Preparation method of continuous filament of asphalt-based carbon fiber

A technology of pitch-based carbon fiber and pitch fiber, which is applied in drafting, can solve the problems of slow spinning speed, easy paralleling and brittleness, and large damage to fiber bundles, and achieve the effect of reducing the diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

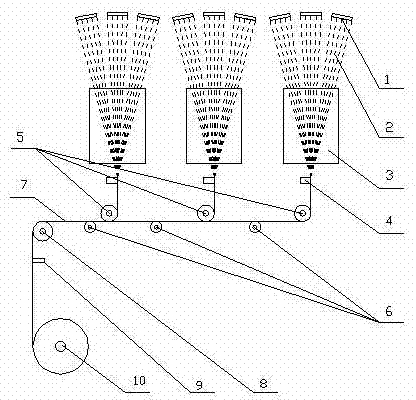

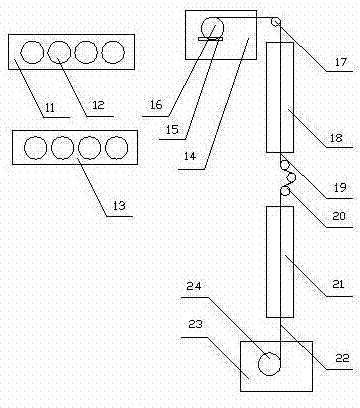

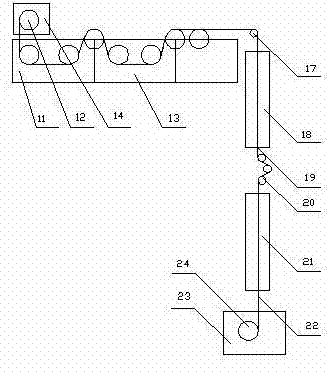

[0042] Such as figure 1 , 2 , Shown in 4, a kind of preparation method of pitch-based carbon fiber continuous filament, its concrete processing steps are as follows:

[0043] a. Choose AR mesophase pitch fiber 2 from Mitsubishi Chemical Corporation, Japan, and use one spinning position 1 and two spinnerets with 200 holes for spinning. The spinneret holes are Ф0.3×0.9mm, and the spinning temperature is 335°C. Die head pressure 1.1MPa, metering pump flow rate 16cc / min. After the atomizing humidifier 3 humidifies the fibers, it is oiled at 1.5m below the spinneret through the oil nozzle 4. The oil agent is a commercially available silicone oil spinning oil agent, and 1 strand of virgin pitch fiber bundles containing 400 pieces is obtained;

[0044] b. Drafted by the first roller 5 of the drafting roller with a diameter of Ф200mm, and passed through the first godet roller 6, and then wound on the second roller of the drafting roller with a "U" groove and an effective diameter of...

Embodiment 2

[0050] Such as figure 1 , 2 , Shown in 4, a kind of preparation method of pitch-based carbon fiber continuous filament, its concrete processing steps are as follows:

[0051] a. Naphthalene-based synthetic mesophase pitch fiber 2 with a softening point of 260°C. Two spinning positions 1 and two spinnerets with 500 holes each are used for spinning. The spinneret holes are Ф0.2×0.6mm. The filament temperature is 330°C, the die head pressure is 2.4MPa, and the flow rate of the metering pump is 65cc / min. The spinneret holes are Ф0.3×0.9mm, after the atomizing humidifier 3 humidifies the fibers, oil them at 1.5m below the spinneret through the nozzle 4, and obtain 2 strands of virgin pitch fiber bundles each containing 1000 pieces;

[0052] b. Drafted by the first roller 5 of the drafting roller with a diameter of Ф200mm, and passed through the first godet roller 6, and then wound on the second roller of the drafting roller with a "U" groove and an effective diameter of Ф200mm 8...

Embodiment 3

[0058] Such as figure 1 , 2 , Shown in 4, a kind of preparation method of pitch-based carbon fiber continuous filament, its concrete processing steps are as follows:

[0059] a. Choose AR mesophase pitch fiber 2 from Mitsubishi Chemical Corporation, Japan, and use two spinning positions 1 and a spinneret with 500 holes for spinning. The spinneret holes are Ф0.25×0.75mm, and the spinning temperature is 338°C. Die head pressure 2.6MPa, metering pump flow rate 20cc / min. After the atomizing humidifier 3 humidifies the fibers, it is oiled at 1.5m below the spinneret through the nozzle 4 to obtain 2 strands of virgin pitch fiber bundles each containing 500 pieces;

[0060] b. Drafted by the first roller 5 of the drafting roller with a diameter of Ф200mm, and passed through the first godet roller 6, and then wound on the second roller of the drafting roller with a "U" groove and an effective diameter of Ф200mm 8, and tensioned to obtain a plied pitch fiber bundle 7 containing 1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com