Jacking method and device of steel structure module

A jacking device and steel structure technology, which is applied in building structure, construction, etc., can solve the problems of high site requirements, uneven hoisting force, module structure deformation, etc., to save a lot of work, low site requirements, and jacking force. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0023] A specific embodiment of the jacking method of the steel structure module of the present invention comprises the following steps:

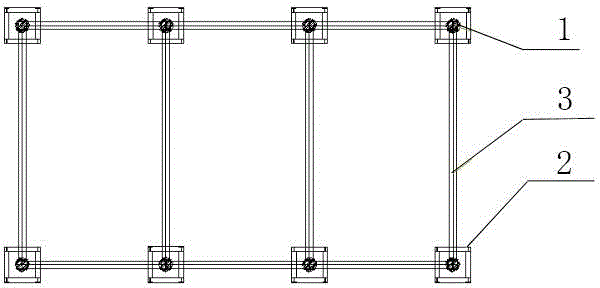

[0024] (1) According to the size of the steel structure module, a sufficient number of hydraulic jacks 1 are evenly arranged in the jacking area to ensure that the structure of the steel structure module will not be deformed under the lifting point of this number of hydraulic jacks, and all hydraulic jacks 1 into the same oil pump. Such as figure 1 As shown, there are two rows of hydraulic jacks 1 in this embodiment, and the distance between the two rows of hydraulic jacks 1 is equal to the width of the steel structure module 3, and each hydraulic jack in each row of hydraulic jacks is within the length of the steel structure module 3 Evenly distributed in the direction.

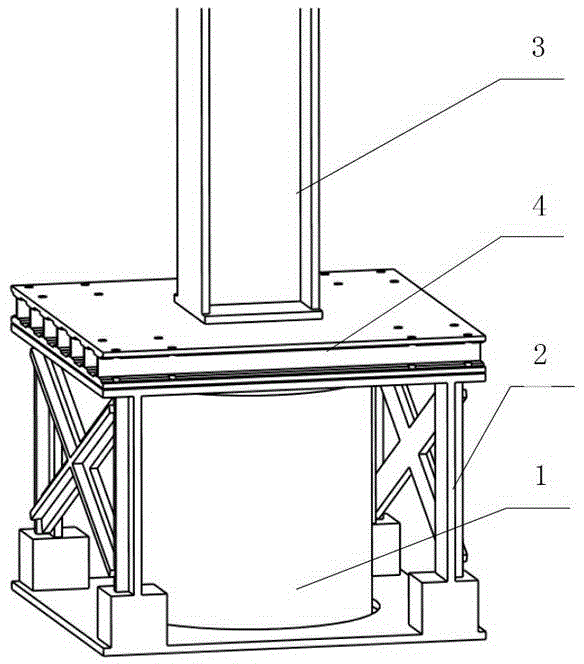

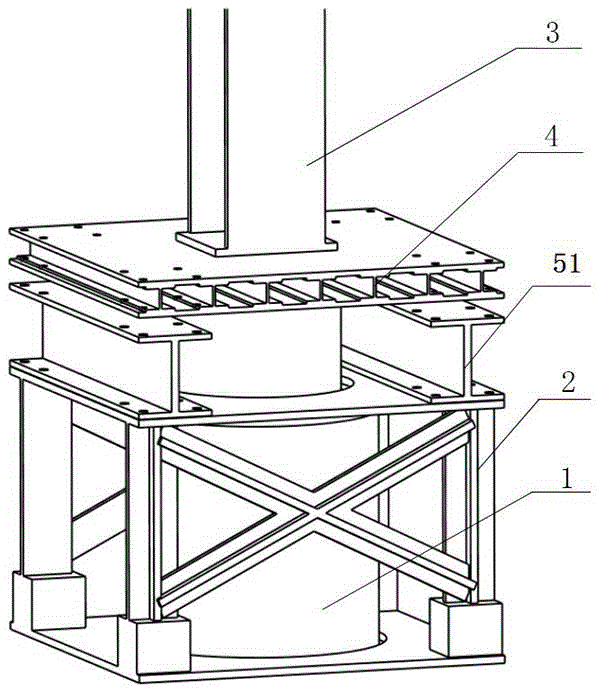

[0025] (2) if figure 2 As shown, the lifting frame platform 2 is placed above the hydraulic jack 1, so that each hydraulic jack 1 is placed in each lifting frame plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com