External casing packer

A packer and casing technology, applied in cementing or logging, oil and gas drilling, and well completion, can solve problems such as reduced elastic properties, tearing, and no anti-skid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0072]It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0073] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without ...

Embodiment 1

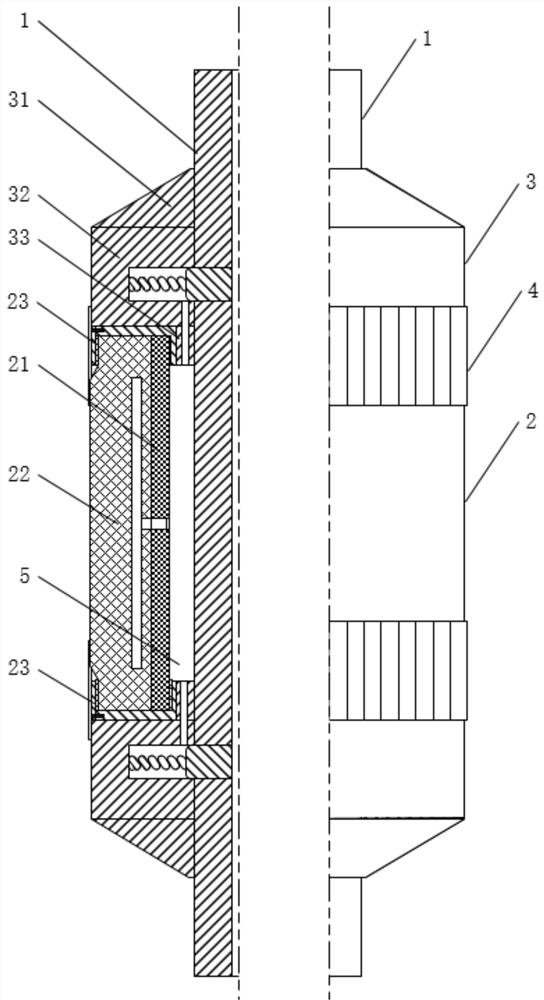

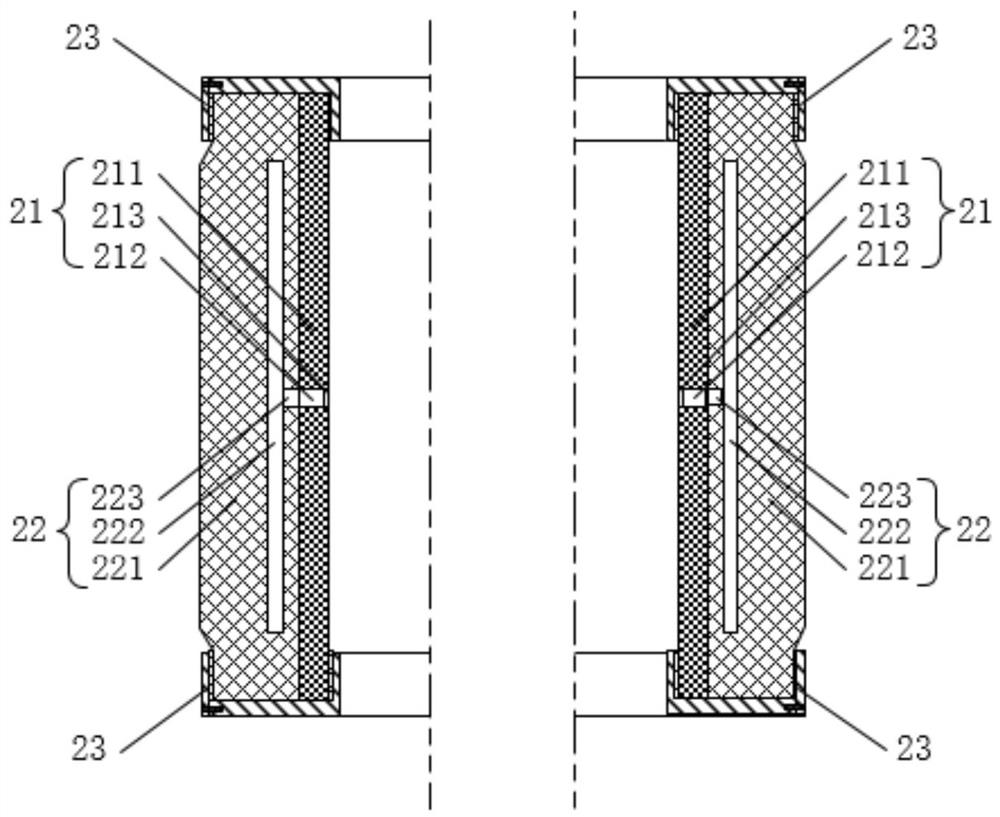

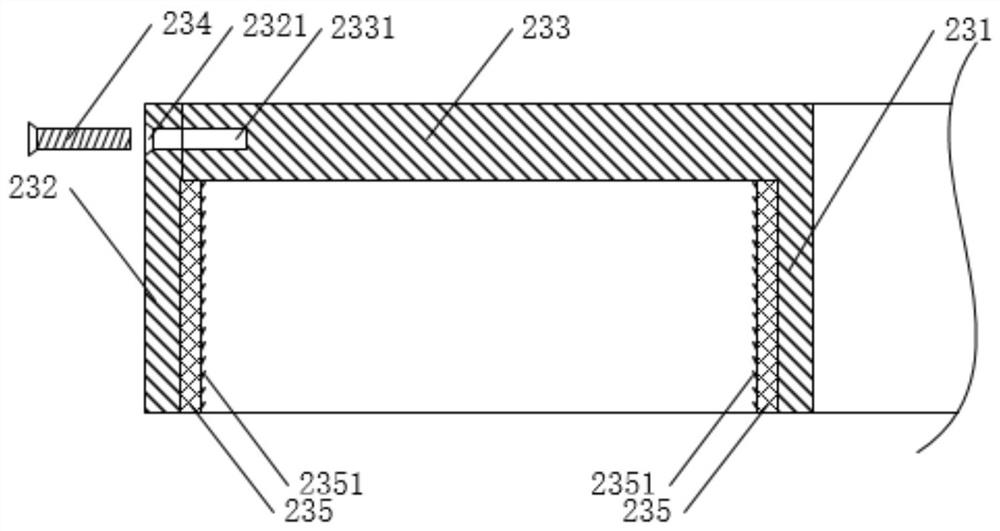

[0075] combined with Figure 1-4 , a casing outer packer, including a central tube 1, a rubber tube 2 and a rubber tube fixing ring 3, the rubber tube 2 is sleeved outside the center tube 1, and the rubber tube fixing ring 3 is fixed on The central tube 1 is fixedly connected to both ends of the rubber tube 2, and there is an annular space 5 between the rubber tube 2 and the central tube 1. The inner cylinder 21 made of elastic material and the outer cylinder 22 made of elastic material that expands in case of liquid, the rubber cylinder fixing ring 3 is provided with a first flow channel 34 leading to the annular space 5, the first flow channel The entrance of the channel 34 is provided with a sealing valve core 35, the inner cylinder 21 includes an inner cylinder 211, and the axial center of the inner cylinder 211 is provided with a radial through hole 212, and the through hole 212 faces the One end of the central tube 1 is provided with a fracturable sealing film 213 , and...

Embodiment 2

[0084] This embodiment is a modified example of the rubber cartridge 2 in the outer casing packer of Embodiment 1. Since traditional self-expanding materials need to make a trade-off between physical and mechanical properties and self-expansion performance, higher self-expansion is desired Performance requires the introduction of more hydrophilic groups, and the more hydrophilic groups introduced, the lower its physical and mechanical properties, and the reduction of physical and mechanical properties will make the rubber tube more prone to tearing during deformation Crack or break, that is, in order to make full use of the expansion properties of the self-expanding material, its elastic physical and mechanical properties will inevitably be greatly weakened, making it easy to burst or fragment and lose the sealing effect. Therefore, this embodiment proposes another technical solution , that is, the expansion performance of the outer cylinder 221 can be fully utilized without af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com