Deburring tool for deburring of nonround contours of workpieces

A workpiece contour and deburring technology, applied in the field of deburring tools, can solve the problem of unsuitable deburring tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

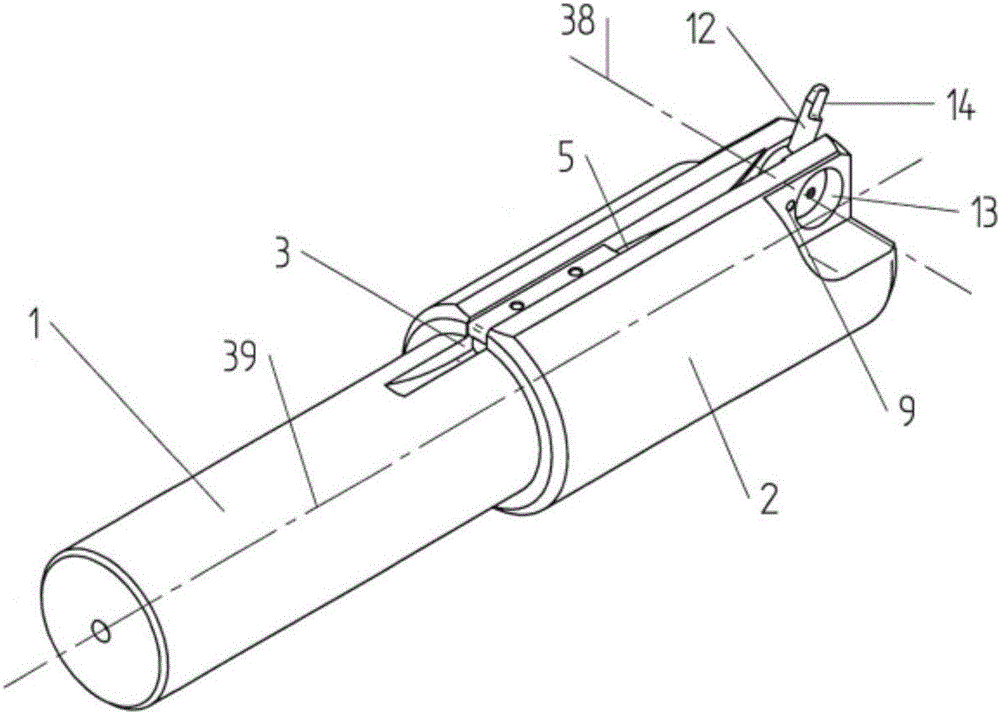

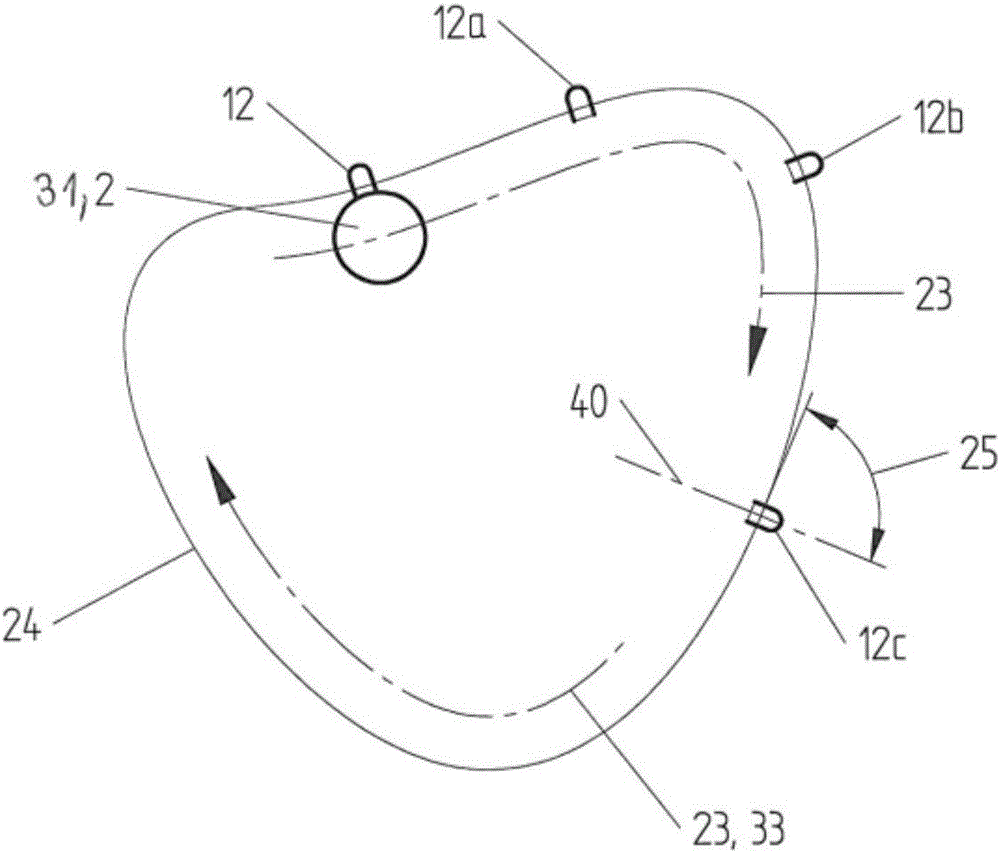

[0051] figure 1 The deburring tool according to the invention in , consists essentially of a cylindrical tool shaft 1 , to which a base body 2 is fastened in one or more parts. A longitudinal groove 3 is machined into the base body 2 on one side on the outer circumference of the base body 2 and extends from the rear part of the base body 2 to the front end face 37 .

