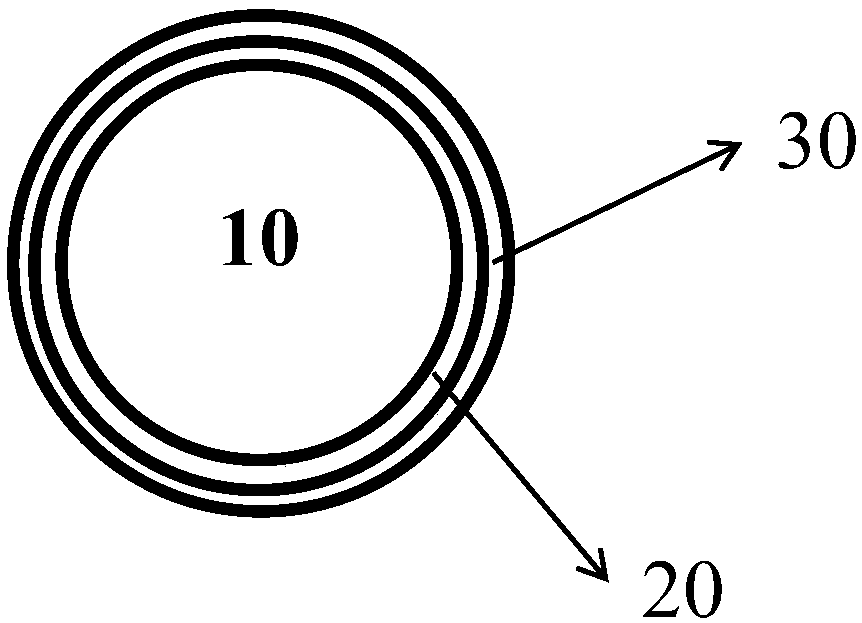

Three-layer core-shell structure positive electrode material, preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, structural parts, etc., can solve problems such as low capacity retention rate, fast decay of battery discharge capacity, unfavorable charge and discharge process, etc., to improve ion conductivity , the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] According to the above thinking, the preparation method of the three-layer core-shell structure cathode material of the present invention can be designed as the following experimental operation steps:

[0059] Step S1: Preparation of the precursor of the ternary positive electrode material: Weigh a certain amount of soluble Ni, Co, Mn salt, add it to the alcohol solution, and then add a certain amount of ammonium bicarbonate solution dropwise to the weak alkaline environment of the solution. Then put it in a reaction kettle for solvothermal reaction at 150-180° C. for 5-20 hours, and then filter and wash to obtain a ternary cathode material precursor.

[0060] Preferably, the soluble Ni salt is any one of nickel nitrate, nickel sulfate, and nickel chloride; preferably, the soluble Co salt is any one of cobalt nitrate, cobalt sulfate, and cobalt chloride; preferably, the soluble Mn salt It is any one of manganese nitrate, manganese sulfate and manganese chloride. Prefer...

Embodiment 1

[0077] In the three-layer core-shell composite positive electrode material of the present embodiment, the inner core is LiNi 0.6 co 0.2 mn 0.2 o 2 , the shell includes the interlayer Al 2 o 3 and outer Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 , where LiNi 0.6 co 0.2 mn 0.2 o 2 with Al 2 o 3 and Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 The mass ratio of is 50:1:1, and the preparation method of its core-shell structure comprises the following steps:

[0078] S1: Nickel cobalt lithium manganese oxide LiNi 0.6 co 0.2 mn 0.2 o 2 Preparation of precursors:

[0079] 109.620g nickel nitrate Ni(NO 3 ) 2 , 58.211g cobalt nitrate Co(NO 3 ) 2 ·6H 2 O, 35.790g manganese nitrate Mn(NO 3 ) 2 Add it to 700ml of butanol, and then add 1mol / L ammonium bicarbonate solution dropwise thereto until the pH of the solution is 10-12. Then place it in a polytetrafluoroethylene reactor for solvothermal reaction at 150° C. for 12 hours, and then filter and wash to obtain a positive electrode m...

Embodiment 2

[0085] In the three-layer core-shell composite positive electrode material of the present embodiment, the inner core is LiNi 0.6 co 0.2 mn 0.2 o 2 , the shell includes the interlayer Al 2 o 3 and outer Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 , where LiNi 0.6 co 0.2 mn 0.2 o 2 with Al 2 o 3 and Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 The mass ratio of is 80:1:1, and the preparation method of its core-shell structure comprises the following steps:

[0086] S1: Nickel cobalt lithium manganese oxide LiNi 0.6 co 0.2 mn 0.2 o 2 Precursor preparation: 109.620g nickel nitrate Ni(NO 3 ) 2 , 58.211g cobalt nitrate Co(NO 3 ) 2 ·6H 2 O, 35.790g manganese nitrate Mn(NO 3 ) 2 Add it to 700ml of isopropanol, and then add 1mol / L ammonium bicarbonate solution dropwise thereto until the pH of the solution is 10-12. Then place it in a polytetrafluoroethylene reactor for solvothermal reaction at 150° C. for 12 hours, and then filter and wash to obtain a positive electrode material pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com