Environment-friendly and energy-saving gasoline engine lubricating oil

A gasoline engine, environmentally friendly technology, applied in lubricating compositions, petroleum industry, additives, etc., to achieve the effect of reducing sulfur and phosphorus content, long oil change cycle, and inhibiting cleaning and dispersing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

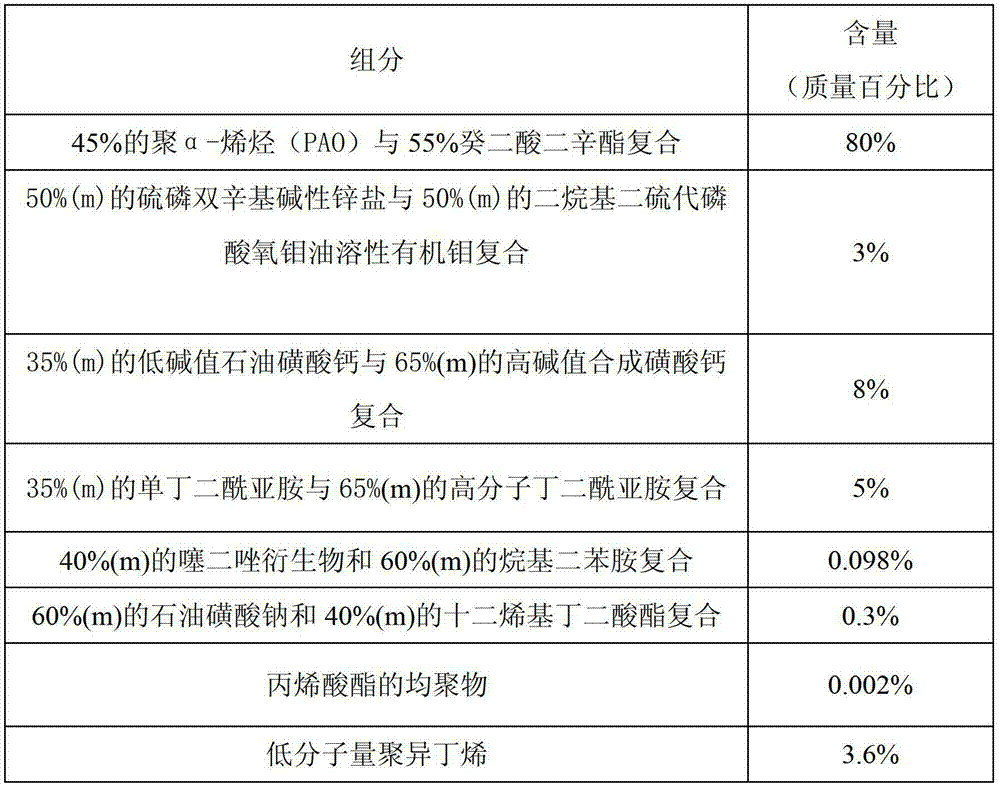

Embodiment 1

[0029] It is prepared by blending the following components in mass percentage:

[0030]

[0031] The preparation steps are: according to the mass percentage ratio, put the composite base oil into the blending kettle, and put the composite anti-oxidant and anti-corrosion agent, the composite metal detergent, and the composite ashless dispersant in sequence under the airtight stirring at 60°C , metal deactivator, antirust agent, antifoam agent, viscosity index improver, stir evenly until completely dissolved, and let stand for 3 hours. Just after filtering.

