Composition of castor-based EC-2 hardened gear face cutting oil

An EC-2, hard tooth surface technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve problems such as easy chipping, rapid rise in workpiece temperature, fast tooth wear, etc., to reduce chipping, reduce friction, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

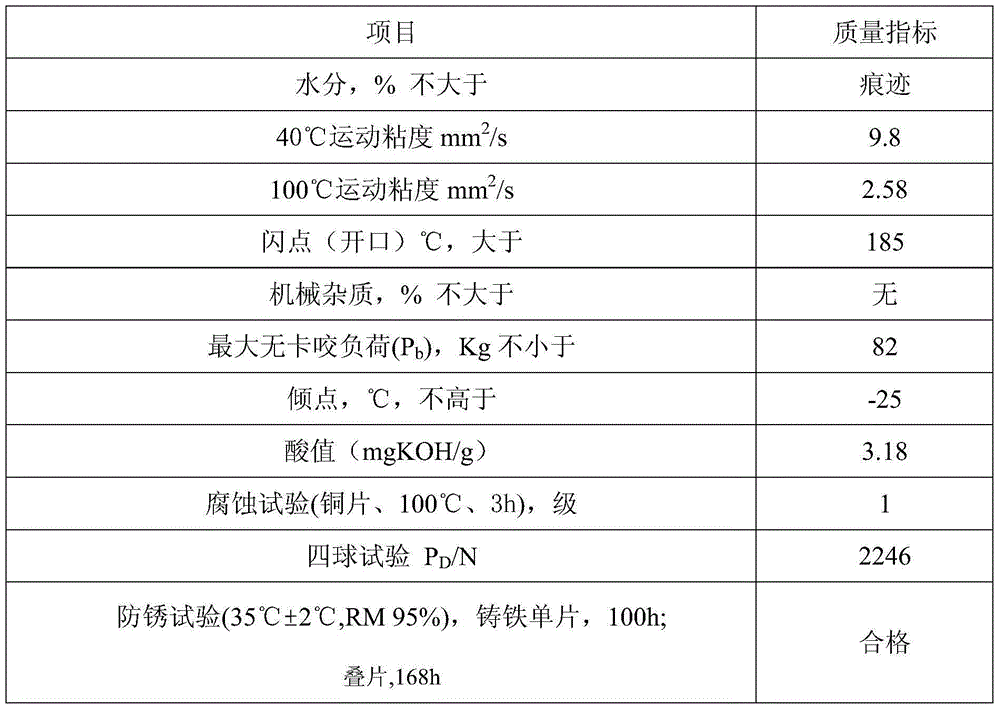

Image

Examples

Embodiment 1

[0019] It is prepared by blending the components according to the following mass percentages:

[0020] components

Embodiment 2

[0022] It is prepared by blending the components according to the following mass percentages:

[0023] components

Embodiment 3

[0025] It is prepared by blending the components according to the following mass percentages:

[0026] components

Content (percentage)

50% polyinternal olefin compounded with 50% ricinoleyl dioctyl sebacate by mass

69.295%

50% mass ratio of tripolybutylene vulcanized and 50% tricresyl phosphate composite

10.0%

The mass ratio of 50% benzotriazole and 50% alkenyl succinic acid half ester compound

1.2%

Jet Fuel No. 5

8.0%

2.0%

Sulfurized castor oil

3.0%

Compounded with 50% simethicone oil and 50% acrylate and ether copolymer (T911) by mass

0.005%

Condensate of amine and epoxy compound (T1001)

1.0%

1.5%

50% mass ratio of 2,6-di-tert-butyl mixed phenol and 50% benzotriazole derivative compound

2.0%

50% molybdenum dithiophosphate and 50% sodium dinonylnaphthalene sulfonate composite

2.0%

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com