Hermetic reciprocating compressor with thrust ball bearing

a reciprocating compressor and thrust ball bearing technology, applied in the direction of positive displacement liquid engine, piston pump, machine/engine, etc., can solve the problems of reducing reliability and wear of cage b>31/b>, and achieve the effect of reducing the centrifugal force, preventing wear of the holder portion, and reducing the surface pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]Hereinafter, an embodiment of the present invention will be explained with reference to the drawings. In addition, the present invention is not limited by the embodiment. (Embodiment)

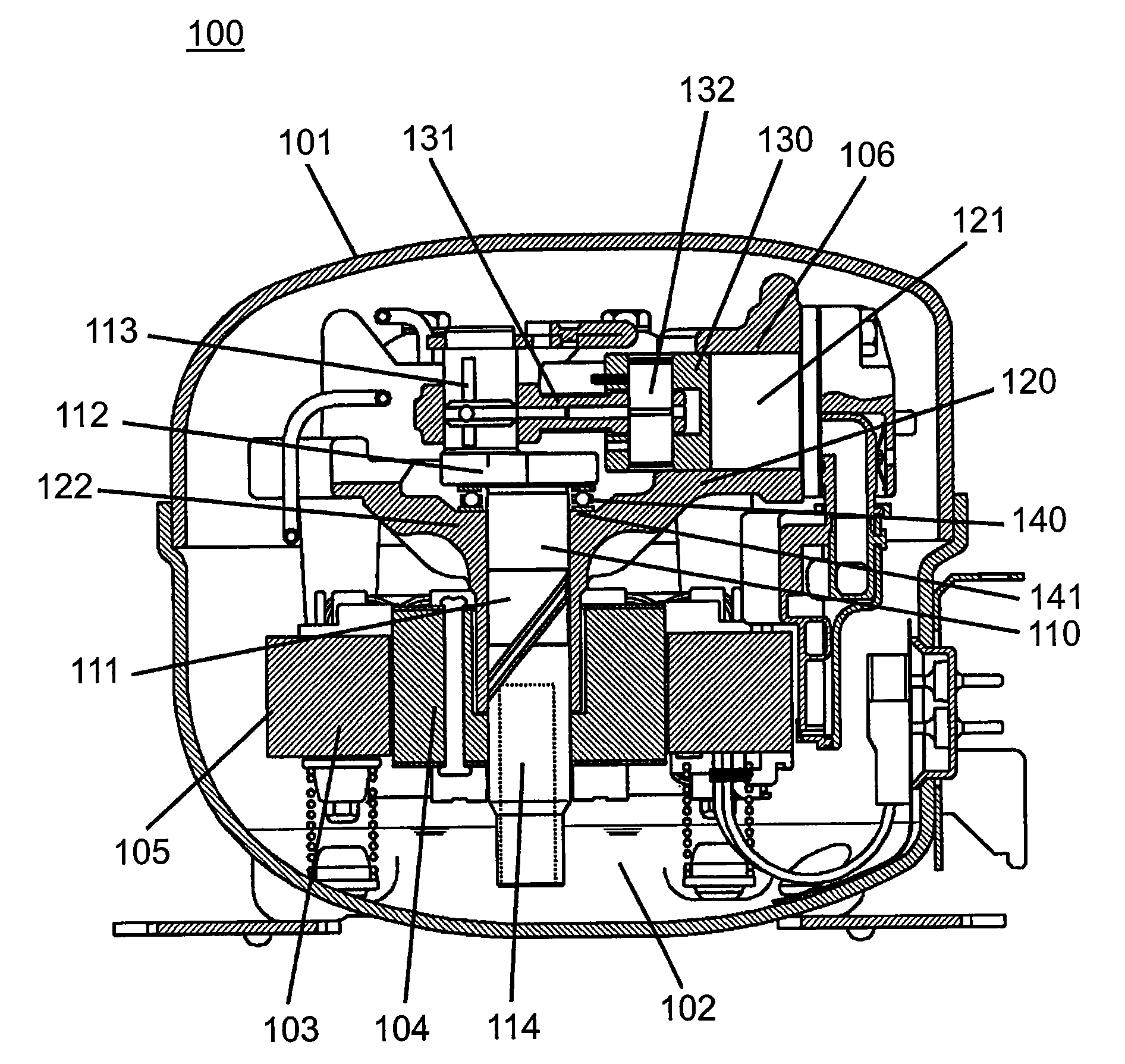

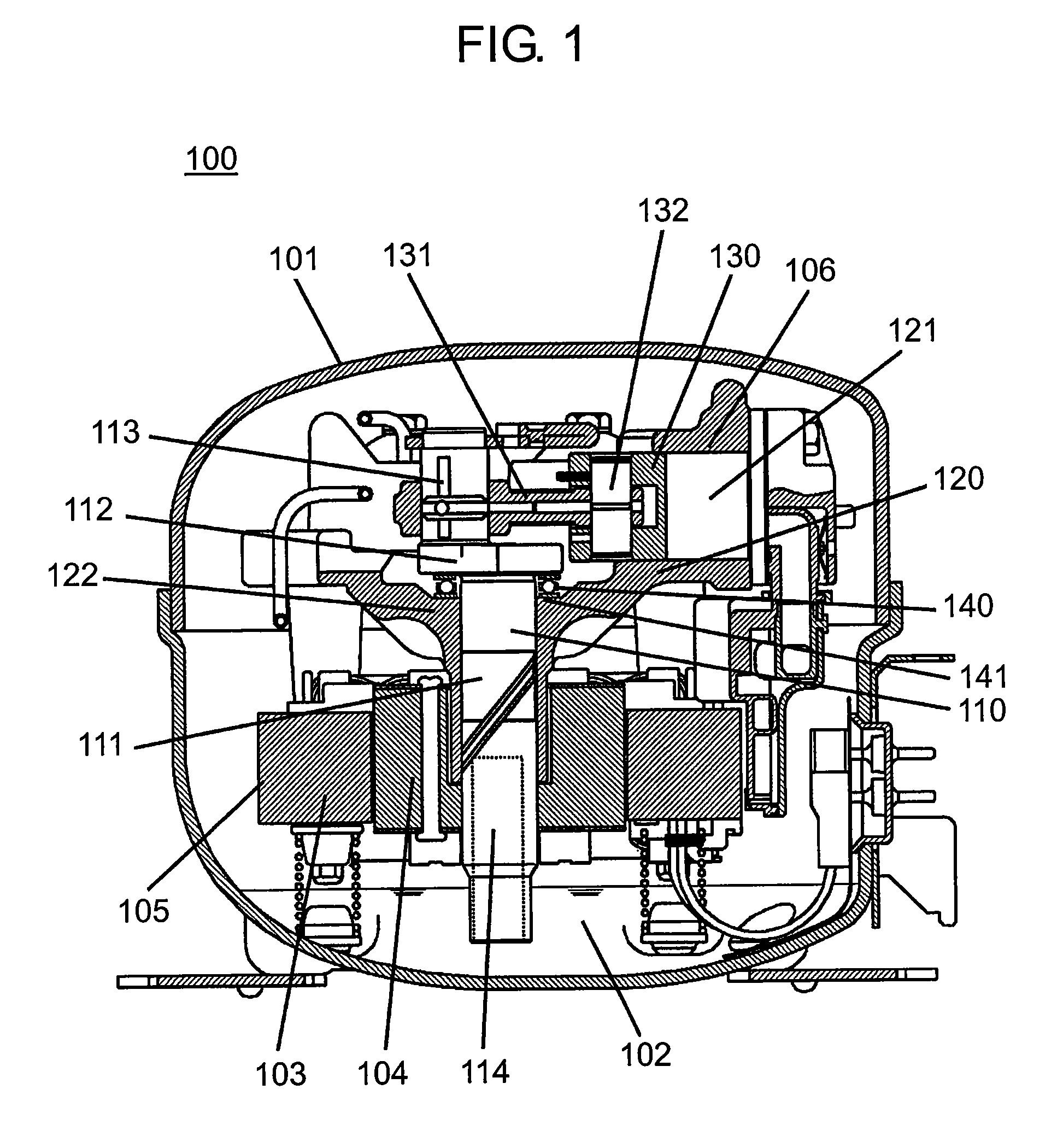

[0053]FIG. 1 is a longitudinal sectional view of a hermetic compressor of the embodiment of the present invention.

[0054]Hermetic compressor 100 stores lubricating oil 102 in hermetic container 101, and electrically-driven element 105 provided with stator 103 and rotor 104, and compressing element 106 that is driven by electrically-driven element 105 and is disposed above electrically-driven element 105 are accommodated.

