Steel pouring mould for concrete barrel-shaped container and assembly and disassembly methods thereof

A technology for pouring molds and concrete, which is applied in the field of pouring radioactive waste concrete disposal containers, can solve the problems of increasing the difficulty of demolding, mold wear, deformation probability, increasing the difficulty of mold processing, and high requirements for product accuracy, and achieves smooth surface. The effect of running pulp and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

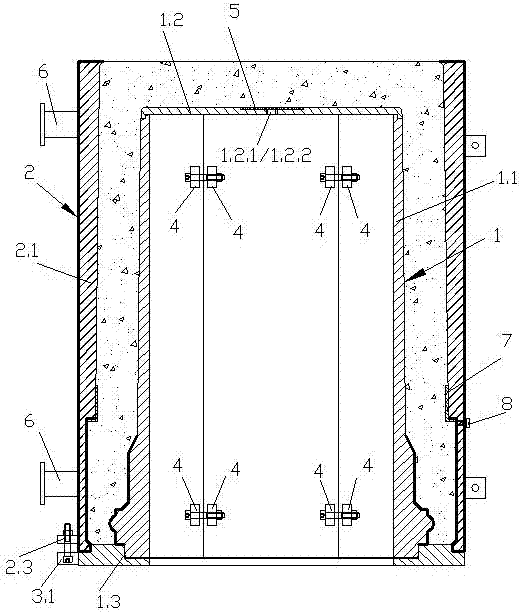

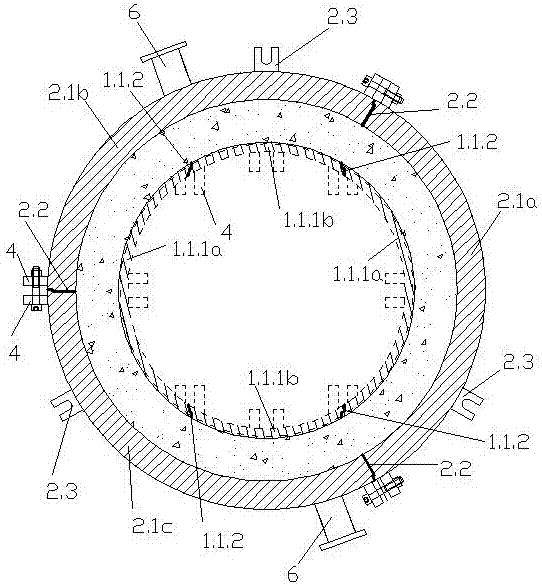

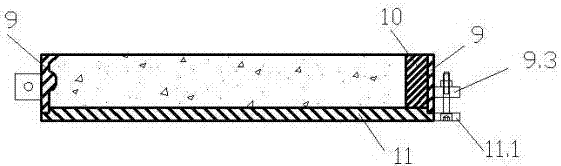

[0050] Embodiment 1: A steel pouring mold for a concrete barrel-shaped container, including a barrel body mold and a barrel lid mold, the barrel body mold includes an inner mold 1, an outer mold 2, and a base 3 for fixing the inner and outer molds (1, 2), The space between the inner and outer molds (1, 2) and the base 3 forms the mold cavity. The inner mold 1 is composed of a wall mold 1.1 and a top plate 1.2. The wall mold 1.1 is an inner mold composed of four arc-shaped modules 1.1.1. The cylinder body, the splicing seam 1.1.2 between the adjacent arc-shaped modules 1.1.1 is a crease line seam, and the arc-shaped modules 1.1.1 of the inner mold are set into two groups of symmetrical large blocks and small blocks, each group There are two pieces, the small arc-shaped module 1.1.1b and the adjacent large arc-shaped module 1.1.1a splicing seam are inner splayed fold line seams, which is convenient for the small arc-shaped module to come out first. The top plate 1.2 is covered o...

Embodiment 2

[0054] Embodiment 2: a kind of assembly method of concrete barrel-shaped container steel pouring mold, comprises the following steps:

[0055] 1. Barrel mold assembly steps:

[0056] (1) Put the inner mold 1 on the base 3, and initially fix the ears 4 on the four arc-shaped modules 1.1.1 with bolts, and adjust the size of the seam 1.1.2 between the two groups until the circle The forming cylinders between the arc-shaped modules 1.1.1 are consistent, and the connecting bolts are tightened;

[0057] (2) Fix the lifting ring in the bolt hole of the top plate 1.2, cover the top plate on the top of the inner mold 1 through the lifting ring, then remove the lifting ring, and cover the panel 5;

[0058] (3) Place the arc-shaped modules of the outer mold 2 on the working platform respectively, use bolts to connect the ears 4 on the arc-shaped modules 2.1 of the outer mold 2 to each other and initially fix them with bolts, and put the prefabricated lifting reinforcing steel ring 7 int...

Embodiment 3

[0067] Embodiment 3: a kind of dismantling method of concrete barrel-shaped container steel pouring mold, comprises the following steps:

[0068] 1. Barrel mold disassembly:

[0069] (1) Remove the connecting bolts on the corresponding lugs of the outer mold 2 and the base 3, lift the outer mold 2 by turning over the lug 6, and remove the base 3;

[0070] (2) Turn over the lifting lug 6 by 90°, place the mold horizontally, and remove the connecting bolts between the four arc-shaped modules 1.1.1 of the inner mold 1;

[0071] (3) Flip the lifting lug 6, and then turn it 90°, turn the mold upside down, and unload the two small arc-shaped modules 1.1.1b of the inner mold 1 inward;

[0072] (4) Use the same method to remove the two large arc-shaped modules 1.1.1a of the inner mold 1;

[0073] (5) Unload the top plate 1.2 by screwing the lifting ring into the bolt hole 1.2.1 of the top plate 1.2;

[0074] (6) Remove the connecting bolts between the positioning bolts 8 of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com