Steel for machine structural purposes for surface hardening use and steel parts for machine structural purposes and method of production of same

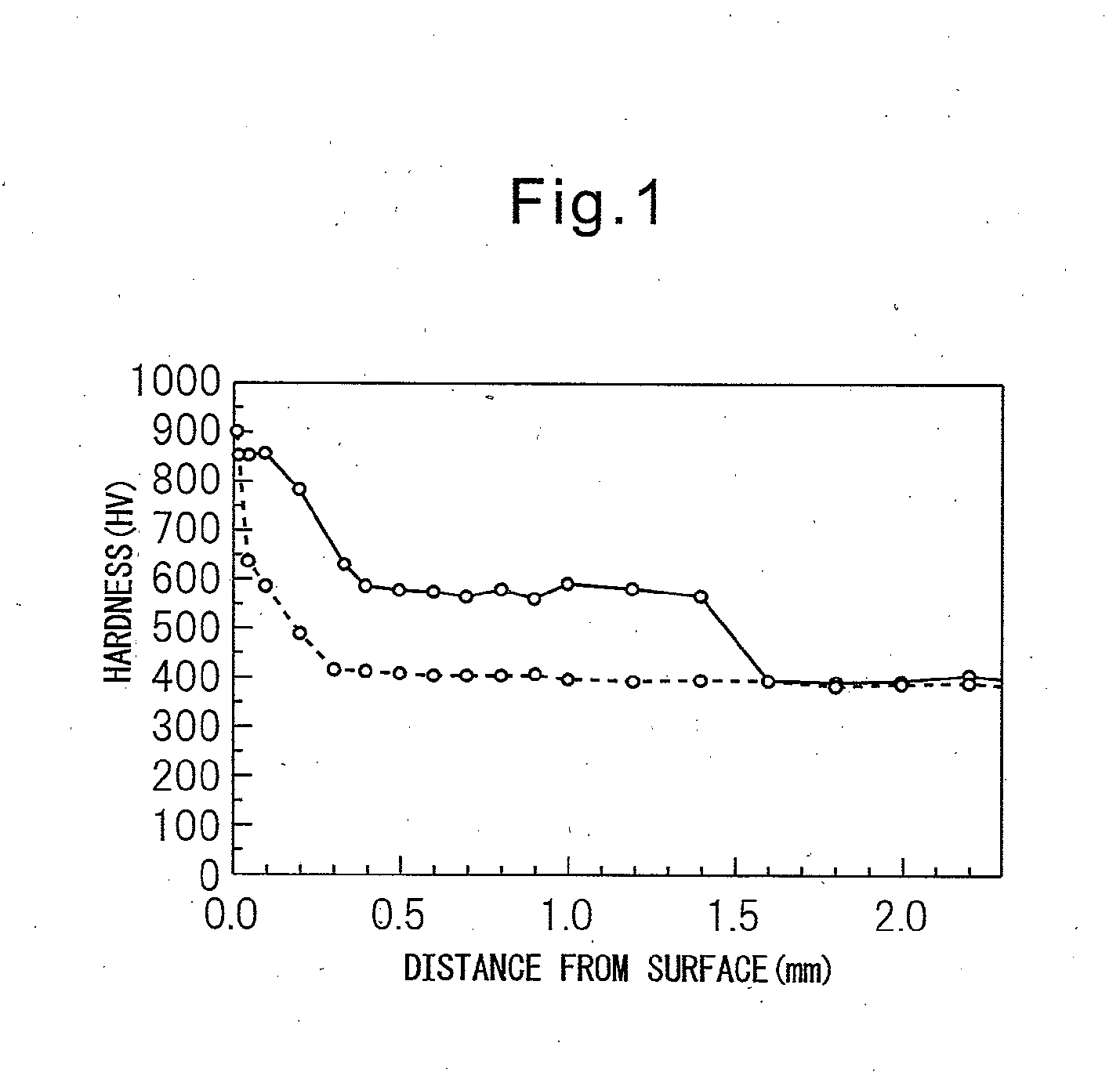

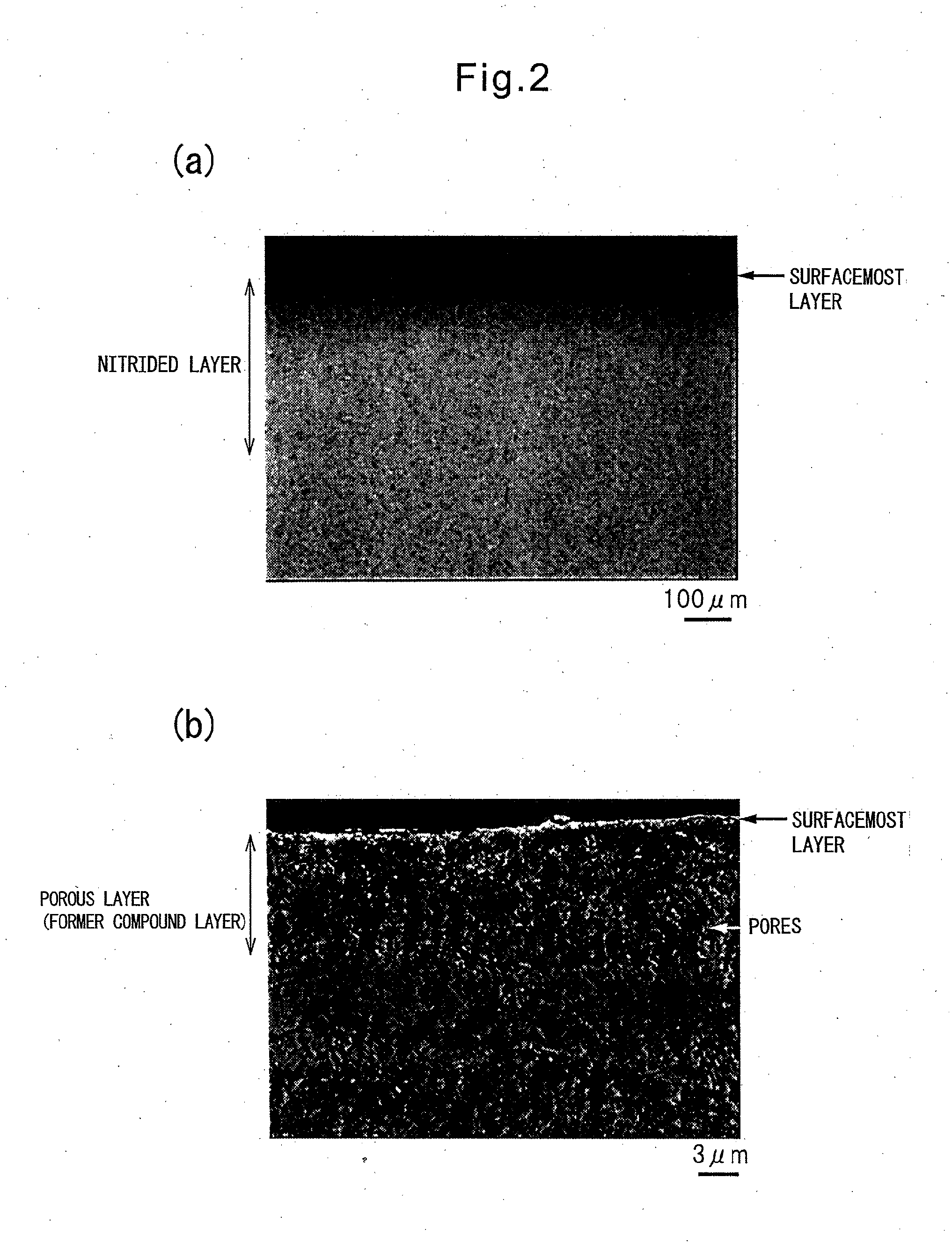

a technology of surface hardening and steel parts, which is applied in the direction of process efficiency improvement, solid-state diffusion coating, coating, etc., can solve the problems of crystal grain coarsening, inability to just increase the amount of c of steel materials, and increase the deformation of heat treatment (quenching distortion) due to crystal grain coarsening unavoidably, etc., to achieve excellent surface fatigue strength and corrosion resistance, high surface hardness, and high surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0209]Steel materials of the compositions of ingredients which are shown in Table 1 and Table 2 (continuation of Table 1) (invention examples) and in Table 3 (comparative examples) were produced.

TABLE 1Composition of ingredients (mass %)Ex.Steel no.ClassCSiMnPSAlCrSnONiCuNB1aInv. ex.0.350.250.880.0140.0070.1200.100.070.0010.010.010.00402bInv. ex.0.540.200.790.0150.0100.0300.110.100.0010.010.010.00393cInv. ex.0.571.350.810.0150.0110.0270.700.150.0020.010.020.00464dInv. ex.0.601.960.360.0140.0050.0350.120.030.0010.010.010.00490.00035eInv. ex.0.310.250.860.0090.0090.0691.200.250.0040.020.010.00426fInv. ex.0.550.051.450.0150.0060.2000.100.030.0030.010.030.00507gInv. ex.0.400.250.680.0020.0090.1261.850.400.0020.010.030.00450.00108hInv. ex.0.550.051.490.0120.0210.3000.100.040.0010.010.020.00460.00259iInv. ex.0.550.250.810.0150.0110.0300.100.050.0020.010.010.00410.000410jInv. ex.0.530.250.750.0140.0090.0200.150.040.0040.010.020.003411kInv. ex.0.550.200.880.0150.0120.0300.120.040.0030.020.0...

