Production process of food-grade white oil

A production process, food-grade technology, applied in the field of food-grade white oil production process, can solve the problems of demanding production process, high requirements for the operation of the reaction system, limited cutting precision of fractions, etc., and achieve good stability, flexible operation, Satisfy the effect of long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of production technology of food-grade white oil, comprises the following steps:

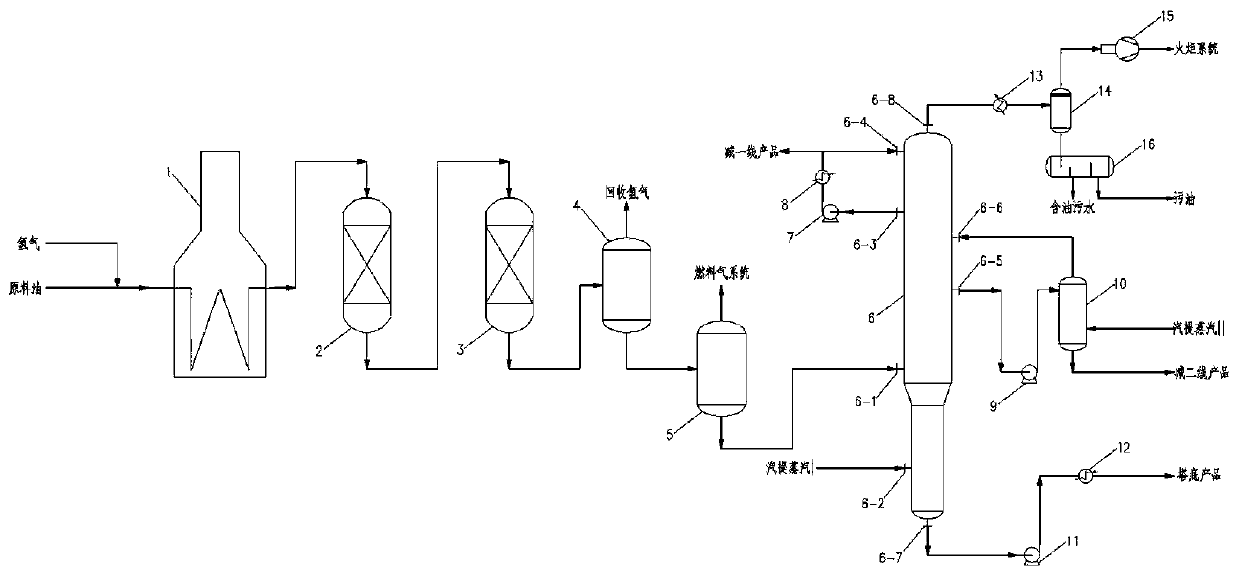

[0025] S1. Enter the reaction system: mix the raw material oil with hydrogen, and after being heated by the heating furnace 1, enter the reactor I 2 equipped with a hydrogenation catalyst, protective agent and ceramic balls, and the reactor with a hydrogenation catalyst and ceramic balls Hydrofining is carried out in II 3, and the unsaturated hydrocarbons in it are subjected to an addition reaction; the reactant passes through the high-pressure separator 4 and the low-pressure separator 5 for gas-liquid separation and then enters the fractionation system; the reactor I 2 and the reactor II 3 adopt The single-stage series form forms a series reaction zone.

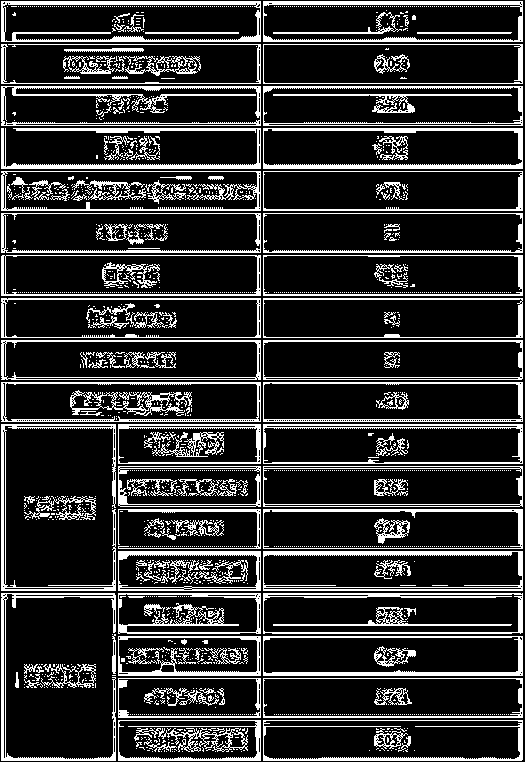

[0026] Wherein, described raw material oil, hydrogenation catalyst and reaction condition are as follows:

[0027] 1) Raw oil properties:

[0028]

[0029] 2) Catalyst and filler:

[0030] Reactor I is filled with ceramic ...

Embodiment 2

[0044] A kind of production technology of food-grade white oil, comprises the following steps:

[0045] S1. Enter the reaction system: mix the raw material oil with hydrogen, and after being heated by the heating furnace 1, enter the reactor I 2 equipped with a hydrogenation catalyst, protective agent and ceramic balls, and the reactor with a hydrogenation catalyst and ceramic balls Hydrofining is carried out in II 3, and the unsaturated hydrocarbons in it are subjected to an addition reaction; the reactant passes through the high-pressure separator 4 and the low-pressure separator 5 for gas-liquid separation and then enters the fractionation system; the reactor I 2 and the reactor II 3 adopt The single-stage series form forms a series reaction zone.

[0046] Wherein, described raw material oil, catalyzer and reaction condition are as follows:

[0047] 1) Raw oil properties:

[0048]

[0049] 2) Catalyst and filler:

[0050] Reactor I is filled with ceramic balls ∅3~∅20,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com