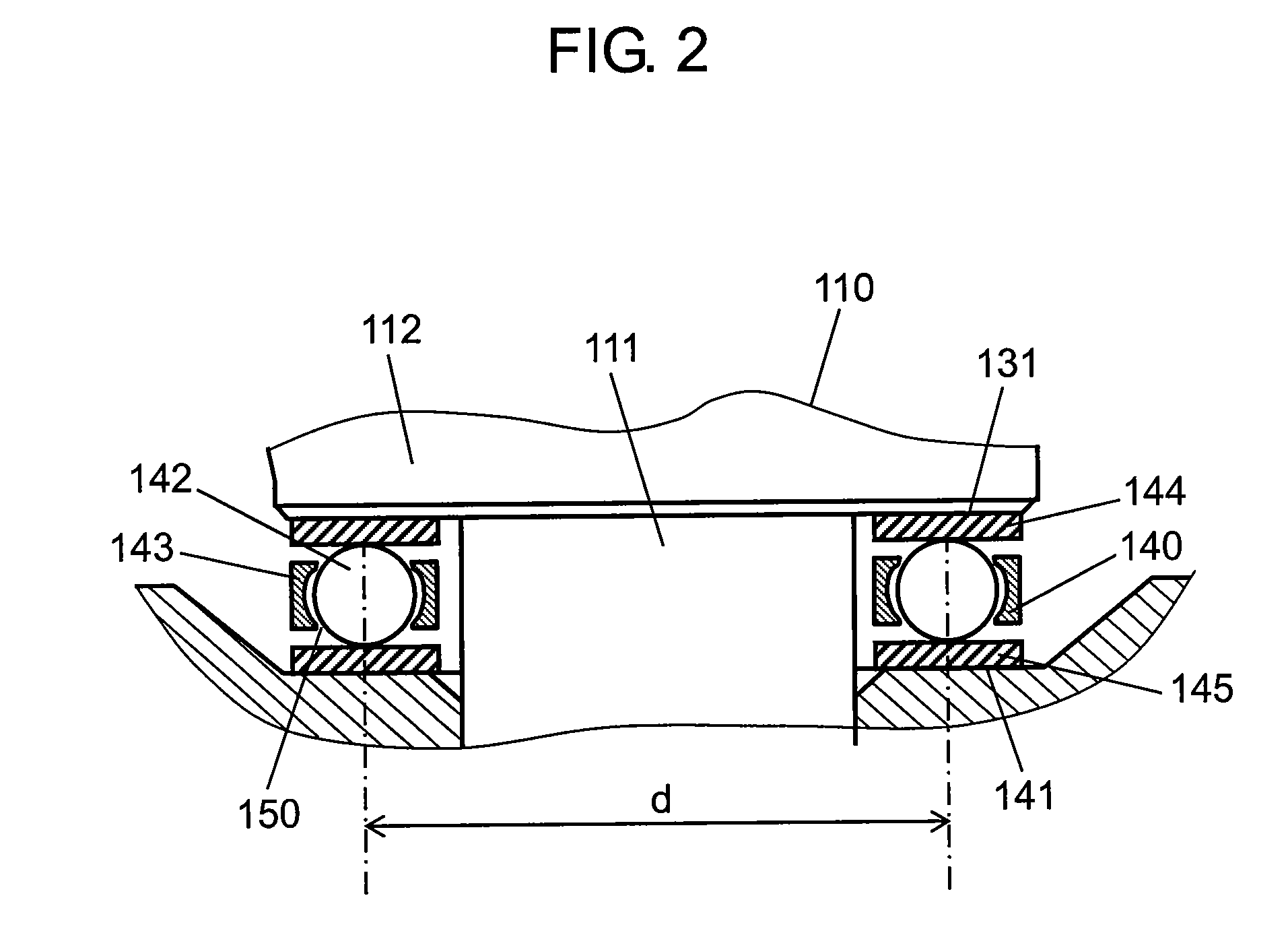

[0055]Shaft 110 constituting compressing element 106 has main shaft portion 111 into which rotor 104 is fixedly shrinkage-fitted, and eccentric shaft portion 113 formed eccentrically from main shaft portion 111 via flange portion 112. Further, oil supply mechanism 114 is formed inside shaft 110.

[0056]Cylinder block 120 has substantially cylindrical compression chamber 121, and is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com