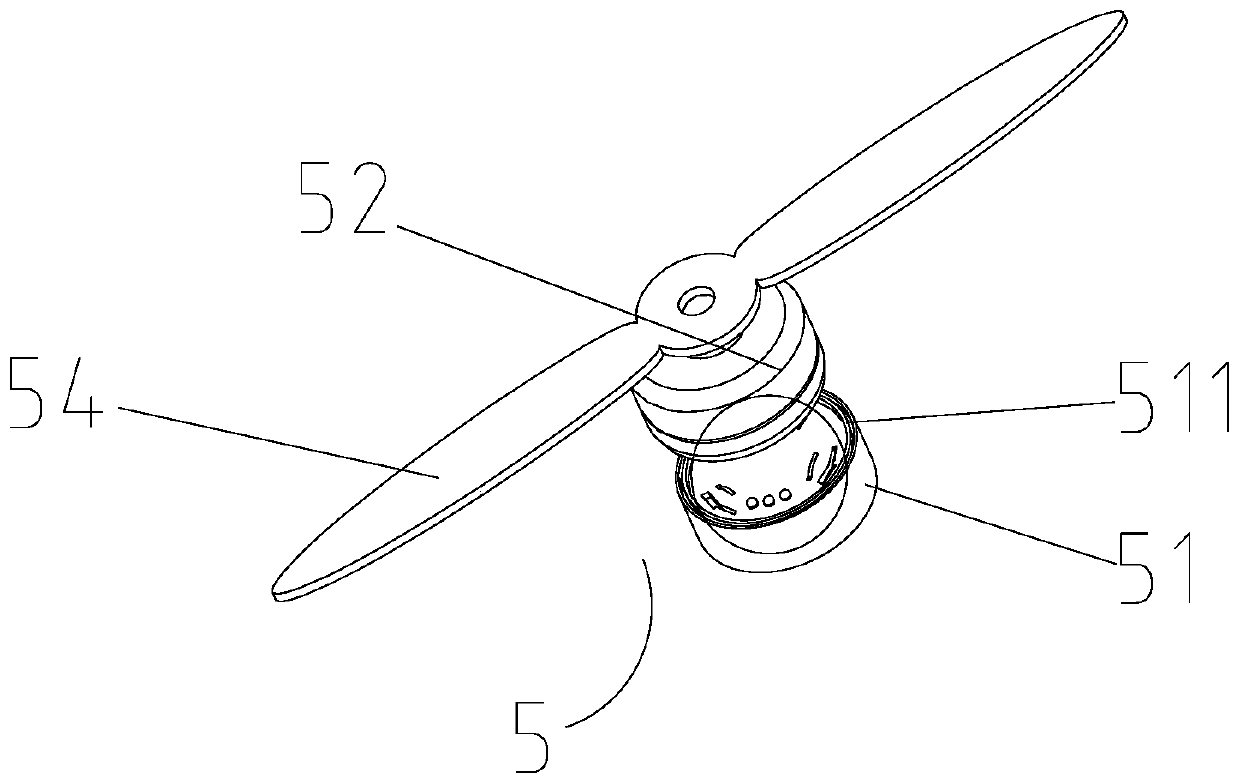

Connection-wing-configuration novel vertical-take-off-and-landing unmanned aerial vehicle

ActiveCN109987223ANo need to add structural weightNo alternating torquePower plant constructionWing shapesCarrying capacityUncrewed vehicle

The invention provides a connection-wing-configuration novel vertical-take-off-and-landing unmanned aerial vehicle. The connection-wing-configuration novel vertical-take-off-and-landing unmanned aerial vehicle comprises a vehicle head, a vehicle body, front wings, back wings and a propeller power mechanism; the vehicle head is connected to the front end of the vehicle body; the two front wings arehorizontally and symmetrically connected to the front end of the vehicle body; the two back wings are horizontally and symmetrically connected to the back end of the vehicle body, the wingtip parts of the back wings and the wingtip parts of the front wings which are located on the same sides of the vehicle body are mutually connected, the two back wings and the two front wings are combined to form a rhombus shape, and the propeller power mechanism is perpendicularly arranged at the lower end of the single back wing and the lower end of the single front wing. According to the connection-wing-configuration novel vertical-take-off-and-landing unmanned aerial vehicle, the problems that unmanned aerial vehicles such as fixed wings, multi-rotation wings and a helicopter cannot meet the rigid requirements that take-off and landing are easy, the carrying capacity is large, control is easy, and the reliability is high are solved, the inherent defects that an existing conventional-layout vertical-take-off-and-landing unmanned aerial vehicle is low in carrying capacity and short in endurance time are overcome, and the application aims that a platform meets different environments, meets different conditions and adapts to different tasks are achieved.

Owner:夏季风

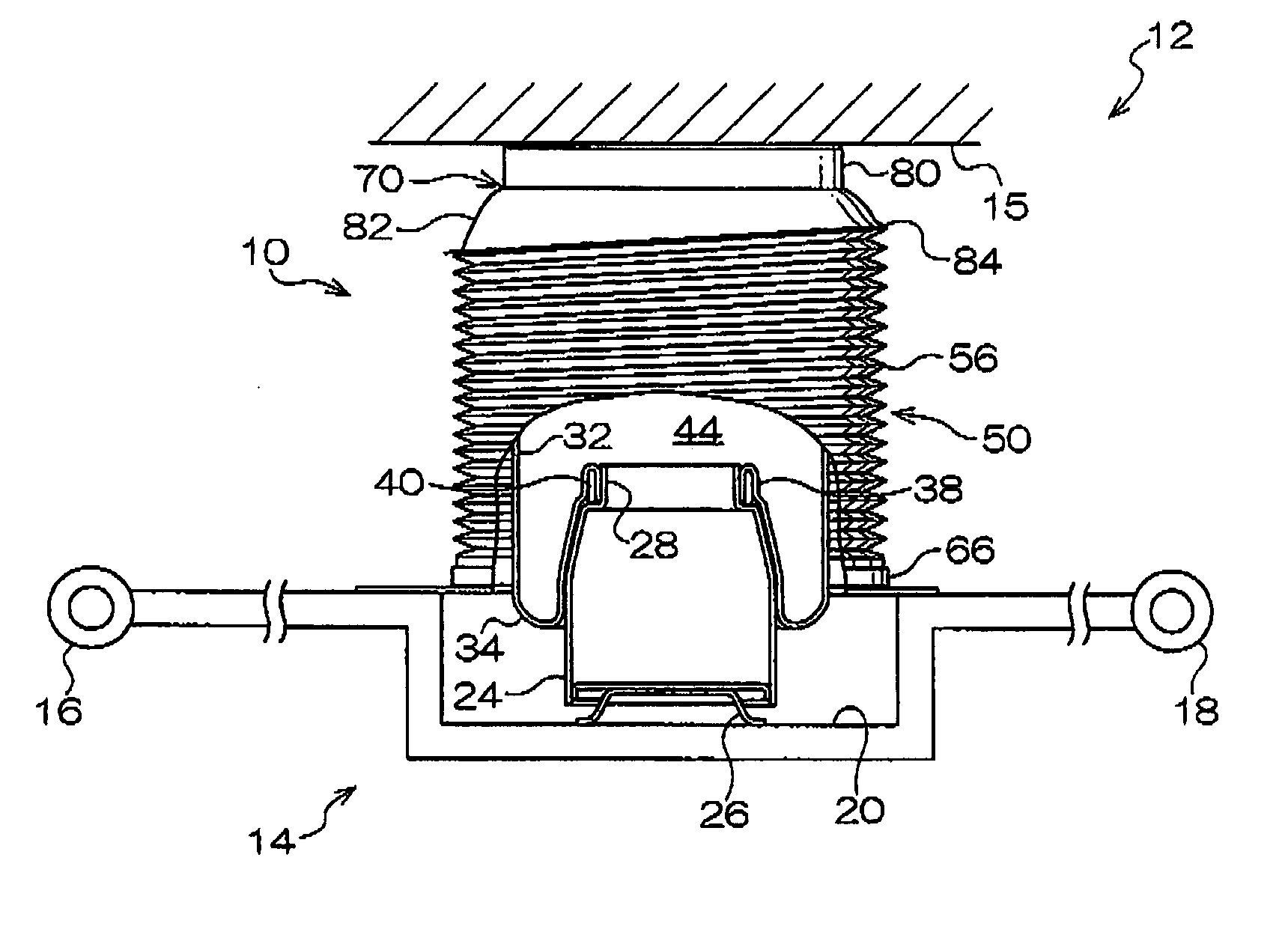

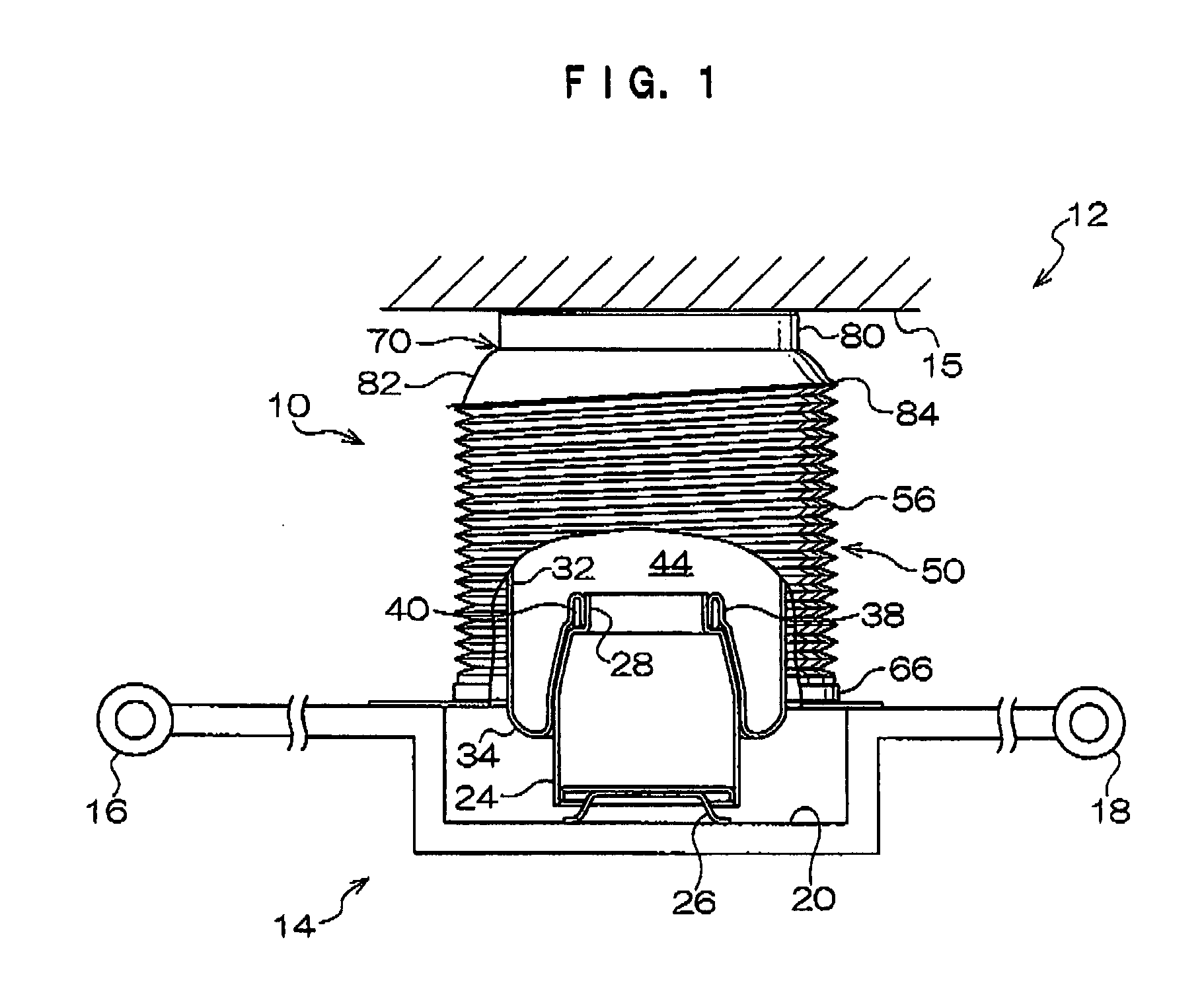

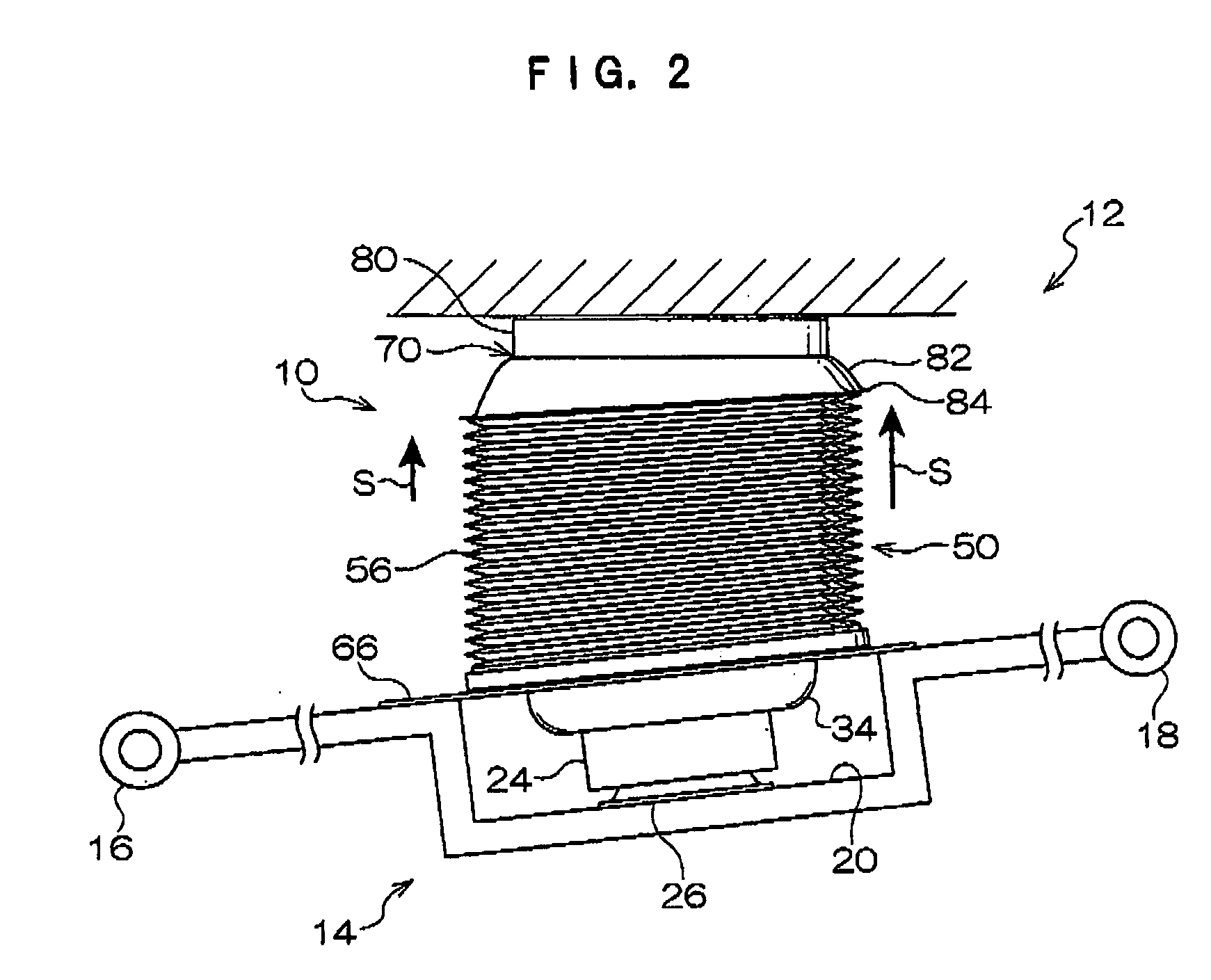

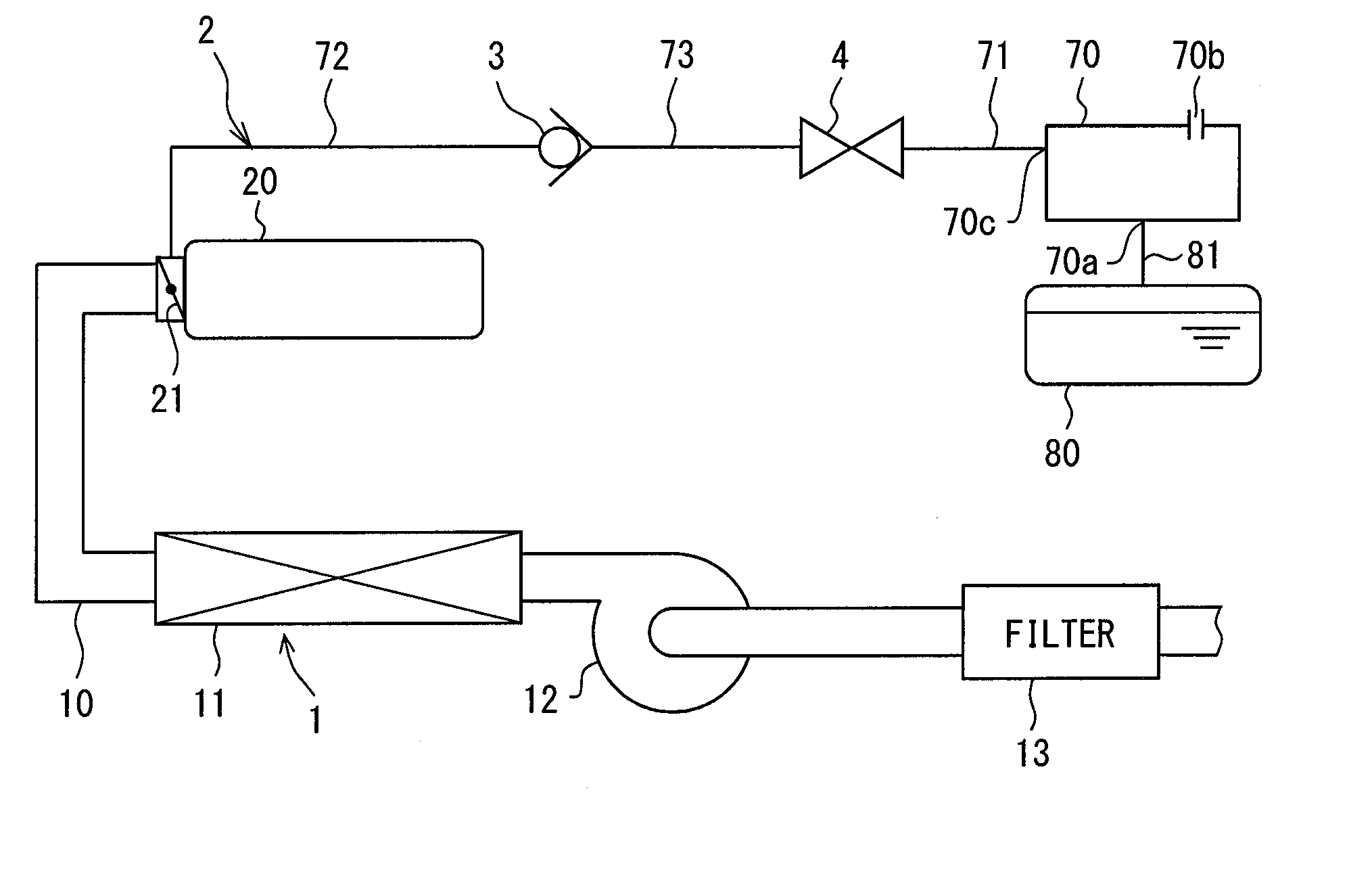

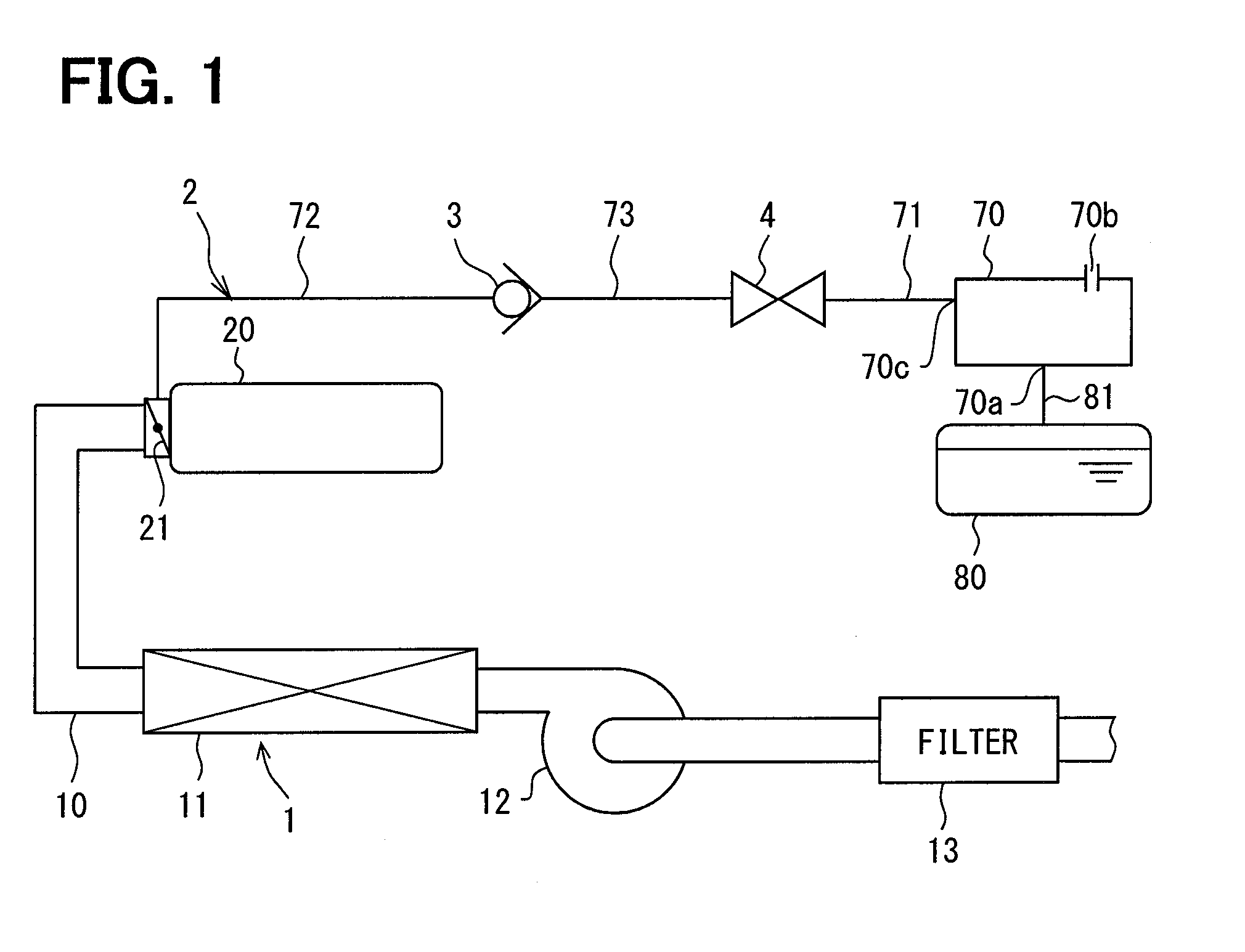

Air spring

ActiveUS20070205546A1Easy to makeHigh strengthLiquid springsResilient suspensionsAir springEngineering

A air spring 10 is provided, where flex deformation of a shoulder portion in a dustcover due to the restorative force of a bellows portion during compression thereof is prevented, whereby deterioration of the life of the dustcover due to such deformation is prevented. With the air spring 10, a stopper 82 of a deformation-preventing cap 70 is arranged at the outer peripheral side of a shoulder portion 54 in a dustcover 50. At the time of compression deformation of a bellows portion 56, the stopper 82 comes into contact with the shoulder portion 54, and flex deformation of the shoulder portion 54 towards a linking tube 52 side is restricted. Due to this, the restorative force from the compression deformed bellows portion 56 via the shoulder portion 54 can be supported by the stopper 82 of the deformation-preventing cap 70. Even in a case where the rigidity of the shoulder portion 54 relative to the restorative force of the compression deformed bellows portion 56 cannot be sufficiently increased, the amount of flex deformation towards the linking tube side of the shoulder portion 54 that received the restorative force of the bellows portion 56 can be decreased.

