Cold-resistance and flame-retardant level PVC (polyvinyl chloride) cable material

A flame retardant, cable material technology, used in insulated cables, cables, circuits, etc., can solve problems such as short circuit, leakage, electric shock, and easy cracking of the outer skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

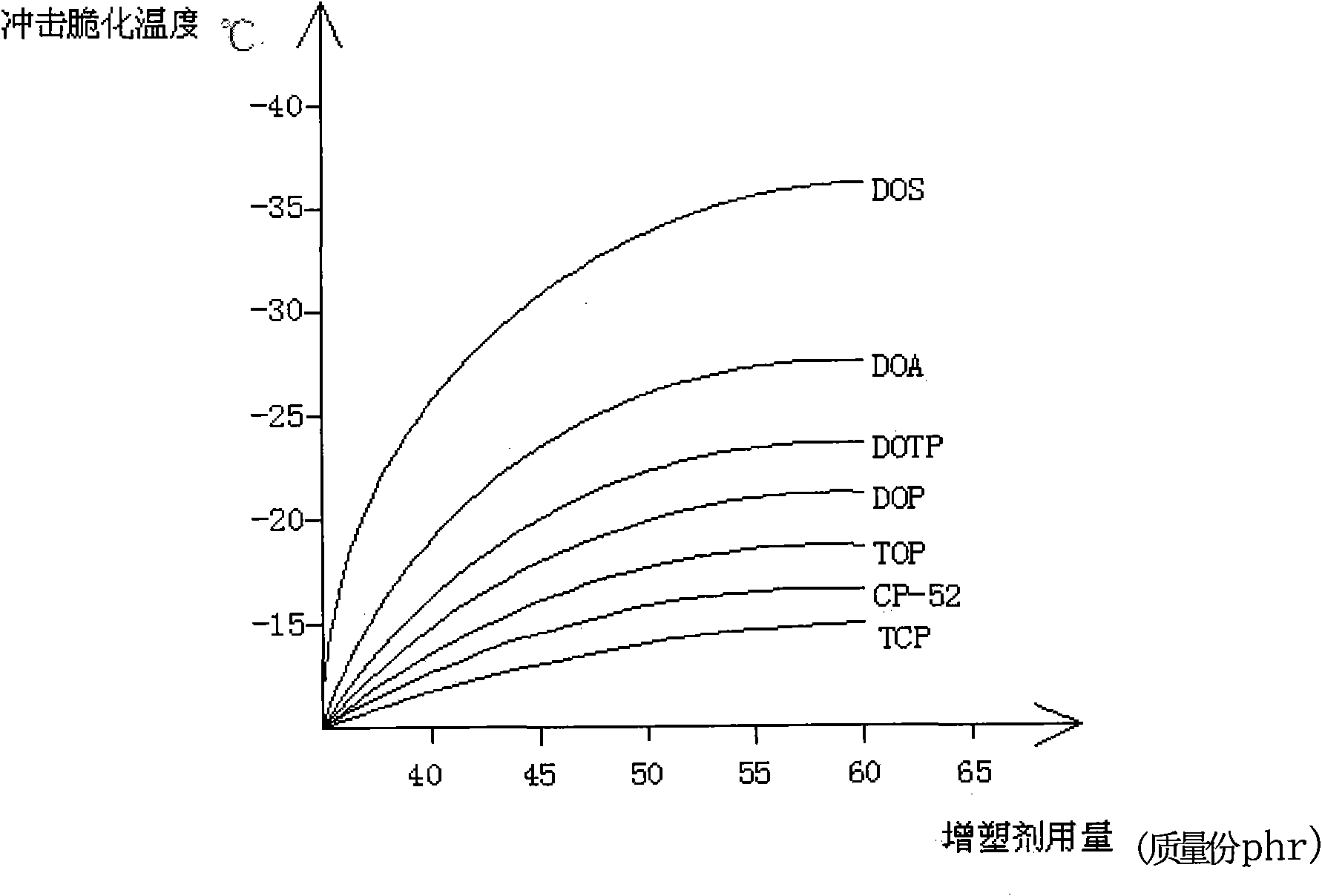

