Powder metallurgy die capable of separating tools conveniently

A technology of powder metallurgy and tooling, which is applied in the field of metallurgy, can solve the problems of prolonging the demoulding time, difficult demoulding operation, and increasing the labor workload of workers, so as to achieve the effect of improving work efficiency and great strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

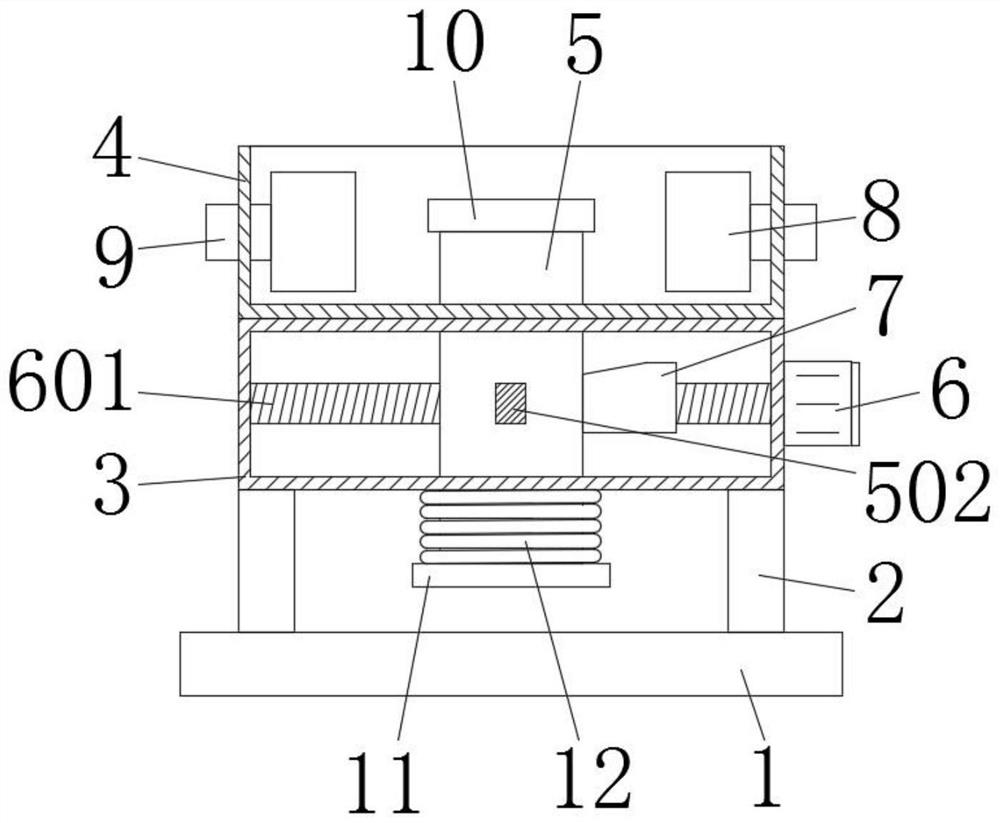

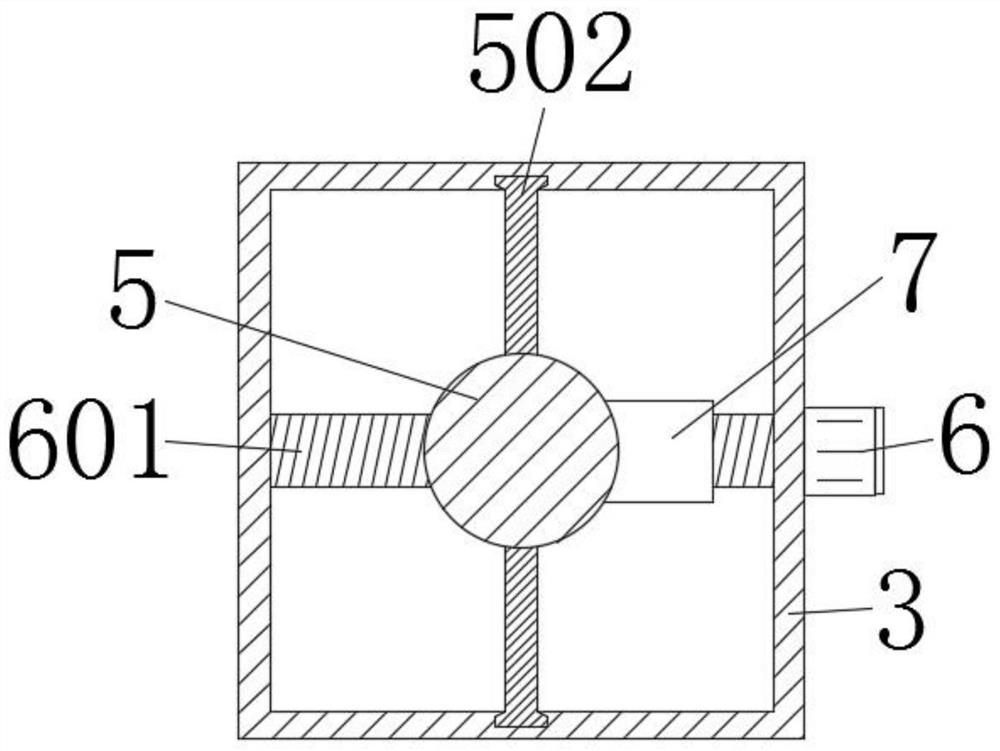

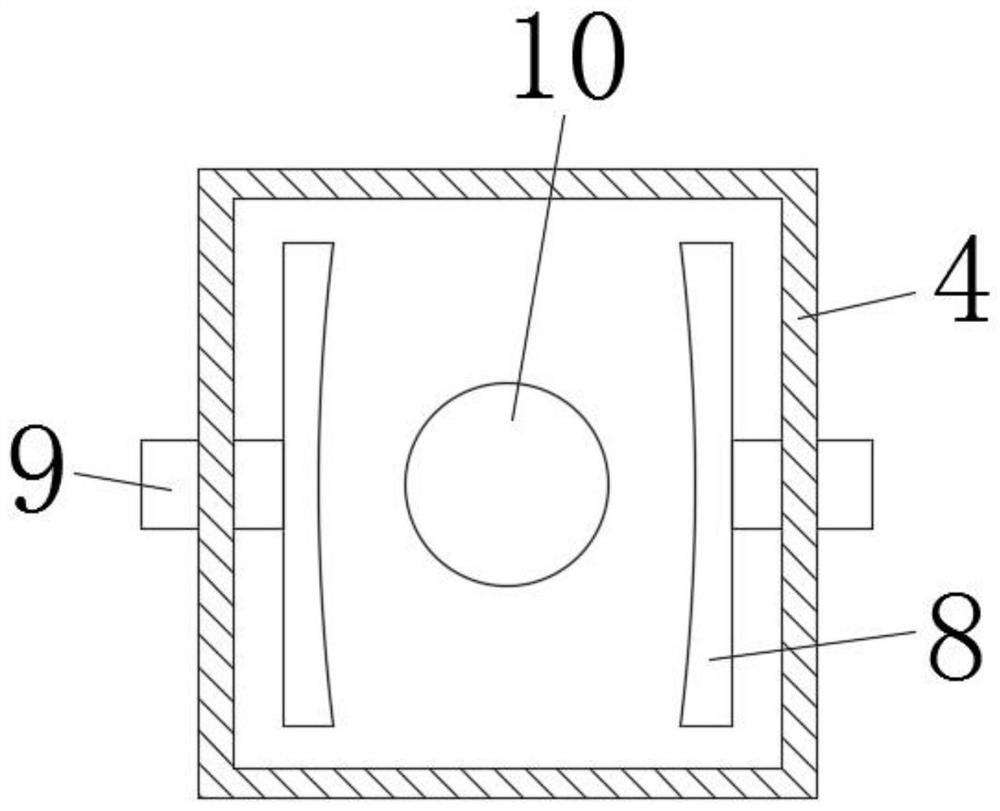

[0025] Specific embodiments: This device is a powder metallurgy mold that facilitates the separation of tooling. The first box body 3 is connected to the second box body 4. The second box body 4 is connected to the base 1 through the supporting legs 2. In the first box body 3 A lead screw 601 and a trapezoidal block 7 threaded with the lead screw 601 are provided. The trapezoidal block 7 can move in the rectangular groove 501 on the connecting column 5 by the thrust of the lead screw 601. After the inclined surface of the trapezoidal block 7 contacts the rectangular groove 501, it can Make the connecting column 5 move upwards, the slope of the trapezoidal block 7 provides a uniform jacking force, and is different from the thrust of the mechanical pump, which is powerful and easy to damage the mold; rotate the locking shaft 9 so that the locking clamp 8 is aligned with the belt The mold with the product is close to and locked, and the lead screw 601 drives the trapezoidal block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com