Owner:PROSPIRA CORP

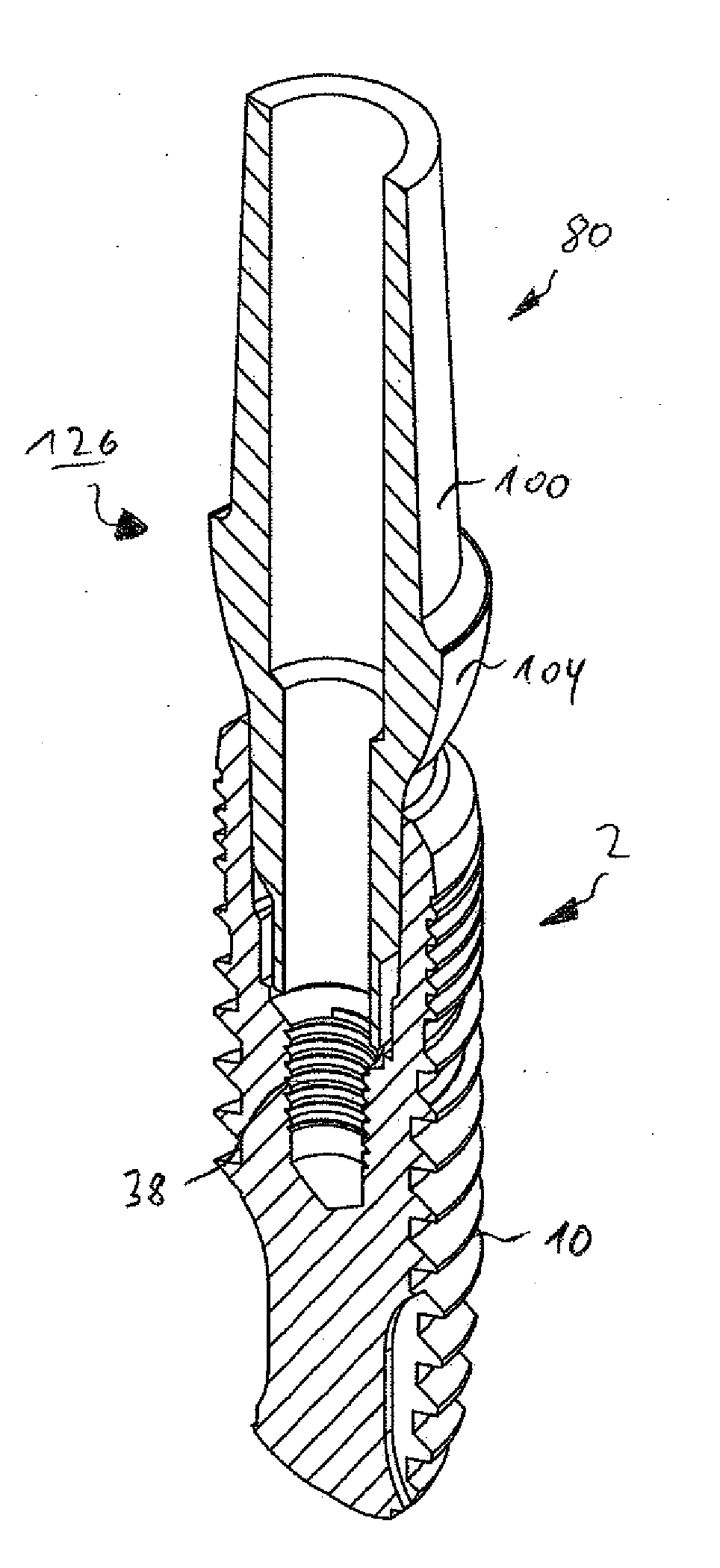

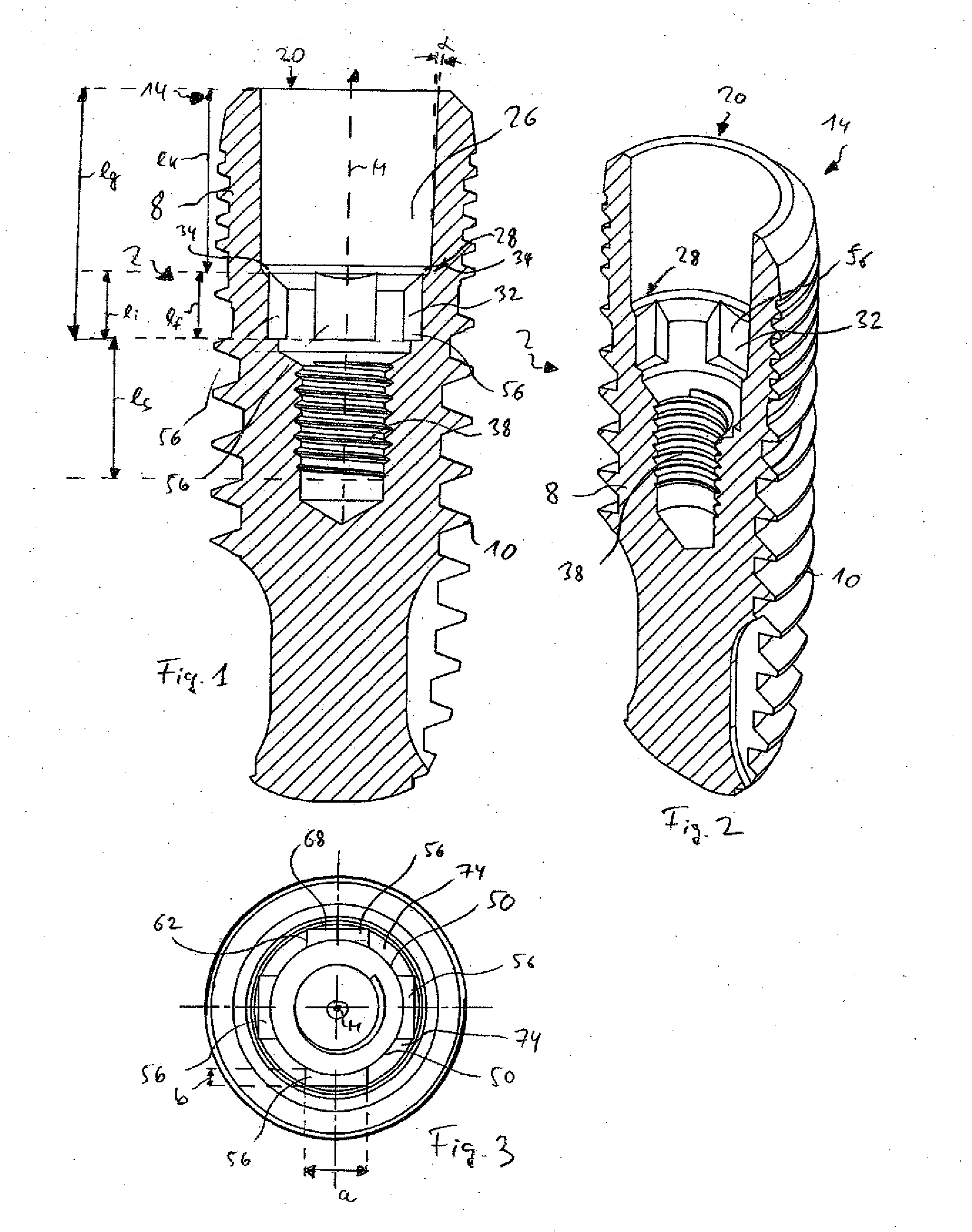

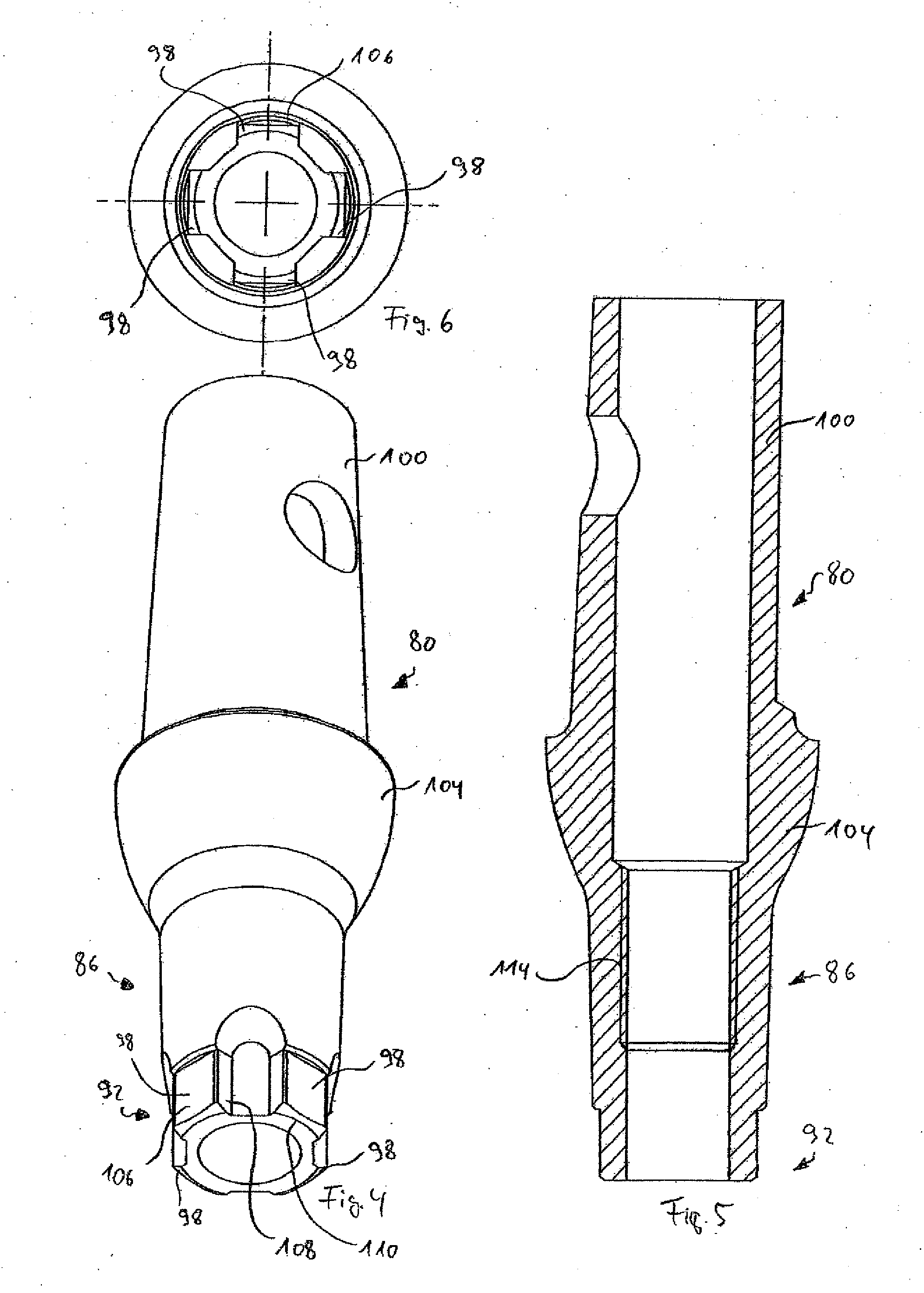

Dental implant, abutment, implant system and implant set

A dental implant for insertion in a jaw bone has a receiving opening arranged on a coronal end of the dental implant for an abutment, the receiving opening when viewed from the coronal end having a taper section and an indexing section, the indexing section having at least one outwardly extending groove arranged along a circular circumference, the taper section having a conical angle of less than 3°.

Owner:SIC INVENT

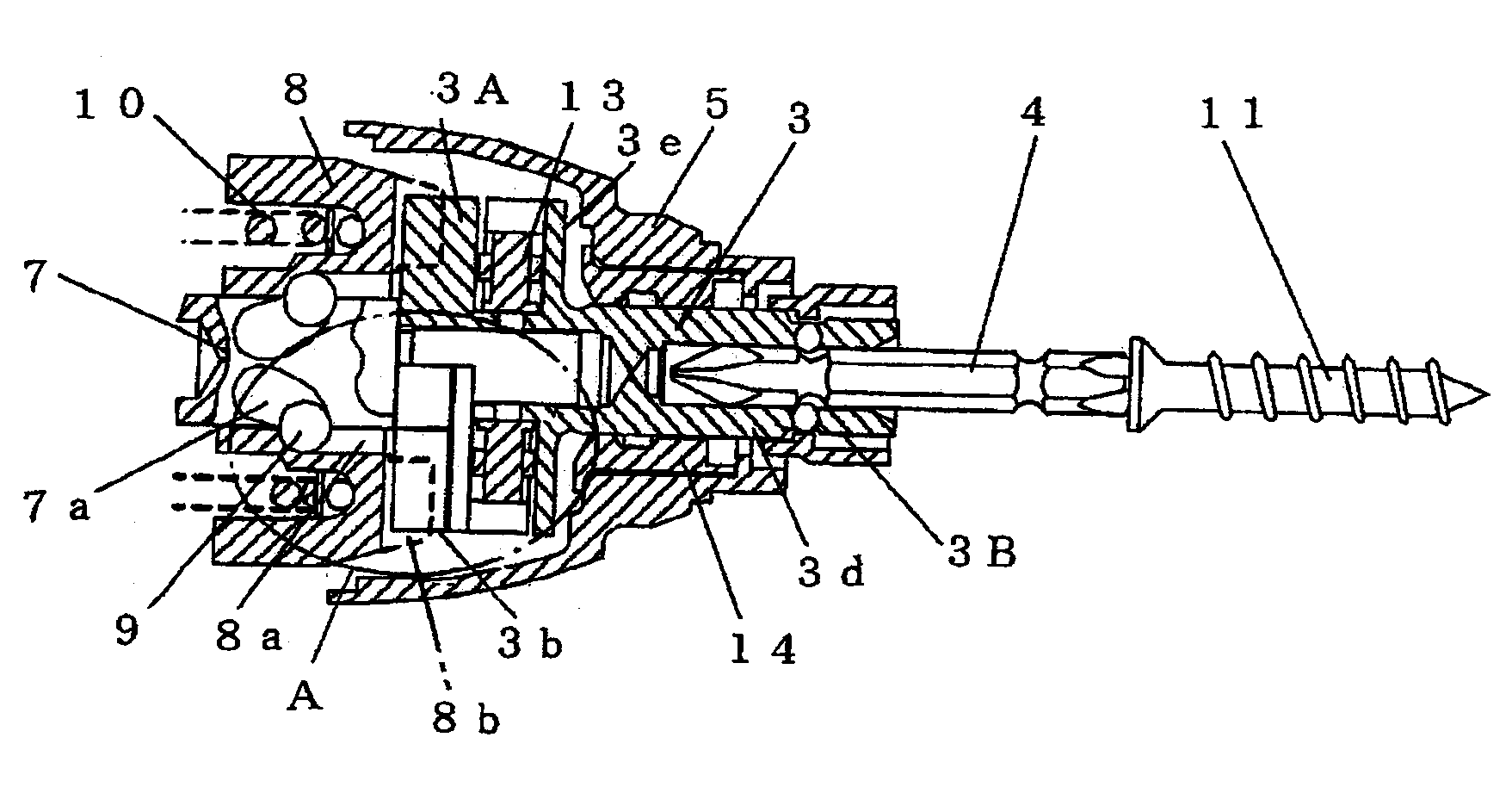

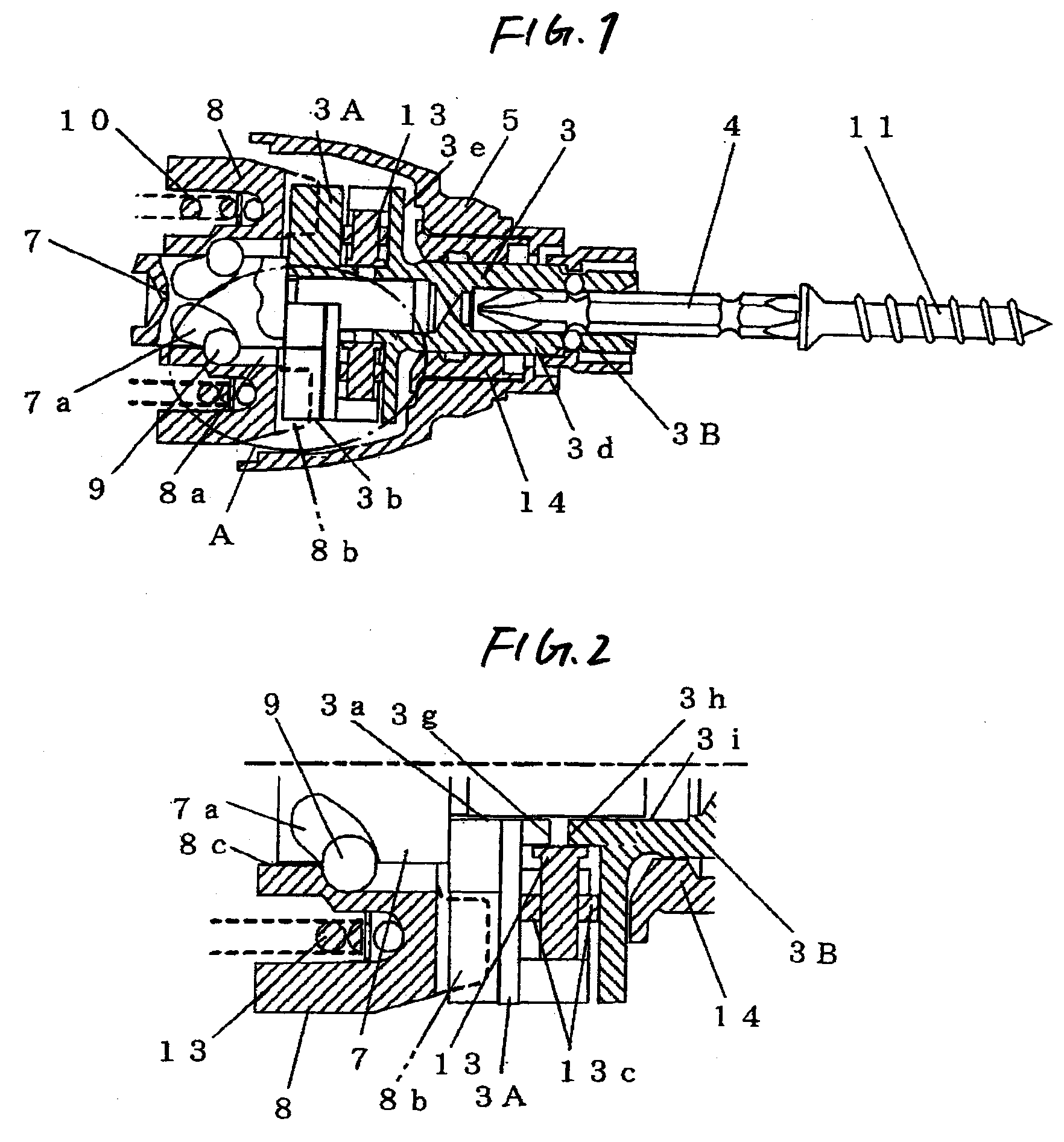

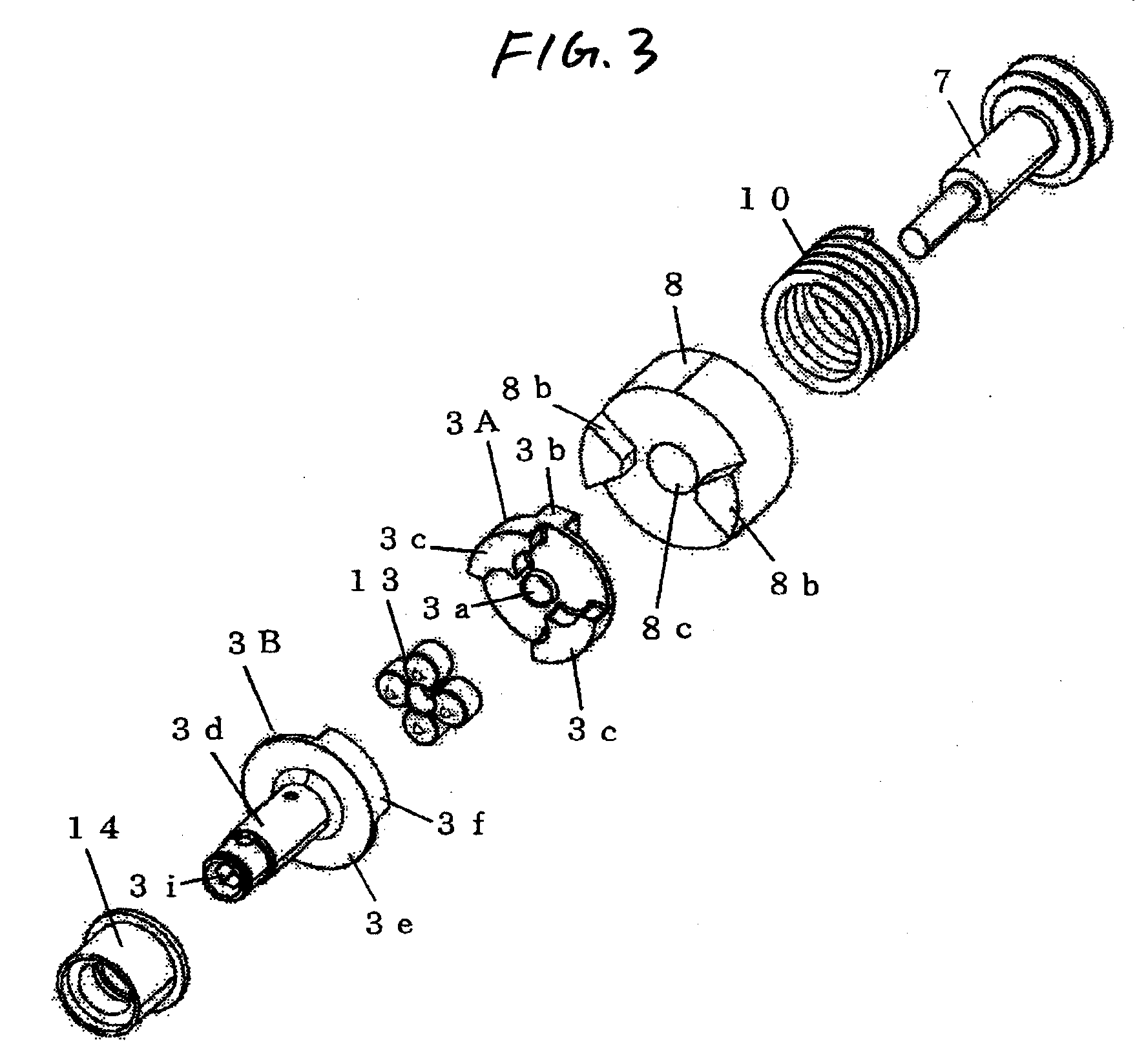

Impact tool

InactiveUS20070179328A1Reduce noiseReduce tightnessHydrocarbonsPower driven toolsEngineeringShock absorber

