Construction method for reserving water feed pipe grooves in prefabricated shear wall

A technology of prefabrication shear force and construction method, which is applied in the preparation of building components on site, the processing of building materials, formwork/template/work frame, etc., can solve the problem of no construction process, save materials and save wood consumption. , The effect of preventing the exposed corrosion of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

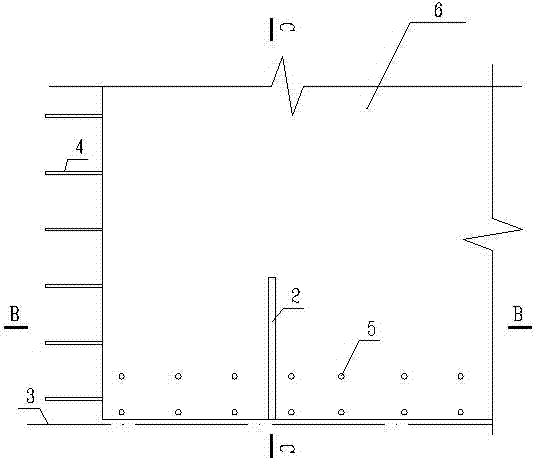

[0024] The present invention reserves the construction method of the water supply pipe groove on the prefabricated shear wall, comprising the following steps:

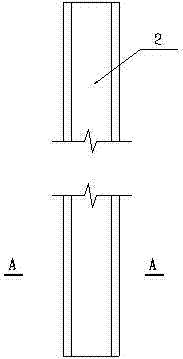

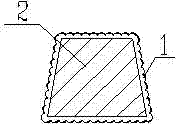

[0025] 1) Make the trapezoidal component 2, the size of the trapezoidal component 2 is slightly larger than the diameter of the water supply pipeline according to the diameter of the embedded water supply pipeline, and the length of the trapezoidal component 2 is the same as the length of the embedded pipeline;

[0026] 2) Wrap a layer of kraft paper or plastic paper 1 on the outside of the trapezoidal member 2, and set aside;

[0027] 3) After the steel frame 4 is finished, place the steel frame 4 on the shear wall body 6, then place the trapezoidal member 2 on the steel frame 4, and then fix the trapezoidal member 2 on the steel frame 4; During the construction of force wall components, place the shear wall body 6 on the horizon 3, which is the finished surface of the floor where the shear wall is located, and fix an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com