Refrigeration equipment and positioning structure for assembling reinforcer on inner container of refrigeration equipment

A positioning structure and reinforcement technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve problems such as damage to other components, affect assembly and foaming, and inaccurate positioning of positioning structures, so as to achieve accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

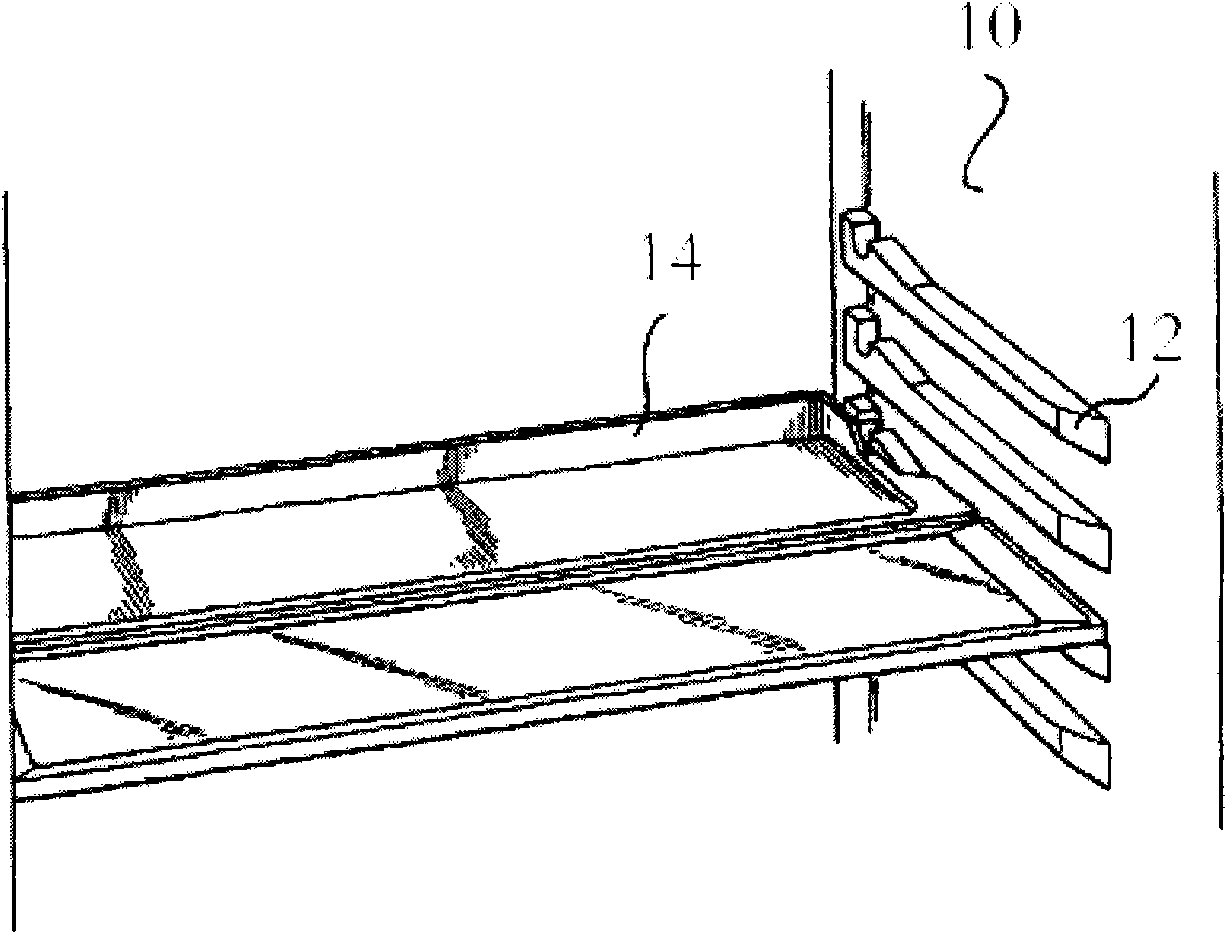

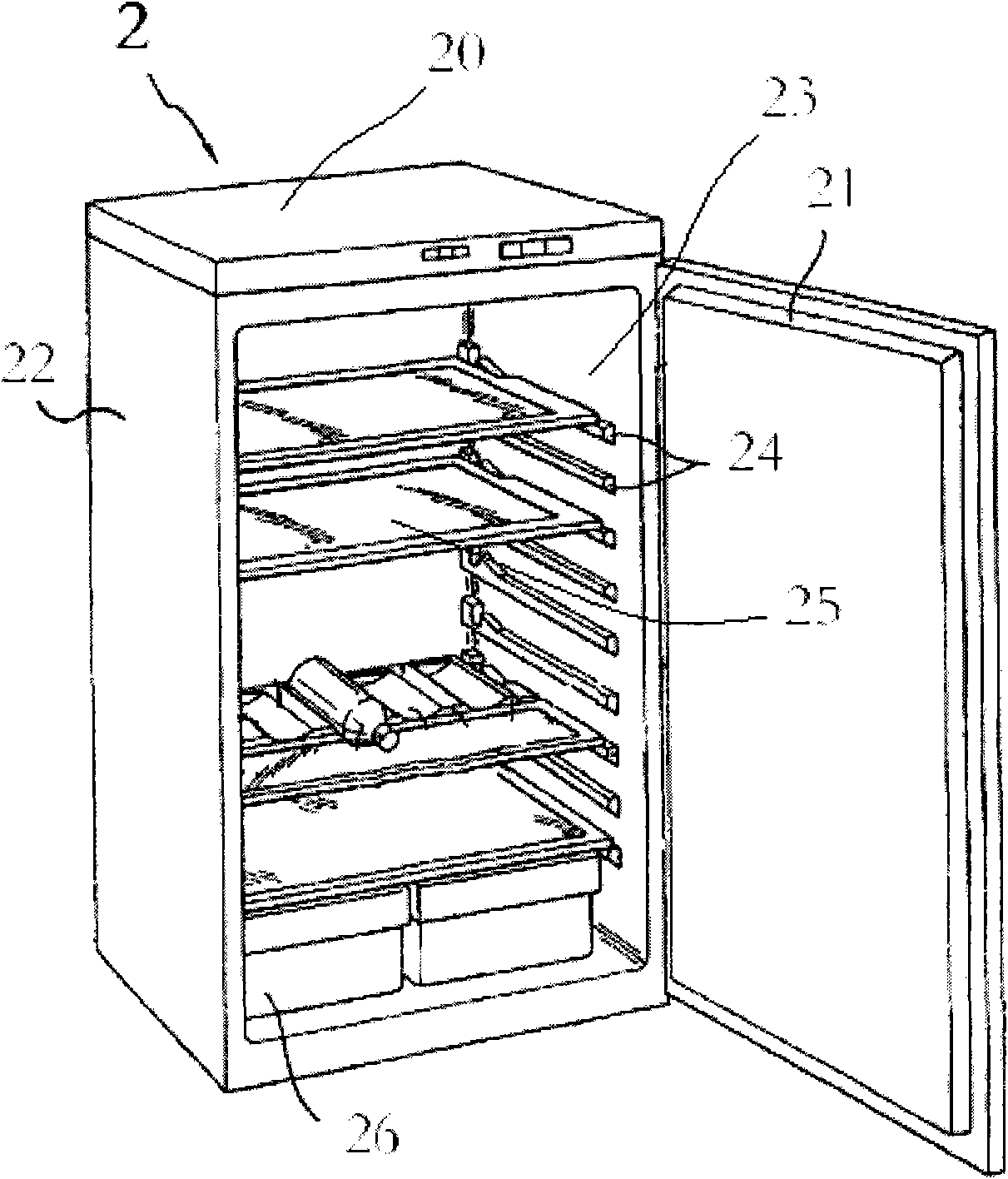

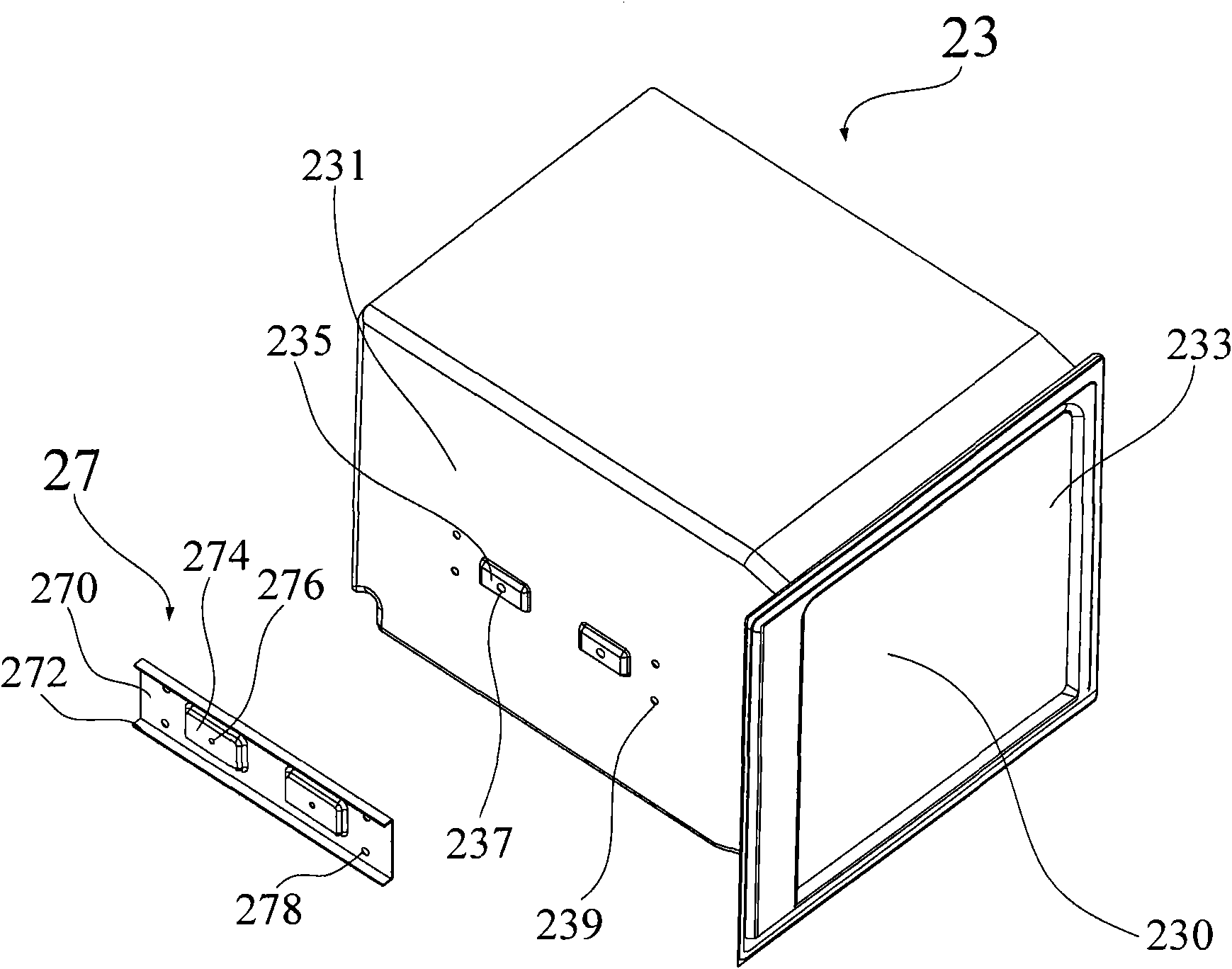

[0042] In order to accurately position the reinforcement 27 on the inner tank 23, the present invention particularly provides a positioning structure for assembling the reinforcement on the inner tank. Described positioning structure specifically comprises: be arranged on the side wall (left side wall 231 and the