An impact tool, which can realize the reduction of noise without inviting the reduction of a fastening ability and which can improve the durability of a damper while preventing its damage. The impact tool includes a rotary impact mechanism mounted on a spindle to be rotationally driven by a motor, so that rotary impact is applied to a tip tool by transmitting the rotary impact intermittently from a hammer through an anvil to the tip tool. A plurality of pawls are formed on two half members of the anvil in the axial direction. A rubber damper is disposed in a space between the pawls arranged alternately in the circumferential direction of the two half members. The minimum sectional area of the space formed between the pawls is set larger than the sectional area of the rubber damper.

Owner:KOKI HLDG CO LTD

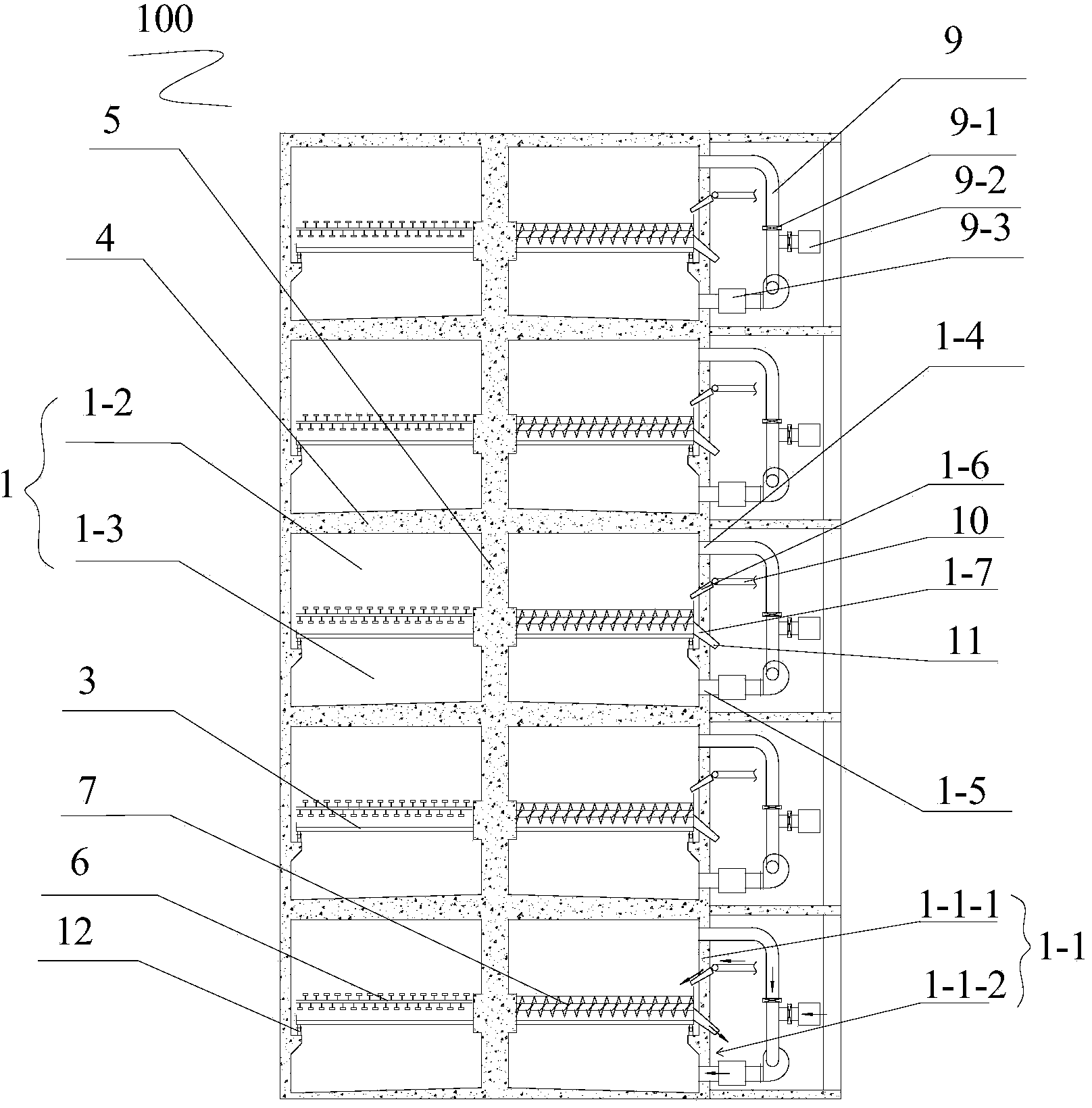

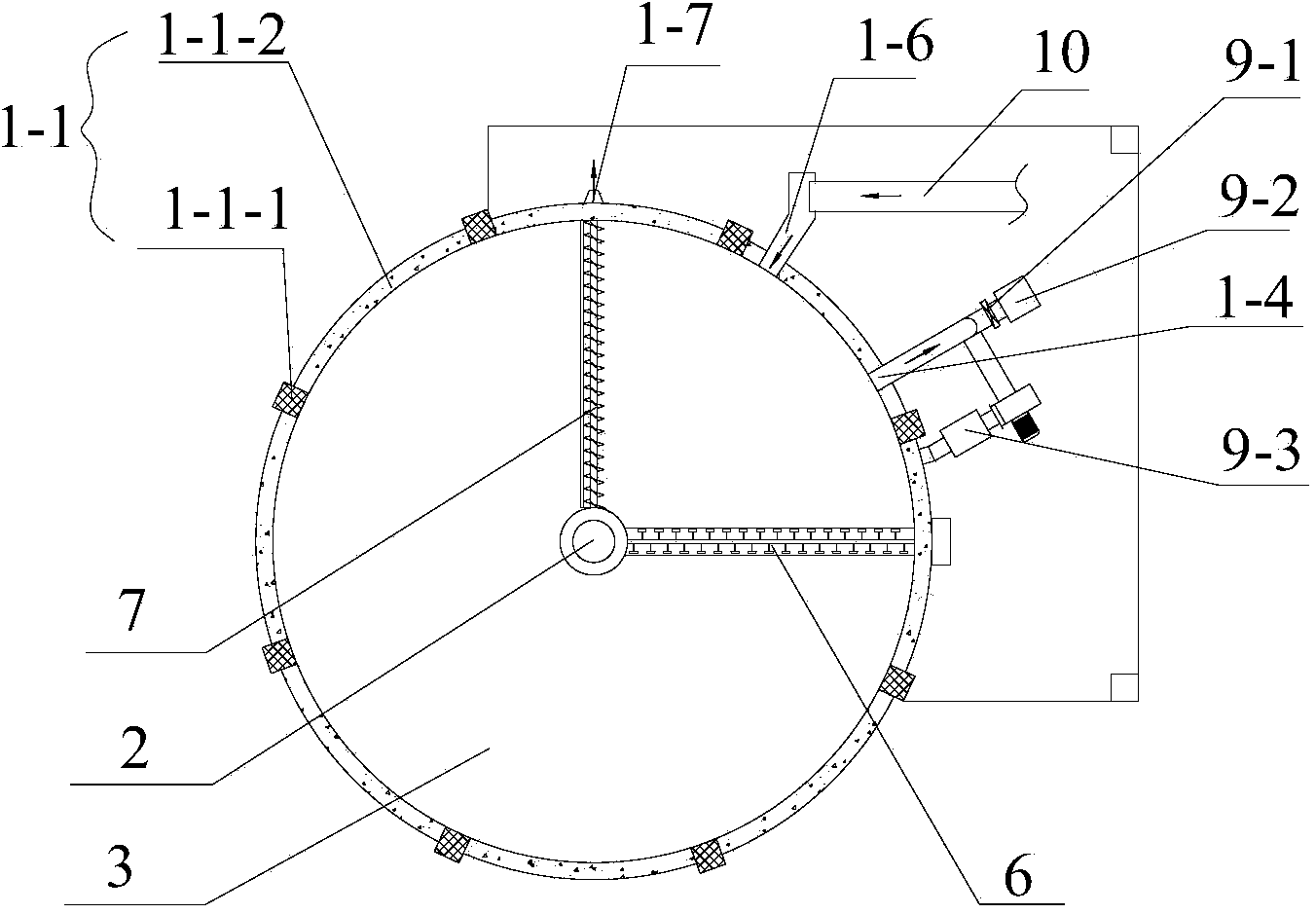

Disc type starter propagation equipment

ActiveCN104046560ATake advantage ofReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringTower

The invention discloses disc type starter propagation equipment. The equipment comprises at least one starter propagation tower, wherein the starter propagation tower is divided into a plurality of starter propagation chambers by clapboards in the tower, the starter propagation chambers are respectively provided with a disc with a net hole, the centers of the disc are fixedly arranged on spindles, the peripheries of the discs are supported by the side walls of the starter propagation chambers, center support columns are arranged between the clapboards in the tower and used for supporting the clapboards in the tower and installing the spindles, the side walls of the starter propagation chambers are provided with disc drive mechanisms for driving the discs to rotate, a starter overturning mechanism and a material flattening and starter discharging mechanism are arranged above the discs, the rotary shafts of the two mechanisms are respectively vertical to the spindle, two ends of the rotary shafts are respectively supported by the side walls of the starter propagation chambers and the center support columns, each starter propagation chamber is divided into an upper starter propagation chamber and a lower starter propagation chamber by one disc, the side walls of the upper and lower starter propagation chambers are respectively provided with a return air inlet and an air inlet which are respectively communicated with an air flue, the side walls of the upper and lower starter propagation chambers are respectively provided with a material inlet and a material outlet which are respectively communicated with a material feed channel and a material discharge channel, and the side walls of the starter propagation chambers and the clapboards in the tower are of a concrete structure. The main body of the equipment is of a concrete structure, so that the land is fully used, the production cost is lowered, and the service life of the equipment is prolonged.

