Joint sealing and stress transmission monitoring device and method under deflection state of pipe-jacking pipe joint

A monitoring device and sealing testing technology, applied in measuring devices, using liquid/vacuum for liquid tightness measurement, and applying stable tension/pressure to test material strength, etc., can solve the problem of poor joint sealing performance, pipe joint axis Deviation, deflection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

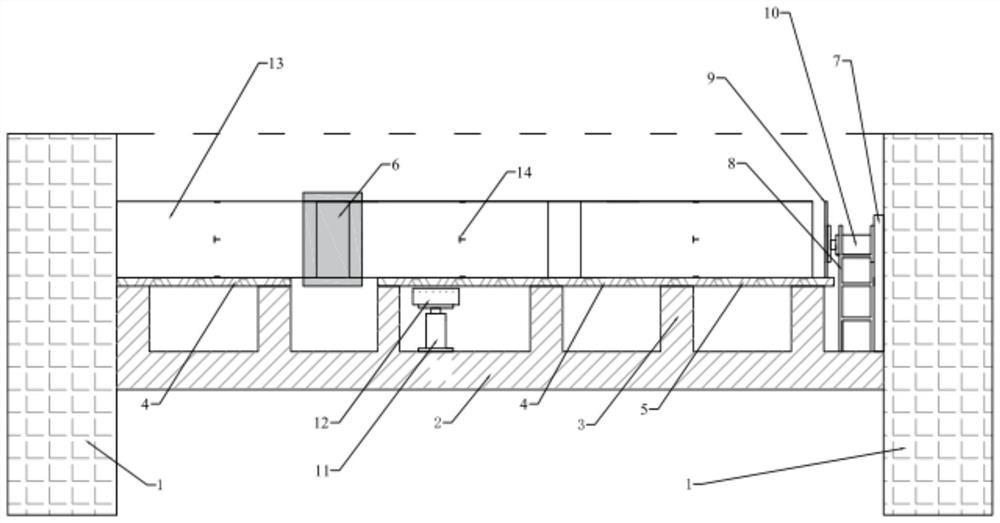

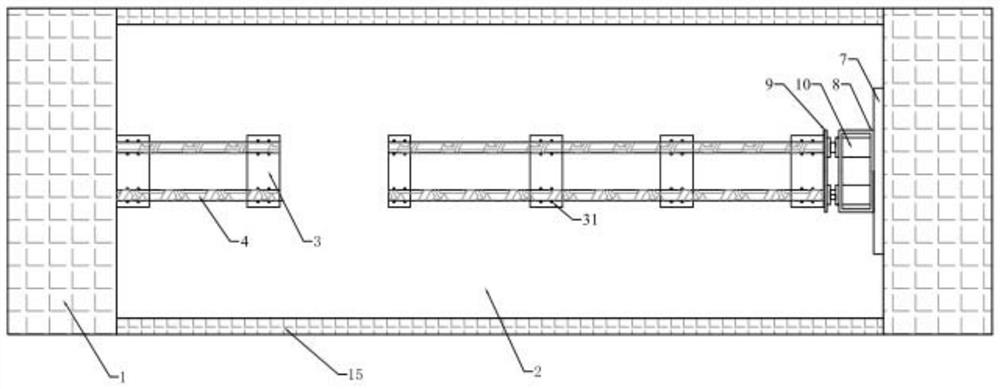

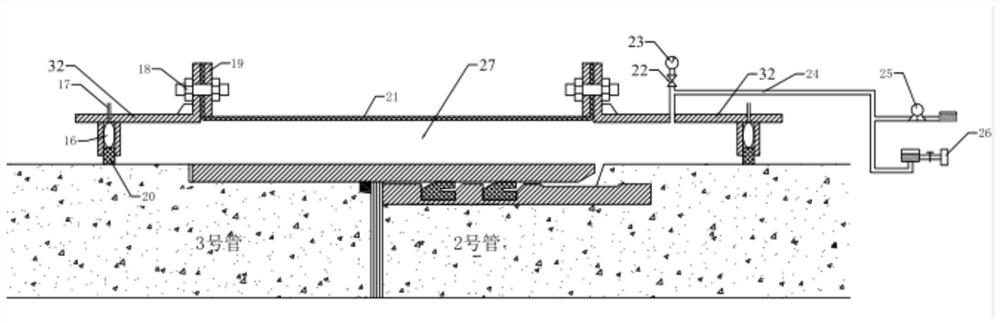

[0030] A joint sealing and force transmission monitoring device in the deflected state of a pipe jacking pipe joint, the device is composed of a fixing and loading device, a joint sealing test device and a pipe joint force monitoring device; the fixing and loading device consists of a test pit, Composed of guide rails, jack brackets, deflection jacks, and main jack jacks, the test pit includes a bottom plate, side walls, bearing walls, and platform brackets; the side walls are located on the side of the test pit as a retaining structure; the bearing walls Designed according to the calculation formula of the bearing capacity of the retaining wall, it is used to bear the jacking force and reaction force of the main jacking jack. The force-bearing wall includes the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com