CoAl-metallic oxide/carbon nano tube composite as well as preparation method and application thereof as ammonium porchlorate catalyst

A carbon nanotube, ammonium perchlorate technology, applied in metal/metal oxide/metal hydroxide catalysts, ammonium perchlorate compositions, physical/chemical process catalysts, etc. Collapse, poor particle dispersion and other problems, to achieve the effect of good catalytic performance and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

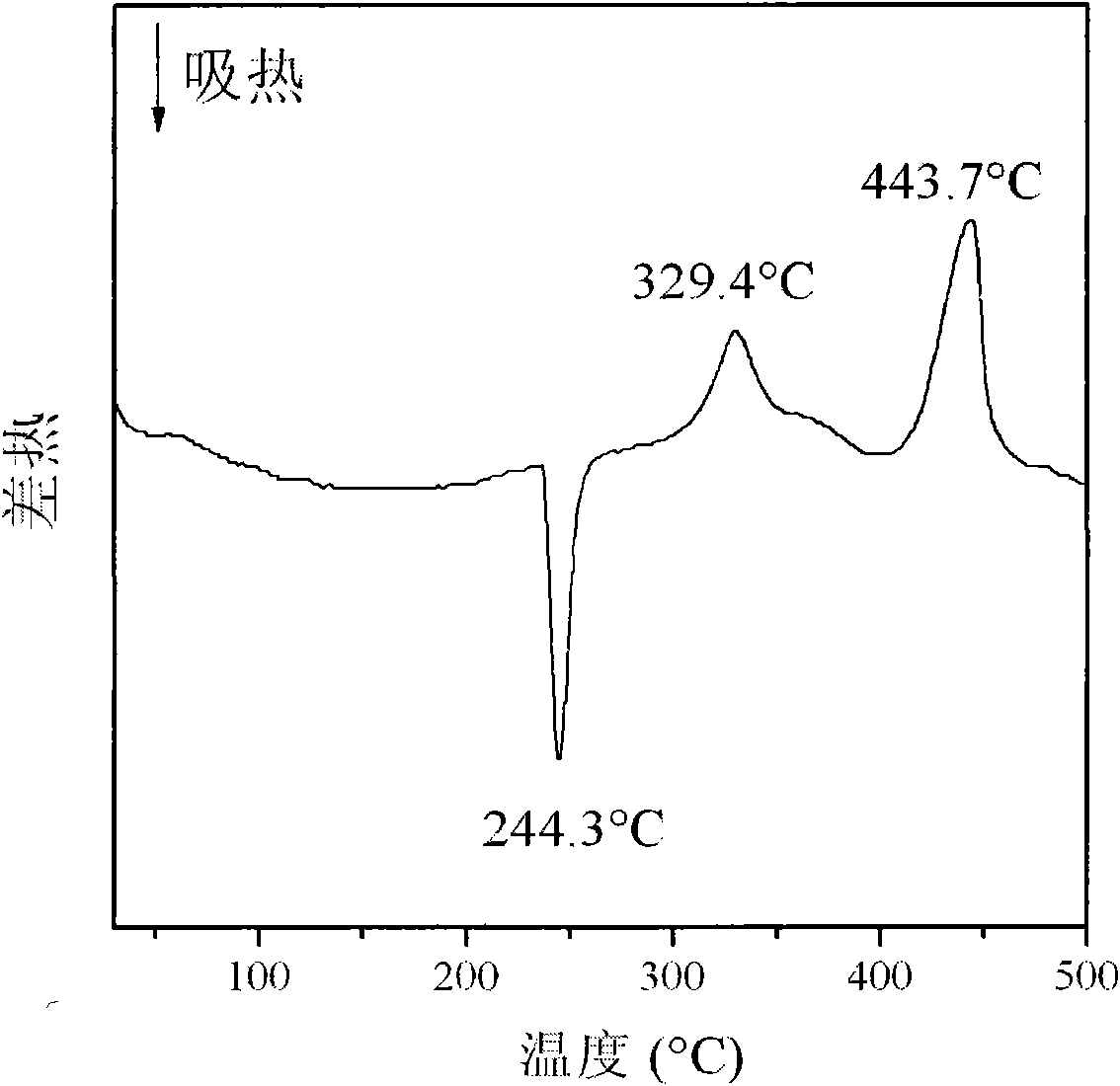

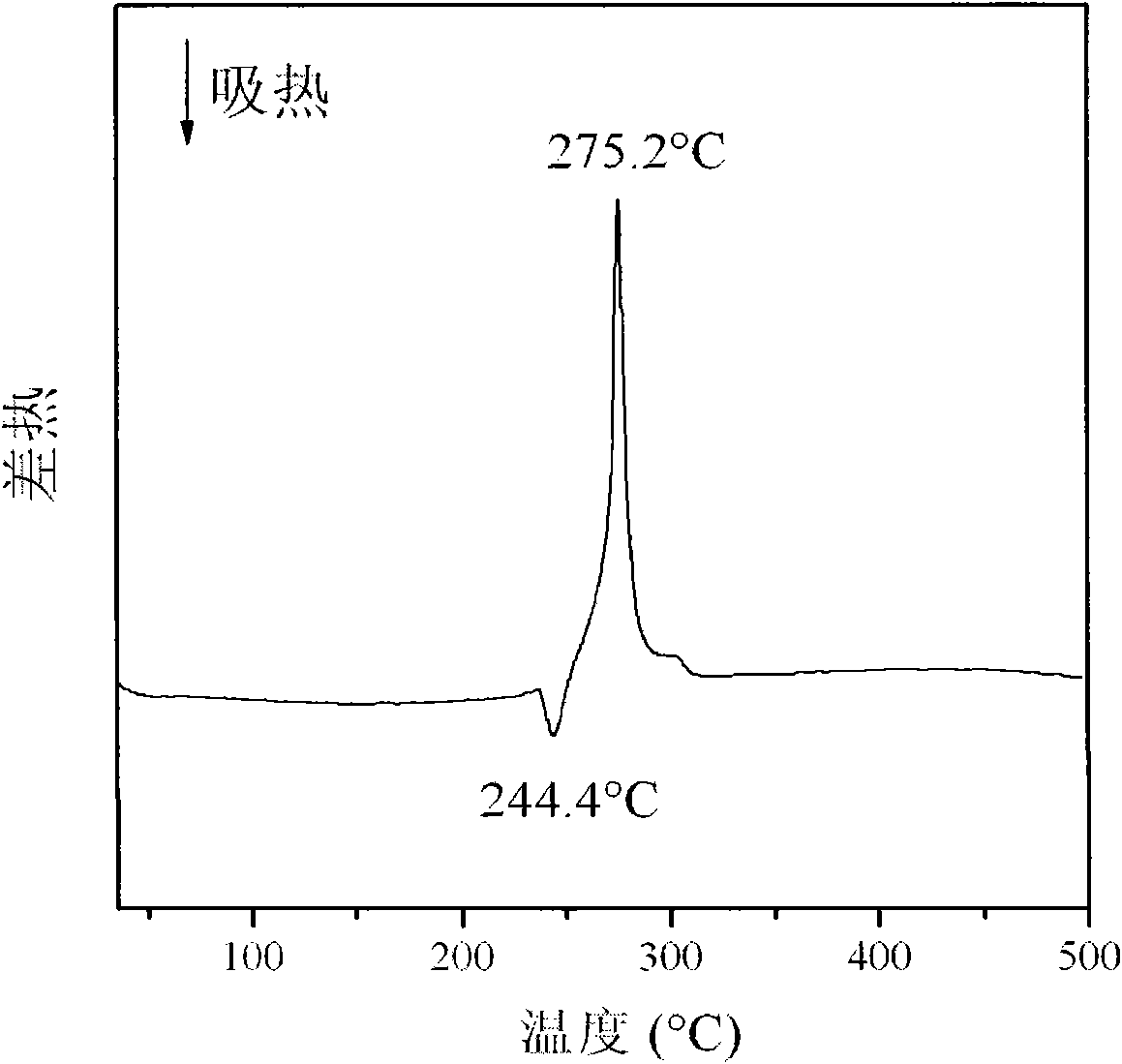

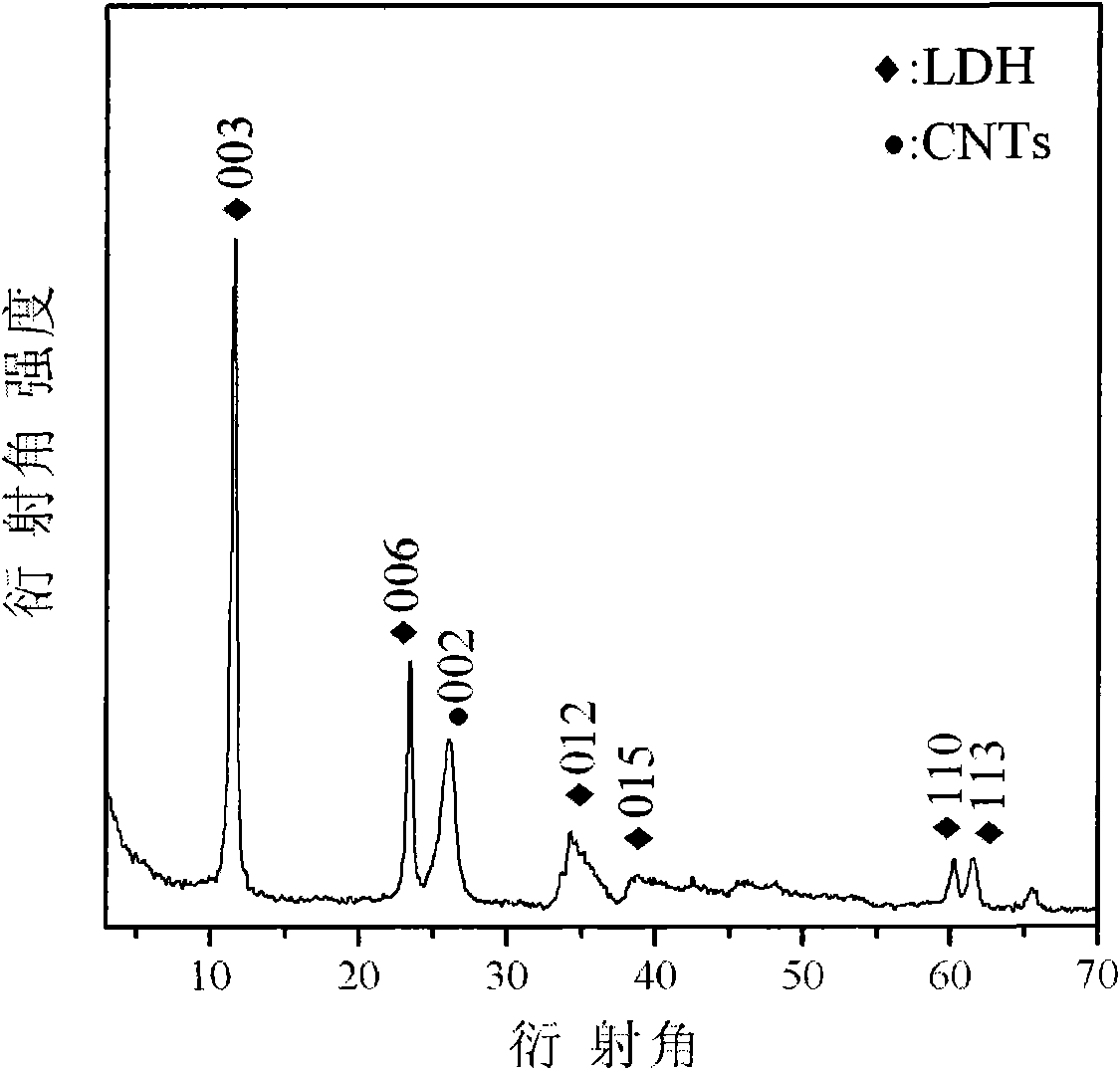

Examples

Embodiment 1

[0025] A. Weigh 4.3655g of Co(NO 3 ) 2 ·6H 2 O and 1.8756g of Al(NO 3 )3 9H 2 O was dissolved in 100ml deionized water to prepare Co(NO 3 ) 2 and Al(NO 3 ) 3 mixed salt solution, where Co(NO 3 ) 2 The concentration is 0.15mol / L, Al(NO 3 ) 3 The concentration is 0.05mol / L; Weigh 