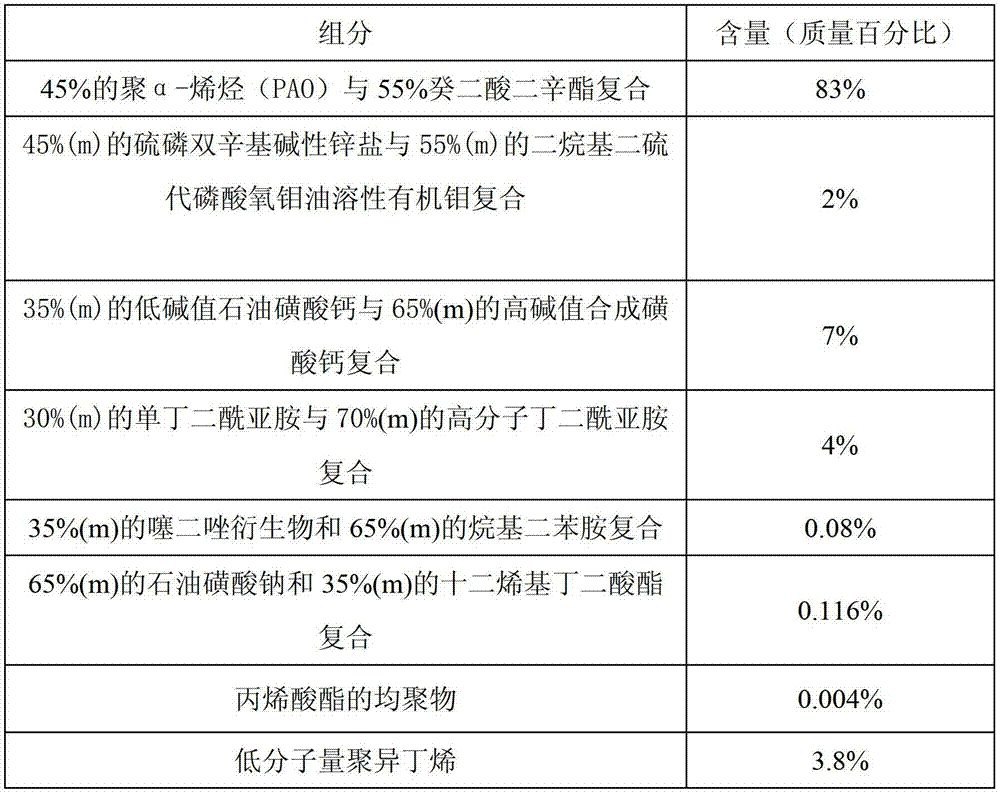

Embodiment 2

[0033] Blend the following components in mass percentage:

[0034]

[0035] The preparation steps are: according to the mass percentage ratio, put the composite base oil into the blending kettle, and put in the composite anti-oxidant and anti-corrosion agent, the composite metal detergent, and the composite ashless dispersant in sequence under the airtight stirring at 80°C , metal deactivator, antirust agent, antifoaming agent, viscosity index improver, stir evenly until completely dissolved, then let stand for 2 hours. Just after filtering.

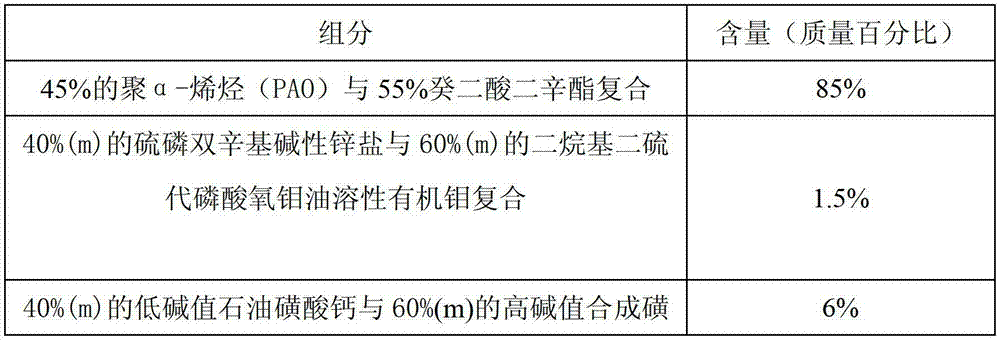

Embodiment 3

[0037] Blend the following percentages by weight:

[0038]

[0039]

[0040] The sum of the above components is 100%.

[0041] Preparation steps are the same as in Example 1.

[0042] Measure through technical supervision department, the physical and chemical index of the oil product of the embodiment of the present invention 1 is:

[0043] Table 2 Typical physical and chemical properties of environmentally friendly and energy-saving gasoline engine oils

[0044]

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com