Extra-large-mining-height high-voltage frequency conversion integrated drive type scraper conveyor

A scraper conveyor, high-voltage frequency conversion technology, applied in high-voltage frequency conversion integrated drive scraper conveyor, super large mining height field, can solve the problems of insufficient power, frequent start-up, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

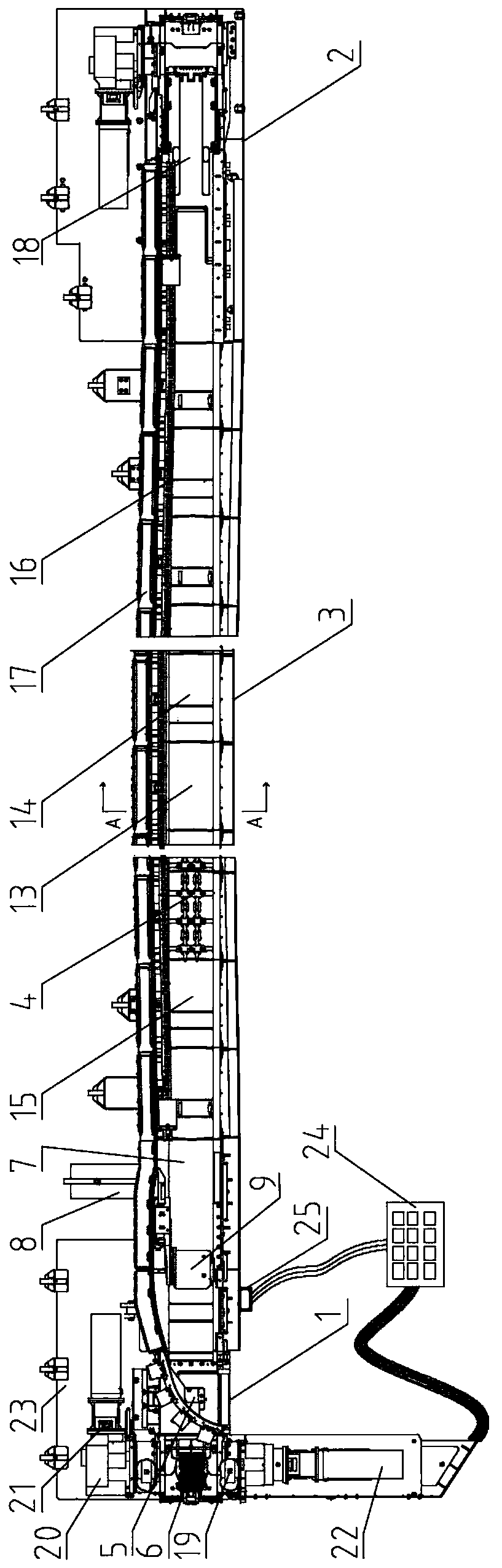

[0065] Embodiment 1: refer to figure 1 — Figure 9 , an ultra-large mining height, high-voltage frequency conversion integrated drive type scraper conveyor, including a head 1, a tail 2, and a middle section 3 connecting the head and tail, and a scraper chain 4 is arranged on the head , the tail and the middle section of the machine rotate in circles;

