Silicone-oil torsional vibration damper with high rigidity and high damping

A technology of torsional vibration damper and high damping, applied in the field of silicone oil torsional vibration damper and silicone oil damper, to achieve the effect of increasing fluid area, improving stiffness and damping, and high shafting torsional vibration demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

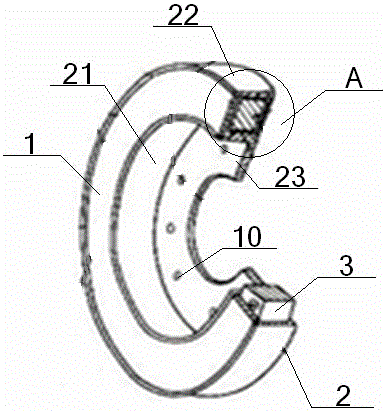

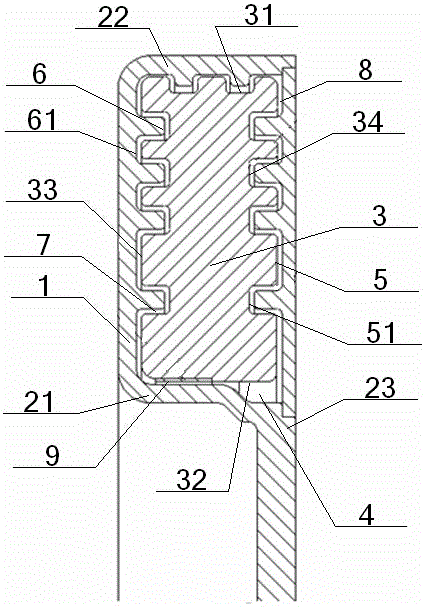

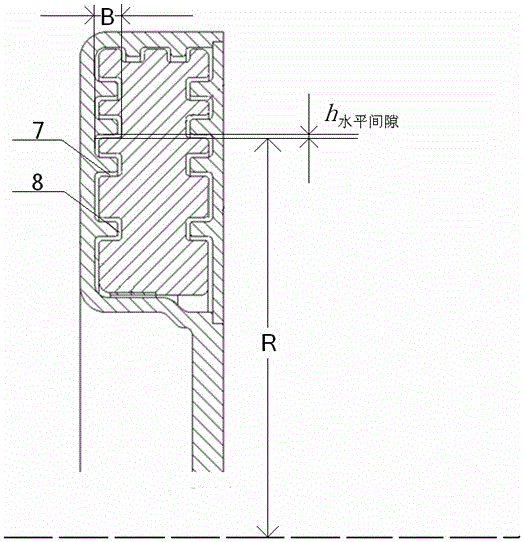

[0056] see Figure 1 to Figure 4 , a silicone oil torsional vibration damper with high stiffness and high damping, including a concentrically arranged shell 2, an inertia ring 3 and a side cover 1, and the said shell 2 includes a concentrically arranged inner shell wall 21, an outer shell wall 22 and a side cover Shell wall 23, one side of the shell wall 22 is connected to one side of the inner shell wall 21 through the side shell wall 23, and the other side of the shell wall 22 is connected to the other side of the inner shell wall 21 through the side cover 1 , the sliding sleeve in the inner cavity 4 surrounded by the side cover 1, the outer shell wall 22, the side shell wall 23, and the inner shell wall 21 has an inertia ring 3 that moves relative to the inner cavity 4, and the inertia ring 3, the inner cavity 4 Silicone oil is injected into the gap between them;

[0057] One side near the shell wall 22 on the inertia ring 3 is the top ring surface 31, one side near the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com