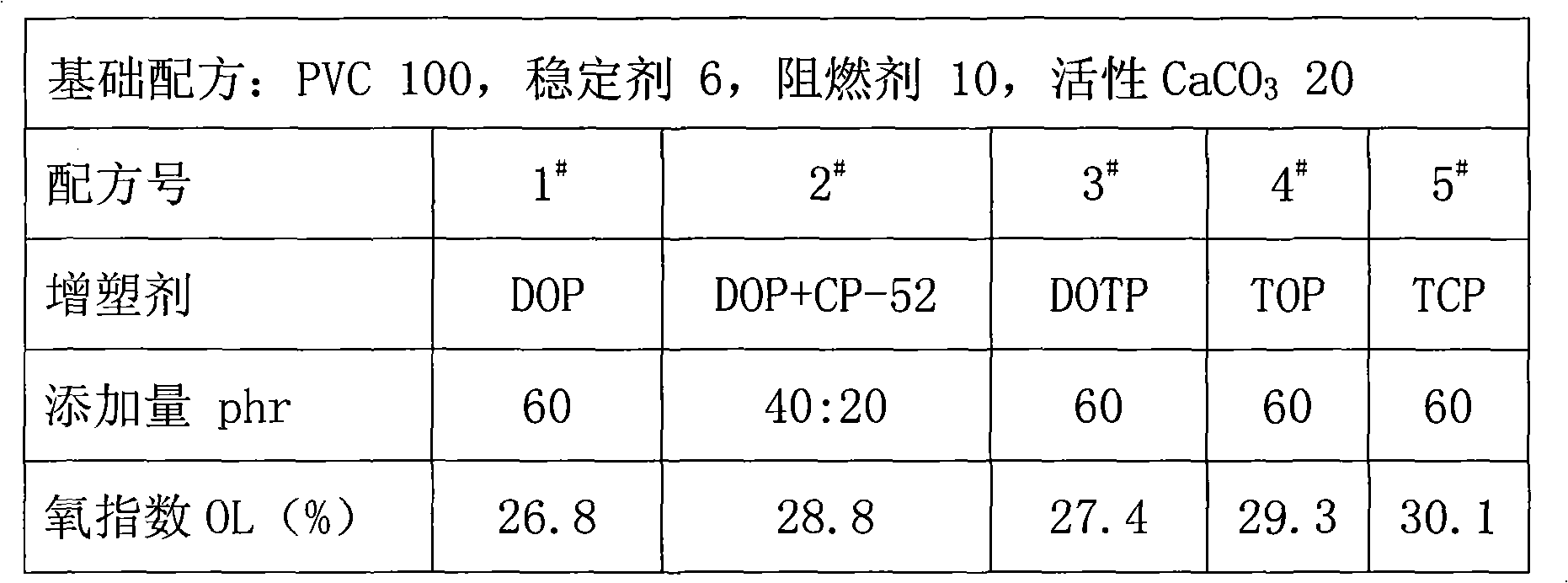

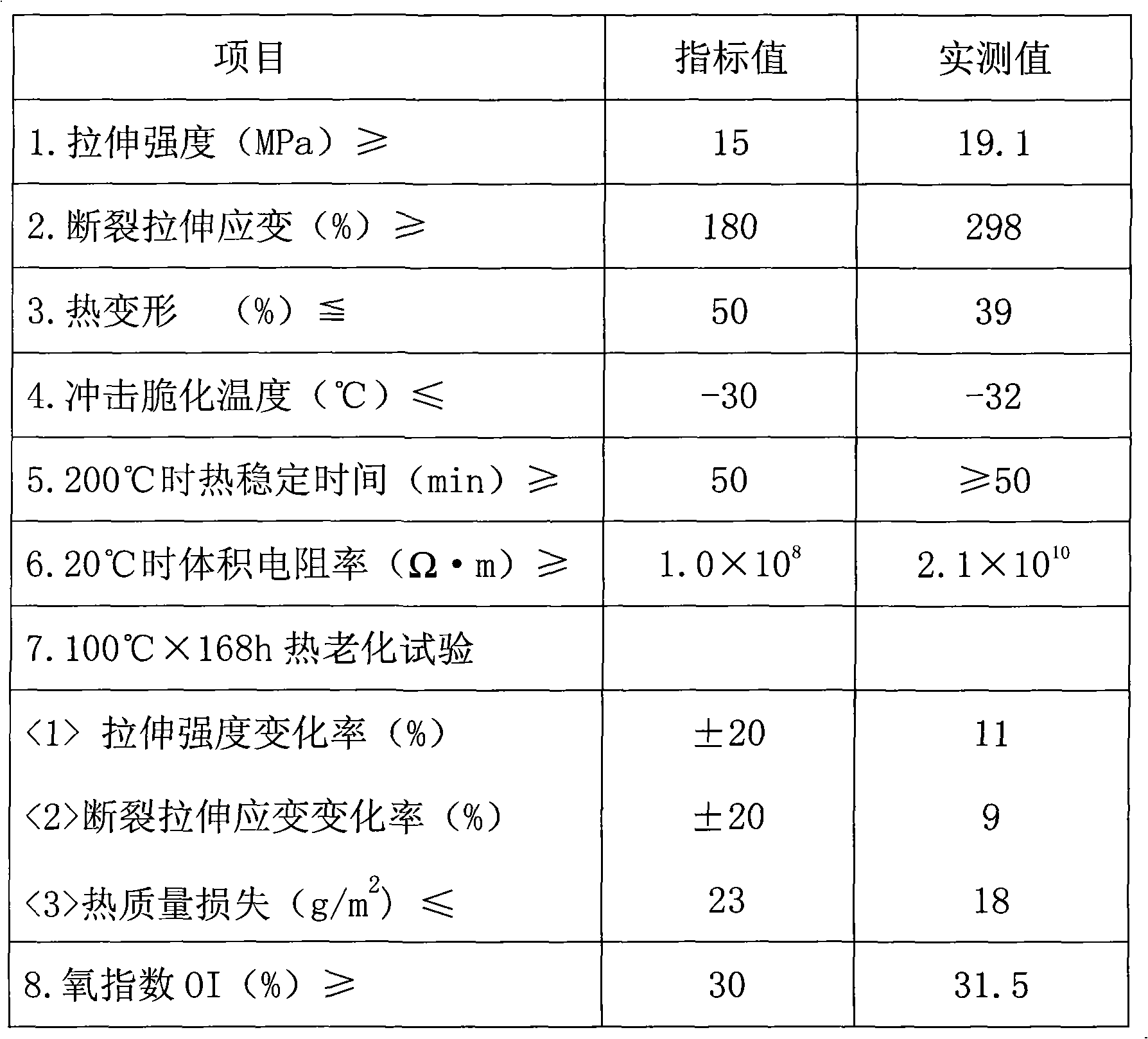

[0009] In general, to improve the low temperature resistance, the first consideration can be solved by increasing the plasticizer. However, increasing the amount of ordinary plasticizers will rapidly reduce the OI, and the tensile strength will also decrease. Therefore, in order to take into account their respective properties, we first test and screen the types and amounts of plasticizers.

[0010] The types of common plasticizers and their codes are as follows:

[0011] Dioctyl Phthalate (DOP), Dioctyl Terephthalate (DOTP), Dioctyl Adipate (DOA), Dioctyl Sebacate (DOS), Tricresyl Phosphate (TCP), Trioctyl Phosphate (TOP), 52 Chlorinated Paraffin (CP-52)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com