Environment-friendly long-life emulsified antirust agent and preparation method thereof

A rust inhibitor, long-life technology, applied in the field of metal rust prevention, can solve the problems of short rust prevention time, large amount of rust prevention oil, not environmental protection, etc., to reduce the harm to the environment and workers, good rust prevention performance, The effect of good anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

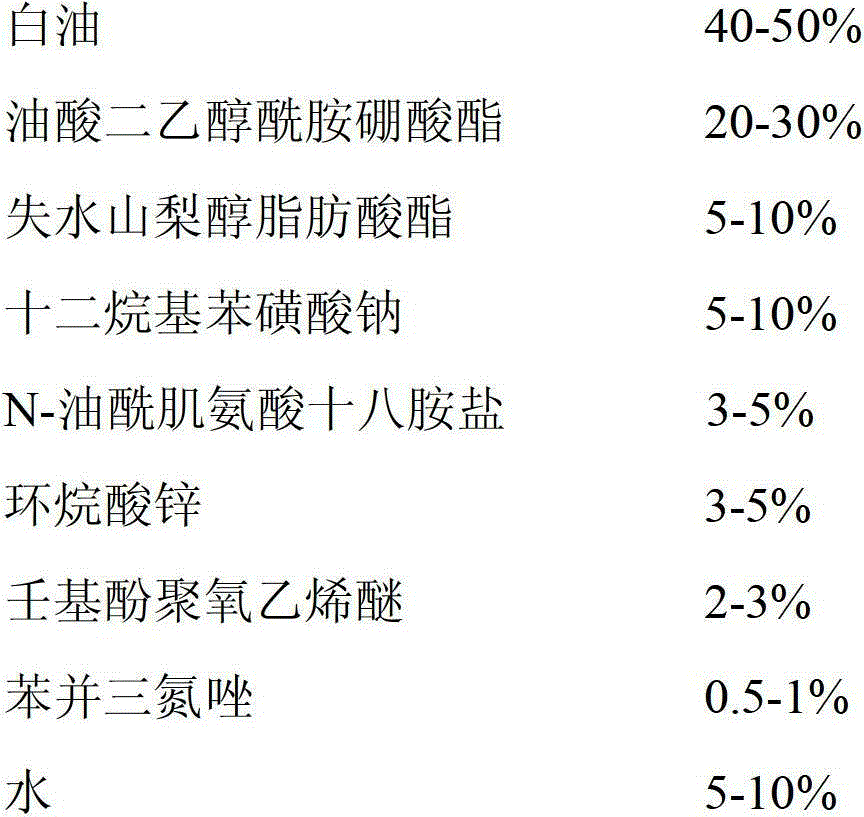

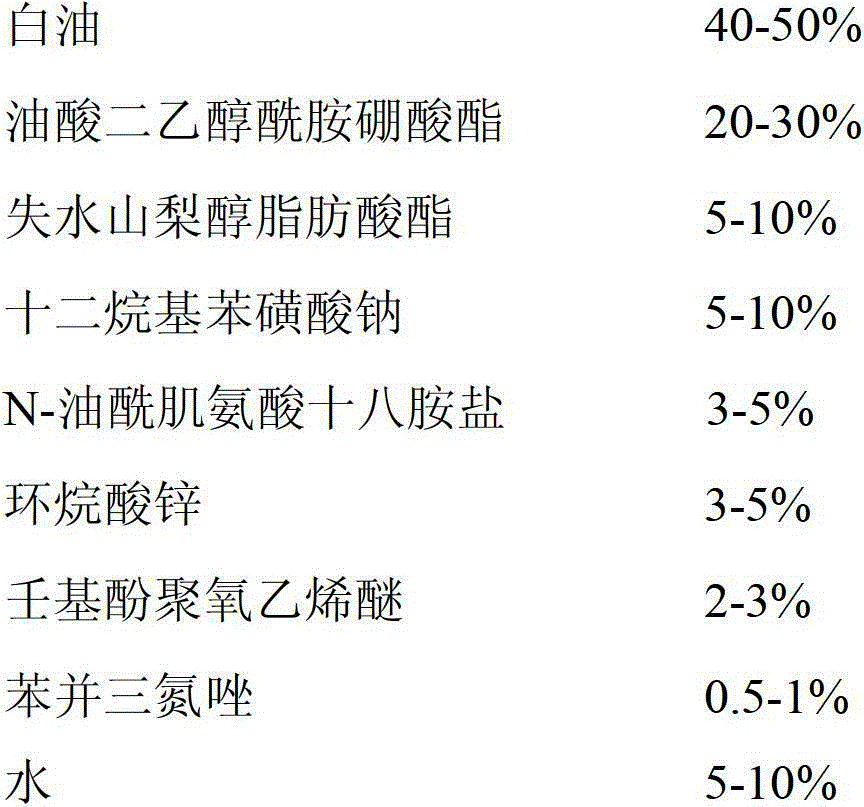

[0023] Weigh 1kg of benzotriazole and 10kg of sorbitan fatty acid ester (S-80) and stir thoroughly, then add 40kg of 46# white oil, 25kg of oleic acid diethanolamide borate, 5kg of N - Oleoyl sarcosine octadecylamine salt, 3 kg of zinc naphthenate, 3 kg of nonylphenol ethoxylate (TX-10), and 5 kg of sodium dodecylbenzene sulfonate pre-mixed with 8 kg of water, Fully stir for 30 minutes at a temperature of 40°C until it is completely transparent, and then package it to obtain an environmentally friendly long-life emulsified rust inhibitor.

[0024] This anti-rust agent liquid, according to GB / T2361-1992 test method to do warm test (14 days), the result is 0 grade, in line with the technical indicators of anti-rust oil.

[0025] This anti-rust agent liquid, according to SH / T0081-1991 salt spray test results: 96 hours, 0 level, in line with the relevant technical indicators of anti-rust oil.

Embodiment 2

[0027] Weigh 0.5kg of benzotriazole and 5kg of sorbitan fatty acid ester (S-80) and stir thoroughly, then add 50kg of 32# white oil, 20kg of oleic acid diethanolamide borate, 3kg of N-oleoyl sarcosine stearylamine salt, 5kg of zinc naphthenate, 2kg of nonylphenol ethoxylate (OP-9), and 7.5kg of dodecylbenzenesulfonic acid mixed in advance with 7kg of water Sodium, fully stirred at 25°C for 60 minutes until completely transparent, packaged to obtain an environmentally friendly long-life emulsified rust inhibitor.