right side wall 233) of liner 23, the first limit boss 235 that is away from the inner wall surface of liner 23, be located at the first limit boss 235. The positioning hole 237 of the platform 235 is located on the main body portion 270 of the reinforcing member 27, away from the assembly surface of the reinforcing member 27, and the second limiting boss 274 that cooperates with the first limiting boss 235 of the liner 23 is located on the second limiting boss 274. Two limiting bosses 274, a boss 276 facing the assembly surface of the reinforcing member 27 and cooperating with the positioning hole 237 of the liner 23 (wherein for the second limiting boss 274 and the b...

no. 2 example

[0053] Please refer to Figure 8, Figure 8 It shows a partial cross-sectional schematic view of the second embodiment of the positioning structure for assembling the reinforcing member on the inner tank. Such as Figure 8 As shown, specifically, the first limiting boss 235 is formed by extending from the inner container 23, and is away from the inner wall surface of the side wall of the inner container 23; The boss 239 on the inner wall of 23 ; the second limiting boss 274 is formed by extending from the main body 270 and away from the assembly surface of the reinforcing member 27 ; the second limiting boss 274 is additionally provided with a positioning hole 278 . In this embodiment, after the first limiting boss 235 is matched with the second limiting boss 274, the protrusion 239 on the first limiting boss 235 is correspondingly inserted into the positioning hole 278 of the second positioning boss 274 When positioning, since the boss 239 is the inner wall surface away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com