Comprehensive maintenance platform of vertical mixed-flow pump

A technology for repairing platforms and mixed-flow pumps, which is applied to workbenches, metal processing, and metal processing equipment. It can solve problems such as increased vibration of equipment, low efficiency of maintenance work, and potential safety hazards such as driving crookedly, pulling and tilting, and achieving convenient disassembly and assembly. in place, easy to clean and maintain, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

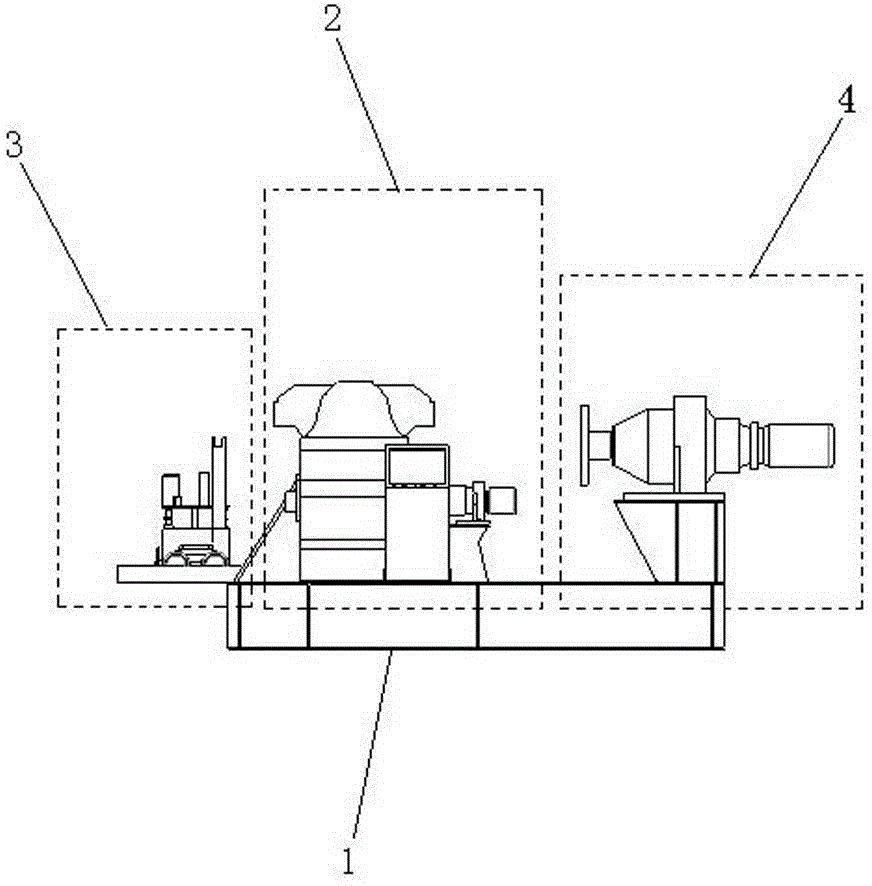

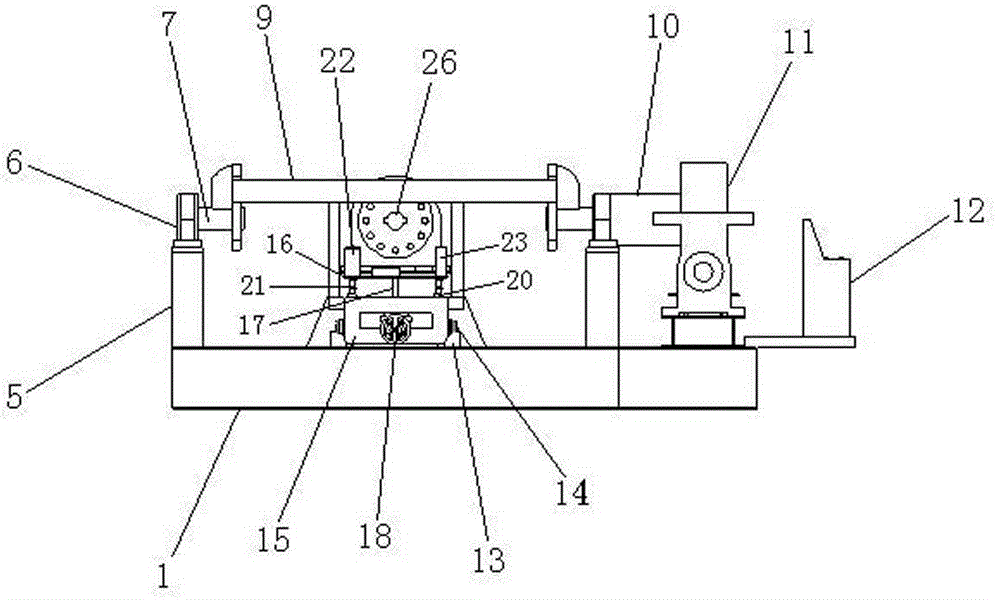

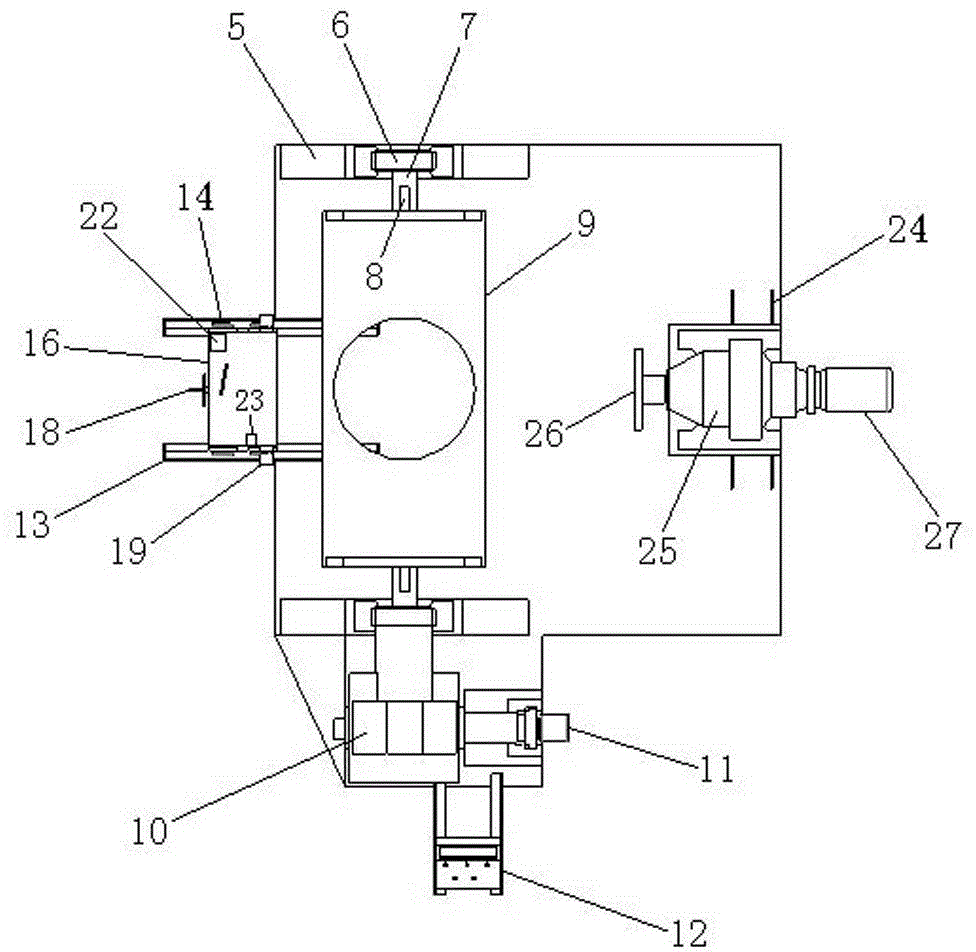

[0019] Example 1, such as figure 1 As shown, a vertical mixed-flow pump comprehensive maintenance platform includes a base 1, a bearing body turning mechanism 2 is arranged on the left side of the front of the base 1, an impeller adjustment mechanism 3 is arranged on the left side of the bearing body turning mechanism 2, and an impeller adjustment mechanism 3 is arranged on the right side of the base 1. The impeller loading and unloading mechanism 4, the bearing body turning mechanism 2 includes a trapezoidal support 5, a bearing seat 6 is arranged on the trapezoidal support 5, a bearing 7 is arranged in the bearing seat 6, a rotating shaft 8 is arranged in the bearing 7, and a rotating shaft 8 is arranged in the middle There is an overturning platform 9, one end of the bearing seat 6 is provided with a reducer 10, the rotating shaft 8 is connected with the output shaft of the reducer 10, the input shaft of the reducer 10 is connected with a driving motor 11, and the rear of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com