Looseness-preventing and seizure-preventing sleeve thread connecting method and assembly

A threaded connection and anti-loosening technology, which is applied in the direction of connecting components, threaded fasteners, screws, etc., can solve problems such as unreliable work, low efficiency, and poor maintainability, and achieve the effects of reducing misoperation, improving efficiency, and being easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. But it is not used as any limitation basis for the present invention.

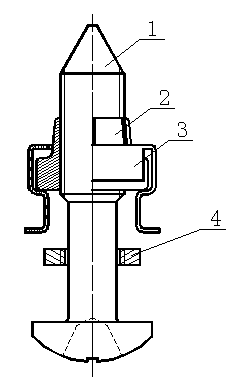

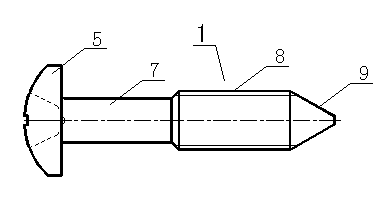

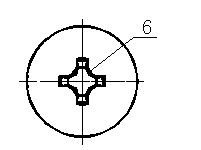

[0024] Embodiments of the present invention: when implementing a loosening-proof and anti-seizure ferrule screw connection method of the present invention, the screw thread of the bolt and nut connection assembly can be made according to the existing method according to the needs of use. Both the nut and the nut are made of stainless steel, or the nut is made of existing high-strength alloy steel; when making, first make 2 to 8 tapered slots at one end of the nut, and then make the nut with the tapered slot at the end After radial extrusion is carried out to close the mouth, a section of tapered hole thread with gradually smaller diameter can be formed in the internal thread at one end of the nut. Through this tapered hole thread, the nut and the bolt have anti-loosening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com