Owner:日照新睿招商发展有限公司

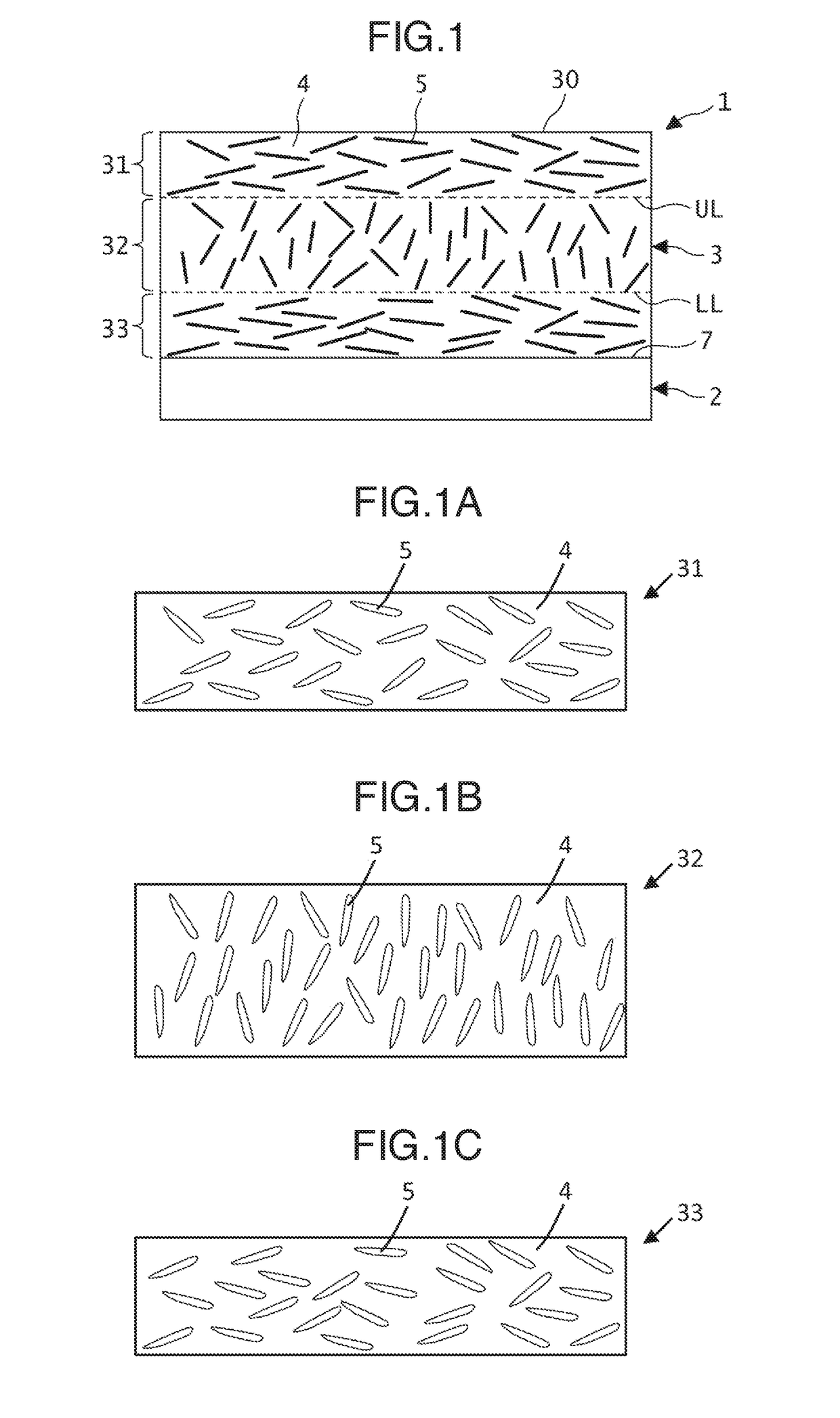

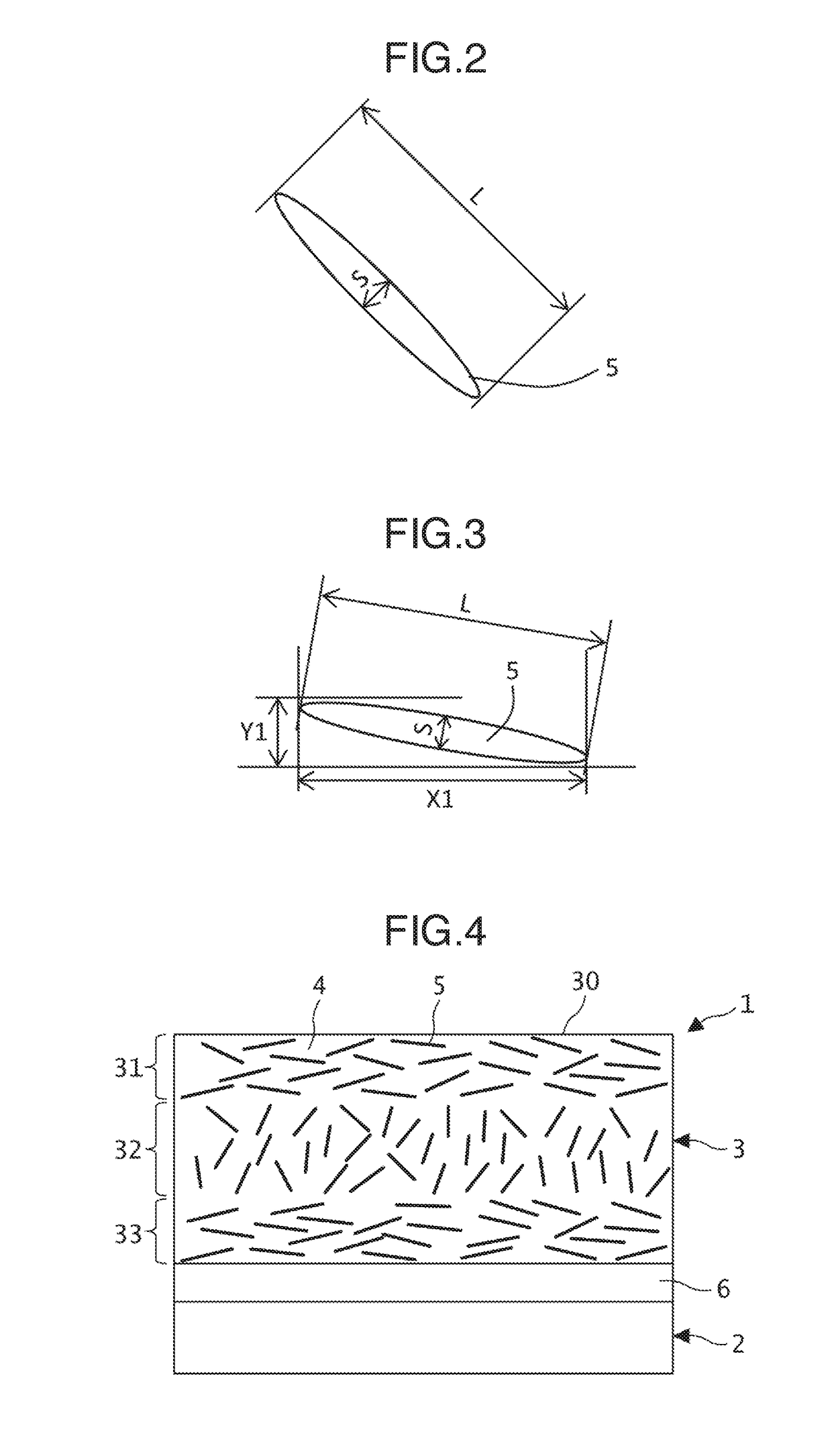

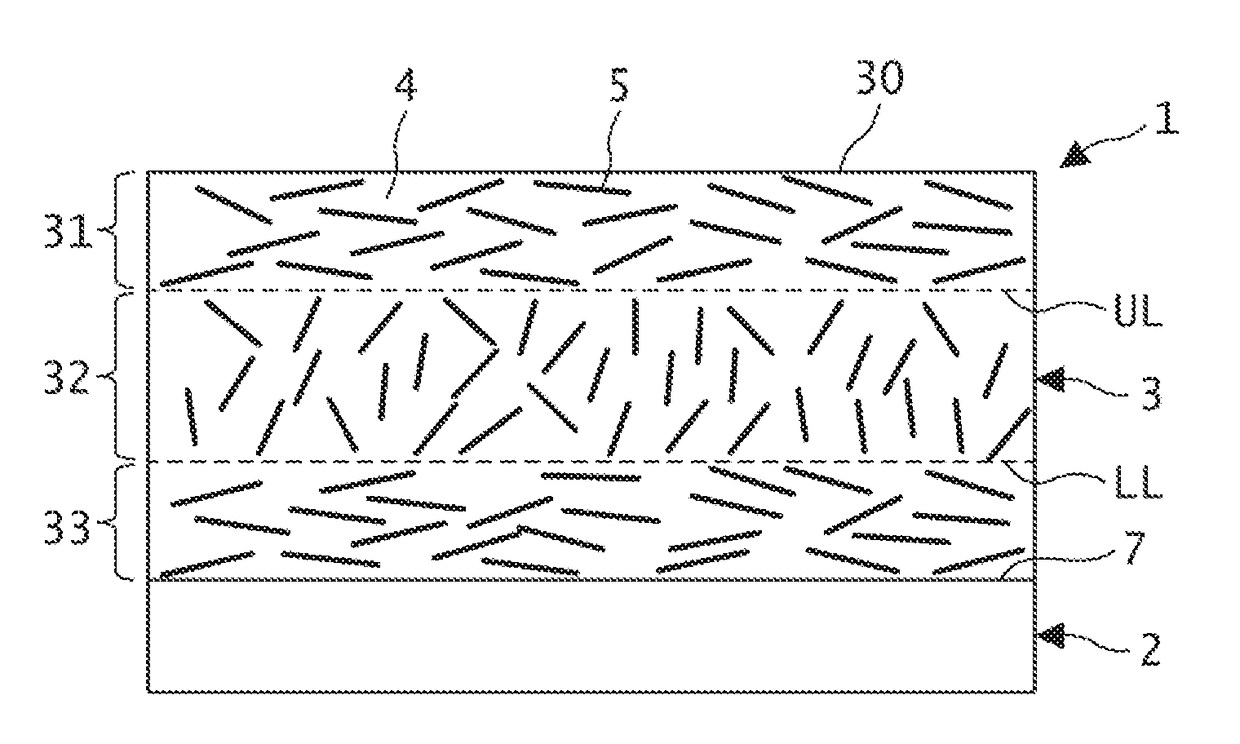

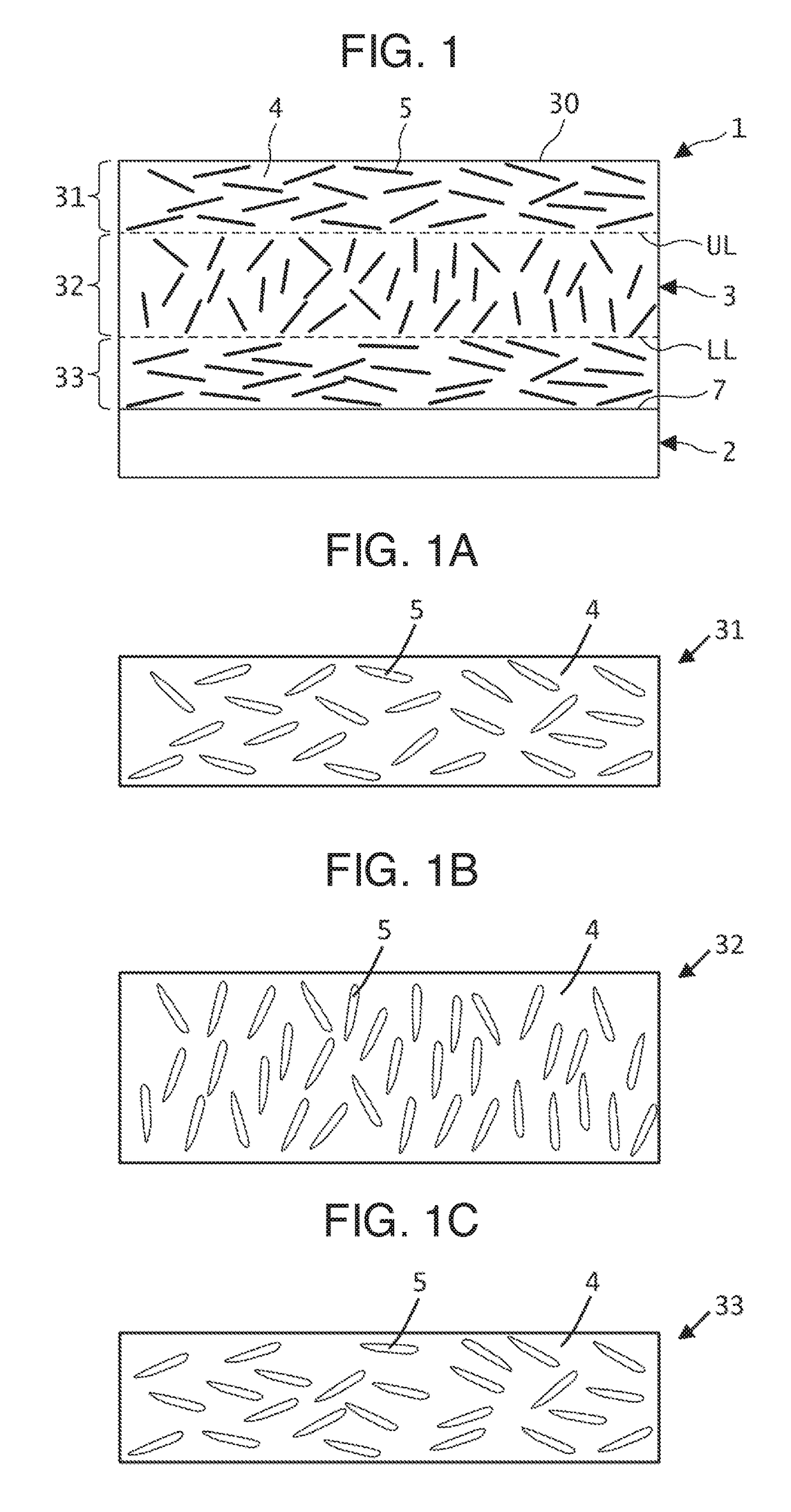

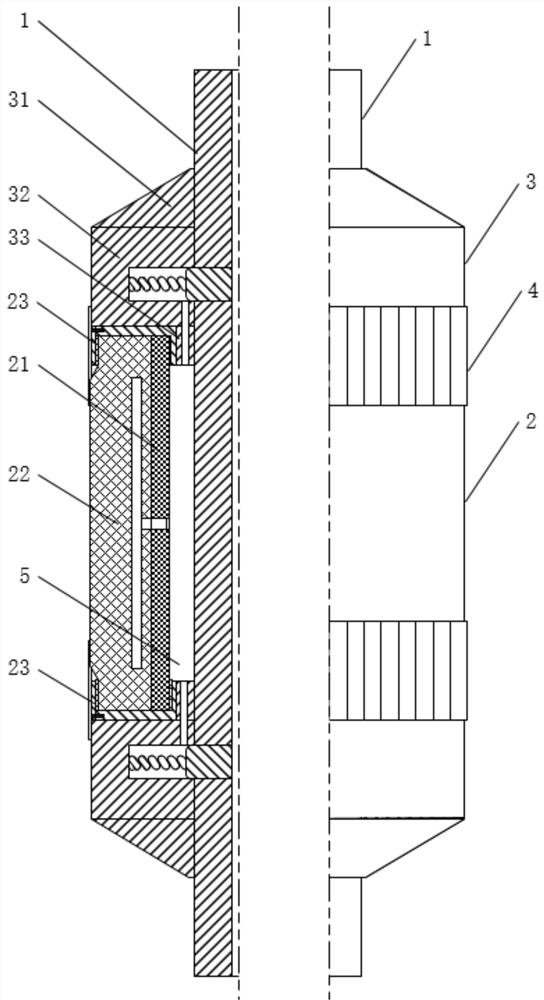

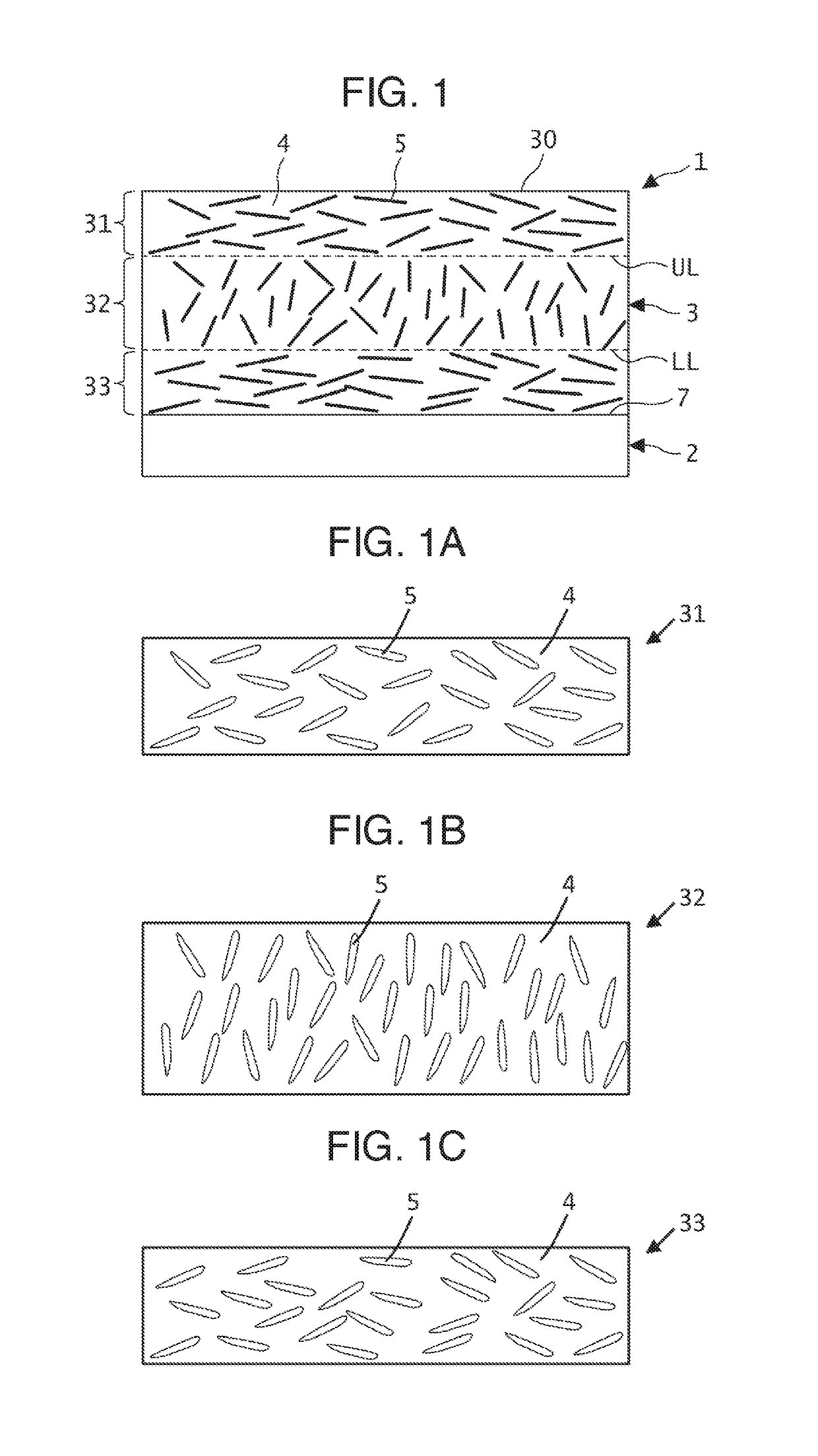

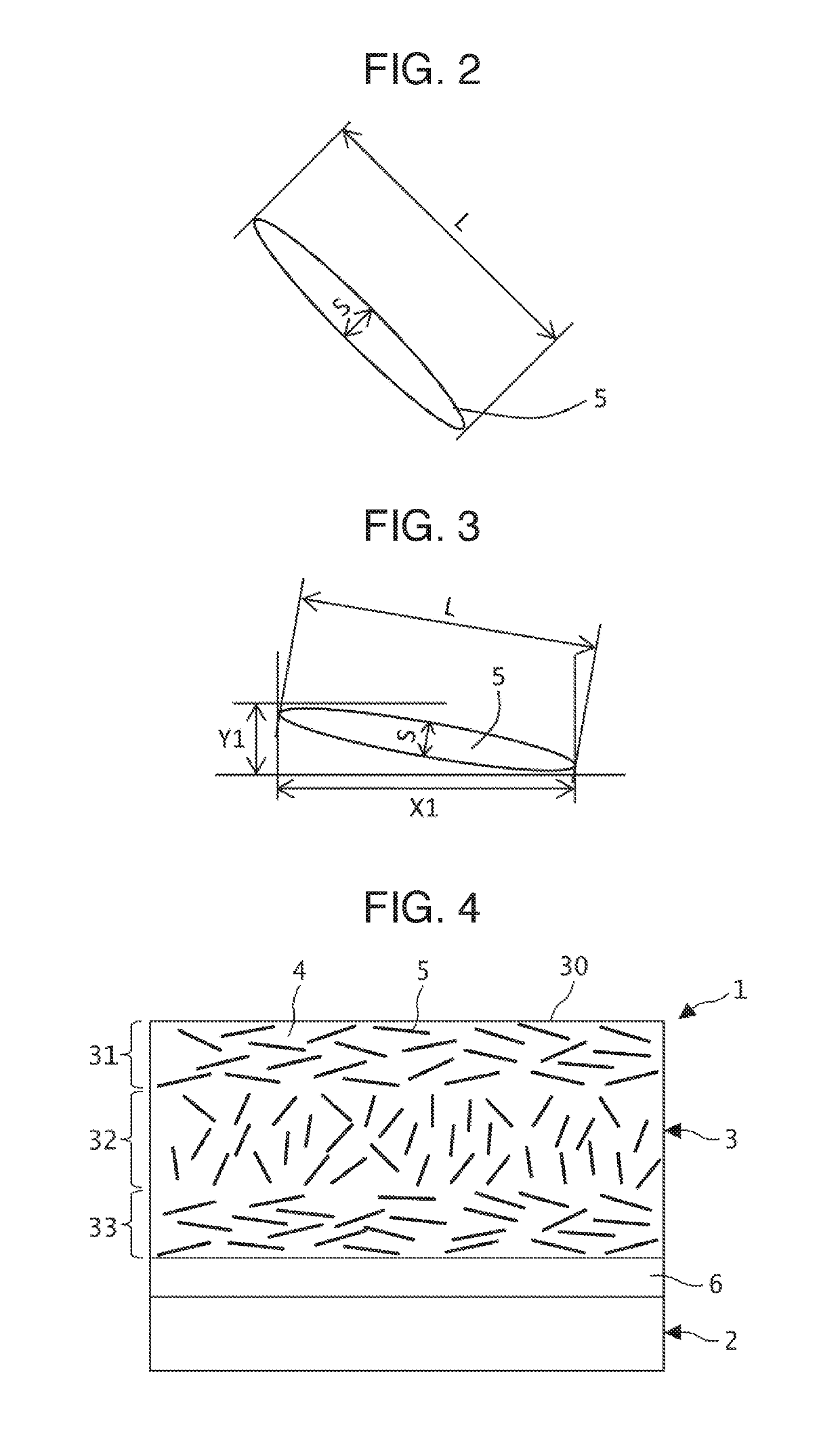

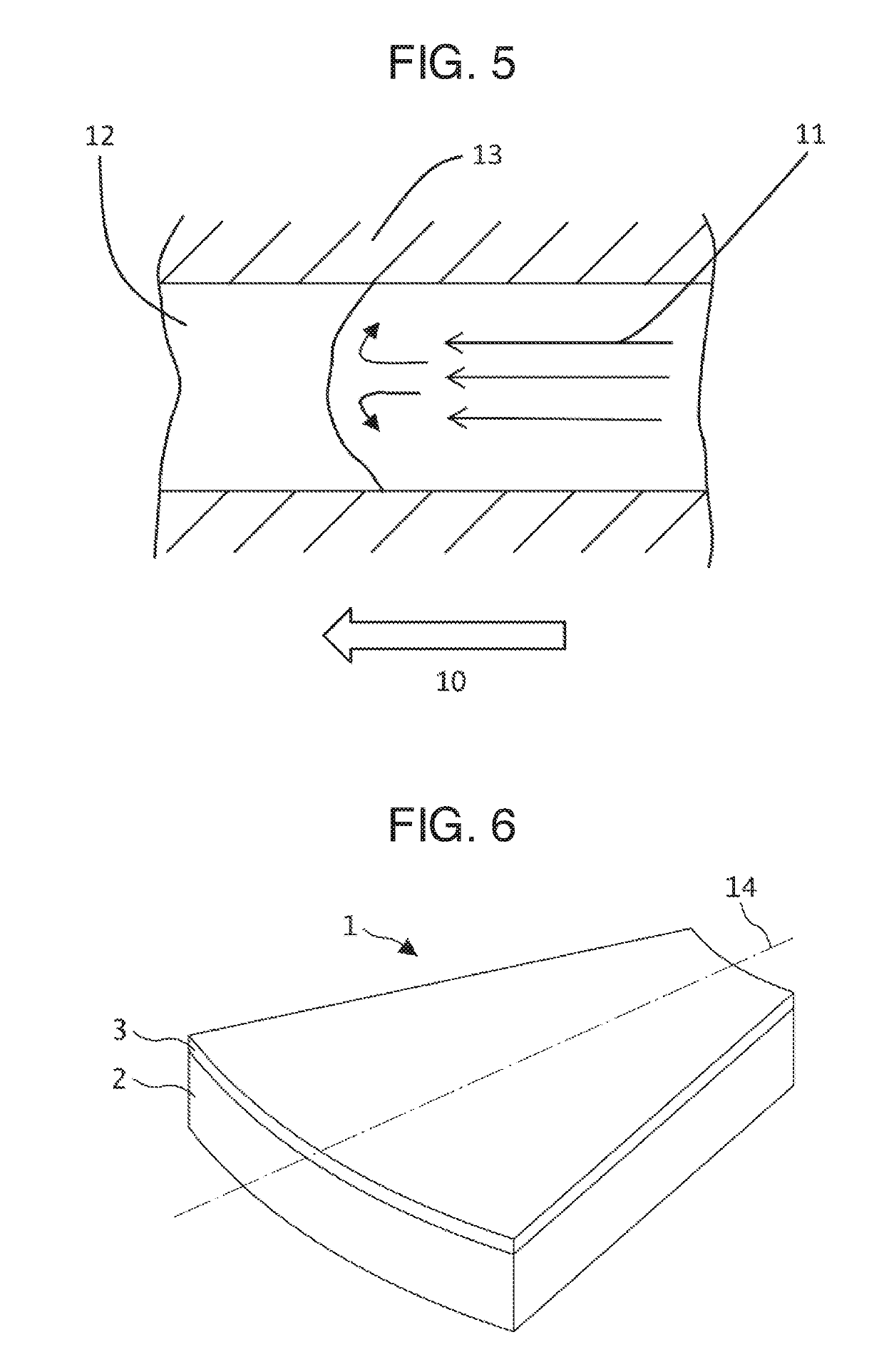

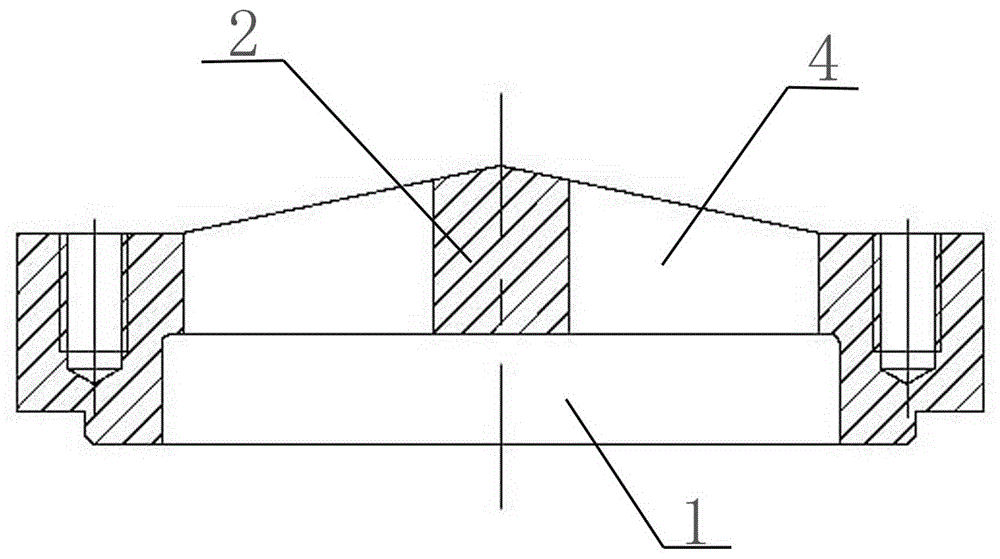

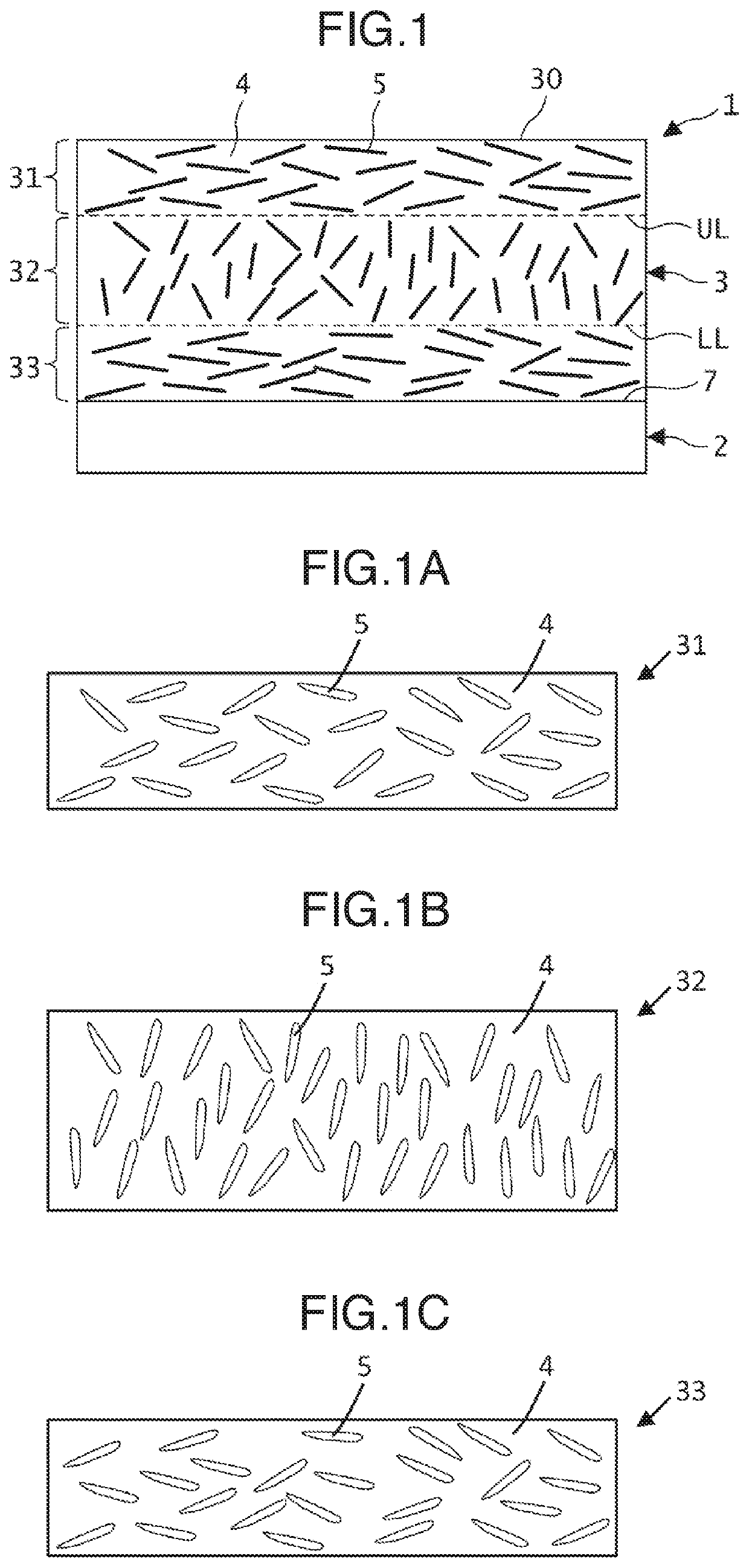

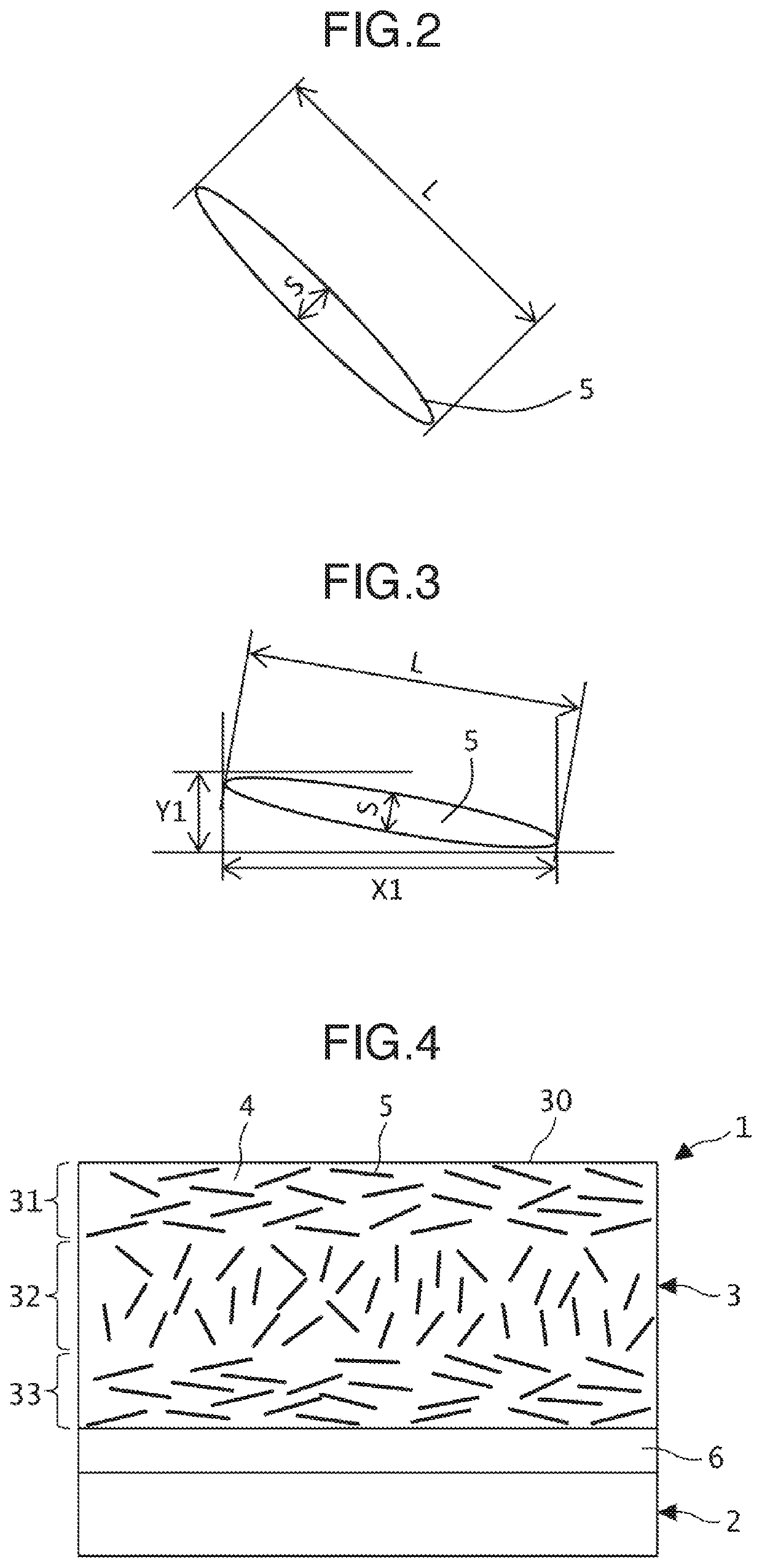

Sliding member

ActiveUS20180258992A1Reduce elastic deformationAvoid damageLayered productsShaftsLayer thicknessSynthetic resin

Provided is a partially-cylindrical sliding member including a sliding layer including fibrous particles having an average particle size of 5-25 μm dispersed in a synthetic resin at a volume ratio of 10-35% of the sliding layer. The particles having a major axis length ≤20 μm are included at a volume ratio of ≥10% to total particles. A sliding surface side area is defined from the sliding surface and has a thickness of 25% of a sliding layer thickness T, where the fibrous particles having a major axis length of ≥20 μm have a dispersion index of 1.1-6. An interface side area is defined from the interface and has a thickness of 25% of T, where the dispersion index is 1.1-6. An intermediate area is defined between the both areas, where the dispersion index is 0.1 to less than 1.

Owner:DAIDO METAL CO LTD

