CPP shafting hydraulic coupling dismounting method

A corbel and hydraulic technology, applied in the field of ships, can solve problems affecting the shipping schedule, narrow location, difficulty in disassembly or installation, etc., and achieve the effect of improving disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

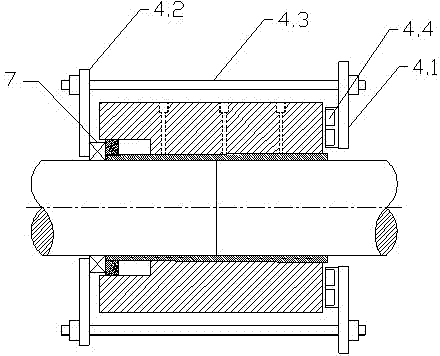

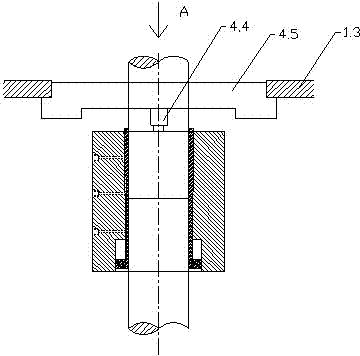

[0052] see figure 1 , a kind of CPP shafting hydraulic pressure corbel dismantling method that the present invention relates to, it comprises the following processing steps:

[0053] Step 1. Loosen the jacket

[0054] 1.1. When the oil leakage is slight, the existing equipment can be used to establish the internal expansion pressure of Corbyne, and use the internal expansion pressure to loosen the jacket

[0055] When dismantling the Corbyne, the Corbyne expands and leaks oil, and the internal expansion pressure cannot be established through ordinary hydraulic devices. At this time, the following conditions must be met in order to ensure the establishment of the internal expansion pressure: a. The hydraulic oil is heavy oil with a high viscosity ; b. During the pumping process, the oil inlet speed of the oil pump should be accelerated.

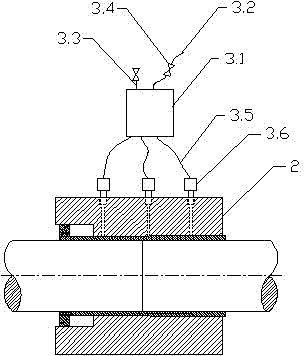

[0056] In a certain case that our company once repaired, our method is as follows: make a closed oil storage tank 3.1 with a capacity of 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com