Disc type starter propagation equipment

A koji-making equipment, disc-type technology, applied in the field of disc-type koji-making equipment, can solve problems such as environmental humidity and temperature conditions, shortening the service life of koji-making equipment, and easy corrosion of steel structures, and achieve low construction requirements, The effect of high utilization rate of land resources and long service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The basic idea of the present invention is to include at least one koji-making tower, which is divided into a plurality of koji-making chambers by partitions in the tower; the main structure of the koji-making tower adopts a concrete structure.

[0037] It will be described in detail below in conjunction with the embodiments and accompanying drawings.

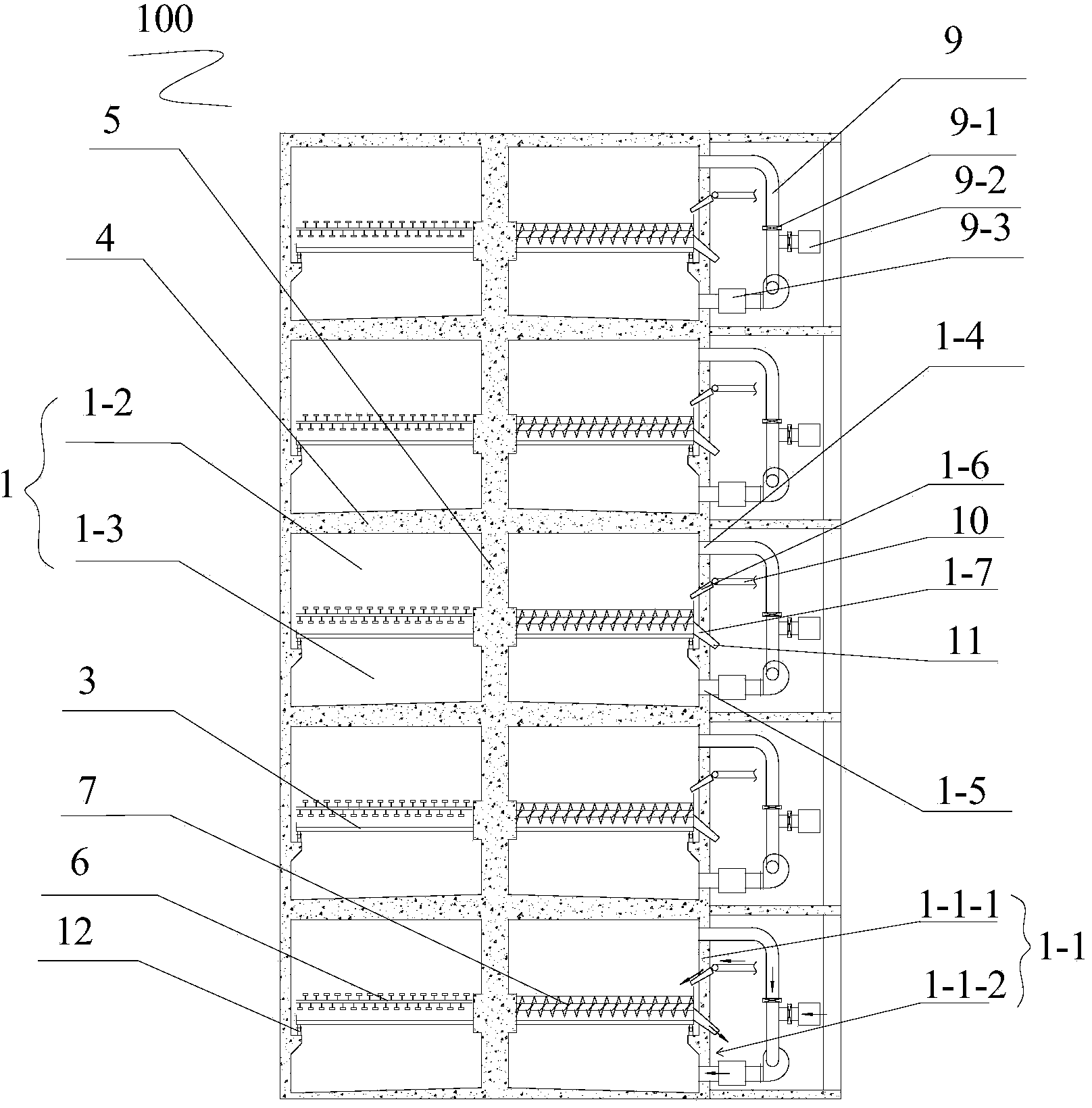

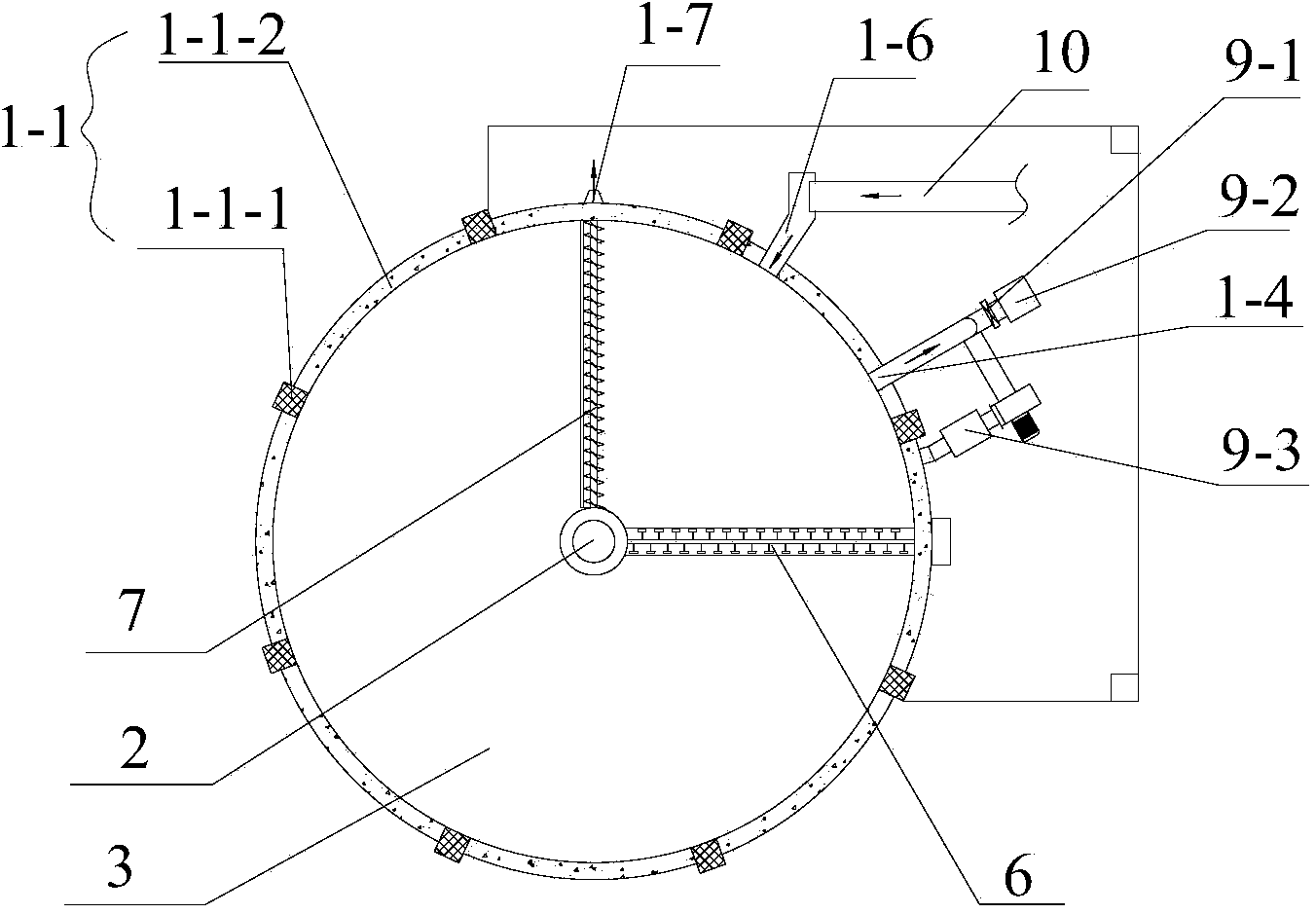

[0038] See figure 2 , image 3 ,in: figure 2 It is a cross-sectional view in the vertical direction of a preferred embodiment of the disc-type koji-making equipment of the present invention, and this figure only shows a koji-making tower; image 3 yes figure 2 Sectional view in the horizontal direction. The disc-type koji-making equipment includes:

[0039] At least one koji-making tower 100 is divided into a plurality of koji-making chambers 1 by partitions 4 in the tower.

[0040] A disc 3 with mesh is arranged in each koji making room, the central part is fixed on the disc main shaft 2, and the edge part is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com