Poly quaternary ammonium polyether polydimethylsiloxane, preparation method thereof and hand feeling finishing agent

A technology based on polyether polydimethylsiloxane and propyl polydimethylsiloxane, which is applied in the field of textile functional finishing agents, can solve the problem of no hydrophilicity, thermal yellowing, large phenolic yellowing, and no Deepening effect and other problems, to achieve the effect of improving the finishing effect of hand feeling, high stability in use, and smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1. Research on deepening effect

[0078] Based on the deepening principle of "high polymers must be homogeneous, uniform and continuous film formation", the applicant found through experiments that there are two methods for obtaining uniform and continuous film formation on fabrics that can be verified experimentally. Method one is: use large, medium and small molecular weight end epoxy silicone oil and amino polyether amine / tertiary ammonium polyether ammonium salt orthogonal experiment; method two is: use medium and large / ultra-large molecular weight end epoxy silicone oil and amino polyether amine / Tertiary ammonium polyether ammonium salt.

[0079] Accordingly, the applicant designed the orthogonal experimental parameters according to the above method 1 and method 2 as described in Table 1 and Table 2 below.

[0080] Table 1. Method 1: Orthogonal experiment with large, medium and small molecular weight terminal epoxy silicone oil and amino polyether ami...

Embodiment 2

[0092] Example 2. Research on the principle of hand feeling finishing, the principle of lasting instant water absorption and the principle of thermal yellowing and phenol yellowing

[0093] The applicant found through research that the principle of hand finishing lies in: fully and evenly adsorbed on the surface of the fabric, and homogeneous, uniform and continuous film formation. Through method one experiment and method one experiment conclusion, it is found that the adsorption capacity (uniform adsorption capacity) of the quaternary ammonium salt cation is far stronger than the weak cation after acidification of primary amine, secondary amine, and tertiary amine.

[0094] Therefore this invention has selected tertiary ammonium polyether ammonium salt, and all become quaternary ammonium salt cations after its reaction.

[0095] In addition, it has been found through research that the principle of long-lasting and instant water absorption lies in: quaternary ammonium polyethe...

Embodiment 3

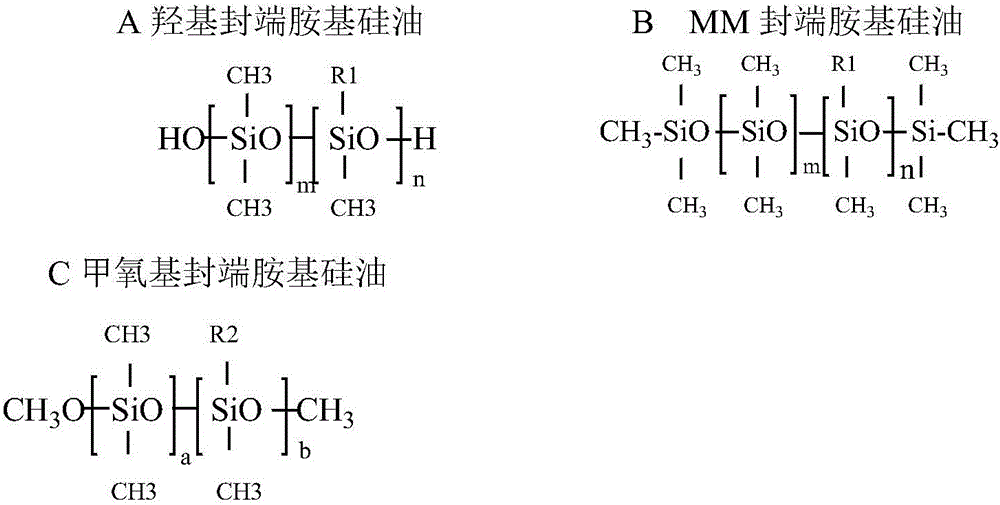

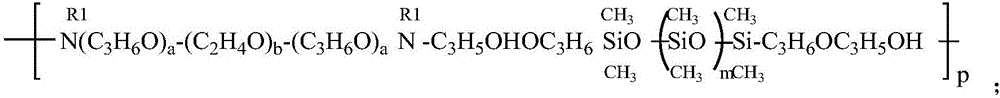

[0099] Example 3. Polyquaternium polyether polydimethylsiloxane

[0100] In this embodiment, a polyquaternium polyether polydimethylsiloxane with a molecular weight between 30,000 and 80,000 is provided, and the polyquaternium polyether polydimethylsiloxane is represented by the following general formula I:

[0101]

[0102] where the R 1 selected from -CH 3 、-C 2 h 5 or -C 4 h 9 one of - from Cl - , Br - , I - , CH 3 COO - One of them; a is an integer selected from 2 to 3; b is an integer selected from 30 to 100, such as 30, 35, 40, 45, 50, 55, 60, 65, 70, 80, 90, 100, etc.

[0103] The synthesis route of the polyquaternary ammonium polyether polydimethylsiloxane is as follows.

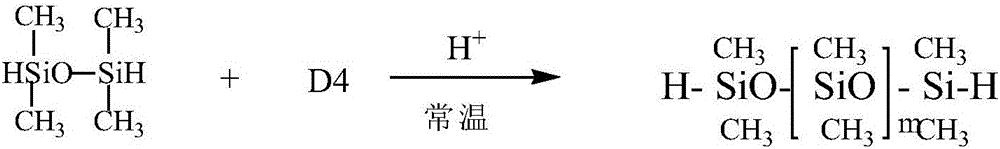

[0104] Step 1. Preparation of Intermediate 1: 1,3-Epoxypropyloxypropyldisiloxane

[0105]

[0106] Under the condition of 45~85℃, using 1% isopropanol solution of chloroplatinic acid as catalyst (the dosage is 0.05~0.1% of the total weight of the system), to 1,1,3,3-tetramethyldihy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com