Ultraviolet light resistant ring protective cover material and white concentric cable produced thereof

A sheathing material and UV-resistant technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve problems such as cracking and embrittlement of PVC, and achieve the effects of good flexibility, strong practicability and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

[0054] A kind of anti-ultraviolet radiation ring protection sheath material, said sheath material is mainly prepared from the following substances by weight:

[0055] PVC resin 470 kg

[0056] Trioctyl trimellitate (TOTM) 70 kg

[0057] Dioctyl sebacate (DOS) 50 kg

[0058] Dioctyl phthalate (DOP) 70kg

[0059] Calcium Zinc Composite Stabilizer 50kg

[0060] Epoxidized soybean oil (ESO) 10 kg

[0061] Antimony trioxide 15 kg

[0062] Magnesium Hydroxide 100kg

[0063] Fine Calcium Carbonate 80kg

[0064] Titanium dioxide 80 kg

[0065] Ultraviolet absorber (UV-531) 5 kg.

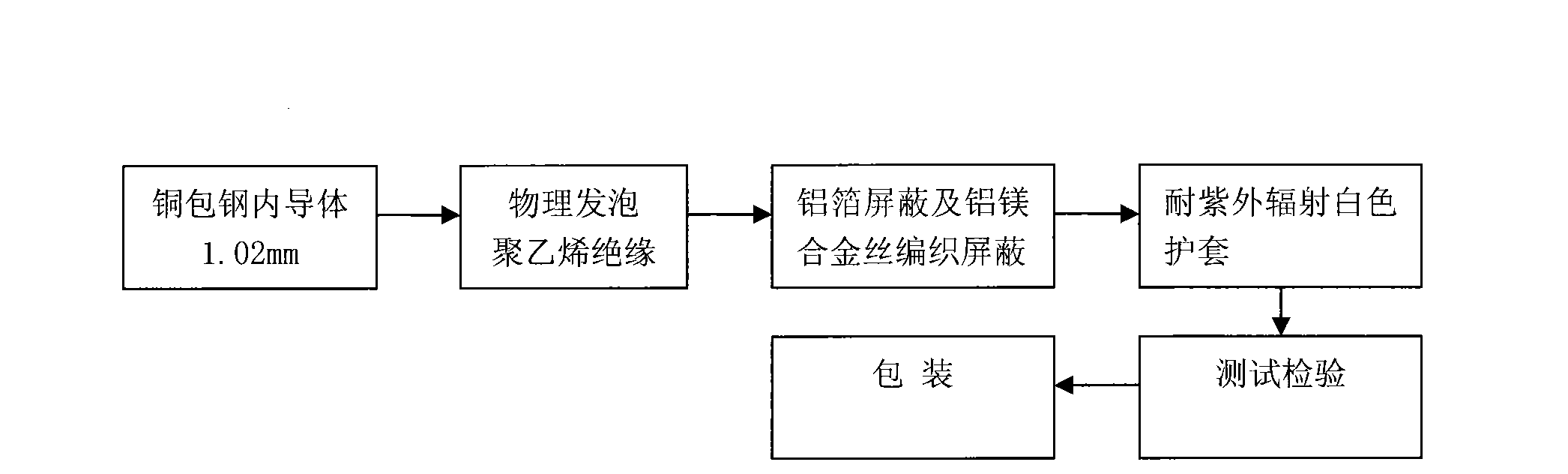

[0066]The above-mentioned production process consists of three major processes of batching, mixing and extrusion. Batching is to mix various raw materials according to the formula; mixing is to mix various raw materials at high sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com