Production technique of lint-lifting parallel dual-component spun-bonded fiber filament non-woven material

A technology of non-woven materials and production technology, which is applied in the direction of non-woven fabrics, textiles and papermaking, filament/thread forming, etc. It can solve the problems of softness and fluffiness, slow production speed, low production capacity, etc., and achieve aesthetics Increase and satisfy the effect of breathability and strong absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

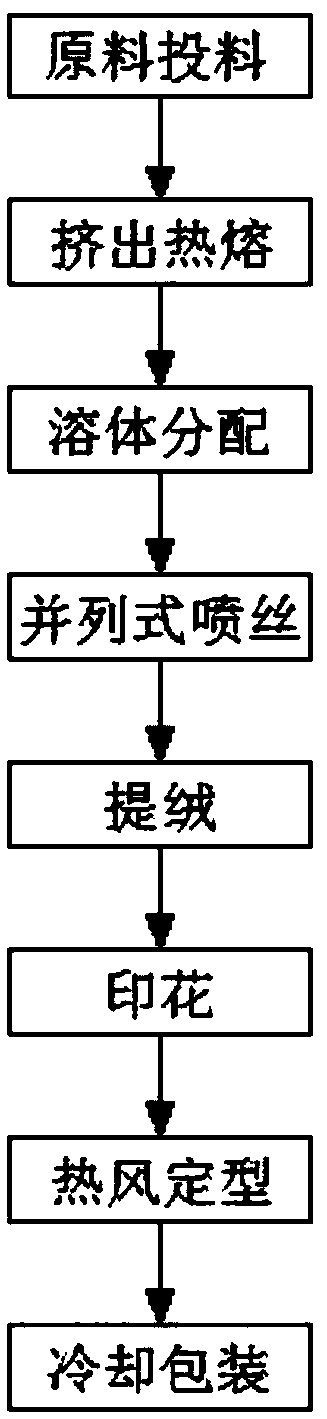

[0025] The production process of the two-component spun-bonded filament nonwoven material in parallel with cashmere comprises the following steps:

[0026] S1: Raw material feeding: Cut two groups of raw materials with different melt indexes into the feeding machine. The raw materials are PP and PE or PP and PP or PP and COPP or PE and PET or PP and PET or PET and COPP, and the raw materials Before feeding, it needs to be dried and sliced. The drying temperature is 100 degrees, and the drying time is 8 hours. Then put it into a ball mill for ball milling, so that the diameter of the raw material is between 5-15 mm;

[0027] S2: Extrusion hot melt: Put two groups of raw materials into two groups of screw extruders respectively. The temperature is controlled at 170 degrees and 180 degrees, and two sets of melts are obtained, the temperatures are 160 degrees and 170 degrees respectively;

[0028] S3: Melt distribution: Pour the two sets of melts extruded in step S2 into two sets...

Embodiment 2

[0035] The production process of the two-component spun-bonded filament nonwoven material in parallel with cashmere comprises the following steps:

[0036] S1: Raw material feeding: Cut two groups of raw materials with different melt indexes into the feeding machine. The raw materials are PP and PE or PP and PP or PP and COPP or PE and PET or PP and PET or PET and COPP, and the raw materials Before feeding, it needs to be dried and sliced. The drying temperature is 80 degrees, and the drying time is 5 hours. Then put it into a ball mill for ball milling, so that the diameter of the raw material is between 5-15 mm;

[0037] S2: Extrusion hot melt: Put two groups of raw materials into two groups of screw extruders respectively. The temperature is controlled at 150 degrees and 160 degrees, and two sets of melts are obtained, the temperatures are 130 degrees and 150 degrees respectively;

[0038] S3: Melt distribution: Pour the two sets of melts extruded in step S2 into two sets ...

Embodiment 3

[0045] The production process of the two-component spun-bonded filament nonwoven material in parallel with the cashmere comprises the following steps:

[0046] S1: Raw material feeding: Cut two groups of raw materials with different melt indexes into the feeding machine. The raw materials are PP and PE or PP and PP or PP and COPP or PE and PET or PP and PET or PET and COPP, and the raw materials Before feeding, it needs to be dried and sliced. The drying temperature is 90 degrees, and the drying time is 6.5 hours. Then put it into a ball mill for ball milling, so that the diameter of the raw material is between 5-15 mm;

[0047] S2: Extrusion hot melt: Put two groups of raw materials into two groups of screw extruders respectively. The temperature is controlled at 160 degrees and 170 degrees, and two sets of melts are obtained, the temperatures are 145 degrees and 160 degrees respectively;

[0048] S3: Melt distribution: Pour the two sets of melts extruded in step S2 into two s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com