Power assembly rear suspension support mechanism for mining vehicle

A technology of rear suspension bracket and powertrain, which is applied to power units, control devices, vehicle components, etc., can solve the problem of high damage frequency of the flywheel housing of the engine, achieve outstanding substantive features, improve the stress state, and protect the flywheel housing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

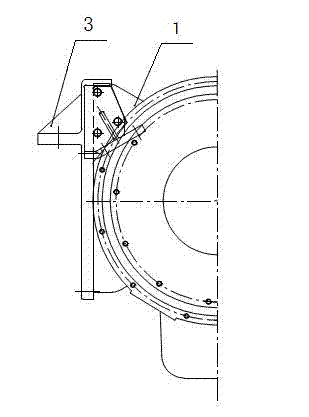

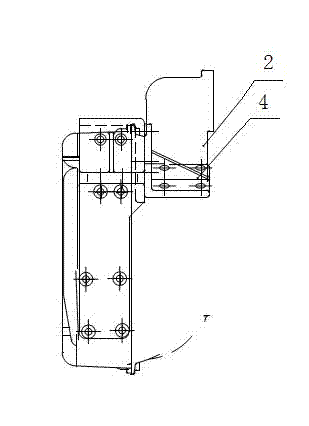

[0010] Example 1, see figure 1 , 2 , processing and assembling the flywheel housing 1, the clutch housing 2 and the rear suspension bracket of the powertrain according to the prior art, the rear suspension bracket of the powertrain comprises the engine rear suspension bracket 3 and the gearbox suspension bracket 4; then Fix the engine rear suspension bracket 3 and the flywheel housing 1 together with bolts, the transmission suspension bracket 4 and the clutch housing 2 through bolts, and then fix the engine rear suspension bracket 3 and the transmission suspension bracket 4 on Together; constitute the rear suspension bracket mechanism of the mining vehicle power assembly of the present invention.

[0011] The rear suspension bracket mechanism of the mining vehicle power assembly of the present invention, when working, the load here is jointly borne by the flywheel housing and the clutch housing, the stress at the flywheel housing is reduced, and the flywheel housing can be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com