Front structure for vehicle

A front structure, vehicle technology, applied in the direction of the upper structure, lower structure, vehicle parts, etc., can solve the problems of complex assembly work and increased number of parts, and achieve the effect of avoiding quantity and weight and effectively absorbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

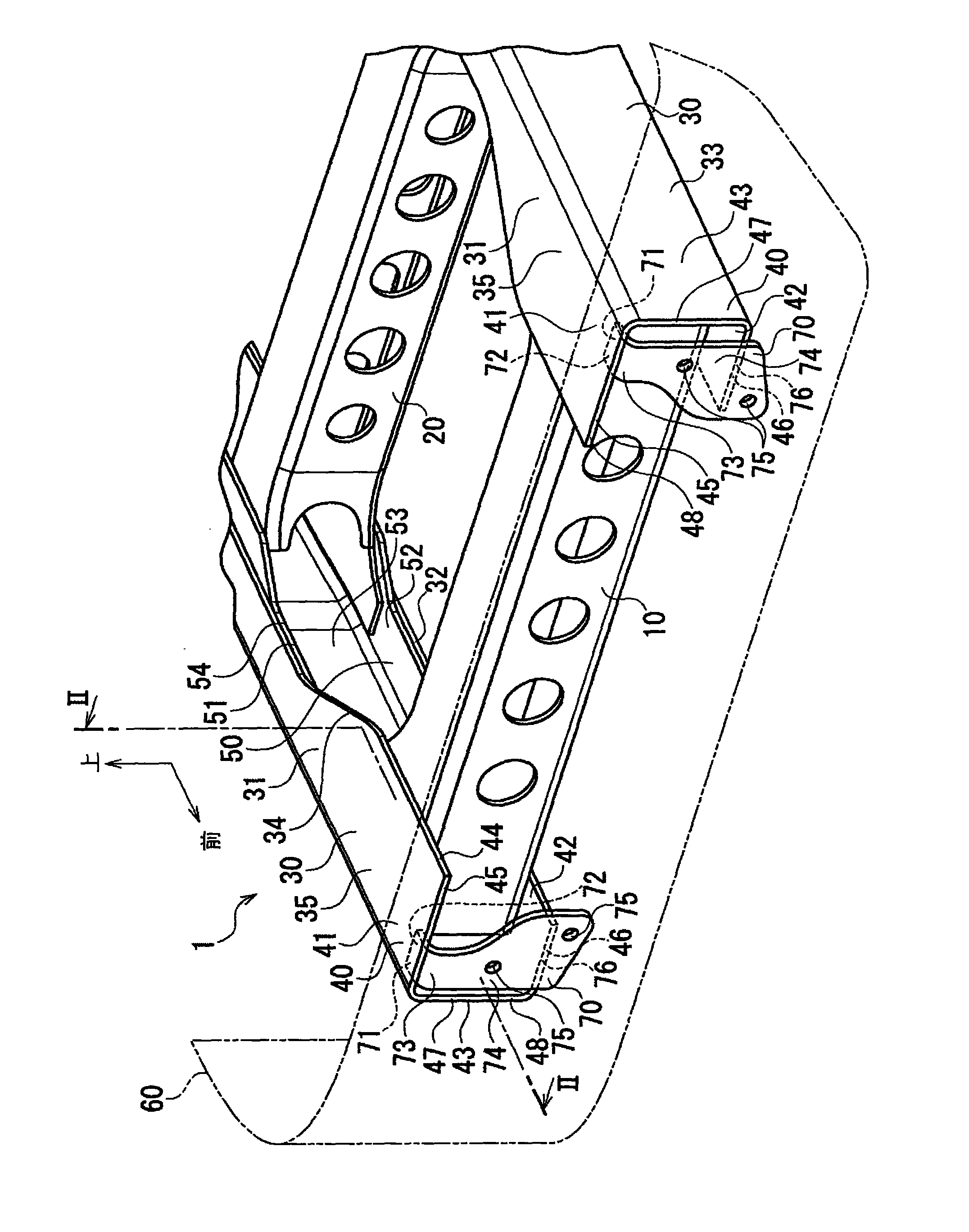

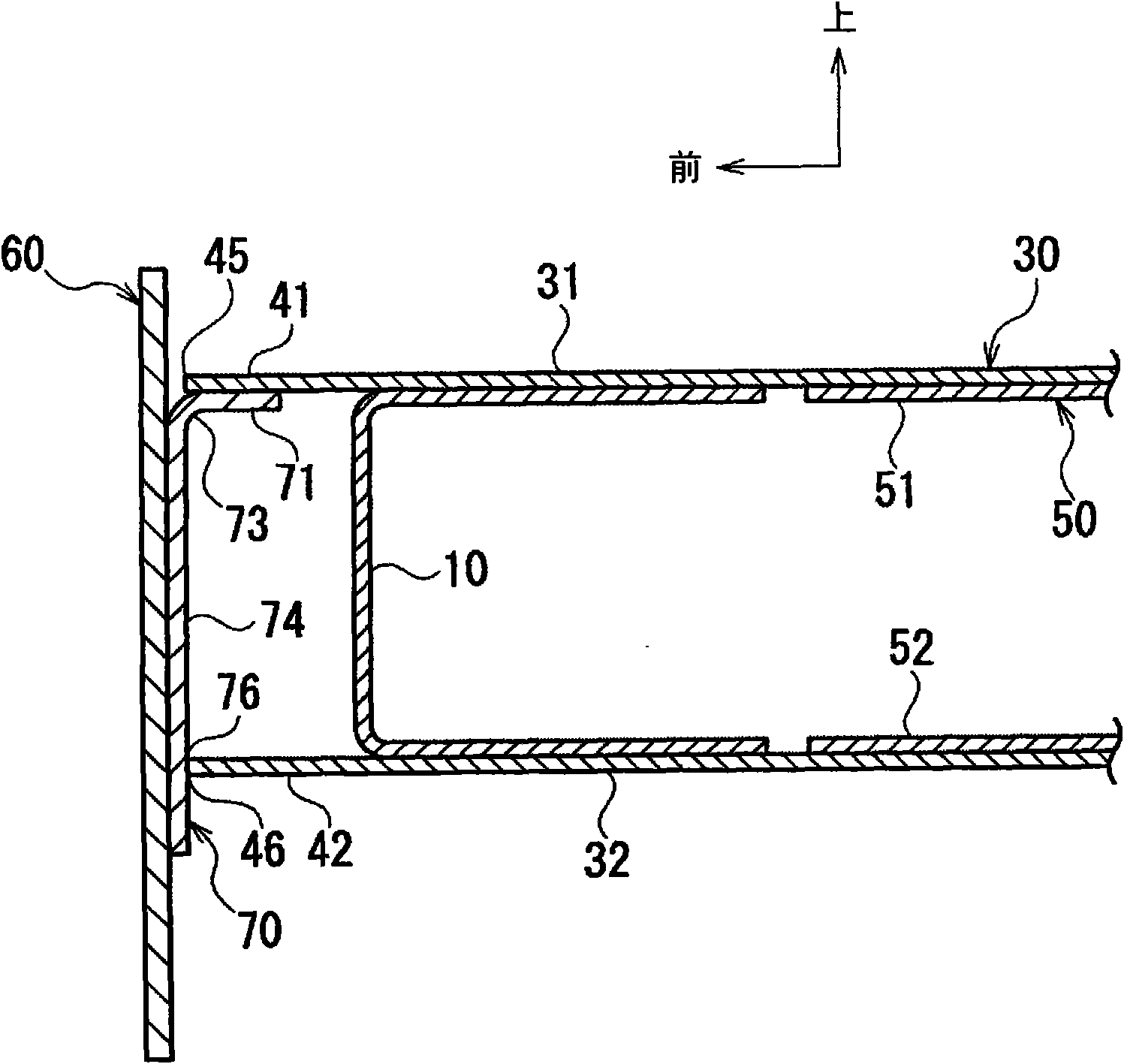

[0034] An embodiment of the present invention will be described below with reference to the accompanying drawings.

[0035] figure 1 It is a perspective view showing the vehicle front structure according to this embodiment. figure 2 show figure 1 Sectional view along arrowed line II-II. Note that the front-rear direction mentioned in the following description refers to the front-rear direction with respect to the traveling direction of the vehicle 1 . In addition, the arrow "front" in the drawings refers to the forward direction of the vehicle, and the arrow "up" refers to the upward direction of the vehicle.

[0036] Such as figure 1 and 2 As shown, the vehicle 1 of this embodiment has a front structure including a first transverse element (transverse element) 10, a second transverse element 20, a pair of side members 30, a protrusion 40, a reinforcing element 50, bumper 60 and bracket 70 .

[0037] The first transverse member 10 has a substantially U-shaped cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com