Die casting machine with L-shape frame

Owner:SUZHOU CHENGSHI CASTING

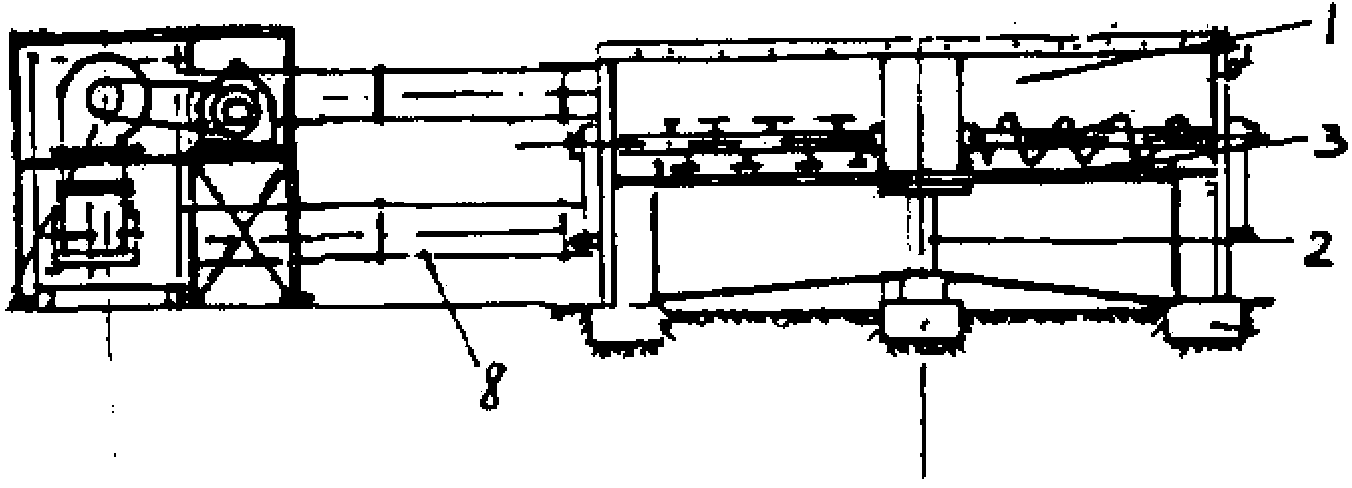

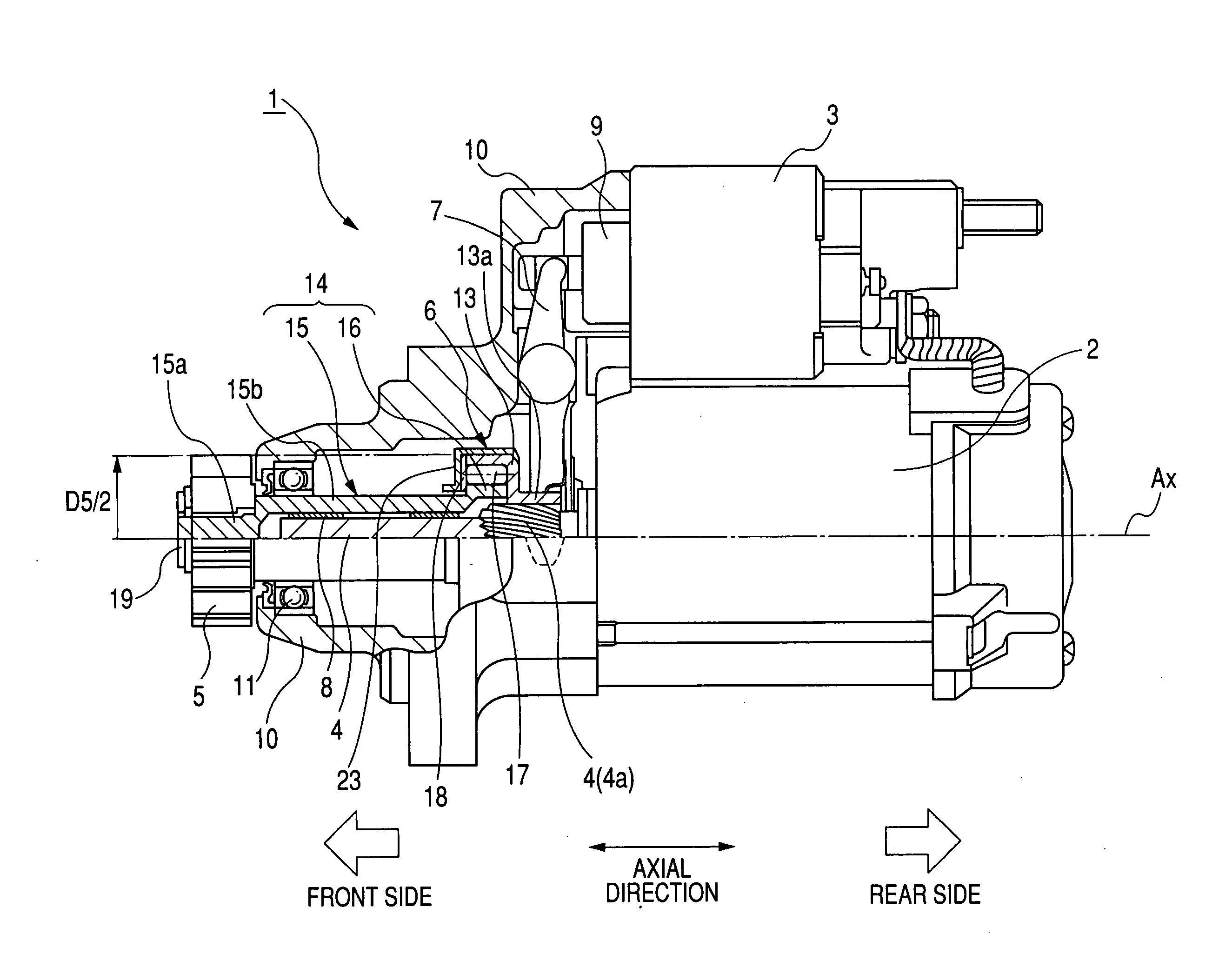

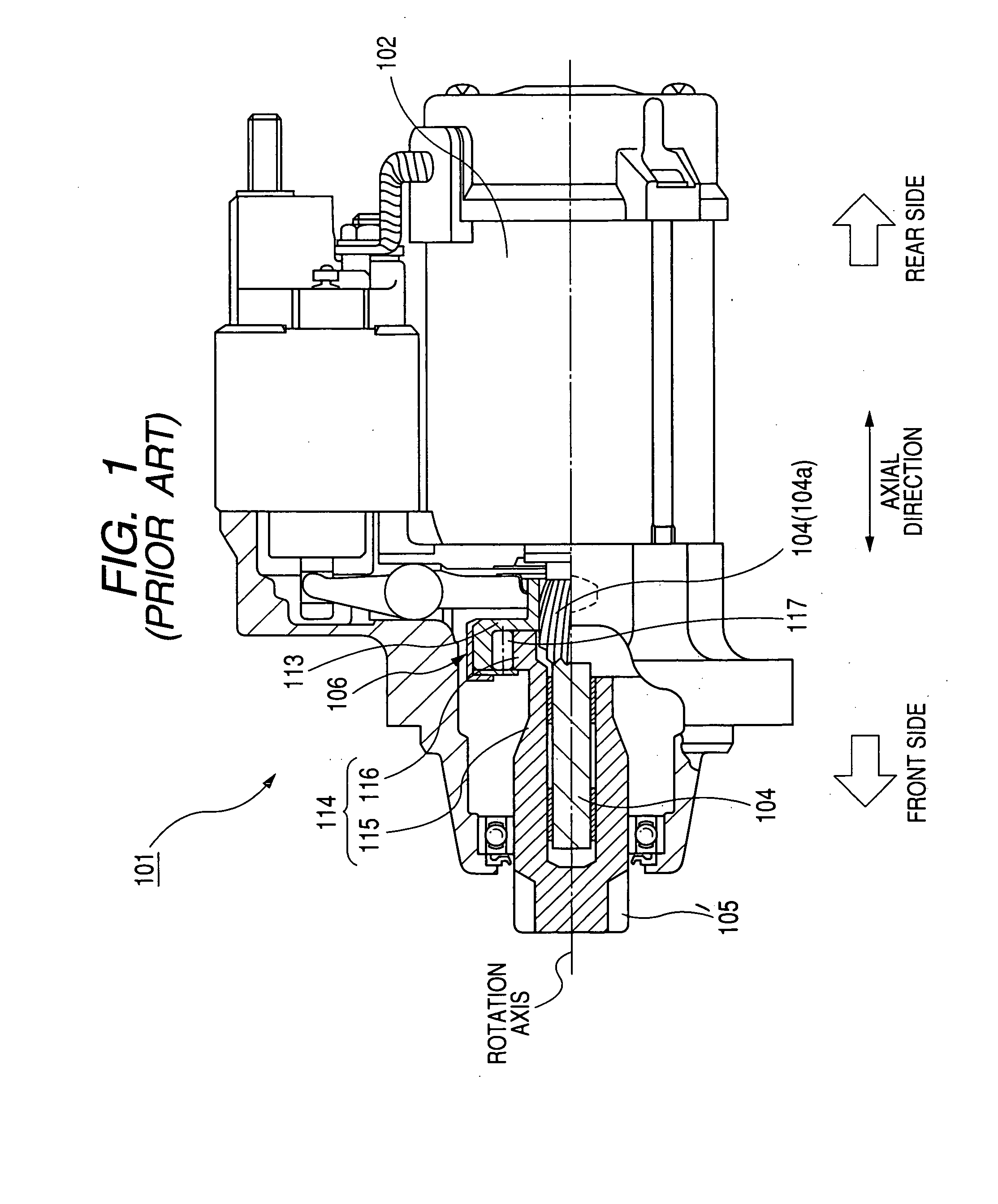

Starter with clutch coaxially disposed on output shaft of motor

InactiveUS20090064806A1Reduce elastic deformationImprove rigidityPower operated startersMachines/enginesElectric machineEngineering

A starter has a clutch coaxially disposed on an output shaft of a motor. The clutch has a clutch outer, an inner member having a clutch inner disposed on an inner side of the outer and a shaft portion disposed on a front side of the inner, a roller disposed between the outer and inner, a clutch cover attached to an outer surface of the outer and extending toward the shaft portion, and a clutch washer disposed on a front surface of the inner between the cover and inner. The distance between the cover and the rotation axis of the clutch is smaller than the distance between the outer end of the inner and the rotation axis. The rotation force of the motor is received in the outer and is transmitted to an engine through the roller and inner member to crank the engine.

Owner:DENSO CORP

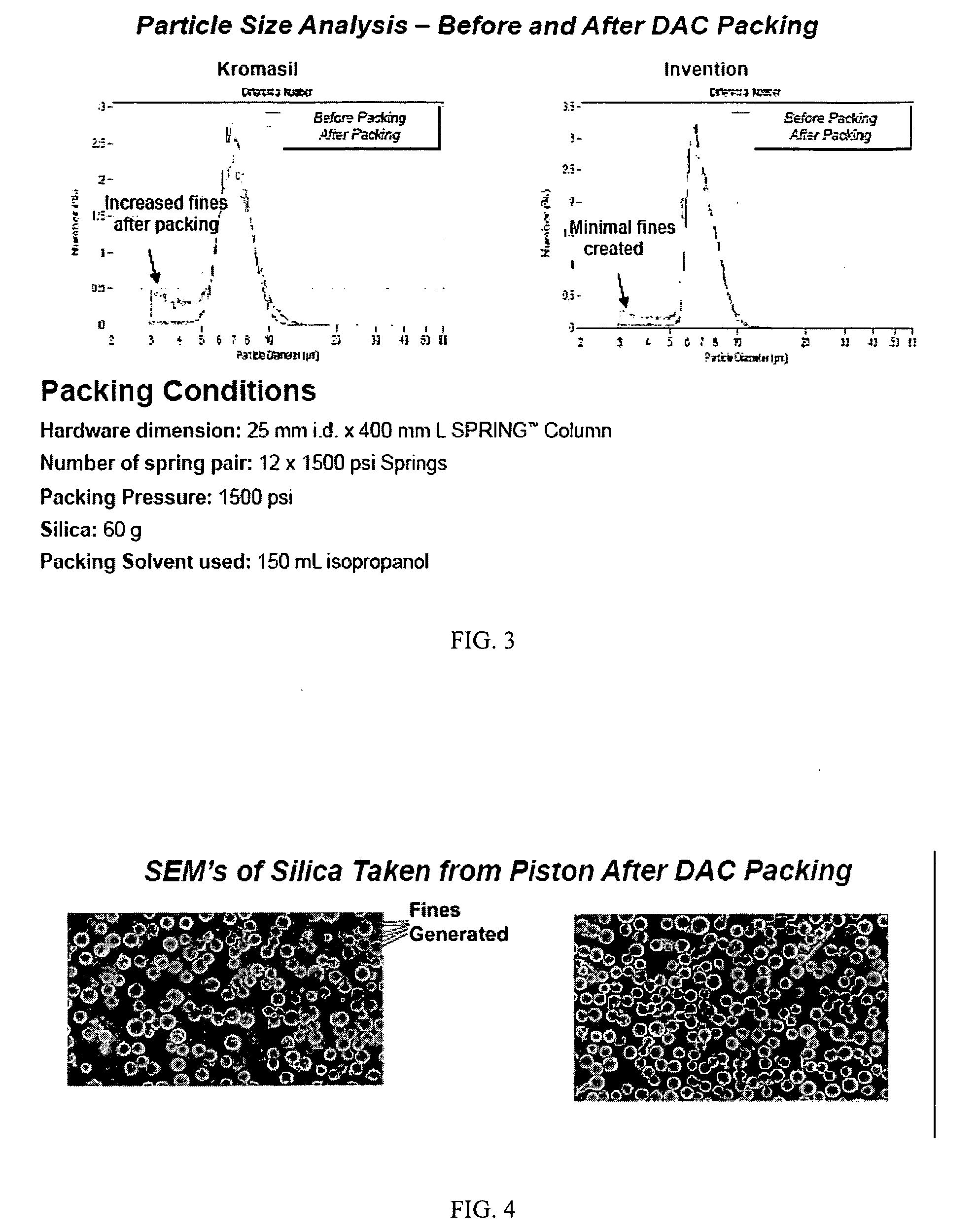

Silica particles and methods of making and using the same

InactiveUS20100116743A1Efficient packagingImprove plastic deformationIon-exchange process apparatusSilicaSilica particleSilicon oxide

