Clean-type universal gear lubricating oil composition

A technology of gear lubricating oil and composition, which is applied in the field of lubricating oil composition and gear transmission system lubricating oil composition, can solve the problems that cannot be used to prepare manual transmission oil for cars, etc., and achieve good economic and social benefits, The effect of low production cost and broad application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

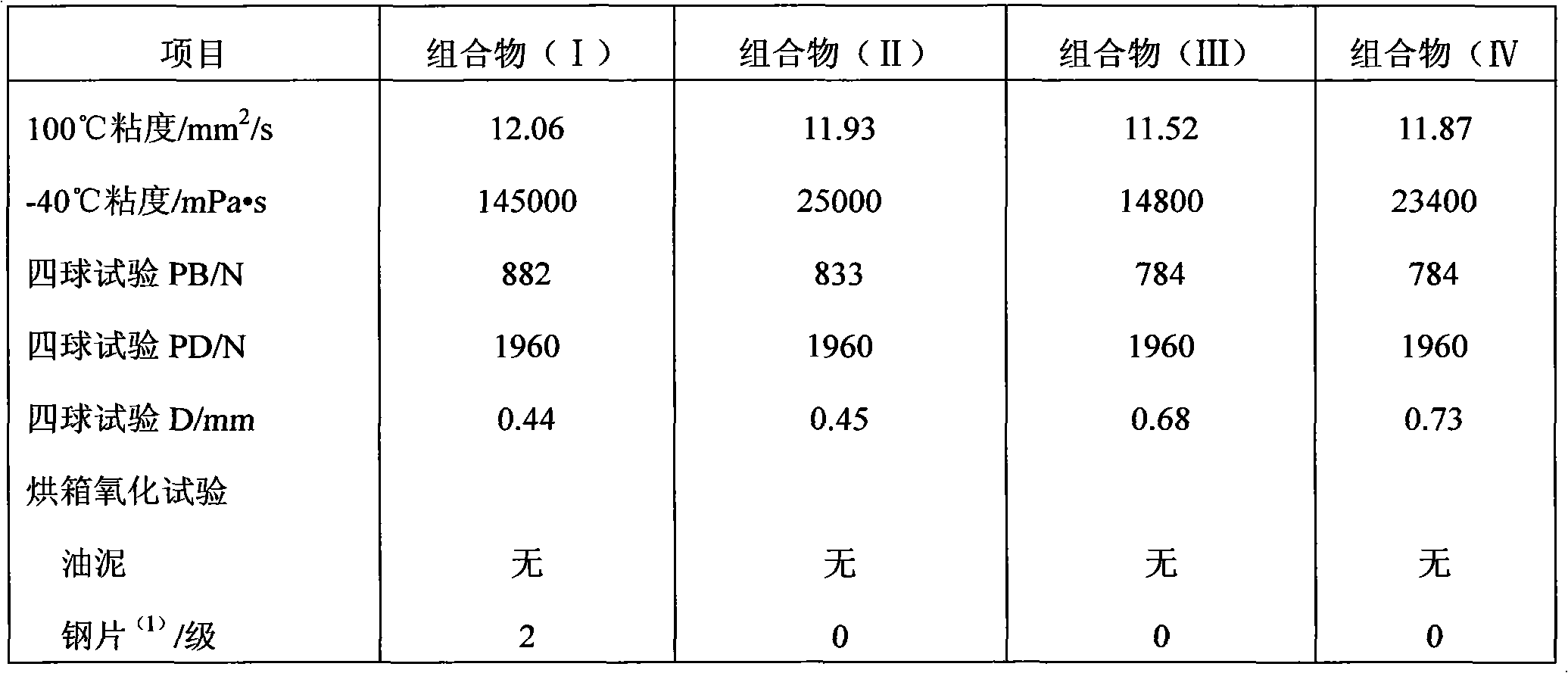

Embodiment 1

[0022] Lubricating oil composition (I), it comprises: No. 5 oil (component A) of Daqing hydroisomerization dewaxed base oil of 79.0wt%; The polymethacrylate (component B) of 16.0wt%; 0.40wt% % polyalphaolefin (component C); 1.0 wt% zinc diisooctyldithiophosphate (component D); 1.50 wt% calcium overbase number alkylsulfonate (component E); 1.50 wt% % of highly active polyisobutylene succinimide (component F); 0.30 wt% of di-n-octyl sulfide (component G); 0.30 wt% of pentaerythritol dioleate (component H). Lubricating oil composition (II) except that 79.0wt% of Daqing hydroisomerized dewaxed base oil No. 5 oil in component (A) is replaced by 79.0wt% poly-a-olefin synthetic oil PAO-4, and the rest are the same combination Object (I). Lubricating