[0028] According to the weight ratio of 5% antirust agent + 95% distilled water, the antirust agent was tested for liquid phase corrosion (distilled water) with the test method of GB / T11143-2008, and the result was qualified.

[0029] According to the weight ratio of 5% antirust agent + 95% distilled water, this antirust agent is subjected to a warm test (7 days) according to the test method of GB / T2361-1992, and the result is grade 1.

[0030] According to the salt...

Embodiment 3

[0032] Weigh 0.6kg of benzotriazole and 6kg of sorbitan fatty acid ester (S-20) and stir thoroughly, then add 45kg of 22# white oil, 22kg of oleic acid diethanolamide borate, 4kg of N-oleoyl sarcosine octadecylamine salt, 4kg of zinc naphthenate, 2.4kg of nonylphenol ethoxylate (OP-9), and 6kg of dodecylbenzenesulfonic acid mixed in advance with 10kg of water Sodium, fully stirred at 35°C for 45 minutes until completely transparent, packaged to obtain an environmentally friendly long-life emulsified rust inhibitor.

[0033] According to the weight ratio of 10% antirust agent + 90% distilled water, the antirust agent was tested for liquid phase corrosion (distilled water) with the test method of GB / T11143-2008, and the result was qualified.

[0034] According to the weight ratio of 10% antirust agent + 90% distilled water, this antirust agent is subjected to a warm test (7 days) according to the test method of GB / T2361-1992, and the result is grade 1.

[0035] The antirust age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com