Owner:PRYOR JAMES NEIL +1

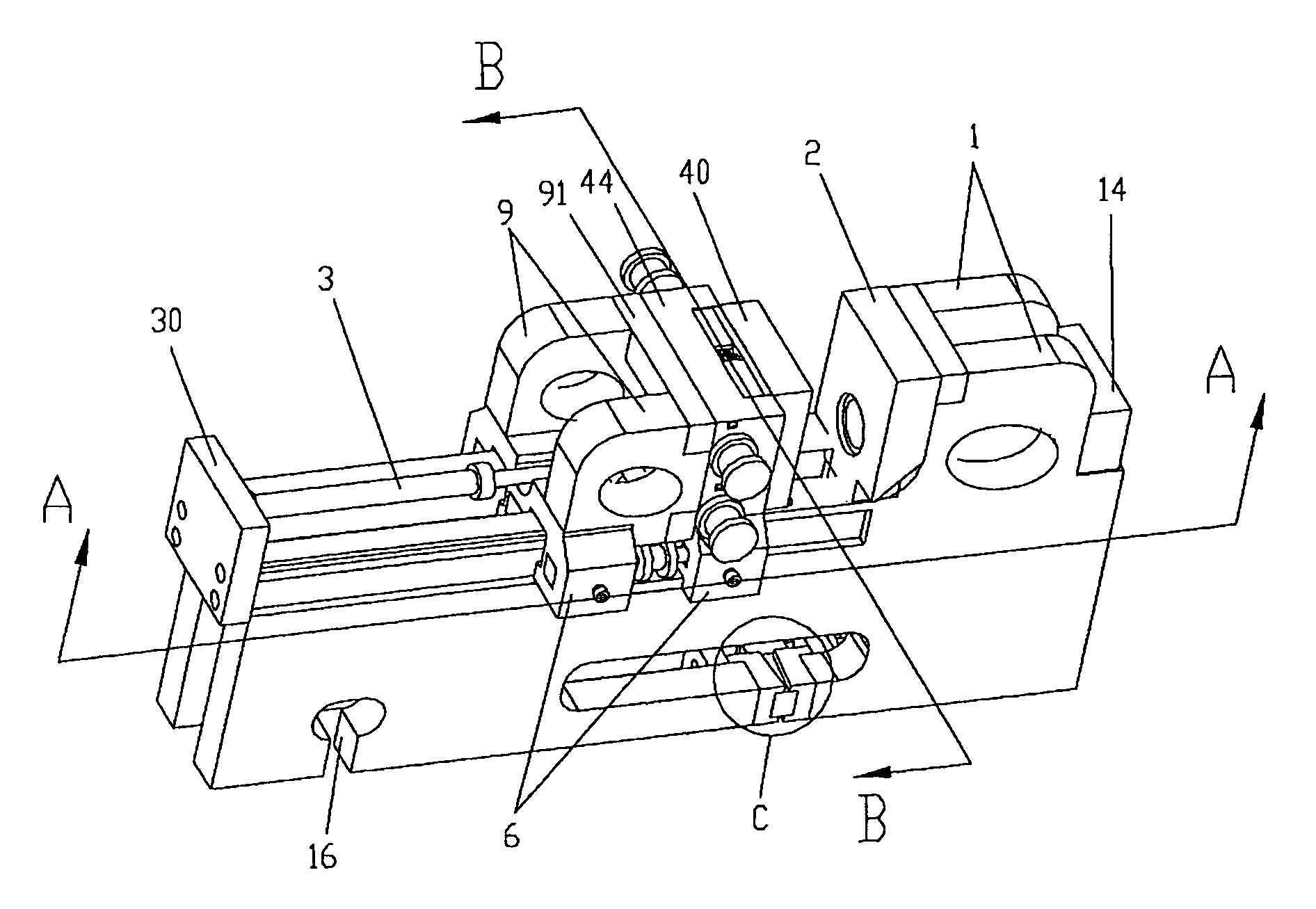

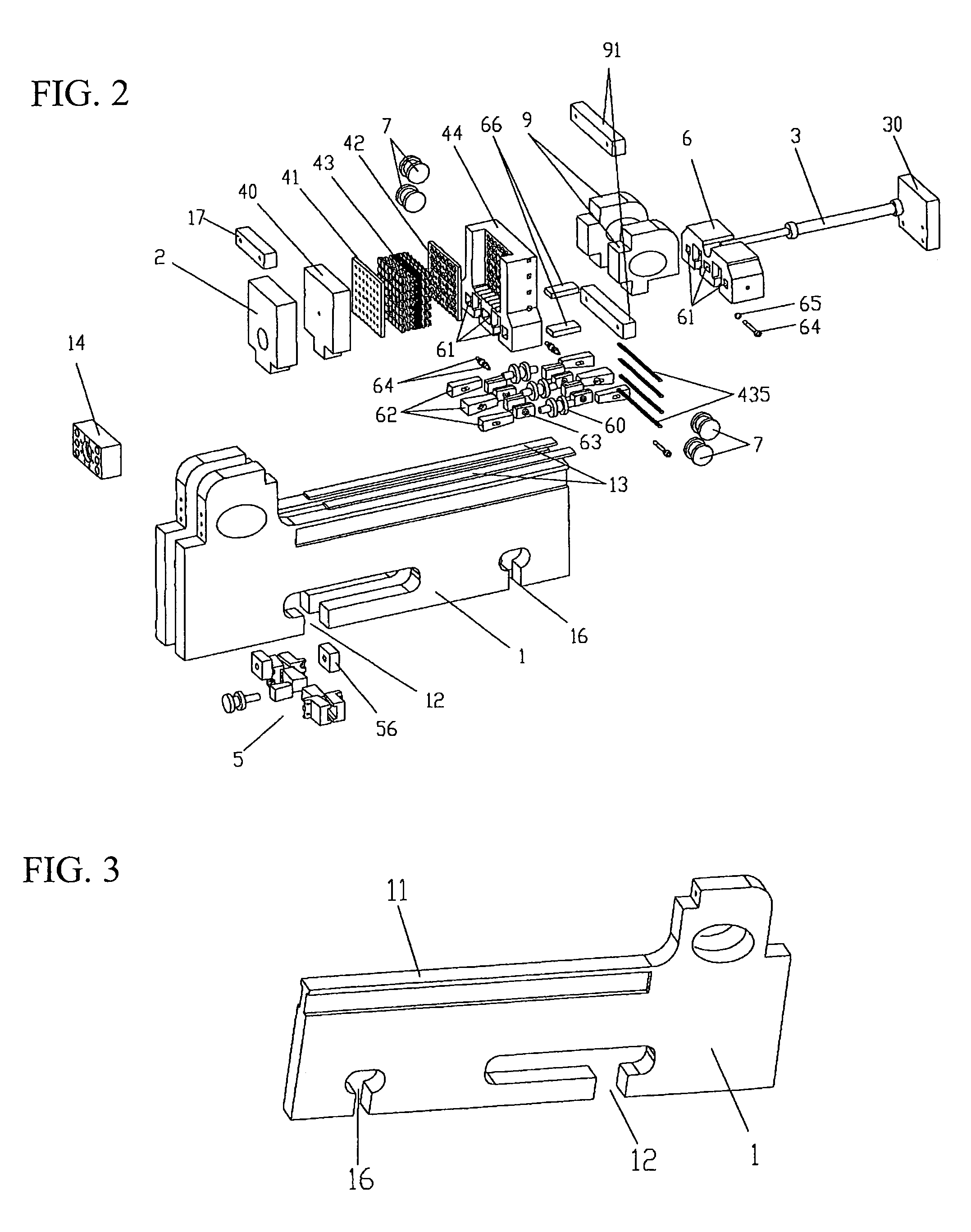

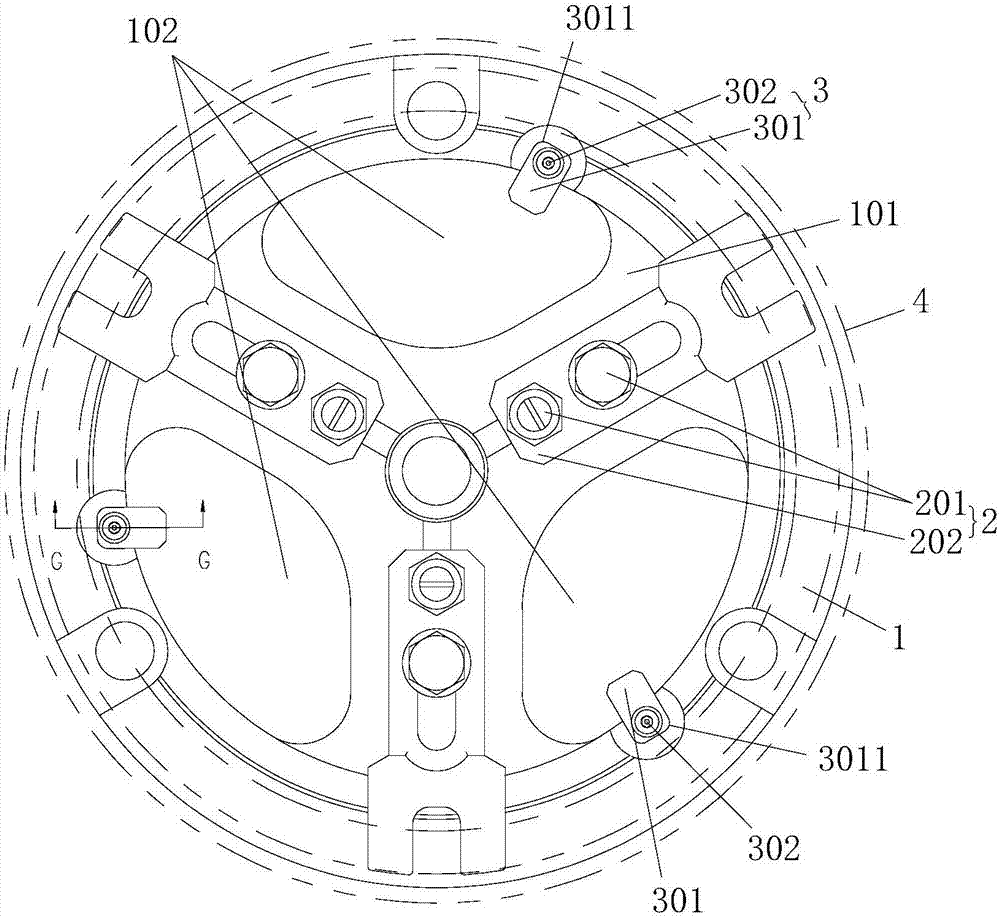

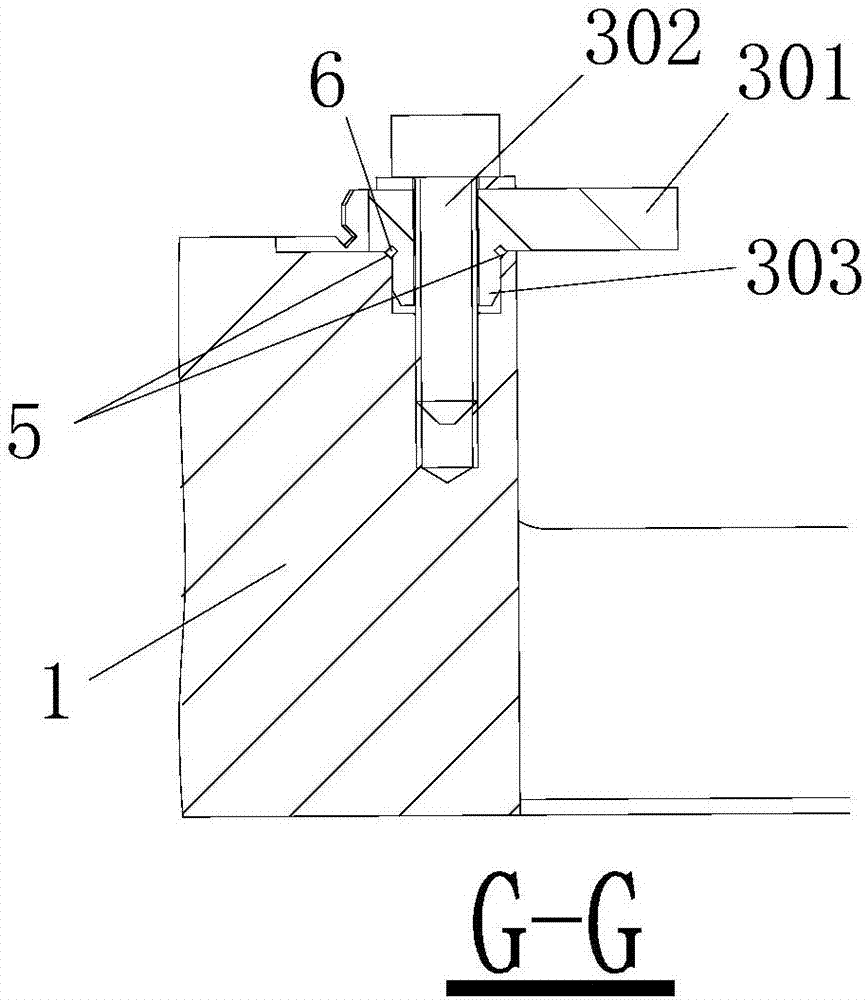

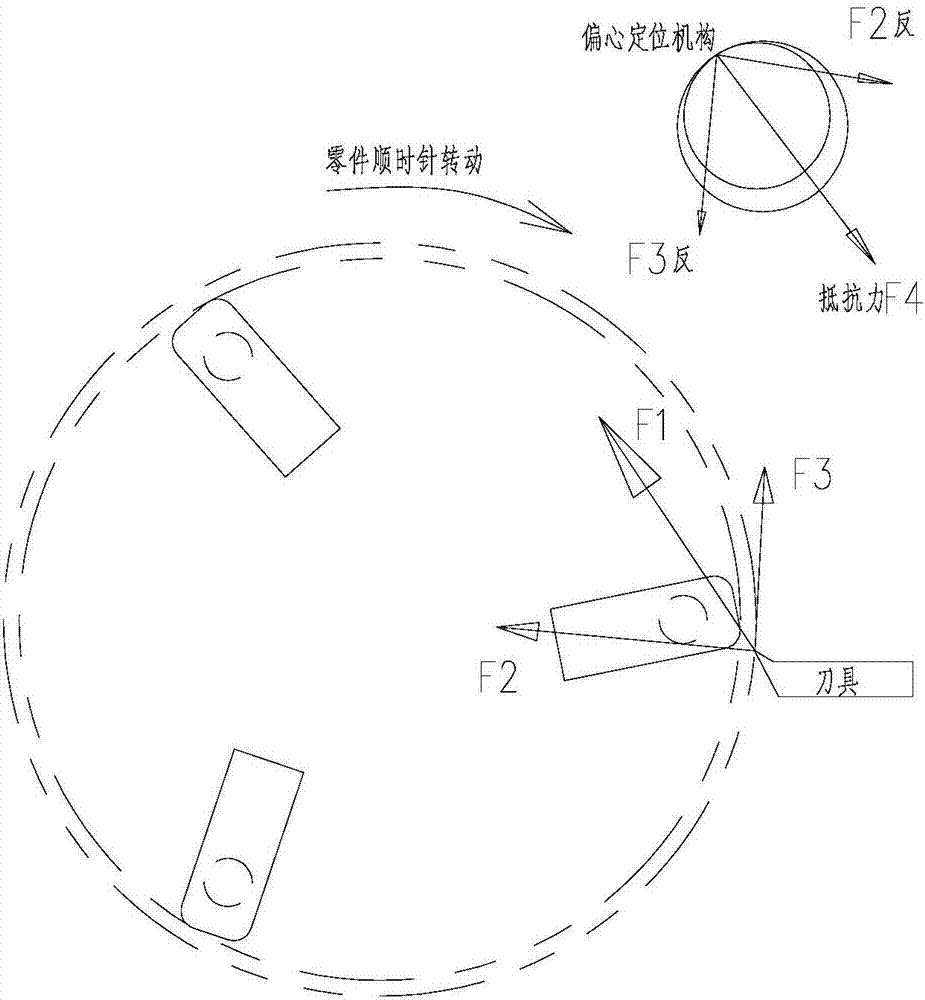

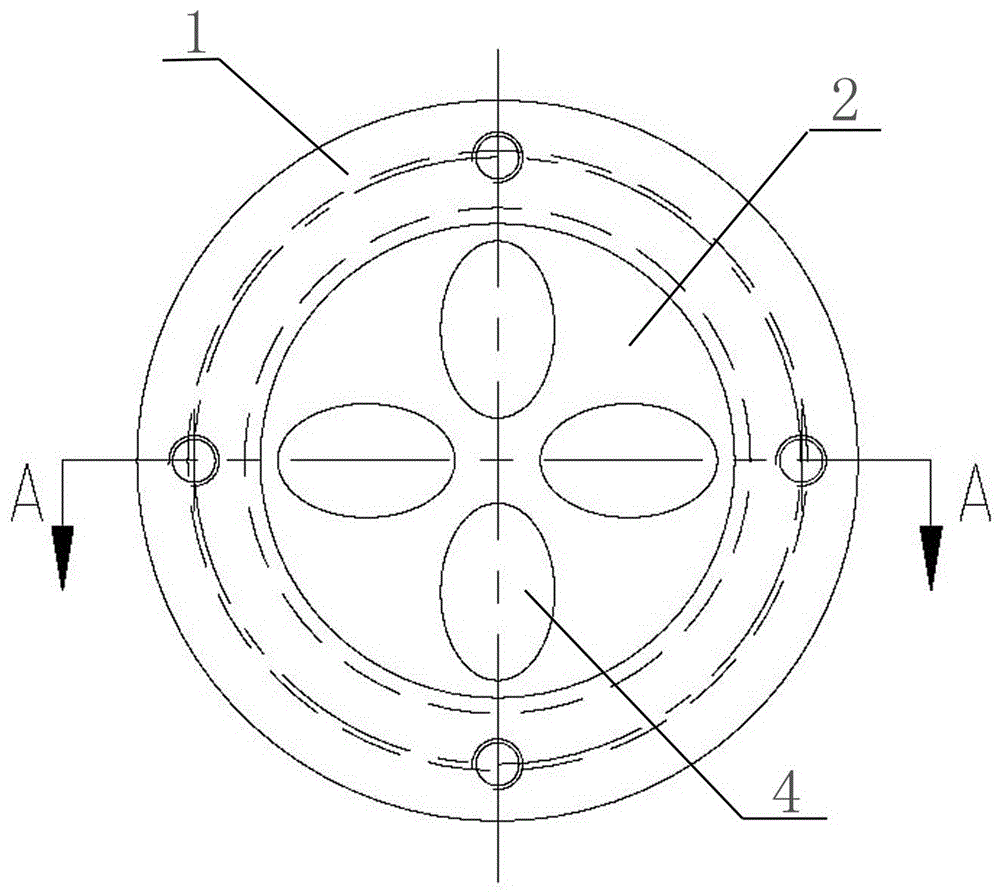

Turning clamp and turning fixing method for thin-wall deforming part

ActiveCN107297635AReliable deformationPrecise lock positionPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a turning clamp and turning fixing method for a thin-wall deforming part. The turning clamp for the thin-wall deforming part comprises a base and a compression mechanism, wherein the base is used for bearing a to-be-processed part and installed on a machine tool spindle and rotates along with the rotation of the machine tool spindle; and the compression mechanism is used for compressing the to-be-processed part on the base. The base is provided with multiple groups of eccentric locating mechanisms, wherein the eccentric locating mechanisms are eccentrically installed on the base and used for making tight contact with the locating face of the to-be-processed part obtained after generating stress deformation through the rotation in the radial direction of the to-be-processed part and radially limiting the to-be-processed part through locking; rotational adjusting contact and locking fixing are conducted by the eccentric locating mechanisms on the to-be-processed part in at least three directions. By means of the turning clamp and the turning fixing method, the elastic deformation of the to-be-processed part after being disassembled from the turning clamp is reduced, the precision of the size, circularity, flatness and the like of the processed to-be-processed part is ensured, and the out-of-tolerance problems are avoided.

