A kind of preparation method and application of polymethyl methacrylate porous microsphere film

A technology of polymethyl methacrylate and porous microspheres, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve excellent mechanical properties, low cost, and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] ⑴Preparation of polymethyl methacrylate solution: Add 5g of fully dried polymethyl methacrylate into 85g of dimethylformamide solvent, stir and dissolve at 25°C for 1h, after completely dissolving, slowly Add 10g of cyclohexanone, stir and heat at 80°C for 2h, vacuum defoam the obtained homogeneous solution, and let stand at 80°C for use;

[0031] ⑵Preparation of the initial state microsphere film: spread the obtained polymethyl methacrylate solution evenly on the stainless steel plate into a thin layer with a thickness of 8mm in an environment of 80°C, and place it in a place with a humidity of 60%. , standing in an environment of 50°C for 0.5h, the primary polymethyl methacrylate microsphere film can be obtained, ready for use;

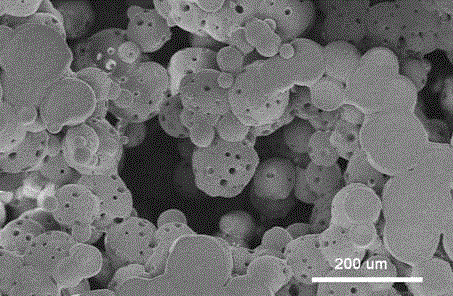

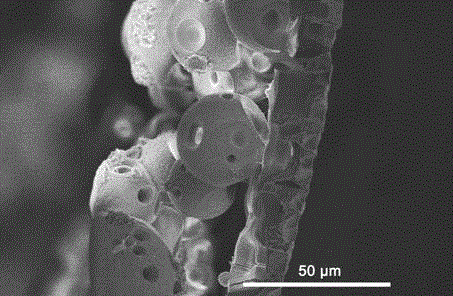

[0032] (3) Post-treatment: Soak the prepared polymethyl methacrylate microsphere membrane in methanol, remove the remaining solvent and diluent, and dry it rapidly in an environment of 100°C, the upper layer is porous microspheres and the low...

Embodiment 2

[0034] ⑴Preparation of polymethyl methacrylate solution: Add 25g of fully dried polymethyl methacrylate into 73g of methyl ethyl ketone solvent, stir and dissolve at 70°C for 2h, after completely dissolving, slowly add 2g of phosphoric acid Stir and heat triethyl ester at 100°C for 4 hours, vacuum defoam the obtained homogeneous solution, and let stand at 100°C for use;

[0035] ⑵Preparation of the initial state microsphere film: spread the obtained polymethyl methacrylate solution evenly on the stainless steel plate into a thin layer with a thickness of 10mm in an environment of 100°C, and place it in a place with a humidity of 60%. , standing in an environment of 100°C for 1.5h, the primary polymethyl methacrylate microsphere film can be obtained, ready for use;

[0036] (3) Post-treatment: Soak the prepared polymethyl methacrylate microsphere membrane in methanol, remove the remaining solvent and diluent, and dry it rapidly at 60°C to obtain the upper layer as the lower lay...

Embodiment 3

[0038] ⑴Preparation of polymethyl methacrylate solution: Add 28g of fully dried polymethyl methacrylate into 65g of polyvinylpyrrolidone solvent, stir and dissolve at 90°C for 3h, after completely dissolving, slowly add 7g Polyethylene glycol ester, stirring and heating at 130°C for 6 hours, vacuum defoaming the obtained homogeneous solution, and standing at 130°C for use;

[0039] ⑵Preparation of initial state microsphere film: at 130°C, evenly spread a thin layer with a thickness of 8mm on a stainless steel plate with a scraping rod, and let it stand for 2 hours in an environment with a humidity of 80% and 60°C to obtain the initial state. state polymethyl methacrylate microsphere membrane.

[0040] (3) Post-treatment: Soak the prepared polymethyl methacrylate microsphere membrane in ethanol, remove the remaining solvent and diluent, and dry it rapidly in an environment of 60°C to obtain the upper layer as the lower layer of porous microspheres It has a network structure, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com