Chain dismounting device

A technology for dismantling devices and chains, which is applied to metal chains, tools for repairing chains by metal processing, manufacturing tools, etc. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

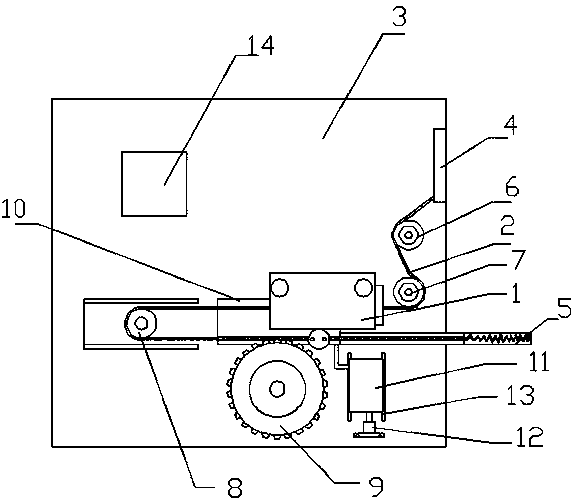

[0038] A chain removal device, comprising a frame, a punch press 1, a chain running track 2, a sprocket and a drive mechanism, the frame is provided with a work surface 3, the chain running track 2 is arranged on the work surface 3, the The sprocket is installed on the frame and protrudes from the work table 3, and the sprocket is arranged next to the chain running track 2, the punch 1 is installed on the work table 3, and the punch of the punch 1 is located on the chain running track 2 Directly above, the drive mechanism is connected with the sprocket to drive the sprocket to rotate.

[0039] Also be provided with chain case 4 and chain collecting groove 5 on described work table surface 3, chain case 4 links to each other with the starting end of chain running track 2, and chain collecting groove 5 links to each other with the end of chain running track 2.

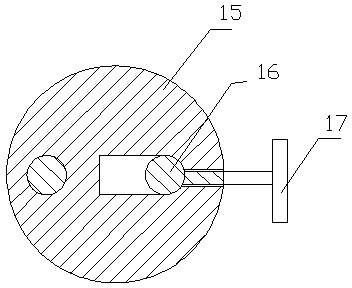

[0040] There are four sprockets, namely starting sprocket 6, tensioning sprocket 7, intermediate sprocket 8 and end sp...

Embodiment 2

[0042] A chain removal device, comprising a frame, a punch press 1, a chain running track 2, a sprocket and a drive mechanism, the frame is provided with a work surface 3, the chain running track 2 is arranged on the work surface 3, the The sprocket is installed on the frame and protrudes from the work table 3, and the sprocket is arranged next to the chain running track 2, the punch 1 is installed on the work table 3, and the punch of the punch 1 is located on the chain running track 2 Directly above, the drive mechanism is connected with the sprocket to drive the sprocket to rotate.

[0043] Also be provided with chain case 4 and chain collecting groove 5 on described work table surface 3, chain case 4 links to each other with the starting end of chain running track 2, and chain collecting groove 5 links to each other with the end of chain running track 2.

[0044] There are four sprockets, namely starting sprocket 6, tensioning sprocket 7, intermediate sprocket 8 and end sp...

Embodiment 3

[0048] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the frame is also provided with a control mechanism 14, which includes a controller, an infrared transmitter and an infrared receiver, and the infrared receiver is installed on the end sprocket Below, the infrared transmitter is installed on the end sprocket, and the infrared transmitter is installed facing the infrared receiver, and the infrared receiver is connected with the controller, and the controller is connected with the drive mechanism and the driving motor of the punch press.

[0049] The controller includes a signal input module, a counting module, a calculation module, a comparison module, a set value input module and a control signal output module, the signal input module accepts the signal transmitted by the infrared receiver, and the counting module counts the received signal and calculates The module calculates the running length of the chain according to the value of the counting module an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com