Acid, alkali, and salt corrosion resistant soft polychloroethylene cable sheath material and corrosion-resistant cable

A technology of soft polyvinyl chloride and cable sheathing materials, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of decreased insulation performance, increased process and cost, hard and brittle plastics, etc., to achieve the reduction of electrical insulation performance, reduce Moisture intrusion, enhanced anti-hydrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiment of the soft polyvinyl chloride cable sheathing material resistant to acid, alkali and salt corrosion of the present invention:

[0053] According to the conventional soft PVC plastic production process, the ingredients in Table 3 are mixed at 80-120°C, plasticized at 150-160°C, cooled and cut into pellets, and the soft PVC cable sheath resistant to acid, alkali, and salt corrosion is obtained. Nesting.

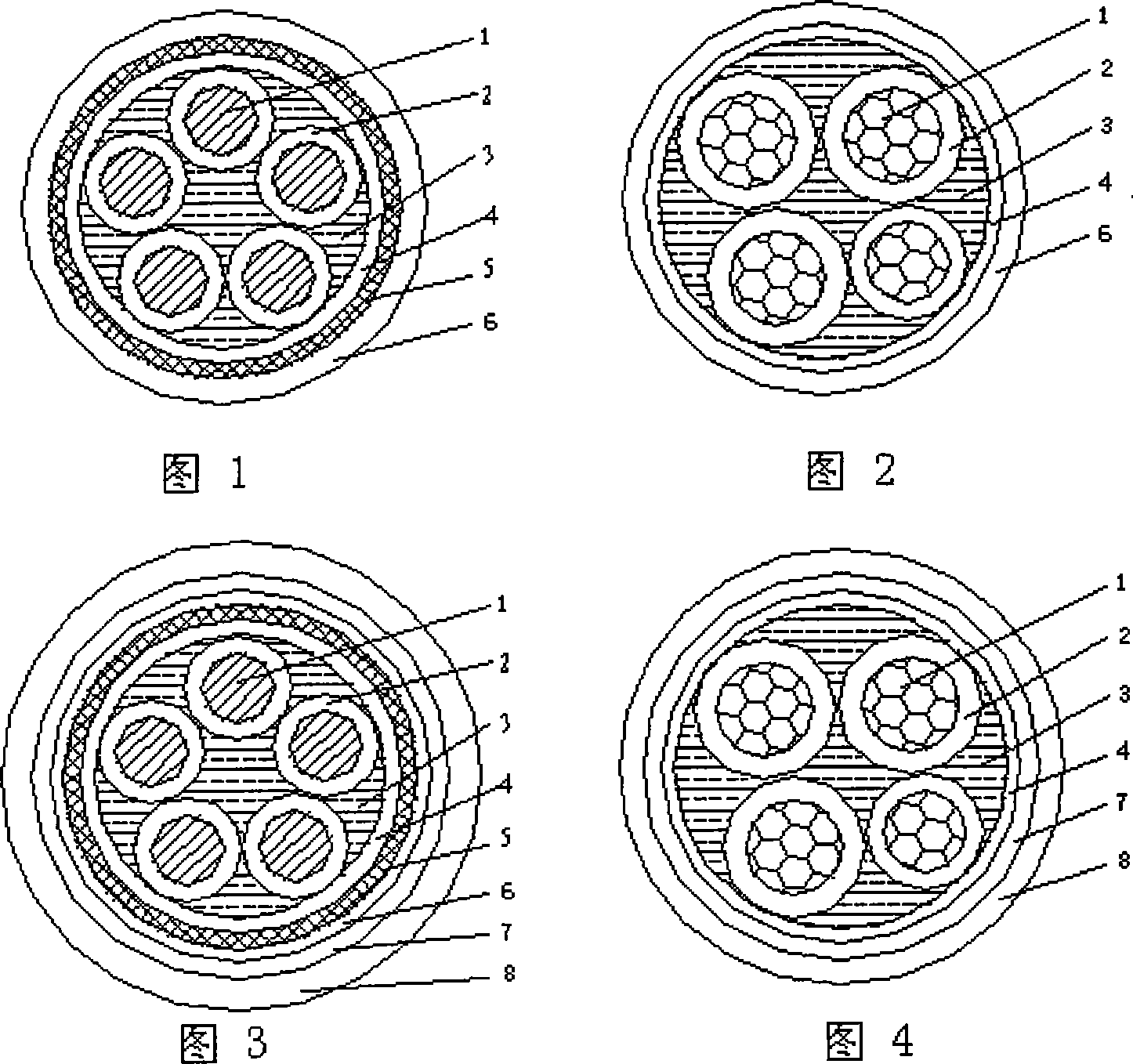

[0054] Corrosion-resistant control cable of the present invention: see Fig. 3, the insulated wire core is composed of a conductive conductor 1 and a plastic insulating layer 2, and is filled with 3 to form a circle after being twisted into a cable. And the shielding protection layer 6, the outer longitudinal wrapping fusion bonding stainless steel plastic composite tape 7, the outermost layer is extruded with the outer sheath 8 of the outer sheath material extruded wrapping of the present invention.

[0055] Corrosion-resistant electric power cable of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com