1.600g of NaOH and 1.0599g of NaOH 2 CO 3 Dissolve in 100ml deionized water to prepare NaOH and Na 2 CO 3 Mixed alkaline solution, wherein the concentration of NaOH is 0.40mol / L, Na 2 CO 3 The concentration is 0.10mol / L; another NaOH supplement with a concentration of 0.40mol / L is prepared with deionized water;

[0026] B. Add 1.5000g acid-treated carbon nanotubes, 0.9087g of L-cysteine and the above-mentioned 100ml mixed alkaline solution into the reaction vessel, wherein the concentration of carbon nanotubes in the solution is 15g / l, bridge Combined agent L-cysteine and Co(NO 3 ) 2 The molar ratio of the substances is 0.5:1, ultrasonically disperse for 30min, take 100ml of the a...

Embodiment 2

[0030] A. prepare several of same concentration and volume with embodiment 1;

[0031] B. Add 1.5000g acid-treated carbon nanotubes, 1.8174g of L-cysteine and the above-mentioned 100ml mixed alkaline solution into the reaction vessel, wherein the concentration of carbon nanotubes in the solution is 15g / l, bridge Combined agent L-cysteine and Co(NO 3 ) 2 The molar ratio of the substances is 1.0:1, ultrasonically disperse for 30min, take 100ml of the above mixed salt solution and add dropwise to the reaction vessel, and at the same time add NaOH supplementary solution dropwise, adjust the pH of the solution to 10.5, until the mixed salt solution is added dropwise, and then ultrasonically Disperse for 30 minutes, control the crystallization temperature to 60° C., and the crystallization time to 6 hours. The whole reaction is carried out under N2 atmosphere. Wash the filter cake with deionized water until neutral, and dry it in an oven at 60°C for 12 hours to obtain a CoAl-l...

Embodiment 3

[0037] A. Weigh 11.6412g of Co(NO 3 ) 2 ·6H 2 O and 7.5026g of Al(NO 3 ) 3 9H 2 O was dissolved in 100ml deionized water to prepare Co(NO 3 ) 2 and Al(NO 3 ) 3 mixed salt solution, where Co(NO 3 ) 2 The concentration is 0.40mol / L, Al(NO 3 ) 3 The concentration is 0.20mol / L; Weigh 4.8000g of NaOH and 4.2395g of NaOH 2 CO 3 Dissolve in 100ml deionized water to prepare NaOH and Na 2 CO 3 Mixed alkaline solution, wherein the concentration of NaOH is 1.20mol / L, Na 2 CO 3 The concentration is 0.40mol / L; another NaOH supplement with a concentration of 1.20mol / L is prepared with deionized water;

[0038] B. Add 2.0000g acid-treated carbon nanotubes, 4.8464g of L-cysteine and the above-mentioned 100ml mixed alkaline solution into the reaction vessel, wherein the concentration of carbon nanotubes in the solution is 20g / l, bridge Combined agent L-cysteine and Co(NO 3 ) 2 The molar ratio of the substances is 1:1, ultrasonically disperse for 30min, take 100ml of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com