example 2

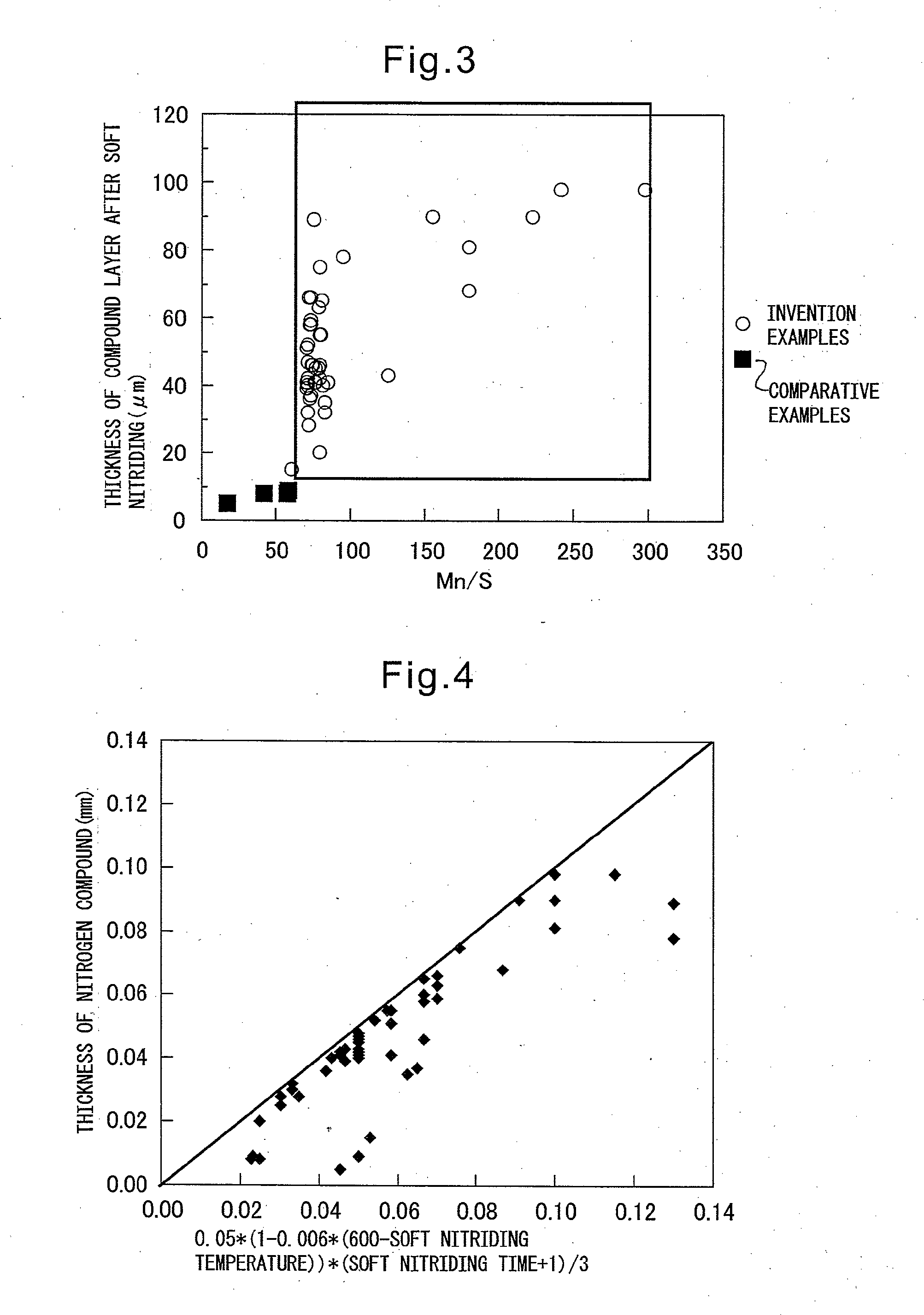

[0260]Even if the composition of ingredients of a steel material is in the range of the present invention, if the temperature and time of the ferritic nitrocarborizing do not satisfy the range of the present invention, the amount of penetration of N in the ferritic nitrocarborizing is insufficient and the durability is inferior.

[0261]Table 7 shows examples (invention examples and comparative examples). In the comparative example of Example 63, the ferritic nitrocarborizing temperature is low, so a sufficient thickness of a nitrided layer is not formed and the fatigue durability in a corrosive environment is insufficient.

[0262]In the comparative example of Example 64, the induction hardening temperature is less than 900° C., a sufficient hardness cannot be obtained, and the fatigue durability in a corrosive environment is insufficient. In the invention examples of Examples 7 and 9, the fatigue durability in a corrosive environment is sufficient.

TABLE 70.05 × {1 −Corrosion resistance0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com