Vehicle middle pillar structure

A pillar structure and vehicle technology, applied in the superstructure, vehicle parts, vehicle safety arrangement, etc., can solve the problems of increasing the size and weight of the inner panel, and achieve the effect of improving rigidity, improving rigidity, and improving driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, exemplary embodiments of the present invention are described with reference to the accompanying drawings.

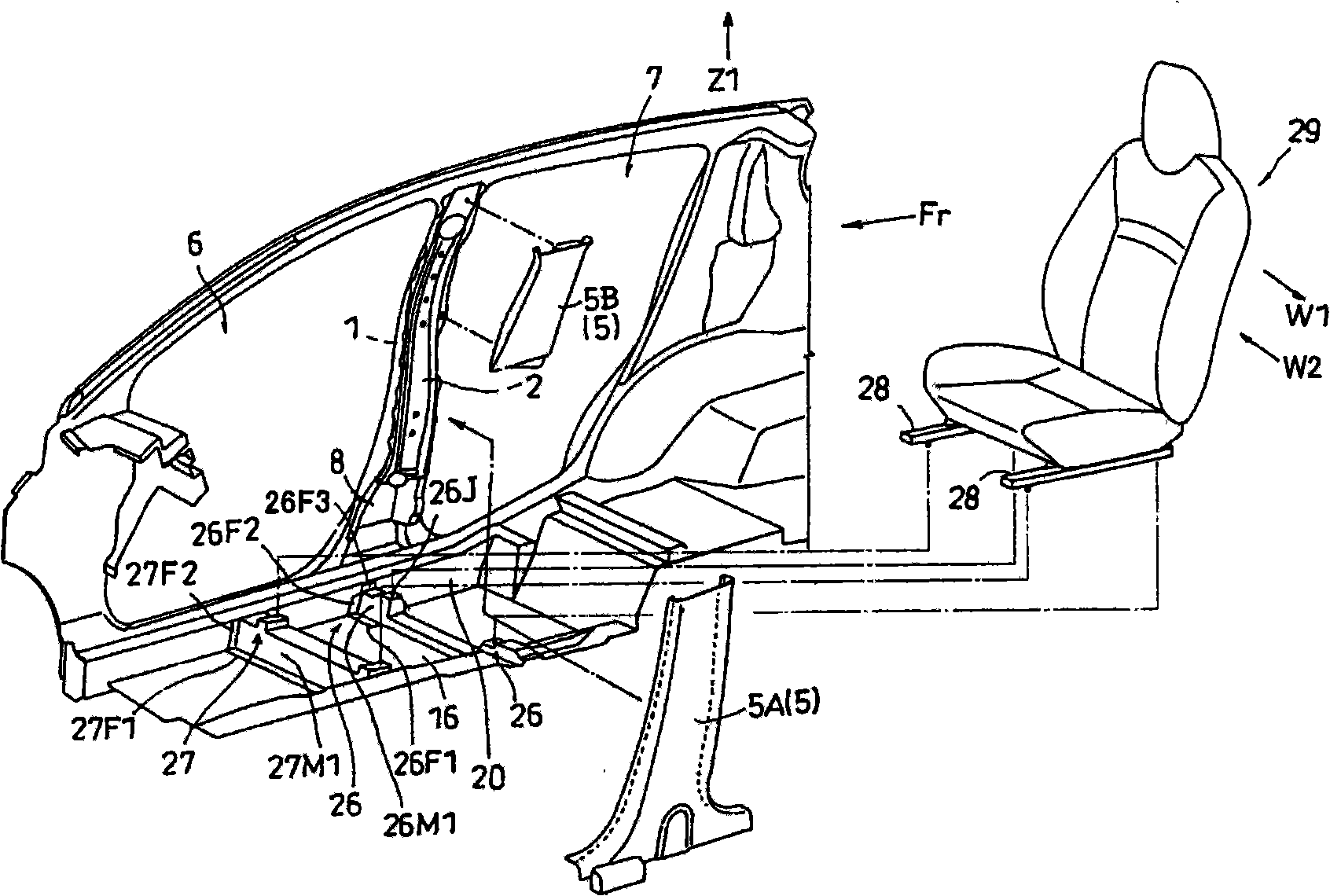

