Pearl blended regenerated cellulose fiber and its preparation process and application

A regenerated cellulose and blending technology, applied in the field of cellulose fiber, can solve the problem of single type of amino acid, and achieve the effect of smooth and cool fiber feel, comfortable wearing, and preventing skin aging and wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

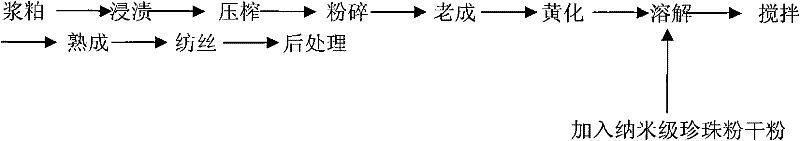

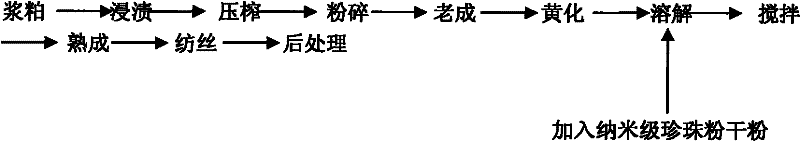

[0037] The preparation process of pearl blended regenerated cellulose fiber comprises the following technical steps:

[0038] (1) pulp;

[0039] (2) Dipping;

[0040] (3) Squeeze and crush;

[0041] (4) mature;

[0042] (5) Yellowing;

[0043] (6) dissolve;

[0044] (7) Add nano-scale pearl powder dry powder

[0045] (8) Stir evenly

[0046] (9) Mature;

[0047] (10) spinning;

[0048] (11) Finished product after post-processing.

[0049] In the above technical solution, the pearl powder described in step (7) is pulverized by low-temperature air flow to a particle size of 0.05um-0.8um.

[0050] The pearl blended regenerated cellulose fiber prepared by the above technical solution can be used to prepare short fibers and filaments.

[0051] The addition amount (weight) of the pearl powder in short fiber and long filament is 5%.

[0052] The manufacturing process and performance of the pearl blended regenerated cellulose fiber prepared in the following examples are ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com