Radiation-proof polyester fiber for emitting negative ions and far infrared rays and preparation method thereof

A technology of far-infrared emission and polyester fiber, applied in fiber treatment, fiber chemical characteristics, single-component polyester rayon, etc., can solve problems such as poor comfort, poor dyeability, and poor softness, and achieve high levels of human and environment The effect of safety, good flexibility, and good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 500g of activated carbon with a particle size of 10-20nm, put it into 5L of 0.5mol / L HCl solution, immerse in the acid solution for 10min, filter, wash with 2L of water, and dry to obtain acidified activated carbon;

[0032] In 10L 0.5mol / L BaCl 2 Put 500g of activated activated carbon after acidification into the above solution, adopt static adsorption method, filter after adsorption for 1.5h at 35°C, and then put into 0.5mol / L H 2 SO 4 Immerse for 30min, then filter, and dry to obtain loaded BaSO 4 activated carbon;

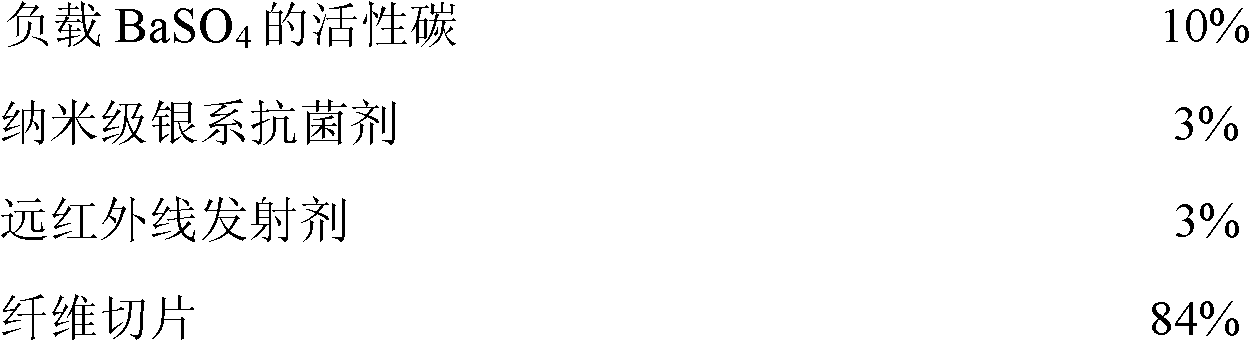

[0033] A kind of polyester fiber of anti-radiation, negative ion and far-infrared emission, its raw material percentage by weight is:

[0034]

[0035] The fiber slices are PET slices;

[0036] Feed according to the above ratio, and then carry out blending and melt spinning; the spinning process conditions are: spinning temperature 270°C, spinning speed 900m / min, side blowing temperature 26°C, air supply relative humidity 70%, wind speed 0.4...

Embodiment 2

[0038] Weigh 500g of activated carbon with a particle size of about 200nm, put it into 5L of 0.5mol / L HCl solution, soak in the acid solution for 10min, filter, wash with 2L of water, and dry to obtain acidified activated carbon;

[0039] In 10L 0.5mol / L BaCl 2 Put 500g of the above acidified activated carbon into the solution, adopt the method of dynamic adsorption, filter after adsorption for 1.5h at 35°C, and then put it into 0.1mol / L H 2 SO 4 Immerse for 30min, then filter, and dry to obtain loaded BaSO 4 activated carbon;

[0040] A kind of polyester fiber of anti-radiation, negative ion and far-infrared emission, its raw material percentage by weight is:

[0041]

[0042] The fiber slices are PTT slices;

[0043] Feed according to the above ratio, and then carry out blending and melt spinning; the spinning process conditions are: spinning temperature 275°C, spinning speed 1200m / min, side blowing temperature 27°C, air supply relative humidity 75%, wind speed 0.45m / s ...

Embodiment 3

[0045] Weigh 500 g of activated carbon with a particle size of about 500 nm, put it into 5 L of 0.5 mol / L HCl solution, immerse in the acid solution for 10 min, filter, wash with 2 L of water, and dry to obtain acidified activated carbon;

[0046] In 10L 0.5mol / L BaCl 2 Put 500g of the above-mentioned acidified activated carbon into the solution, adopt the method of static adsorption, filter after adsorption for 1.5h at 35°C, and then put it into 5mol / L H 2 SO 4 Immerse for 30min, then filter, and dry to obtain loaded BaSO 4 activated carbon;

[0047] A kind of polyester fiber of anti-radiation, negative ion and far-infrared emission, its raw material percentage by weight is:

[0048]

[0049] The fiber slices are PET slices and PTT slices, and the weight ratio of the two is 1:1;

[0050] Feed according to the above ratio, and then carry out blending and melt spinning; the spinning process conditions are: spinning temperature 300°C, spinning speed 1600m / min, side blowin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com