Stepless adjustable shifting fork structure

A stepless, fork shaft technology, applied in the controlled components, control/adjustment systems, mechanical control devices, etc., can solve the problems of cumbersome and complicated classification and selection of fork shafts, and achieve the effect of low cost and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to more clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

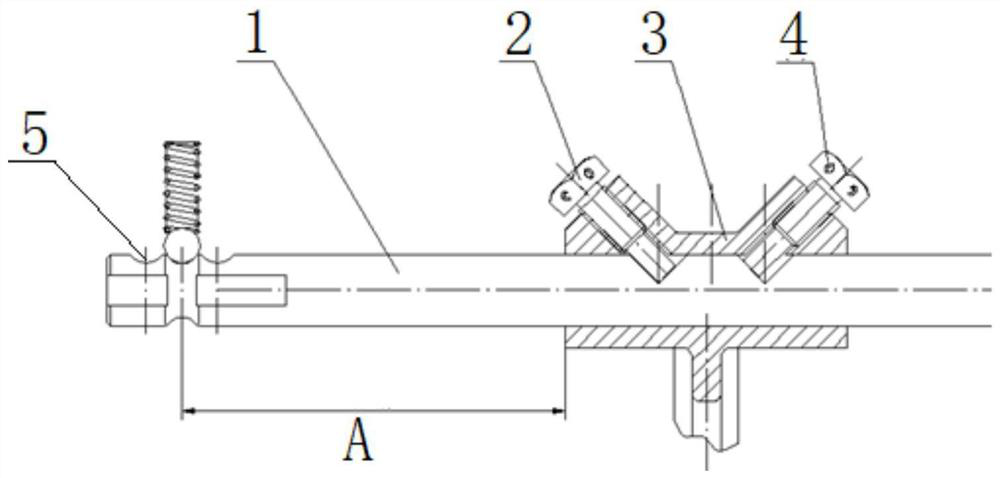

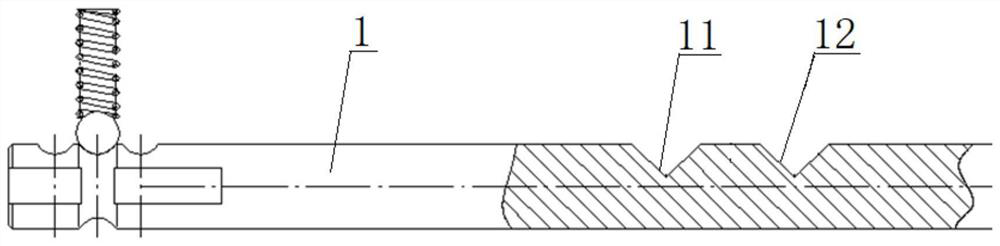

[0021] see figure 1 and figure 2 , a shifting fork structure that can be adjusted steplessly, comprising a shifting fork shaft 1, a shifting fork head 5 and a shifting fork foot respectively arranged at both ends of the shifting fork shaft 1, and a shifting fork 3 sleeved on the shifting fork shaft 1;

[0022] The side of the shifting fork shaft 1 is provided with two oblique wedge openings, and the shifting fork 3 is provided with two inclined locking screws in an inverted figure, two locking screws (that is, locking screw 1 2 and locking screw 2 4 ). ) respectively abut in the two wedge openings.

[0023] The included angle of the inner end of the wedge opening is 90°, or greater than 90°, or less than 90°.

[0024] The shifting fork 3 is provided with two inclined threaded holes, and the threaded holes are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com