Two-dimensional and double-cycle ordered structure array and preparation method thereof

An ordered structure, double-period technology, applied in nanostructure manufacturing, microstructure technology, microstructure devices, etc., can solve problems such as time-consuming, inability to obtain double-period ordered structure arrays, difficulty in controlling the size of silver branches, etc., to achieve The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The concrete steps of preparation are:

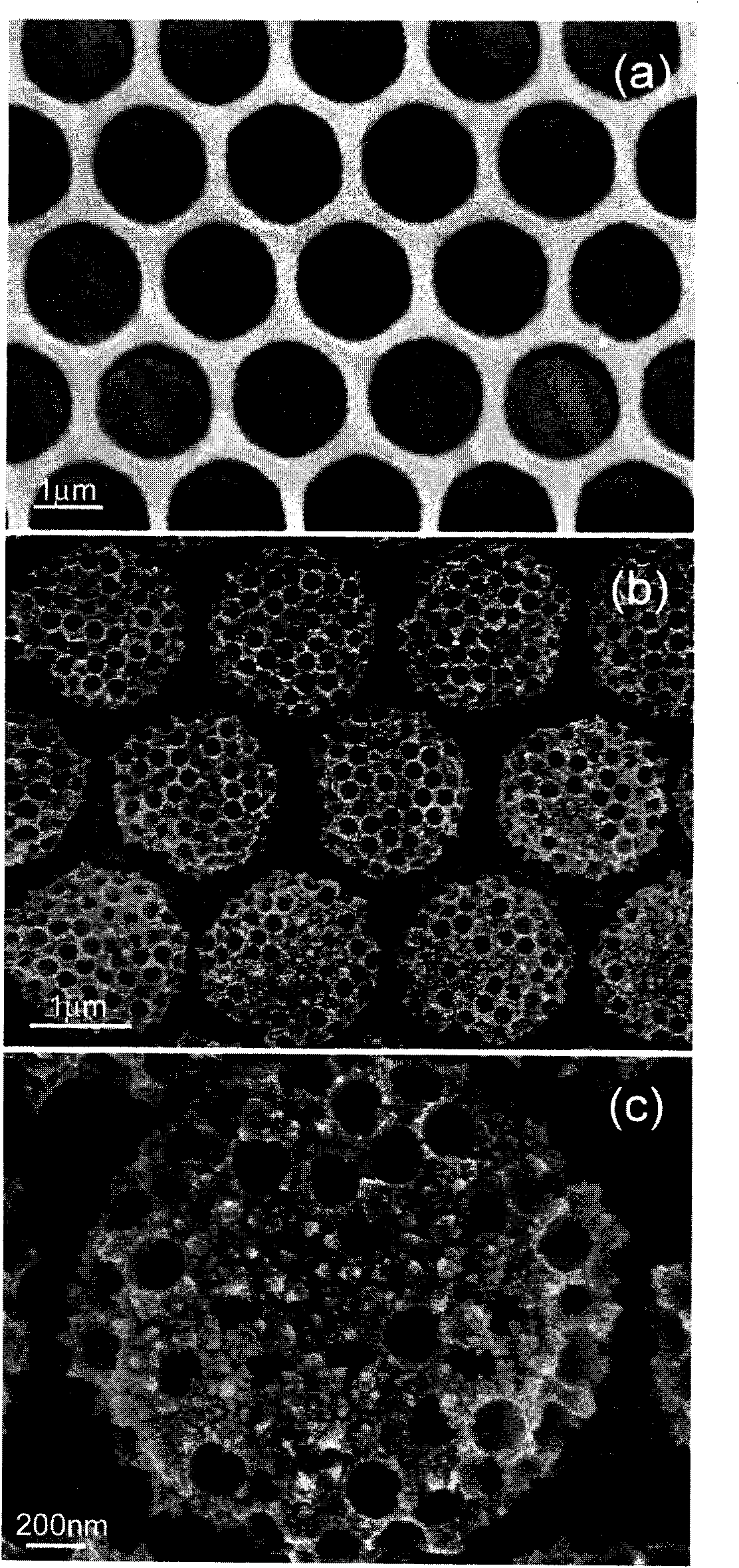

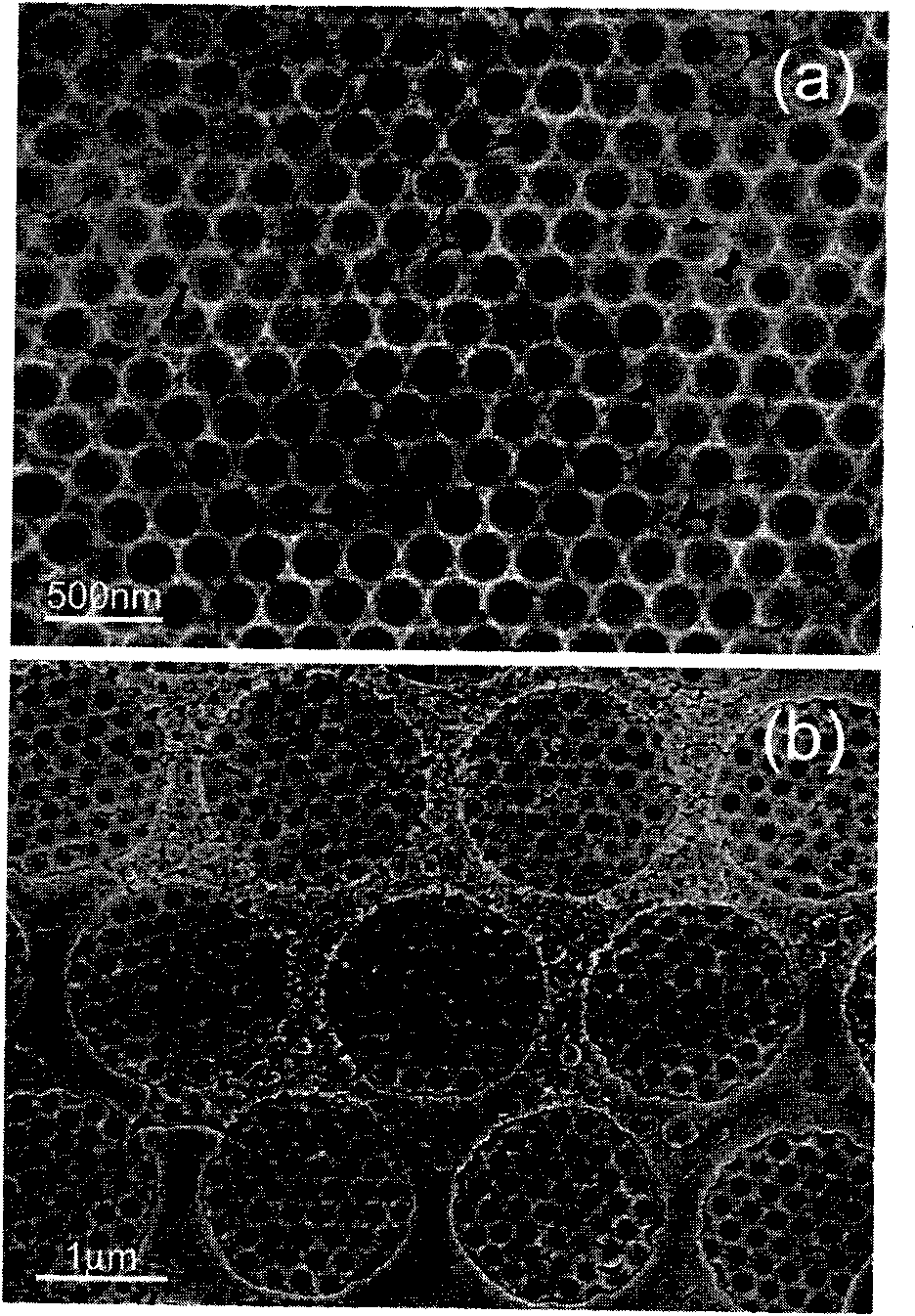

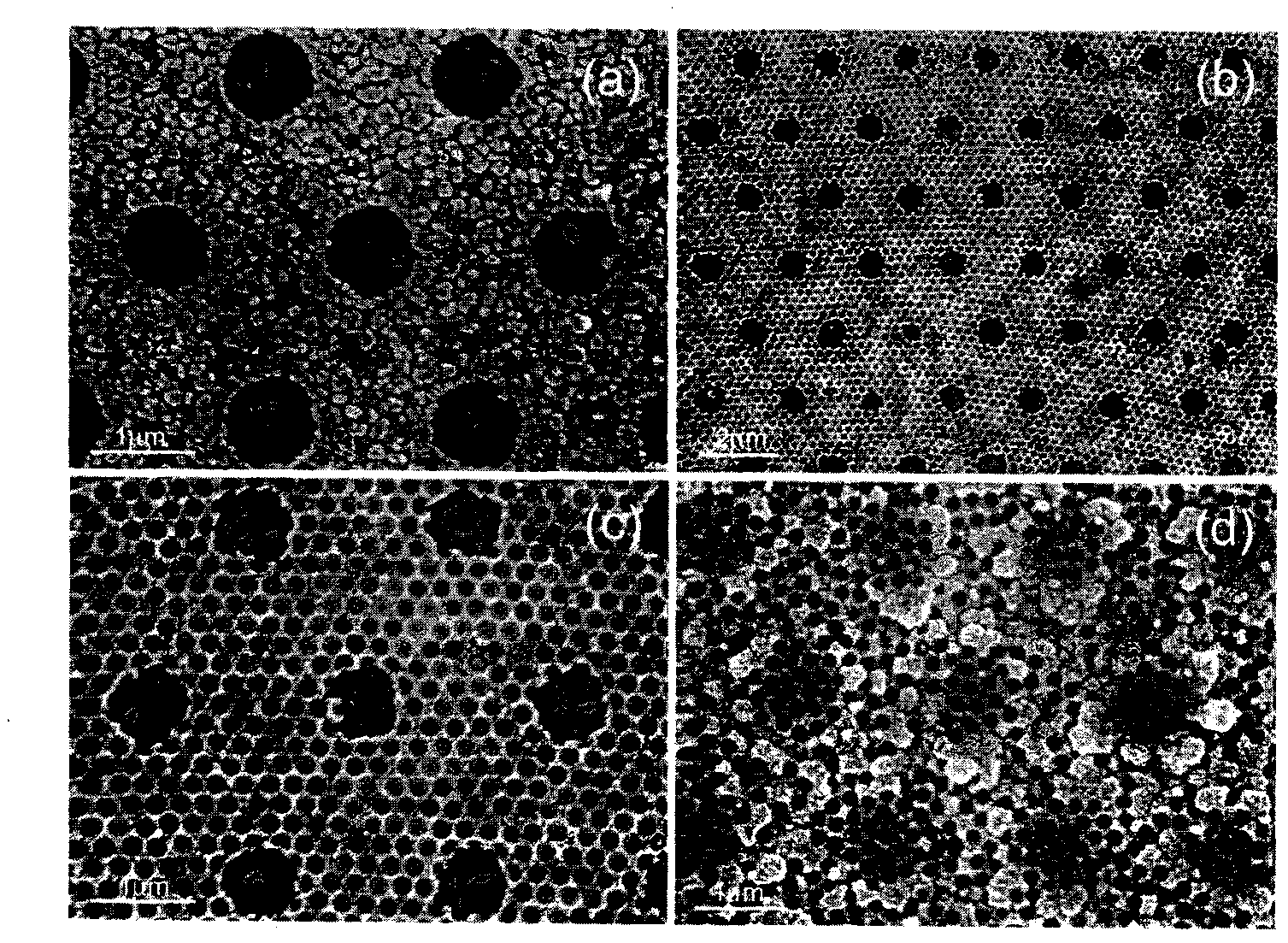

[0029] First place the conductive substrate with a single-layer colloidal crystal template with a spherical diameter of 1800nm on it and heat it for 18 minutes at a temperature of 80°C, then drop an aluminum nitrate solution with a concentration of 0.2M on it, and place it Rotate for 35 minutes at a rotational speed of 100r / min; wherein, the conductive substrate is conductive glass. Next, it was first heated at 110°C for 1.2h, then immersed in dichloromethane solvent to remove polystyrene colloidal balls, and then heated at 140°C for 9h to obtain an approximate figure 1 