Threaded connection device with anti-loosening function

A threaded connection and anti-loosening nut technology, applied in the direction of connecting components, threaded fasteners, screws, etc., can solve problems such as safety accidents and loose connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

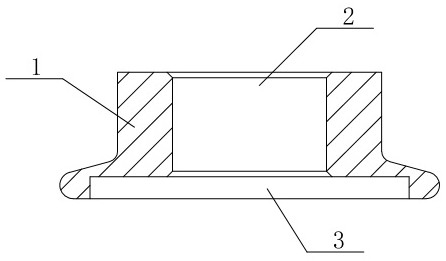

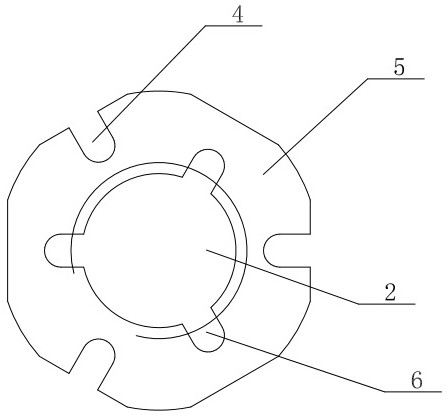

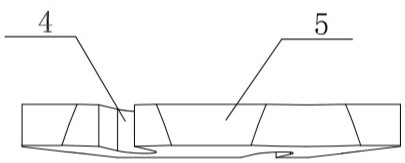

[0019] Embodiment 1: see Figure 1-3 As shown, the anti-loosening nut body 1 and the dish nut 5 are all provided with threaded holes 2 that cooperate with the bolt 7; the lower end surface of the anti-loosening nut body 1 is provided with a limit groove 3; the dish nut 5 is conical as a whole; The nut 5 is placed in the limit groove 3; the outside of the disc nut 5 is a polygon; the polygon is provided with some disc nut outer telescopic slots 4; the threaded hole of the disc nut 5 is provided with some disc nut inner telescopic slots 6 ; The internal and external telescopic grooves of the disc nut 5 are arranged to facilitate expansion and contraction when the disc nut 5 is compressed, and enhance the fastening and anti-loosening effect;

[0020] see Figure 4 As shown, when in use, pass the bolt 7 through the fastened part 10 and the fastened part 1 9, and fix it with the common nut 1 8, after the butterfly nut 5 is fastened to the common nut 1 8, the locknut The body 1 co...

Embodiment 2

[0021] Embodiment 2: see Figure 5 As shown, the difference from Embodiment 1 is that after the bolt 7 is passed through the second fastener 10 and the first fastener 9, it is fixed directly with the wing nut 5, and then the locknut body 1 Compress the wing nut 5 tightly.

Embodiment 3

[0022] Embodiment 3: see Image 6 As shown, the difference from Example 1 is that, after the bolt 7 passes through the fastened part 10 and the fastened part 1 9, it is directly fixed with the wing nut 5, and then the ordinary bolt with a gasket is used to fix it. Thread two 11 compresses the wing nut 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com