oil composition (III) is the same as composition (I) except that 79.0wt% of Daqing hydroisomerized dewaxed base oil No. 5 oil in component (A) is replaced by 79.0wt% diester synthetic oil. Lubricating oil composition (IV) is the same as...

Embodiment 2

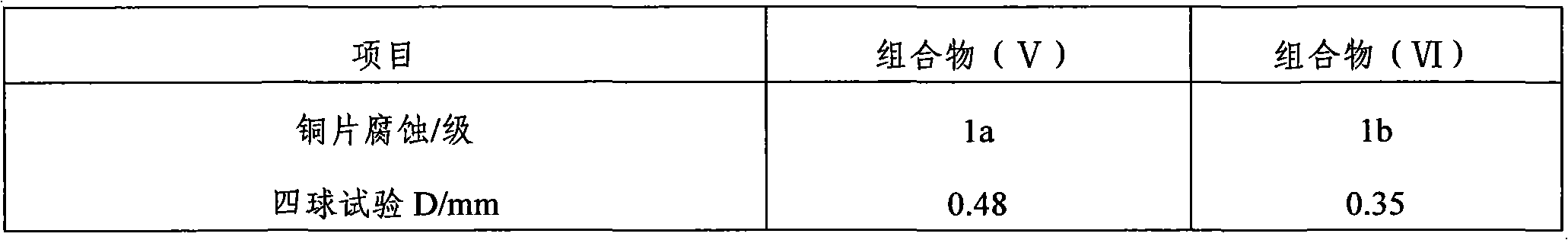

[0028] Lubricating oil composition (V), it comprises: 81.3wt% Daqing hydroisomerization dewaxed base oil No. 5 oil (component A); 8.0wt% polyisobutylene (component B); 1.5wt% polyformaldehyde 1.5 wt% zinc diisooctyldithiophosphate (component D); 3.0 wt% calcium overbased alkyl salicylate (component E); 3.0 wt% 0.7 wt% of dinonyl diphenylamine (component G); 1.0 wt% of dodecylamine oleate (component H). The lubricating oil composition (VI) except component (D) 1.5% zinc diisooctyl dithiophosphate is replaced by 0.75wt% isooctyl acidic phosphoric acid ester dodecylamine salt and 0.75wt% acidic phosphite octadecyl Except for the substitution of alkyl ester, the rest are the same as composition (V). Compositions (V), (VI) in the main properties, performance list 2.

[0029] Table 2 Composition main properties performance

[0030]

[0031] The results in Table 2 show that the anticorrosion performance of diisooctyl zinc dithiophosphate is better than that of isooctyl acid pho...

