Thin oil lubrication bearing device of motor for coal mine main ventilator

A thin oil lubrication and bearing device technology, which is applied in the direction of electromechanical devices, casings/covers/supports, electrical components, etc., can solve problems such as bearing temperature rise, high bearing operating temperature, and poor natural heat dissipation conditions, and achieve improved Operational reliability, improved sealing reliability, enhanced lubrication and cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

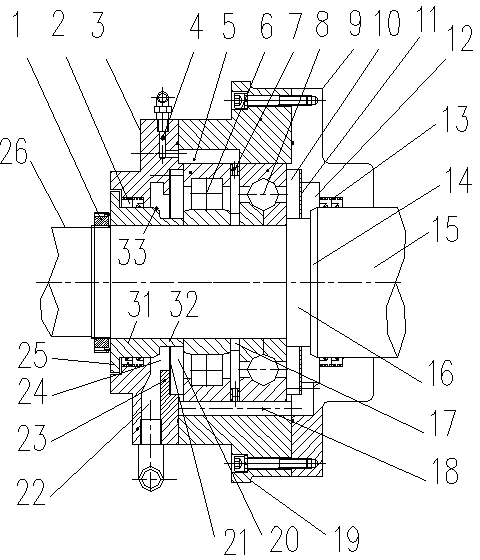

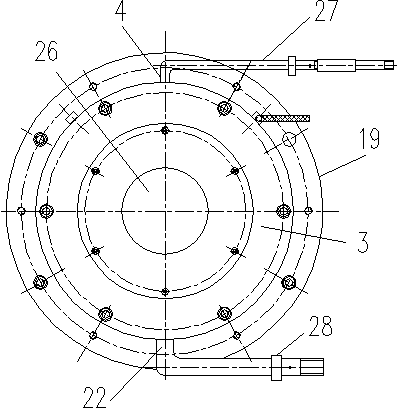

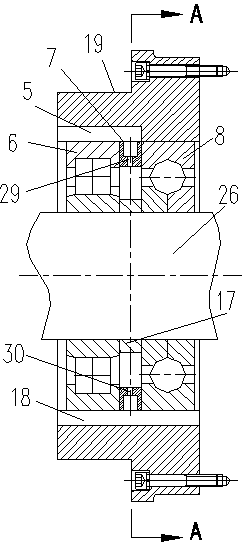

[0026] Depend on Figure 1-Figure 4 The thin oil lubricated bearing device of the motor for the coal mine main ventilator shown includes a rotating shaft, and the rotating shaft is provided with a front bearing cover 3, a first bearing 6, a second bearing 8 and a bearing rear cover 9 in sequence from front to back. The first bearing 6, the outer spacer ring 7 and the second bearing 8 are all arranged in the bearing seat 19, and the bearing seat 19 is sandwiched between the bearing front cover 3 and the bearing back cover 9, and the front end surface of the first bearing 6 and the bearing seat The front end face of 19 constitutes the joint surface of the front spigot, and the joint surface of the front spigot cooperates with the slit surface of the rear end of the bearing front cover 3 to form a spigot structure; similarly, the rear end surface of the second bearing 8 and the rear end surface of the bearing seat 19 Constitute the rear seam joint surface, the rear seam joint sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com