Owner:CHINA HANGFA SOUTH IND CO LTD

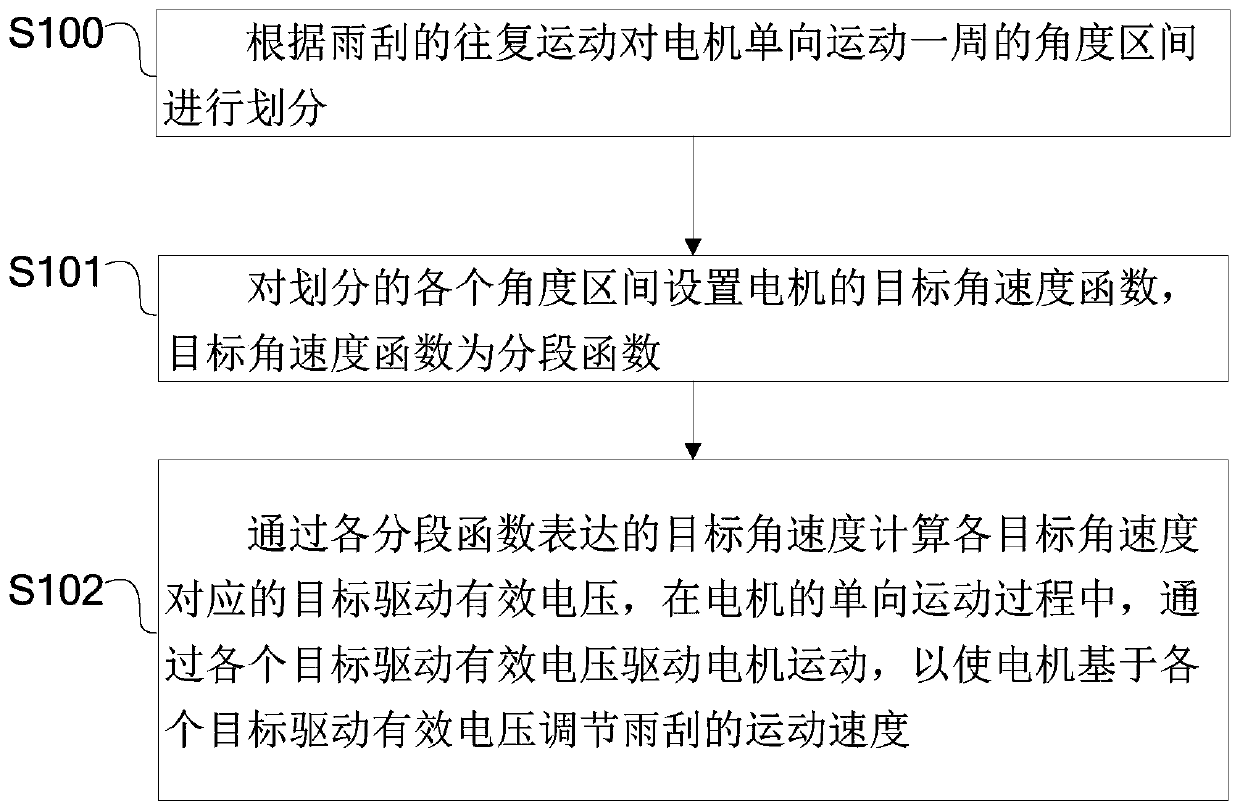

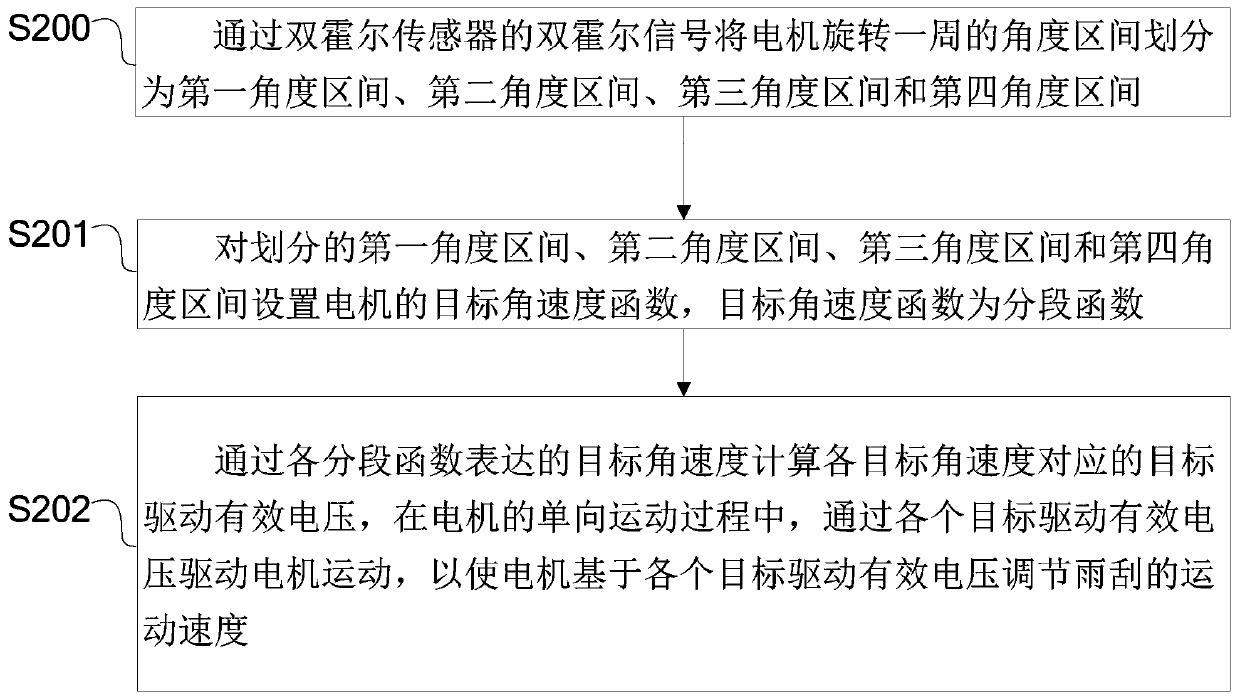

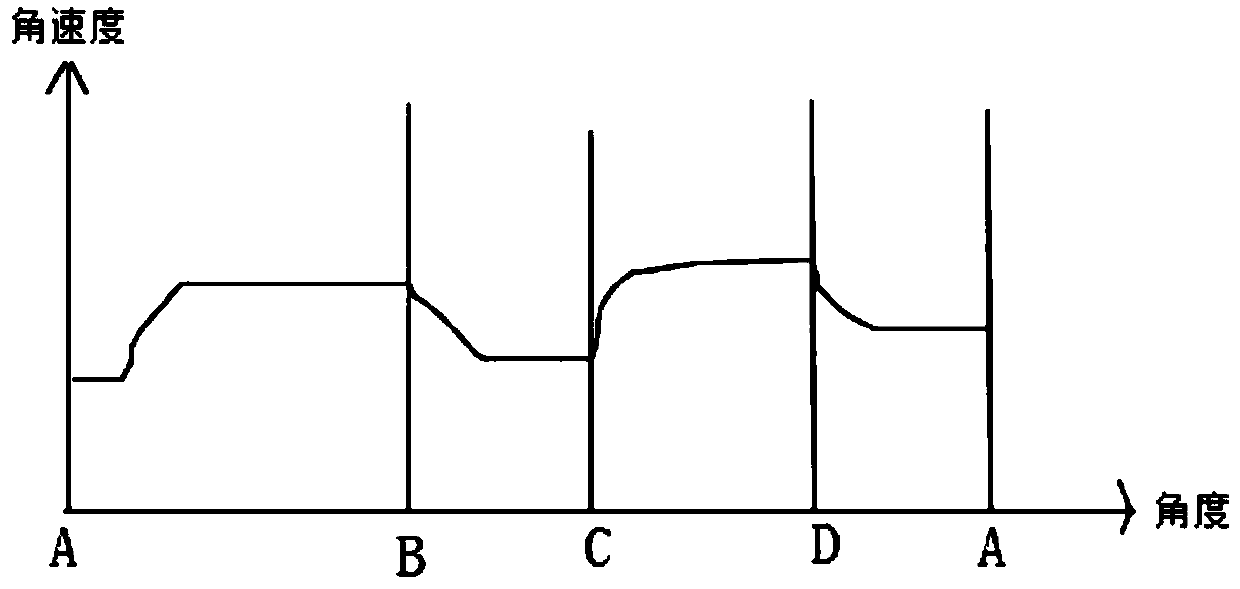

Wiper speed regulating control method, system and controller

PendingCN110015267AAdjustable running speedReduce reverse noiseSingle motor speed/torque controlVehicle cleaningControl systemVoltage regulation

The invention discloses a wiper speed regulating control method. The wiper speed regulating control method comprises the steps that a rotation angle interval of a motor is divided into four angle intervals through a double hall signal of a double hall sensor; target angular velocity functions of the motor are set for each divided angle interval, wherein the target angular velocity functions are piecewise functions; and target driving effective voltage corresponding to each target angular velocity is calculated through the target angular velocity expressed by each piecewise function, in the process of one-way movement of the motor, and the motor is driven to move by each target driving effective voltage to make the motor adjust the motion speed of a wiper based on each target driving effective voltage. By controlling the driving effective voltage of the motor to control variable motion of the wiper, for instance, the wiper can slow down near a reversal point, the wiper is controlled toaccelerate in a certain way in the middle of the reversal point, the wiper speed is increased, thus the adjustable speed of the wiper throughout the wiper cycle is ensured, elastic deformation of a blade during the high-speed wiper is reduced, and at the same inversion noise of the wiper is reduced.

Owner:SHANGHAI YUDIAN ELECTRONICS TECH CO LTD

Sliding member

ActiveUS20180258990A1Strong effectAvoid damageShaftsBearing componentsMaterials scienceSynthetic resin

Provided is a partially-annular sliding member including a sliding layer including fibrous particles having an average particle size of 5-25 μm dispersed in a synthetic resin at a volume ratio of 10-35% of the sliding layer. The particles having a major axis length ≤20 μm are included at a volume ratio of ≥10% to total particles. A sliding surface side area is defined from the sliding surface and has a thickness of 25% of a sliding layer thickness T, where the fibrous particles having a major axis length of ≥20 μm have a dispersion index of 1.1-6. An interface side area is defined from the interface and has a thickness of 25% of T, where the dispersion index is 1.1-6. An intermediate area is defined between the both areas, where the dispersion index is 0.1 to less than 1.

Owner:DAIDO METAL CO LTD

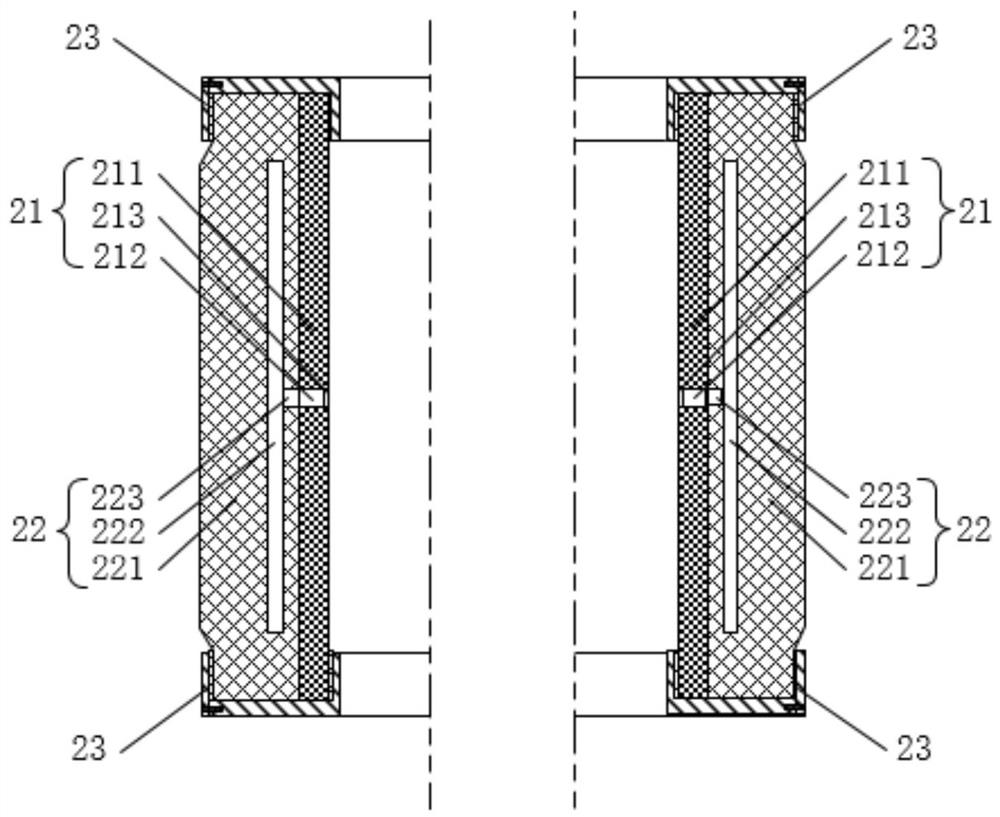

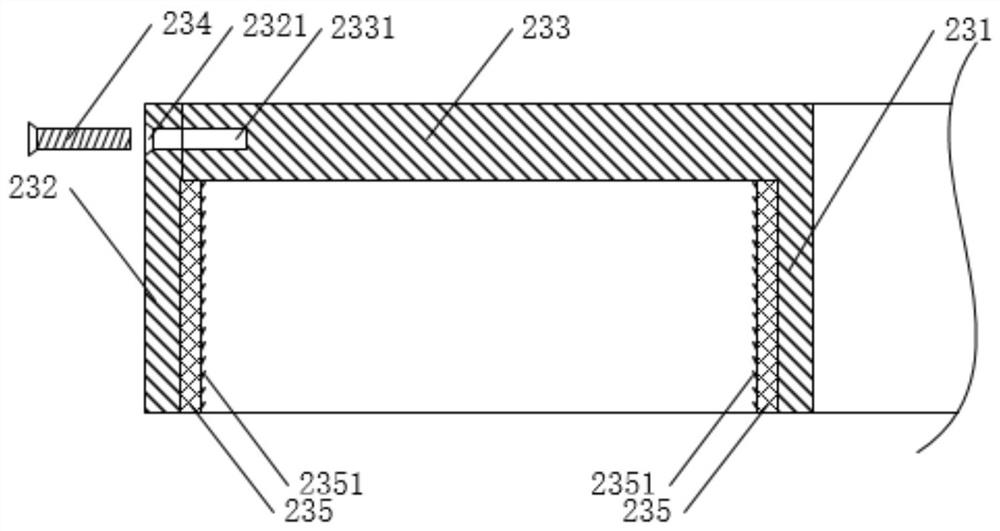

External casing packer

The invention relates to the technical field of oil and gas drilling, well completion, well cementation or well logging, in particular to an external casing packer. The external casing packer comprises a center pipe, a rubber sleeve and a rubber sleeve fixing ring, the rubber sleeve is arranged outside the center pipe in a sleeving mode, the rubber sleeve fixing ring is fixed to the center pipe and fixedly connected with the two ends of the rubber sleeve, and an annular space is reserved between the rubber sleeve and the center pipe. The rubber sleeve comprises an inner sleeve made of an elastic material which does not expand when encountering liquid and an outer sleeve made of an elastic material which expands when encountering oil, a first flow channel leading to the annular space is formed in the rubber sleeve fixing ring, and a sealing valve element is arranged at an inlet of the first flow channel; and the inner sleeve comprises an inner sleeve body, a radial through hole is formed in the axial center of the inner sleeve body, a fracturing sealing film is arranged at the end, facing the center pipe, of the through hole, and a finger-shaped reed is arranged at the joint of therubber sleeve and the rubber sleeve fixing ring in a surrounding mode. The external casing packer can prevent the rubber sleeve from bursting, tearing and extruding, and the packing effect is improved.

Owner:DONGYING XIN HUALIAN PETROLEUM MACHINERY

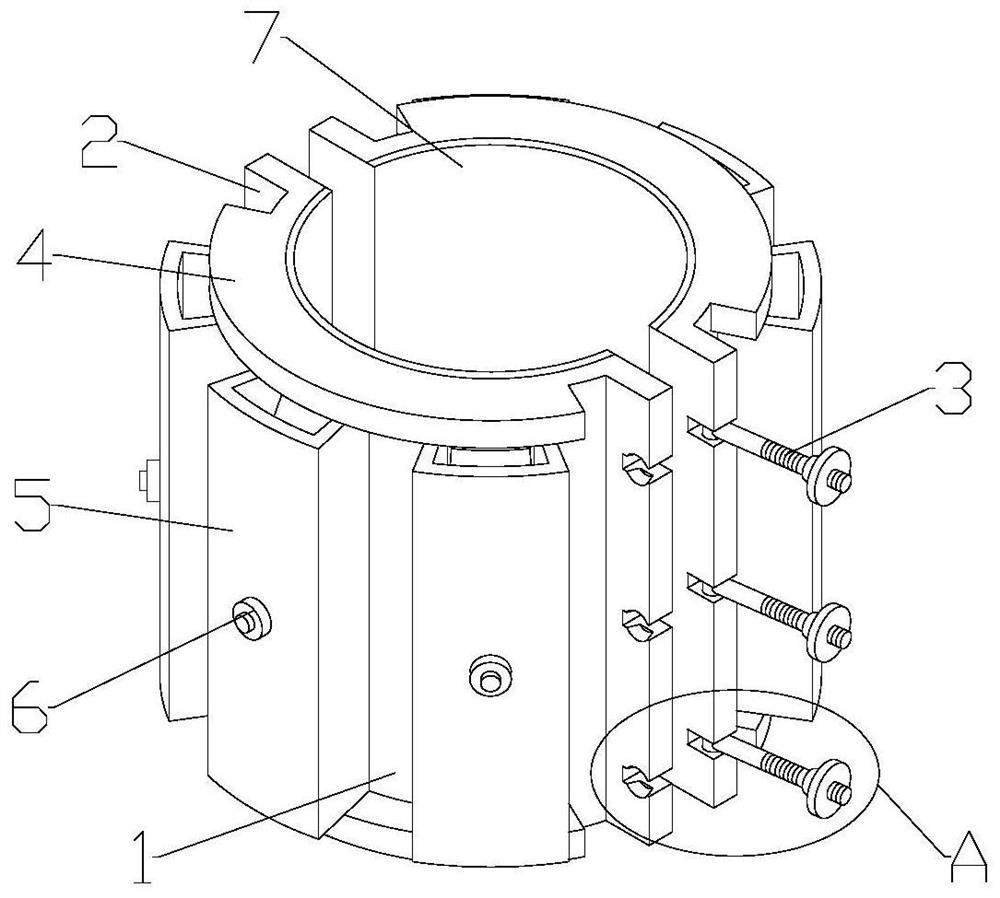

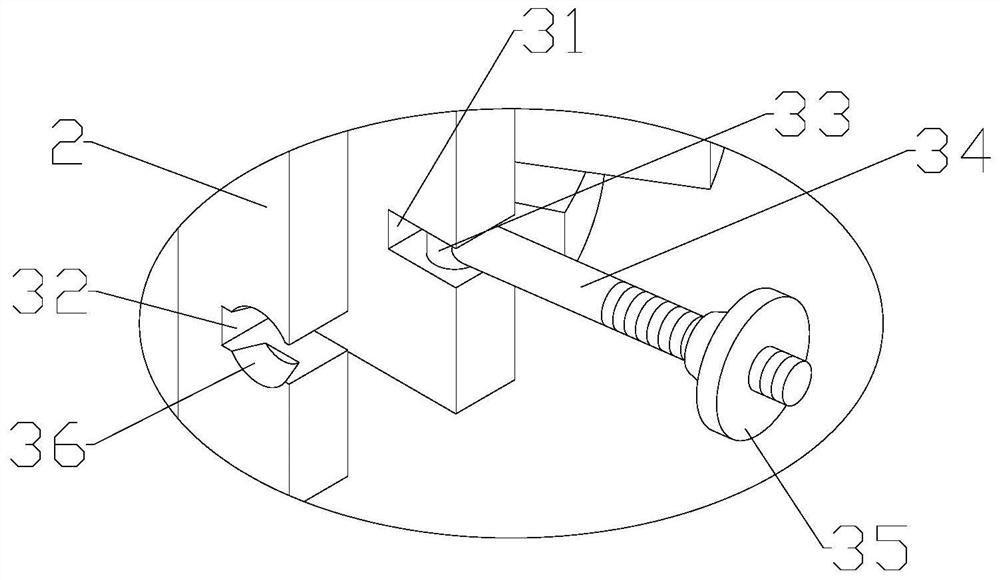

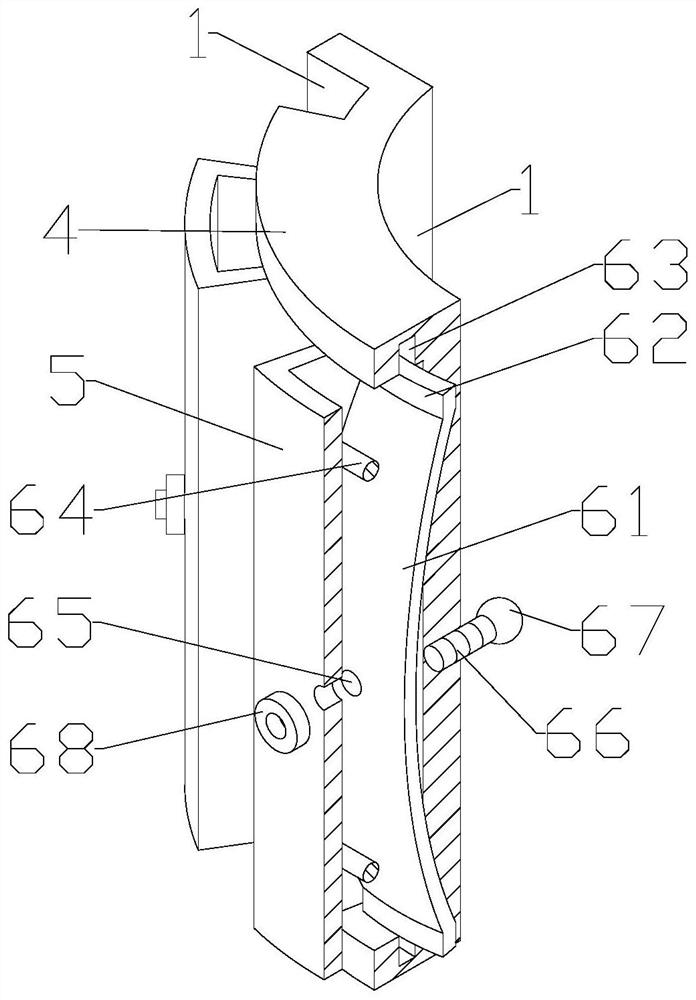

Reinforcing protection device for ancient building restoration

PendingCN112196304AEasy to installEasy to useBuilding repairsArchitectural engineeringStructural engineering

The invention discloses a reinforcing protection device for ancient building restoration. The reinforcing protection device comprises two protection cylinders, connecting plates are fixedly mounted onthe side walls of the two protection cylinders, tensioning mechanisms are mounted between the connecting plates, outer flanges are integrally formed at the tops and the bottoms of the outer walls ofthe protection cylinders correspondingly, a plurality of mounting shells are evenly clamped between the outer flanges in the circumferential directions of the protection cylinders, reinforcing mechanisms are mounted between inner cavities of the mounting shells and the outer flanges, and rubber pads are fixedly mounted on the circumferential inner walls of the protection cylinders. The two protection cylinders are attached to a protection area and then tensioned and fixed to a column through the tensioning mechanism, so that the damaged part is supported in an auxiliary mode; and the rubber pads prevent the intact part of the column from being clamped and damaged, then the reinforcing mechanisms are mounted between the outer flanges through the mounting shells, the reinforcing mechanisms give inward prestress to the outer flanges and the protection cylinders, so that the column is prevented from inclining outwards and collapsing, the reinforcing strength is improved, the reinforcing mechanisms provide buffering for external collision, and the damaged part of the column is prevented from being further damaged or even broken due to collision.