a. Figure 4 a Al2O3 ordered hole array attached to a conductive substrate shown in II. Afterwards, polystyrene colloidal spheres with a diameter of 180 nm were self-assembled into the holes of the ordered hole array of Al2O3 by spin-coating method to obtain an approximate Figure 4 The complex array shown in aIII; wherein, the rotation speed of the conductiv...

Embodiment 2

[0035] The concrete steps of preparation are:

[0036] First place the conductive substrate with a single-layer colloidal crystal template with a spherical diameter of 1900nm on it and heat it for 17 minutes at a temperature of 90°C, then drop an aluminum nitrate solution with a concentration of 0.4M on it, and place it Rotate for 33 minutes at a rotational speed of 150r / min; wherein, the conductive substrate is conductive glass. Next, it was first heated at 115°C for 1.1h, then immersed in dichloromethane solvent to remove polystyrene colloidal balls, and then heated at 145°C for 8.5h to obtain an approximate figure 1 a. Figure 4 Al2O3 ordered hole array attached to a conductive substrate shown in aII. Afterwards, polystyrene colloidal spheres with a diameter of 190 nm were self-assembled into the pores of the Al2O3 ordered pore array by spin-coating method to obtain an approximate Figure 4 The composite array shown in aIII; wherein, the rotation speed of the conductive ...

Embodiment 3

[0042] The concrete steps of preparation are:

[0043] First place the conductive substrate with a single-layer colloidal crystal template with a spherical diameter of 2000nm on it and heat it for 16min at a temperature of 100°C, then drop an aluminum nitrate solution with a concentration of 0.6M on it, and place it Rotate at a rotational speed of 200r / min for 30min; wherein, the conductive substrate is conductive glass. Next, it was first heated at 120°C for 1 hour, then immersed in dichloromethane solvent to remove polystyrene colloidal balls, and then heated at 150°C for 8 hours to obtain the following: figure 1 a. Figure 4 Al2O3 ordered hole array attached to a conductive substrate shown in aII. Afterwards, polystyrene colloidal spheres with a diameter of 200 nm were self-assembled into the holes of the Al2O3 ordered hole array by the spin coating method to obtain the following: Figure 4 The composite array shown in aIII; wherein, the rotation speed of the conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com