Ratchet-type buckle and snowboard binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

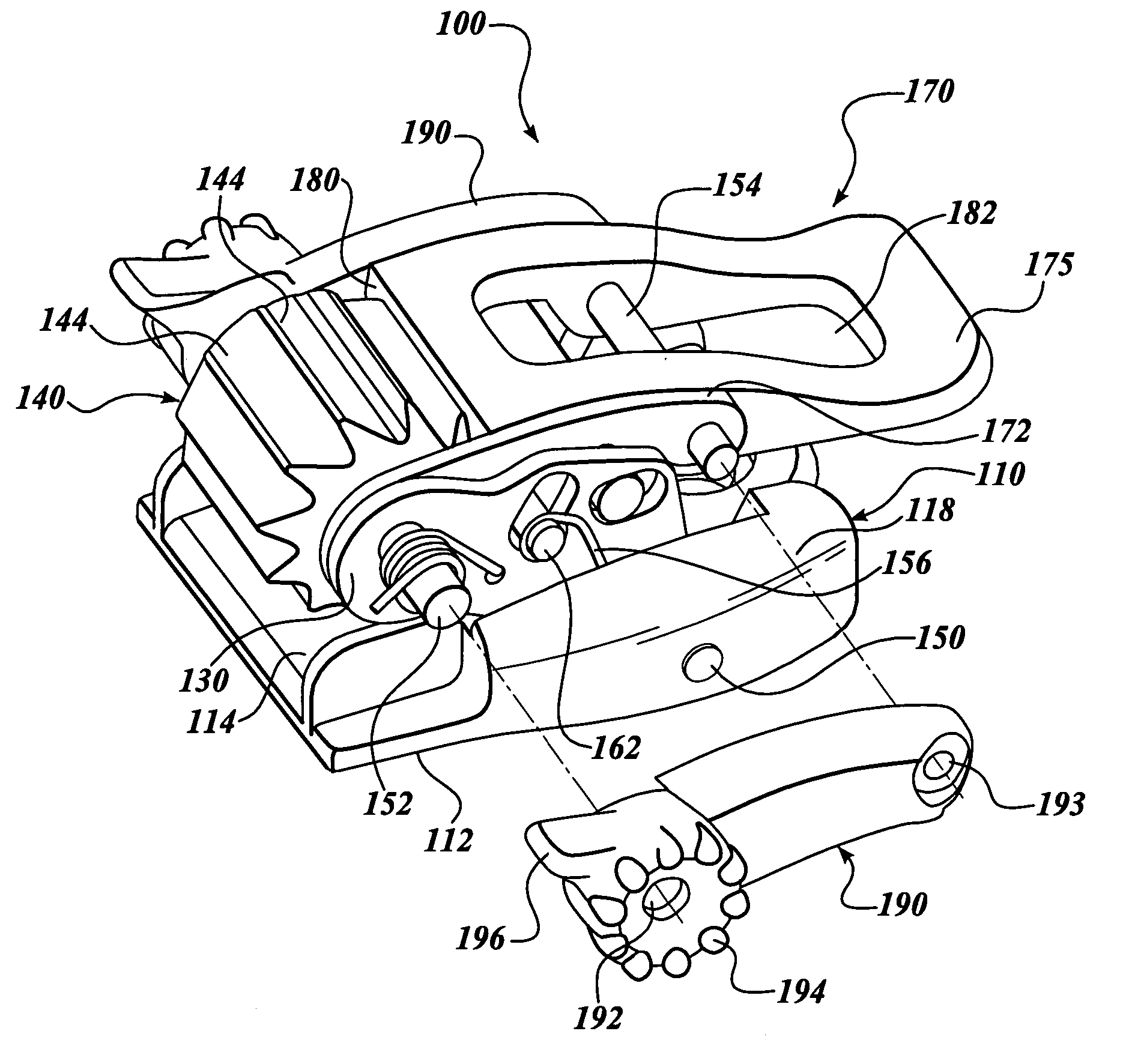

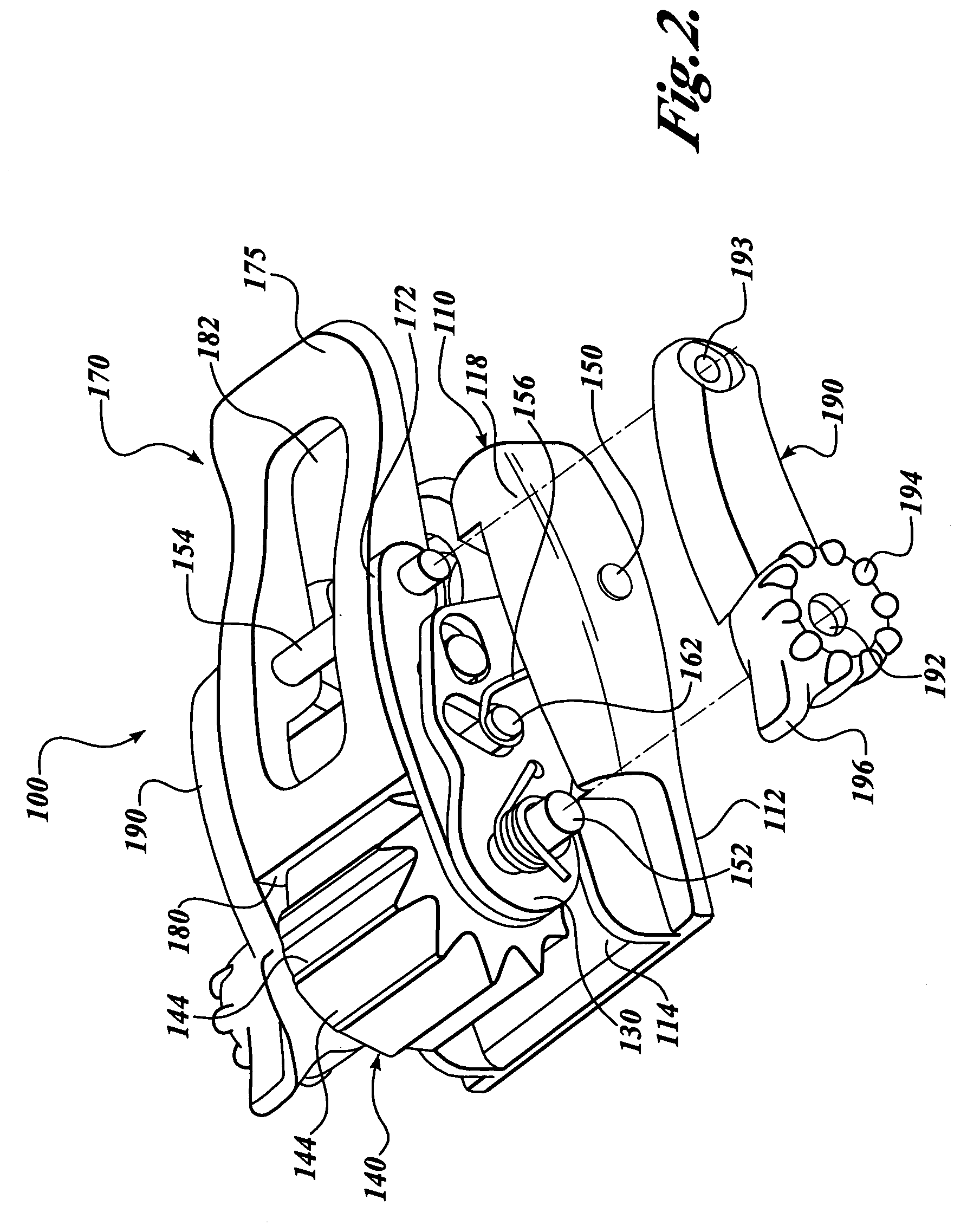

first embodiment

[0039]Another embodiment of a buckle according to the present invention is shown in FIG. 6, which shows a buckle 200 having a one-piece lever 270. The base 110, sidewalls 130, toothed barrel 140, and holding pawl 160 are generally the same as that described above. The lever 270 is preferably of unitary construction, having a proximal end 272 having oppositely disposed elongate transverse apertures 273 (one shown) that rotatably engage the barrel pivot pin 152. Release tabs 296 disposed at the proximal end 272 facilitate gripping of the lever 270 for releasing the strap, similar to the first embodiment described above. The elongate apertures 273 permit the lever proximal end 272 to be slidably moved between a first (lower) position and an second (upper) position (the lever 270 is shown in the first position in FIG. 6). The lever 270 includes a center pawl portion 280 that is located such that when the lever proximal end 272 is in the first position, the pawl portion 280 engages the b...

third embodiment

[0043]a buckle according to the present invention is shown in FIG. 7, which shows a buckle 300 having a base 110, sidewalls 130, and toothed barrel 140 substantially the same as described above. The holding pawl 360 is also similar to the holding pawl 160 described above, and functions in substantially the same manner. The holding pawl 360, however, is unitary in construction, which may be less expensive to manufacture and assembly.

[0044]In this third embodiment, a lever assembly 370 includes a lever body 375 having a proximal end 372 with oppositely disposed transverse apertures 373 that pivotally engage the barrel pivot pin 152. The lever body 375 includes a distal portion 376 and a central portion 378. The central portion 378 includes a cavity 371 disposed generally adjacent the barrel 140. A driving pawl member 390 is slidably and springedly captured within the rectangular cavity 371, the driving pawl member 390 being elastically biased towards the barrel 140, and positioned suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com