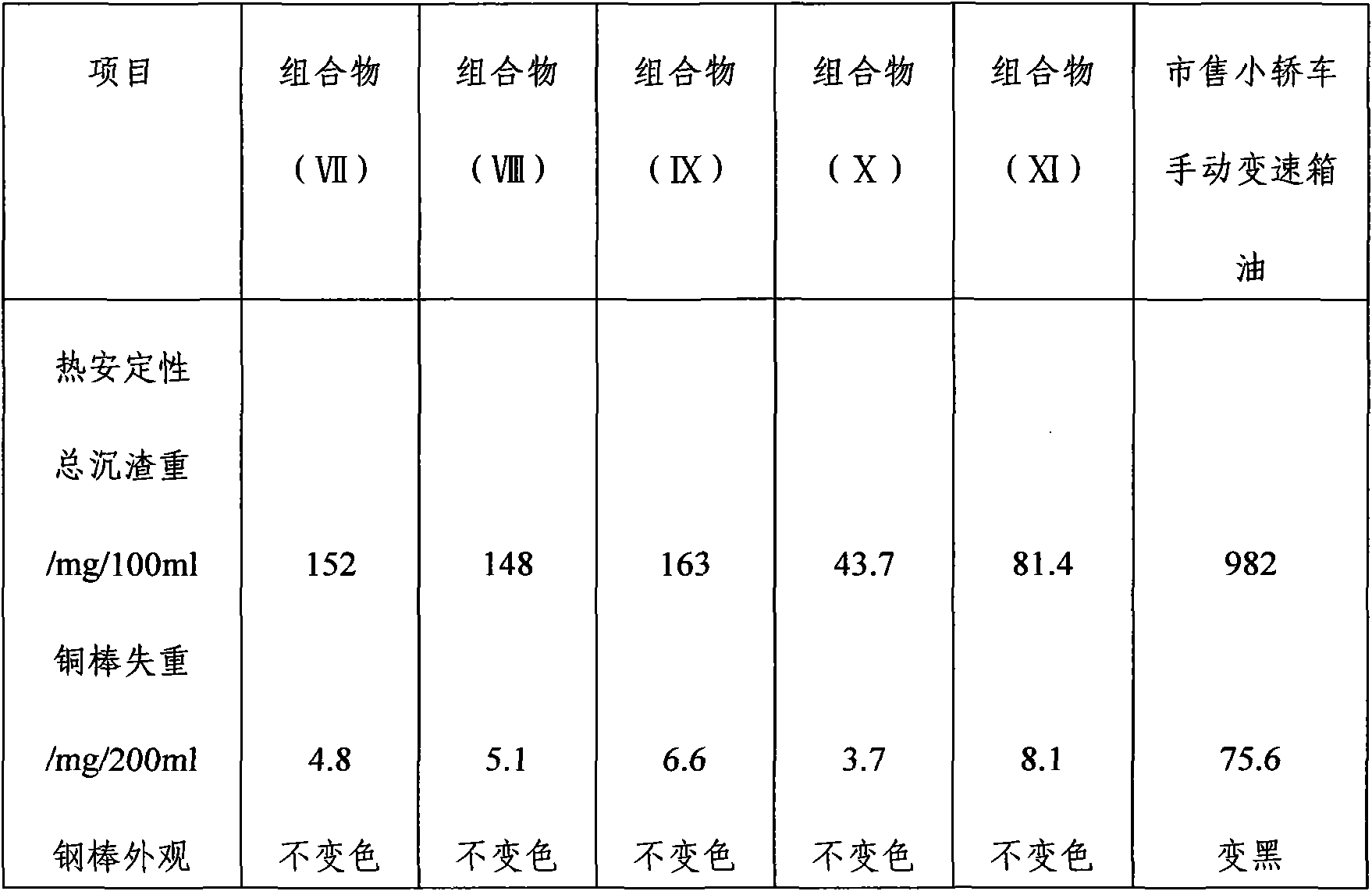

Embodiment 3

[0033] Lubricating oil composition (VII), it comprises: 71.0wt% Daqing hydroisomerization dewaxed base oil No. 5 oil (component A); 12.0wt% polyisobutylene (component B); 1.5wt% polyformaldehyde Acrylate (component C); 1.0 wt% zinc diisooctyl dithiophosphate, 1.5 wt% isooctyl acid phosphate dodecylamine salt, 1.5 wt% acid lauryl phosphite (Component D); 4.5 wt% of overbase number sulfurized calcium alkylphenate (component E); 2.5 wt% of boronated highly reactive polyisobutylene succinimide, 2.0 wt% of boronated highly reactive polyisobutylene succinimide High molecular weight polyisobutylene succinimide (component F); 2.0 wt% phenolic antioxidant (component G); 0.5 wt% lauryl alcohol (component H). The lubricating oil composition (VIII) is the same as the composition (VII) except that 4.5wt% of the high-basic sulfurized alkylphenate calcium in the component (E) is replaced by 4.5wt% of the high-basic calcium alkylsulfonate. The lubricating oil composition (IX) is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com