Owner:广东南秀古建筑石雕园林工程有限公司

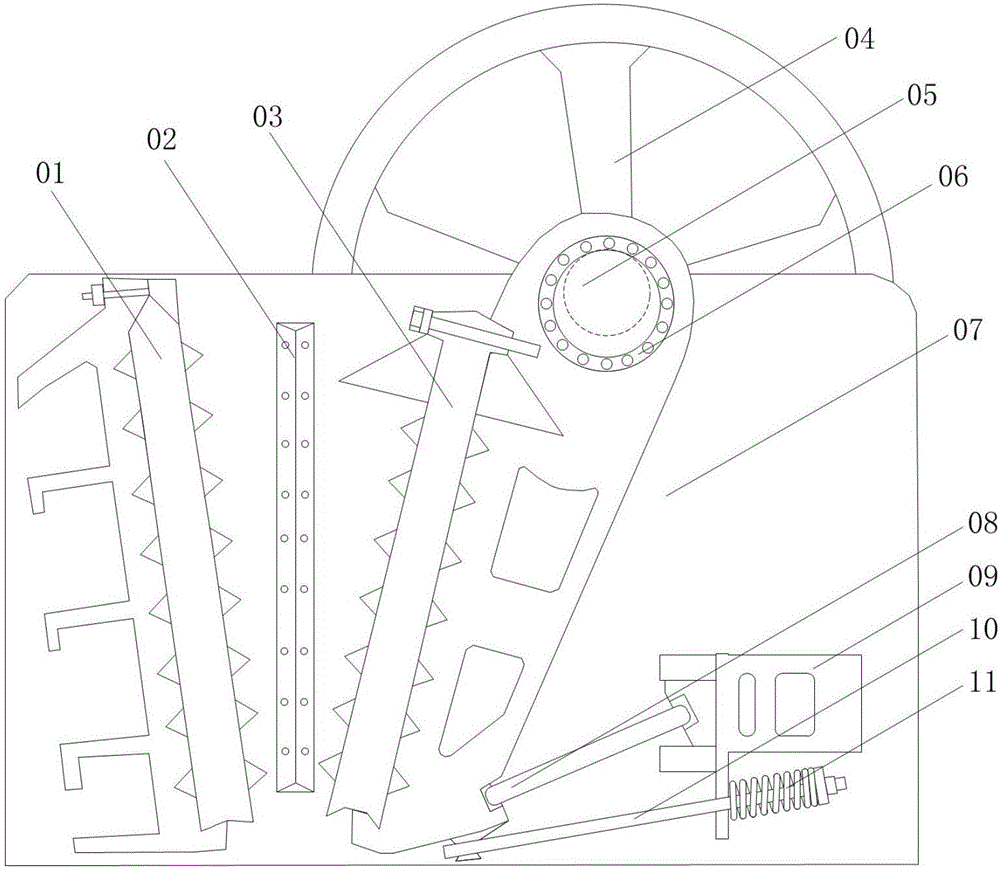

Jaw crusher

PendingCN106622460AImprove crushing effectImprove crushing efficiencyGrain treatmentsMoving jawEngineering

The invention discloses a jaw crusher. The jaw crusher comprises a rack, a motor, a belt pulley, an eccentric shaft, a bearing, a moving jaw set, a fixed jaw set, a wrist plate, an adjusting seat, a pull rod, a spring, water spray pipes, saw blades and saw blade bolts. The water spray pipes are vertically arranged on the inner plate surfaces of side plates of the two sides of the rack correspondingly and located between moving jaw plates and fixed jaw plates. The water spray pipes are each provided with a row of first water spray holes facing the moving jaw plates and a row of second water spray holes facing the fixed jaw plates. First clamping grooves corresponding to the saw blades are formed in moving jaws at the gaps between the moving jaw plates. Second clamping grooves corresponding to the saw blades are formed in mixed jaws at gaps between the fixed jaw plates. Sawteeth of the first saw blade protrude out of the plate surfaces of the moving jaw plates. Sawteeth of the second saw blade protrude out of the plate surfaces of the fixed jaw plates. The jaw crush can improve the crushing efficiency, reduce heating deformation of jaw plates and decrease materials returning from a feed port.

Owner:湖南山瑞重工科技有限公司

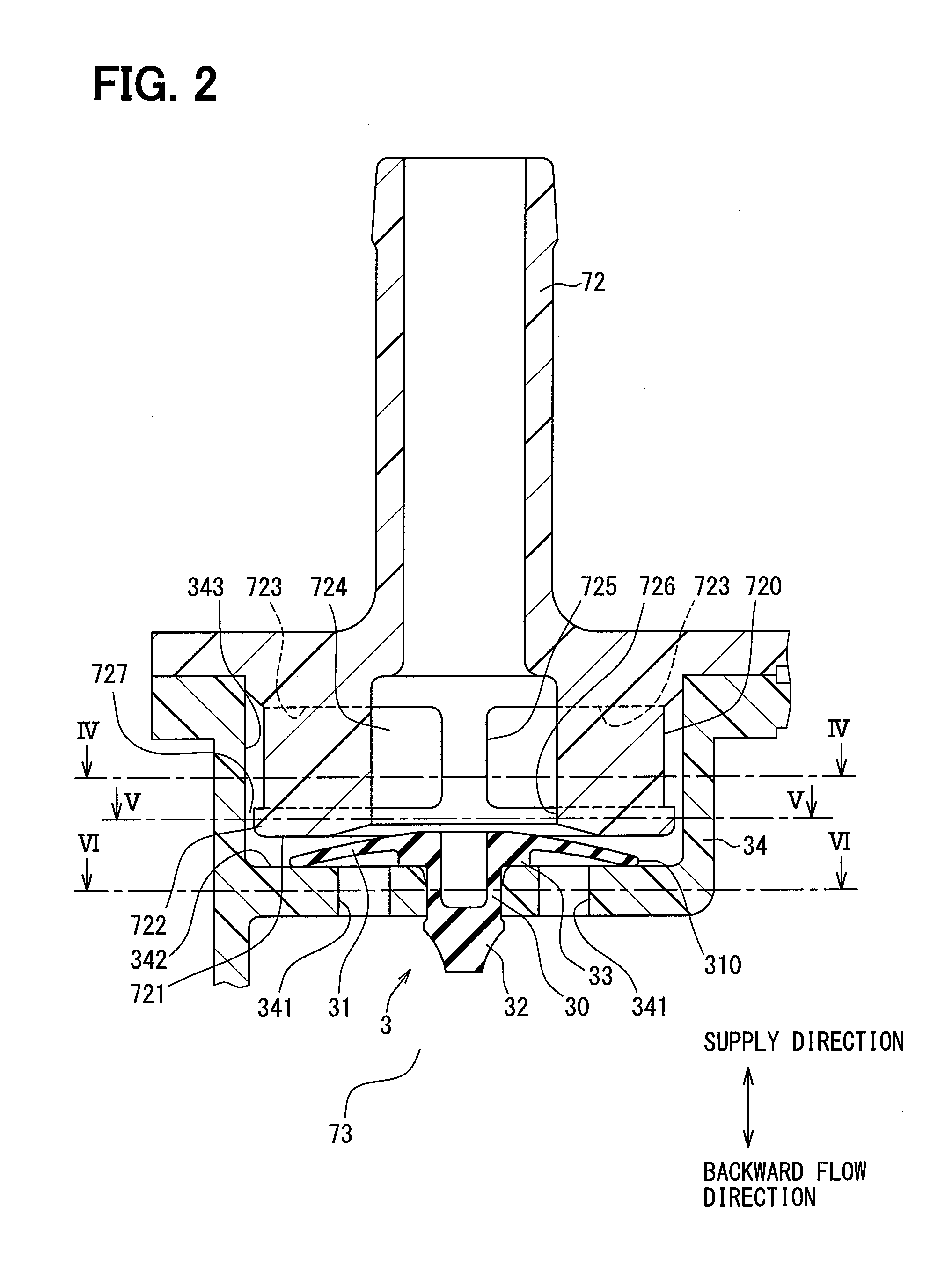

Check Valve Device And Vapor Fuel Supply System

ActiveUS20170030301A1Increased durabilityControl flowNon-fuel substance addition to fuelMachines/enginesCheck valveFuel supply

A check valve device includes a valve portion elastically deformable to prevent or allow a flow of a vapor fuel through a fluid passage in one direction by contacting with or separating from a valve seat. An upstream passage forming member has the valve seat and the fluid passage located upstream of the valve portion. A downstream passage forming member includes a terminal portion housed in the upstream passage forming member and having a downstream passage. A narrowed passage provided inside the terminal portion or between the upstream passage forming member and the terminal portion. A cross-sectional area of the narrowed passage is set to be smaller than any of the fluid passage and the downstream passage.

Owner:HAMANAKODENSO

Sliding member

ActiveUS10458471B2Avoid damageReduce elastic deformationShaftsBearing componentsFiberLayer thickness

Provided is a partially-annular sliding member including a sliding layer including fibrous particles having an average particle size of 5-25 μm dispersed in a synthetic resin at a volume ratio of 10-35% of the sliding layer. The particles having a major axis length≤20 μm are included at a volume ratio of ≥10% to total particles. A sliding surface side area is defined from the sliding surface and has a thickness of 25% of a sliding layer thickness T, where the fibrous particles having a major axis length of ≥20 μm have a dispersion index of 1.1-6. An interface side area is defined from the interface and has a thickness of 25% of T, where the dispersion index is 1.1-6. An intermediate area is defined between the both areas, where the dispersion index is 0.1 to less than 1.

Owner:DAIDO METAL CO LTD

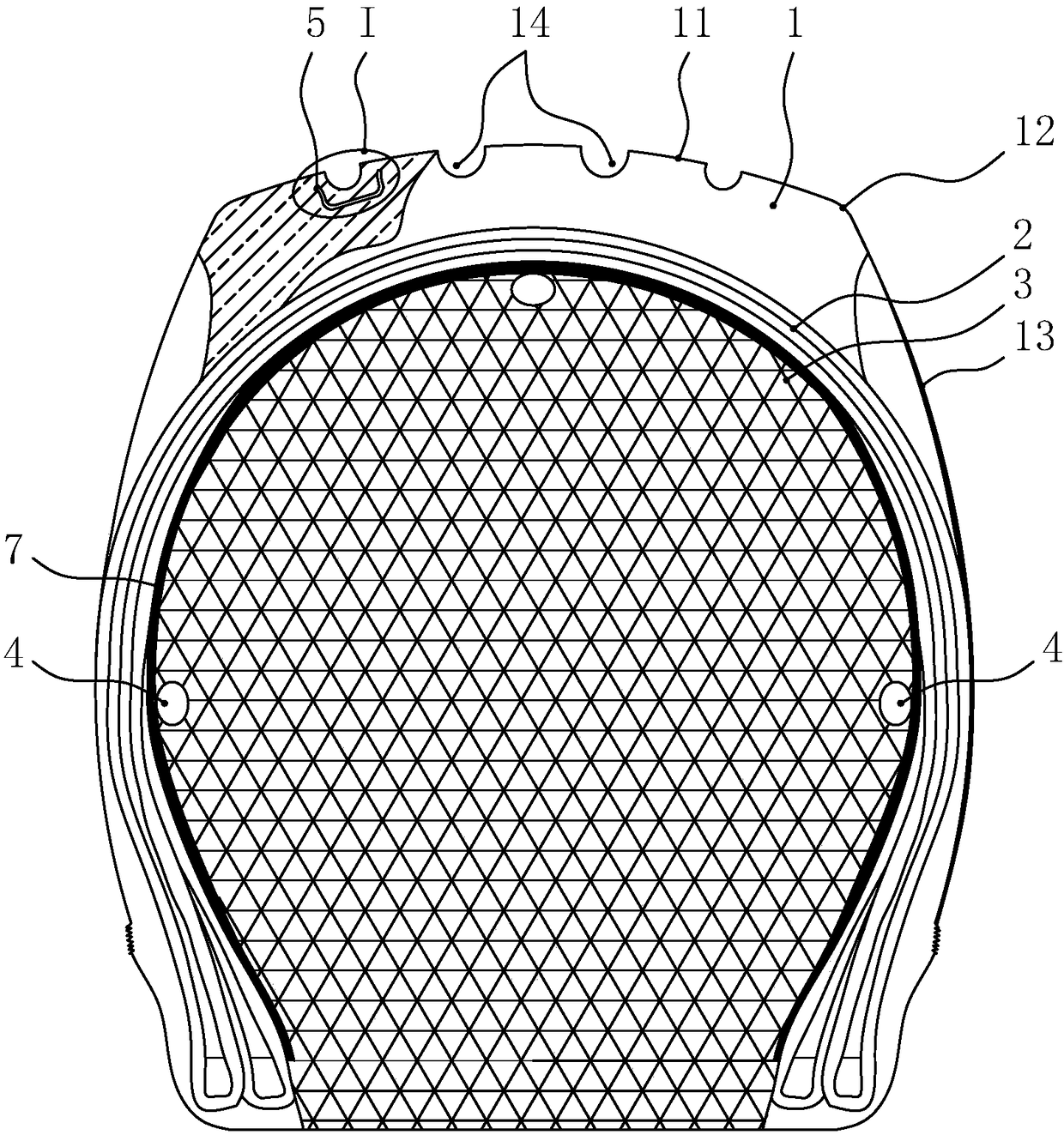

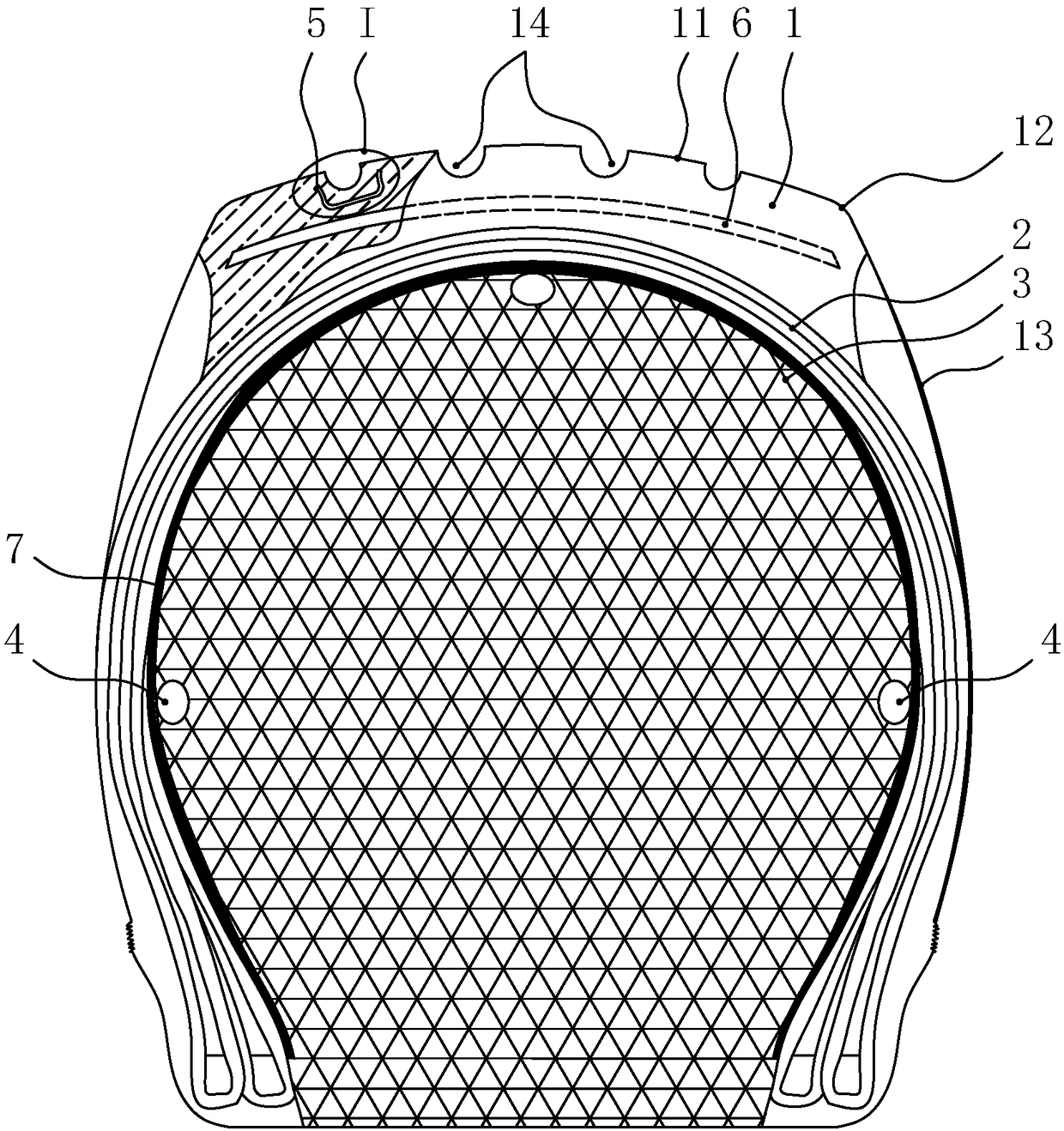

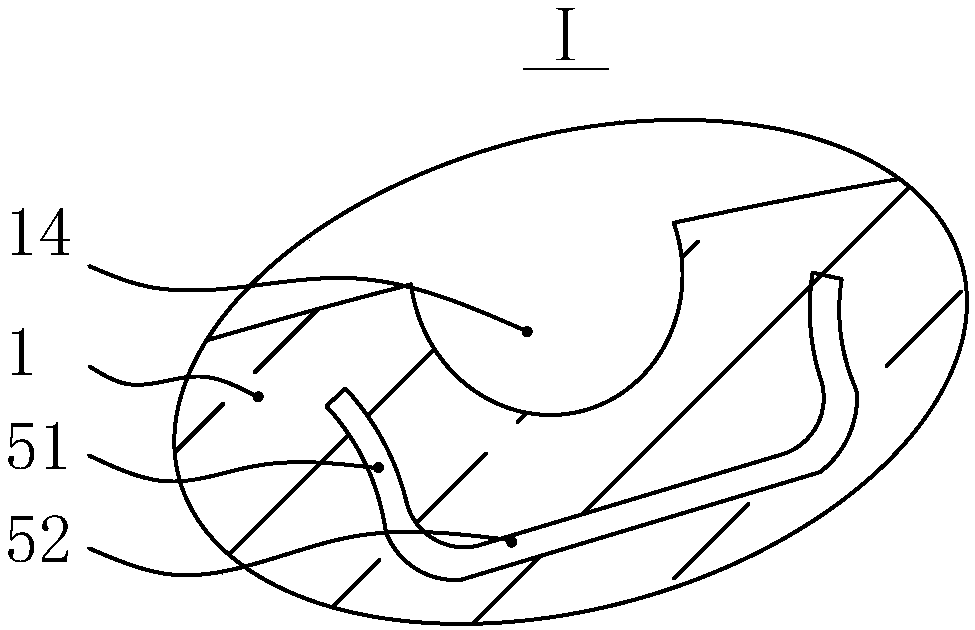

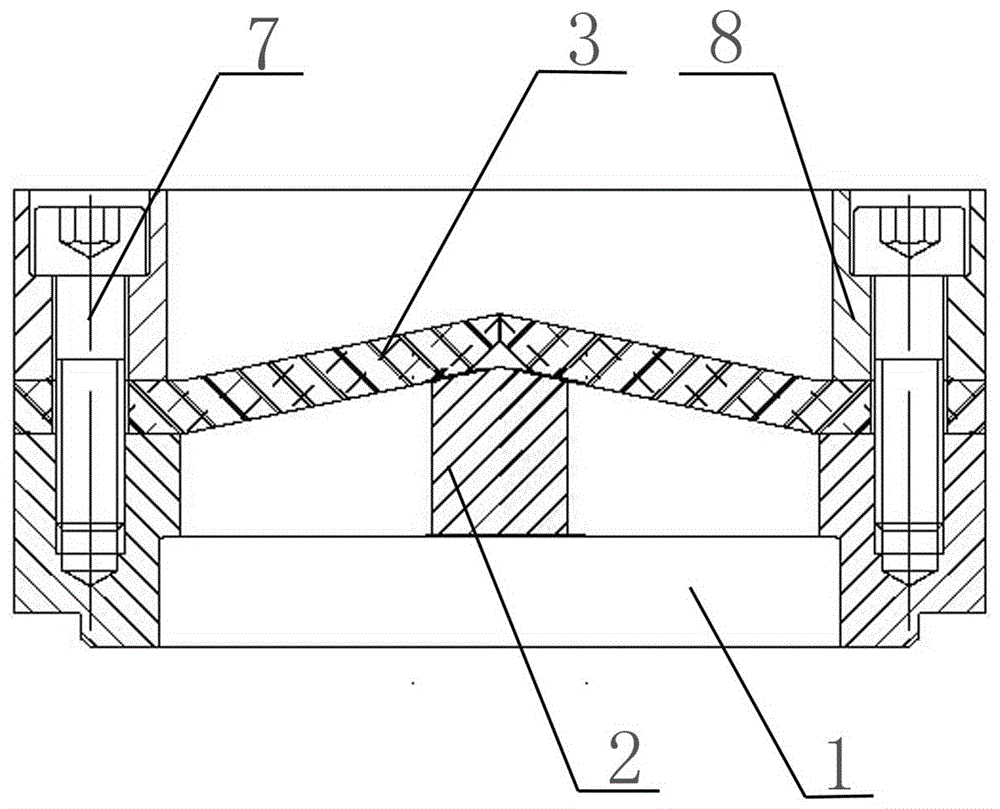

Special filled type solid tire with high performance

PendingCN108501621AOvercome the effects of gripIncrease frictionNon-inflatable tyresTyre tread bands/patternsTreadHigh polymer

The invention discloses a special filled type solid tire with high performance. The special filled type solid tire with the high performance comprises a tire cover which consists of a tread, a tire shoulder and a sidewall; a tire body is arranged on the internal side of the tire cover; a plurality of extra-deep patterns which are transversely connected with each other are arranged on the tread; the depths of the extra-deep patterns are gradually reduced from the middle part of the tread to the two sides of the tire shoulder; grasping supporting pieces which are transversely connected with eachother are arranged in positions, on the lower sides of the extra-deep patterns, in the tread; openings of the grasping supporting pieces face towards the extra-deep patterns; each grasping supportingpiece comprises a bottom edge and two side edges, wherein the two side edges are correspondingly positioned on the two longitudinal sides of the bottom edge, and the side edges are in arc shapes which are bent towards the internal sides; the tire body is a cord fabric layer; the tire body and the tire body are an integrated structure; and the internal side of the tire body is filled with high polymer materials to form the solid tire. According to the special filled type solid tire with the high performance, as the extra-deep patterns and a self-sealed polyurethane material layer are arranged,the grip of the tire is increased, the anti-puncture effect of the tire is improved, influence of gravity extrusion on the grip of the tire is overcome, the running stability is guaranteed, and slipping is avoided.

Owner:青岛富耐特矿业科技有限公司

Novel anti-blocking cutter head soil modifier agent ejection nozzle device

ActiveCN106437733AImprove tear resistanceReduce elastic deformationTunnelsEngineeringStructure matching

The invention belongs to the technical field of tunneling shield. The nozzle device comprises a nozzle ring, a middle support plate placed at the center of the nozzle ring and an elastic sealing plate placed pressingly on the nozzle ring through a press ring. The side of the middle support plate is a convex conical structure. A plurality of the modifier agent ejection nozzles are evenly arranged on the middle support plate in a circle. The inner surface of the elastic sealing plate is a conical surface structure matching and adhering to the middle support plate. The elastic sealing plate comprises two fan shape sealing plates number 1 and number 2 matching with the elastic sealing plate. The sealing material of the elastic sealing plate is polyurethane which enhances the anti-tearing capacity of the ejection nozzle sealing. The nozzle ring is applies the design of the convex conical surface structure. The elastic sealing plate at the nozzle applies the conical surface design which can effectively reduce the elastic deformation in the working condition of the ejection nozzle, enhances the returning force and prolongs the service life of the sealing.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Sliding member

Owner:DAIDO METAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com