Gasoline engine oil composition

A gasoline engine oil and composition technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as environmental hazards, difficulty in long-term stability, difficulty in uniform dispersion of nanoparticles, etc., to reduce friction, improve gasoline mileage and durability , to ensure the effect of extreme performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

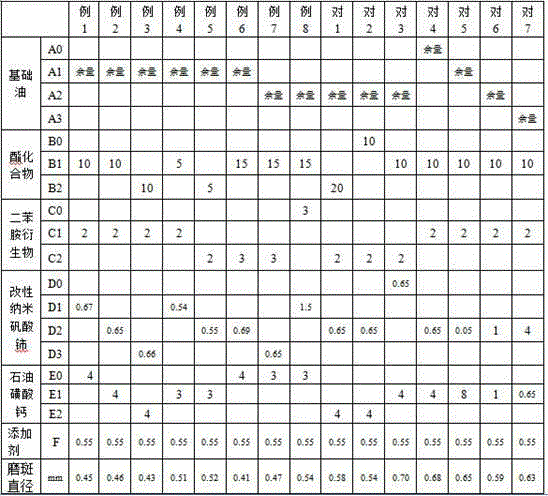

[0067] In Preparation Examples and Comparative Examples, the following component materials were prepared.

[0068] A base oil :

[0069] A0 natural oil: has a kinematic viscosity of 25.26mm at 100°C 2 repurified animal oil

[0070] A1 synthetic oil: having a kinematic viscosity of 4.25mm at 100°C 2 A low viscosity polyalphaolefin and has a kinematic viscosity of 43.50mm at 100°C 2 A mixture of high-viscosity poly-α-olefins, the mass ratio of the two is 3:1

[0071] A2 synthetic oil: having a kinematic viscosity of 5.5mm at 100°C 2 A low viscosity polyalphaolefin and has a kinematic viscosity of 40.68mm at 100°C 2 A mixture of high-viscosity poly-α-olefins, the mass ratio of the two is 3:1

[0072] A3 synthetic oil: has a kinematic viscosity of 5.84mm at 100°C 2 A low viscosity polyalphaolefin and has a kinematic viscosity of 42.68mm at 100°C 2 A mixture of high-viscosity poly-α-olefins, the mass ratio of the two is 1:1

[0073] B ester compound :

[0074] B0 Fatt...

Embodiment

[0099]

[0100] From the above data, it can be seen that the diameter of wear spots produced by the gasoline engine oil composition of the present invention provides the beneficial technical effect of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com