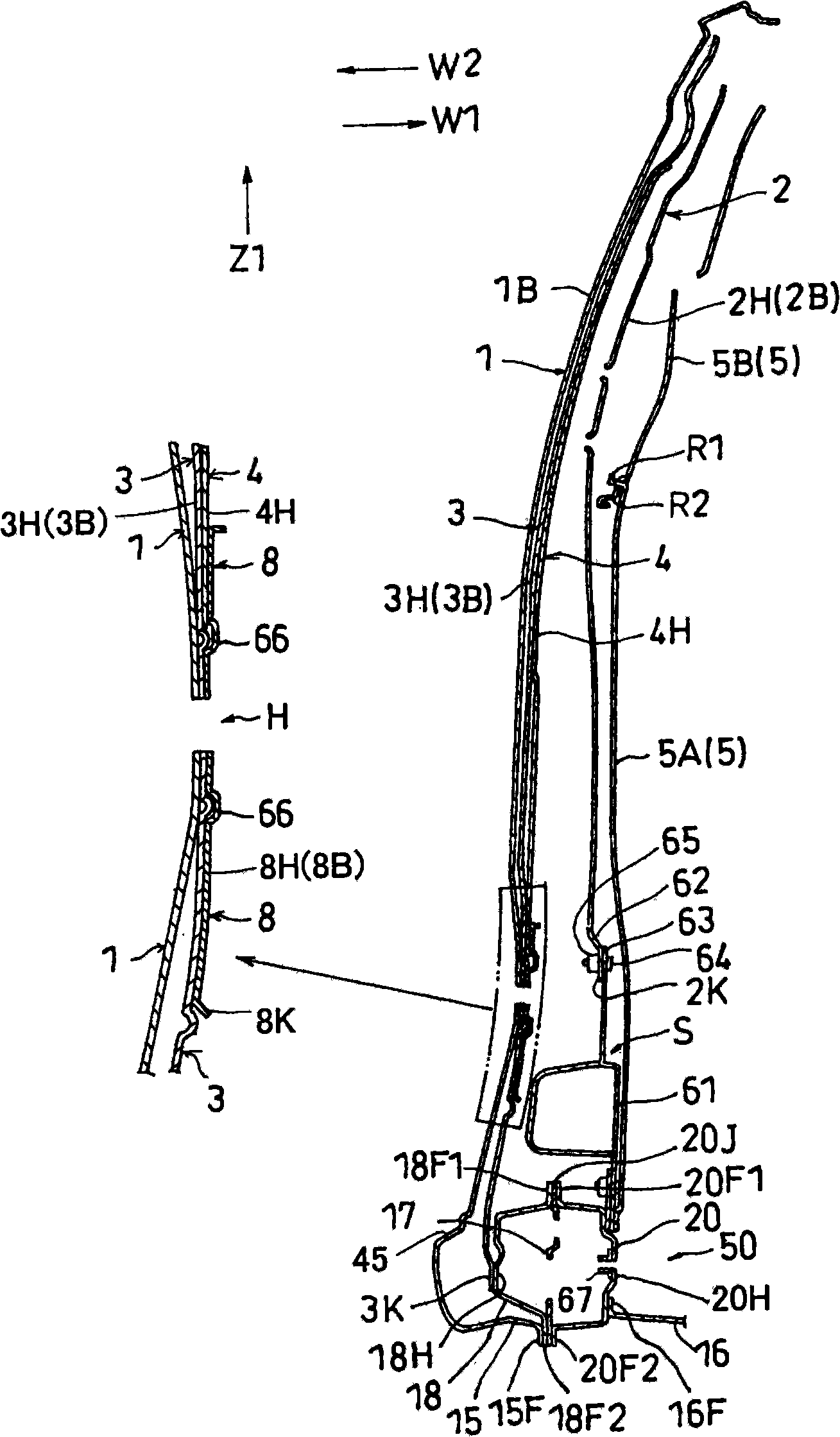

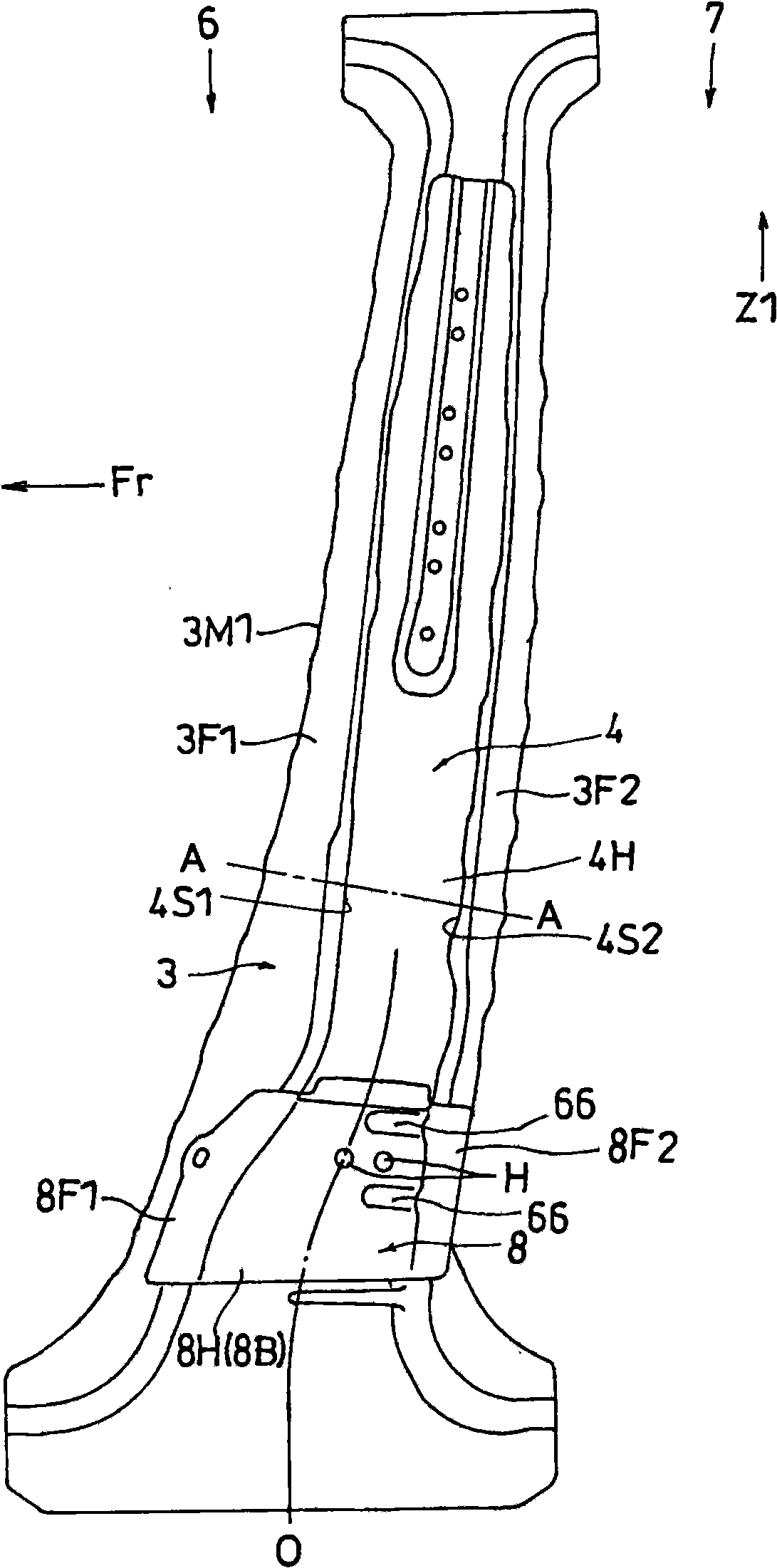

[0037] Figures 1 to 5 A vehicle (automobile) center pillar structure is shown, including an outer panel 1 , an inner panel (center pillar inner panel) 2 , a first reinforcement member 3 , a second reinforcement member 4 , and a center pillar trim 5 . The central pillar has a configuration in which the outer panel 1, the inner panel 2, the first reinforcement member 3, the second reinforcement member 4, and the intermediate pillar modification 5 extend in an obliquely vertical direction so that the upper end is more dense than the lower end. Slightly closer to the rear of the vehicle. The middle pillar modification 5 includes a lower modification 5A and an upper modification 5B separated from each other. Such as figure 2 As shown, the upper end-side joining portion R1 of the lower modification 5A is joined to the lower end-side joining portion R2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com