Fastening support rod

A support rod and fastening technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of inability to achieve standardized management, high cost of parts operation and management, poor solution assembly process, etc. The effect of machining accuracy and machining efficiency, small footprint and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

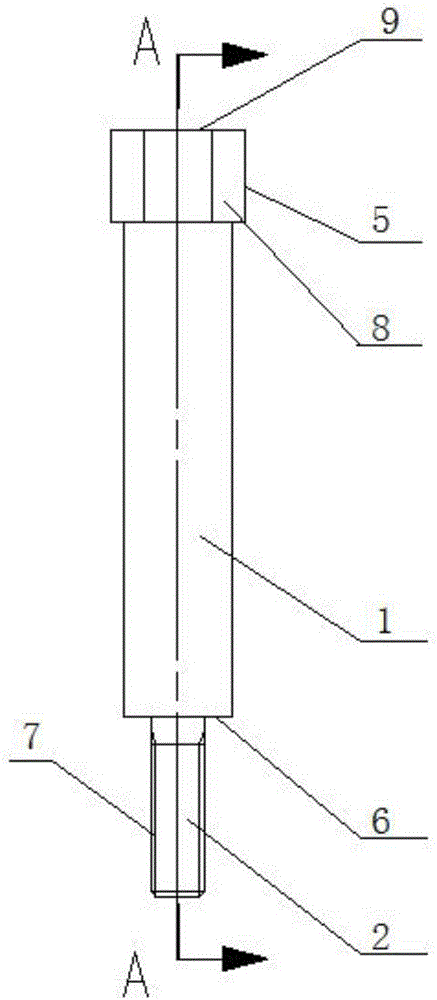

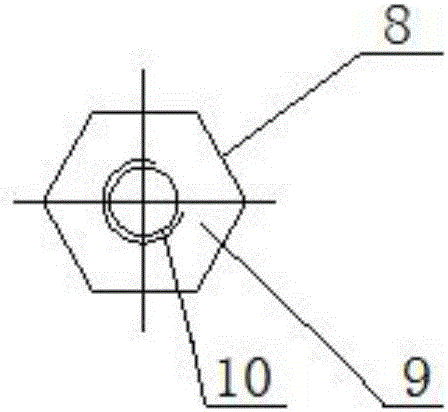

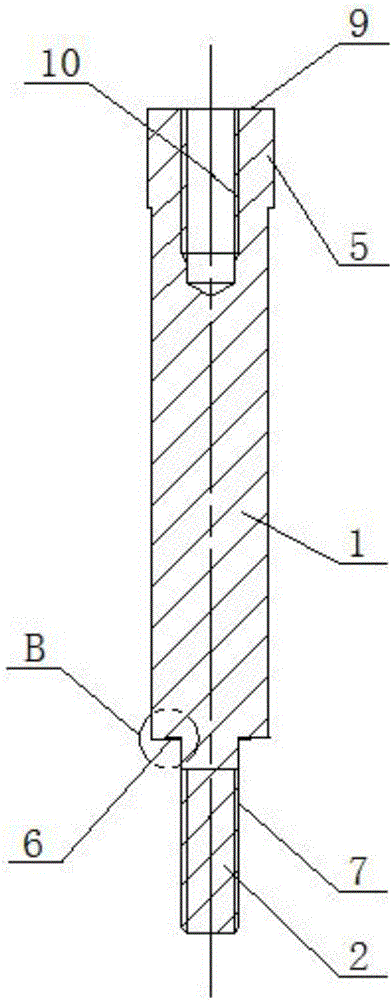

[0022] The specific embodiment of the present invention is like this: with reference to Figure 1-Figure 5 As shown, a fastening support rod includes a support rod body 1. One end of the support rod body 1 is narrowed and provided with an insertion part 2 that can pass through the first connecting part 3 and be locked with the base part 12. In the insertion part 2 There is a limit step surface adapted to the first connecting piece 3, and the other end of the support rod body 1 protrudes outwards to provide a supporting part 5 that can support the second connecting piece 4 and be in close contact with it. A locking structure tightly connected to the second connecting piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com