A new conveyor chain

A conveyor chain, a new type of technology, applied in the field of new conveyor chains, can solve the problems of cigarettes or sticks, long replacement time, waste of manpower and material resources, etc., to meet individual needs, convenient disassembly and maintenance, and smooth turning transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

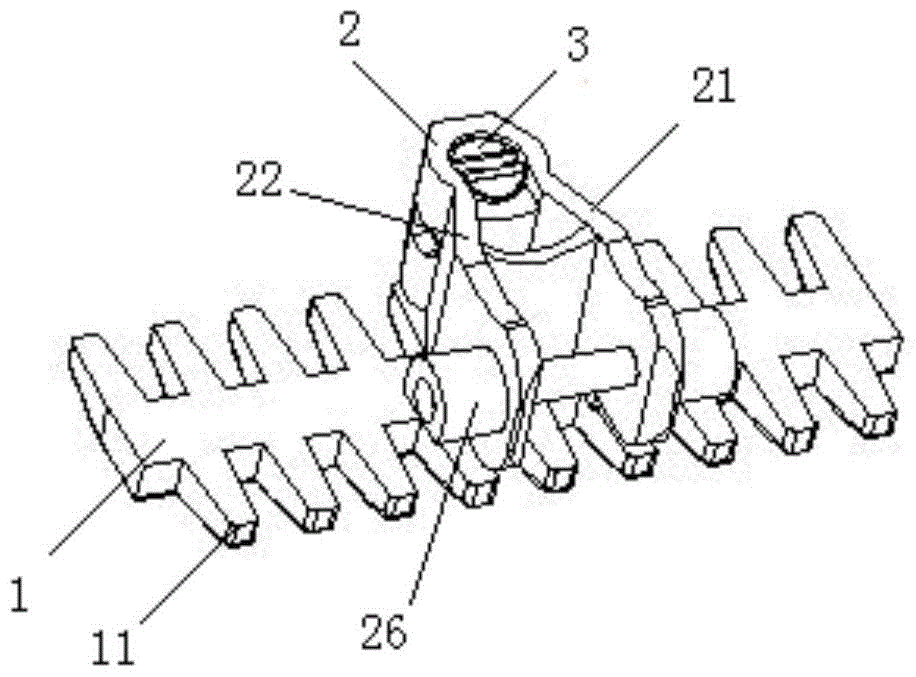

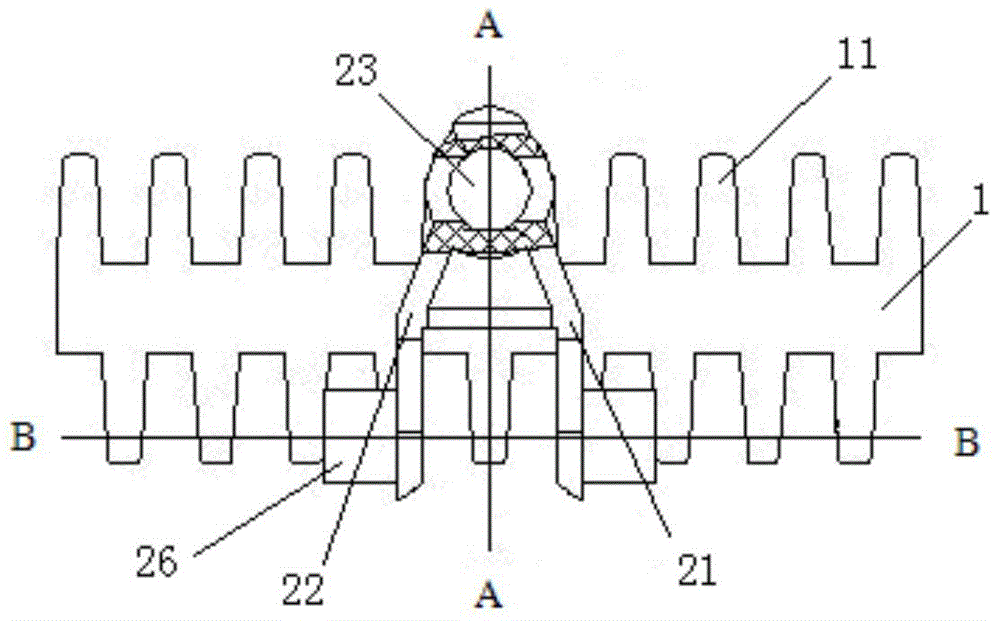

[0029] as attached Figure 1-11 As shown, the present invention provides a new type of conveyor chain, which is composed of a plurality of unit link bodies connected in sequence.

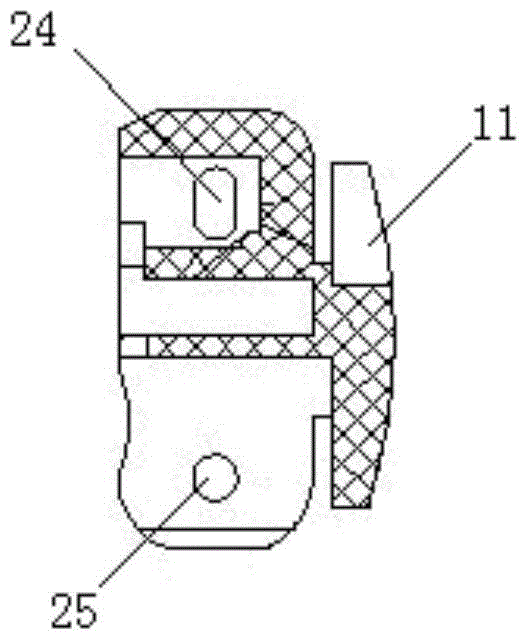

[0030] The unit chain link body includes: a support body 1, a V-shaped frame 2, a plastic pin 3, and a steel pin 4. The two sides of the support body 1 are dislocated and equidistantly provided with racks 11; one side of the support body 1 is provided with The V-shaped frame 2, the V-shaped frame 2 is provided with a first side wall 21 and a second side wall 22, and the junction of the first side wall 21 and the second side wall 22 is provided with a plastic pin hole 23, and the first side wall The wall 21 and the second side wall 22 are provided with elongated holes 24, and the elongated holes 24 are vertically arranged with the plastic pin holes 23, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com