Sensor installation device

A technology for installing devices and sensors, which is applied in the direction of supporting machines, mechanical equipment, machine platforms/supports, etc., which can solve problems such as inconvenient operation, limited position adjustment range, and changes, and achieve error compensation, large adjustment range, adjustment and locking The effect of synchronous completion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

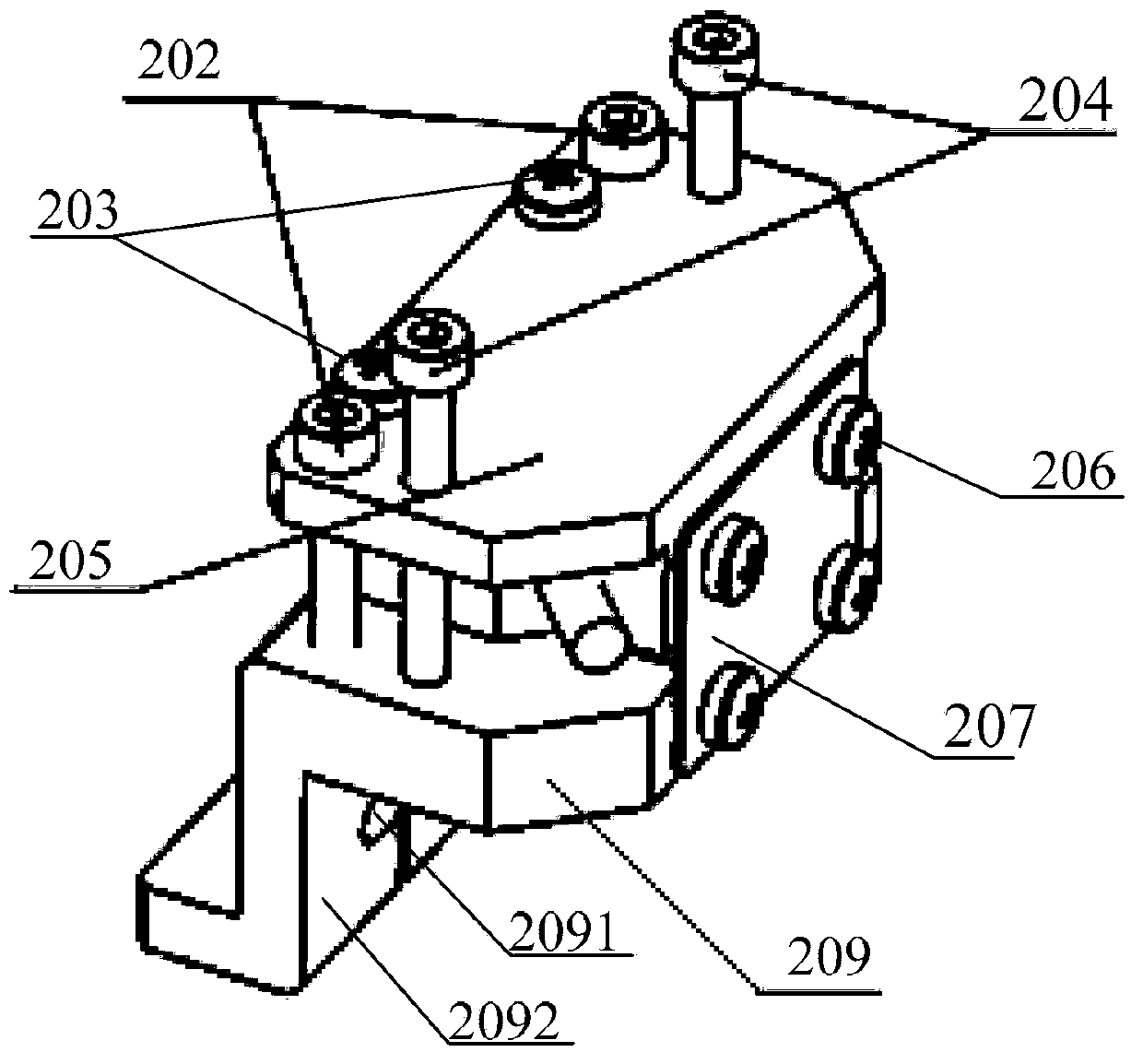

[0043] An embodiment of the present invention provides a sensor installation device, referring to figure 2 As shown, the device includes: an angle adjustment block 205, a movement adjustment block 209 and an elastic connector 207, wherein:

[0044] The angle adjustment block 205 and the movement adjustment block 209 are arranged in parallel, and the sensor (not shown) is fixedly connected with one end of the angle adjustment block 209, so that the sensor is positioned in the parallel space between the angle adjustment block 205 and the movement adjustment block 209, and the angle The adjustment block 205 is used to adjust the angle of the sensor; the moving adjustment block 209 is used to adjust the position of the sensor.

[0045] The elastic connector 207 is perpendicular to the angle adjustment block 205 and the mobile adjustment block 209, and the two ends of the elastic connector 207 are respectively fixedly linked with the side of the other end (that is, the end away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com