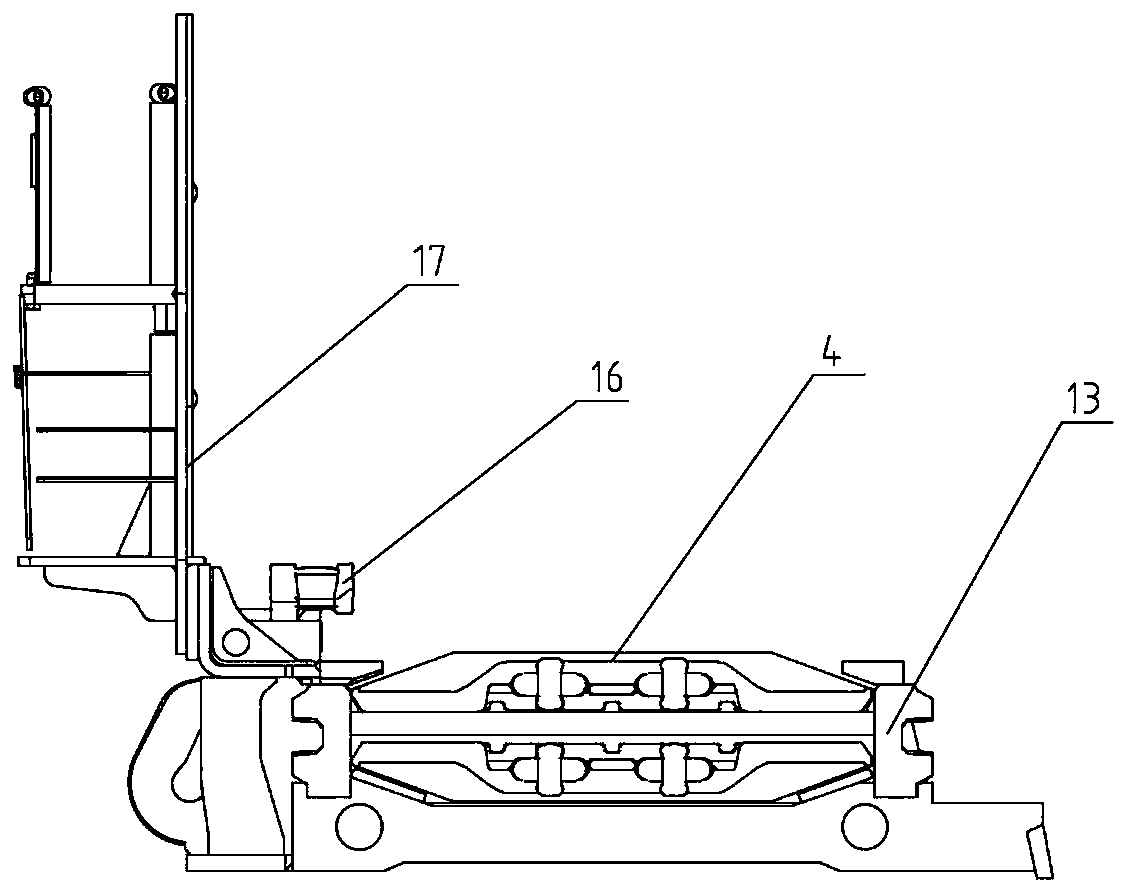

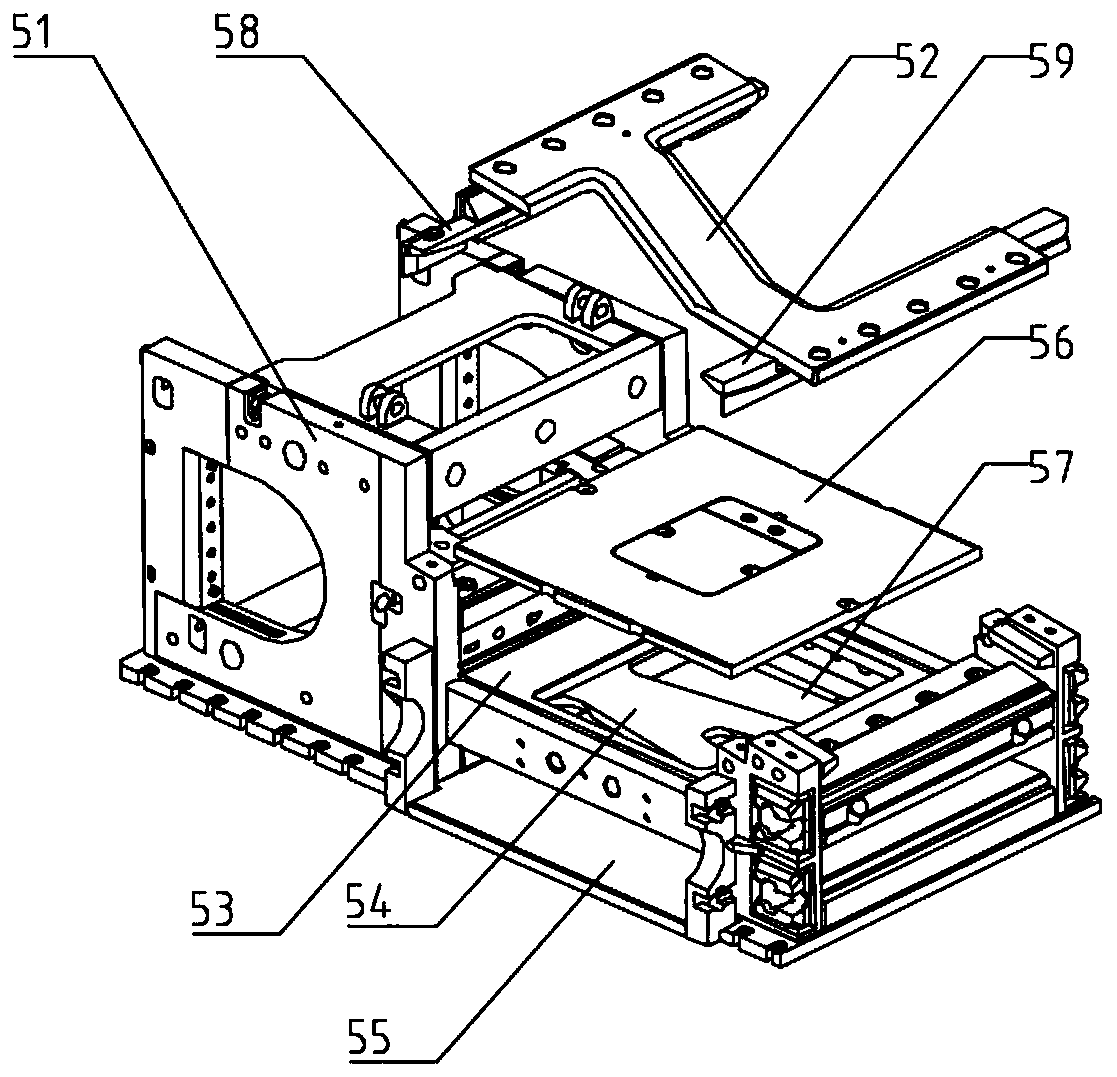

[0066] The head includes a cross-side unloading head frame 5, and the cross-side unloading head frame includes a head frame body 51, and the head frame body is fixedly installed with a scraper conveyor upper chain path middle plate 52, The head frame middle plate 53, the head frame partition plate 54 and the head frame bottom plate 55, the sprocket assembly 6 is installed between the two side plates of the head frame body; The upper chain path of the machine, the upper chain path of the reloading machine is set between the upper chain path middle plate of the scraper conveyor and the head frame middle plate, and the lower cha...

Embodiment 2

[0098] Embodiment 2: refer to Figure 10 , Figure 11 , in a kind of ultra-large mining height, high-voltage frequency conversion integrated drive type scraper conveyor described in Embodiment 1, the tail frame of the automatic telescopic machine includes a fixed groove 181, a telescopic frame 182 slidingly connected to the fixed groove and a hydraulic telescopic system 183. The telescopic frame slides back and forth along the fixed groove under the action of the hydraulic telescopic system;

[0099] The side of the fixing groove located on the side of the coal wall of the working face is provided with a connecting ear I184, and the connecting ear I is provided with a connecting pin hole I185;

[0100] Described telescopic frame comprises the main frame that is welded together by tail frame base plate 186, tail frame middle plate 187, tail frame shovel plate side vertical plate 188 and tail frame baffle side vertical plate 189, and the tail frame The shovel side vertical pla...

Embodiment 3

[0103] Embodiment 3: refer to Figure 12 , in an ultra-large mining height, high-voltage frequency conversion integrated drive type scraper conveyor described in Example 1, the sprocket assembly includes a sprocket shaft 61, and the middle part of the sprocket shaft is sleeved with a sprocket body 62, and the sprocket shaft Transmission gears 63 are sleeved at both ends, and bearings 64 and bearing seats 65 are sleeved on the sprocket shafts on both sides of the sprocket body; a floating sealing device I66 is provided between the inner end of the bearing seat and the sprocket body. A gland 67 is installed on the back of the transmission gear, a pressure sleeve 68 is arranged between the outer end of the bearing and the transmission gear, and a floating sealing device II 69 is arranged between the pressure sleeve and the gland.

[0104] The sprocket body is a seven-tooth sprocket, the diameter of the circular link chain is ¢60mm, and the sprocket shaft is equipped with splines,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com