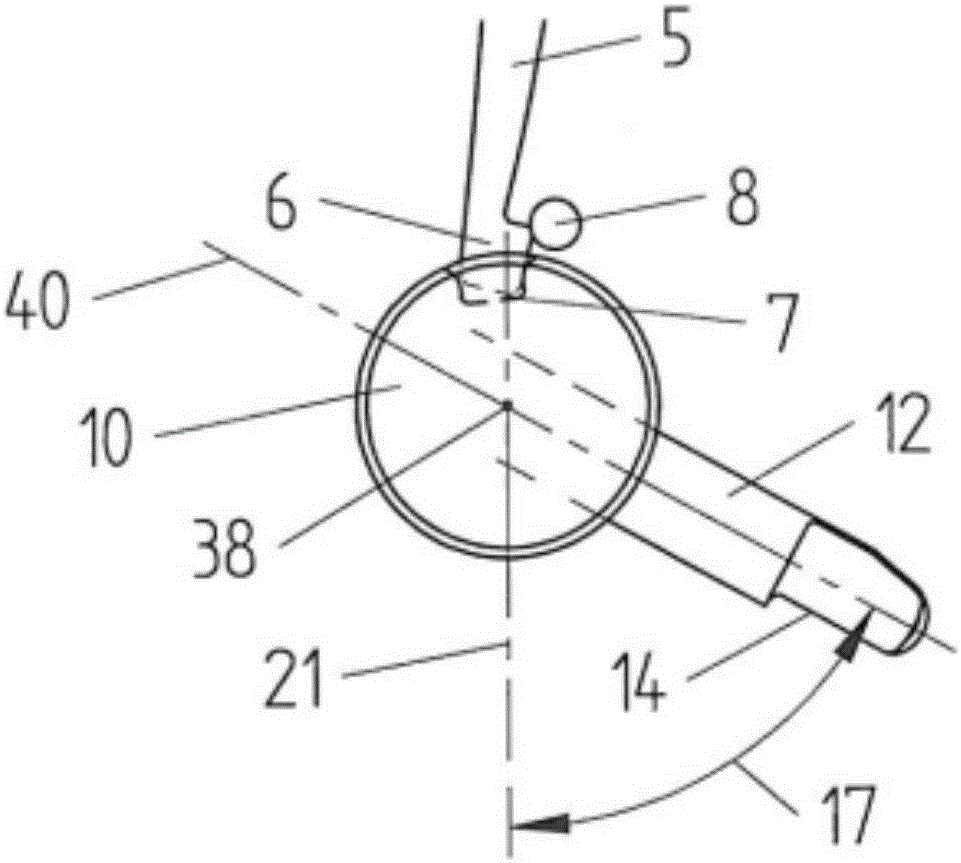

[0052] according to Figure 5 , clamped in the region of the longitudinal groove 3 is a bending spring 5 , the rear end of which is held by the clamping strip 4 . The clamping strip 4 is fastened in the region of the base body 2 by means of clamping screws 16 , so that the rear end of the bending spring 5 is clamped in the rear part of the base body 2 .

[0053] The free end of the front part of the bending spring 5 according to Figure 5 Engages in a radially deepened groove 7 machined at the outer circumference of the tool holder 10 and is immovably supported there.

[0054] Tool holder 10 of preferably cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com