Spinning device and spinning nozzle assembly used for the spinning device

A spinning device and component technology, applied in the field of spinning nozzle components, can solve the problems of inability to compensate for material fatigue, large operating force, etc., and achieve the effects of avoiding overload, avoiding excessive adjustment of spring preload, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

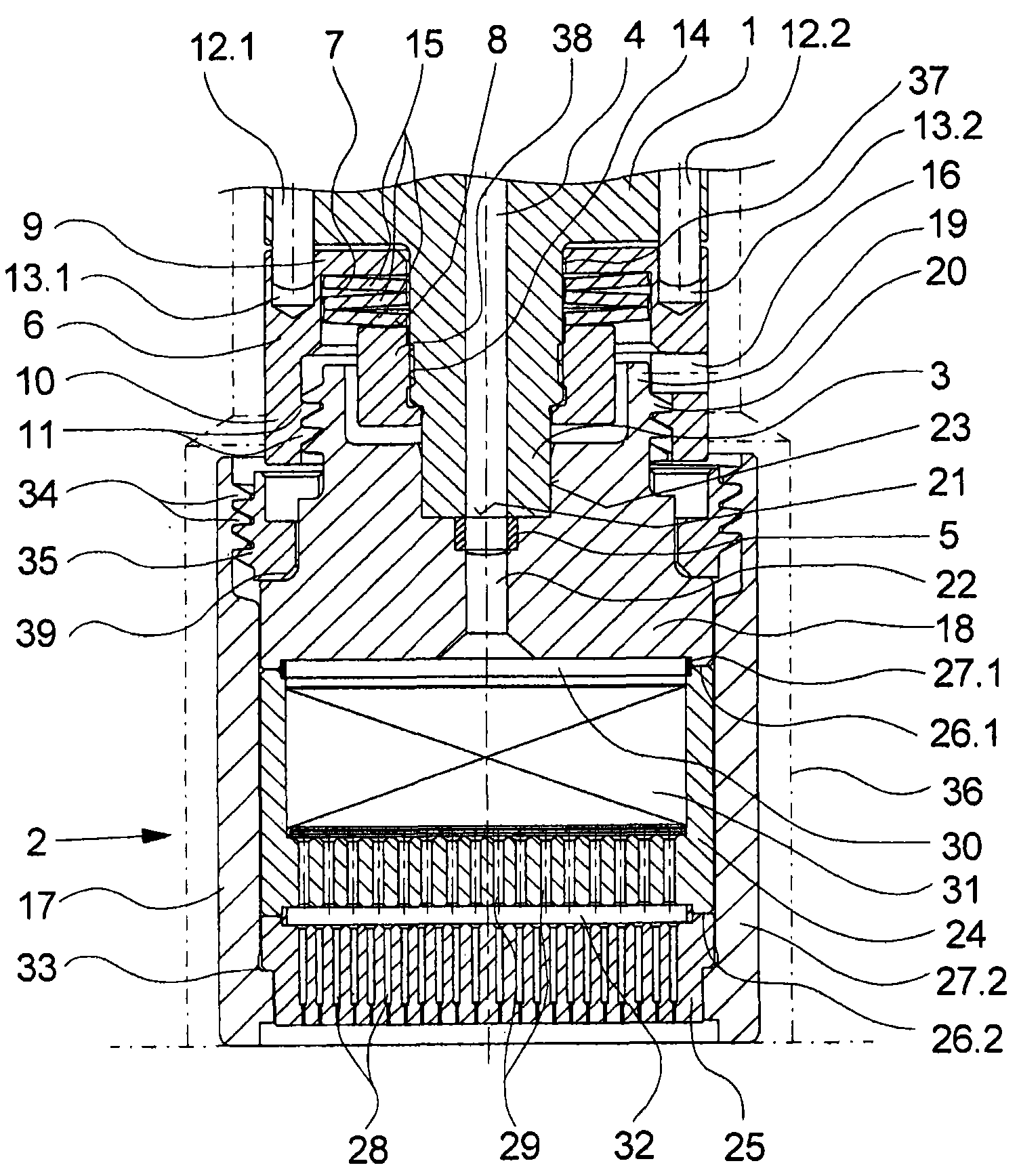

[0030] exist figure 1 A first embodiment of a spinning device according to the invention is shown in . This exemplary embodiment comprises a nozzle holder 1 with a cylindrically protruding melt connection 3 on its underside. In the present exemplary embodiment, the nozzle holder 1 is only partially shown. Typically, a plurality of nozzle holders are arranged side by side in a spinning apparatus to receive a plurality of spinning nozzle assemblies. For this purpose, the nozzle holder has nozzle receiving openings which are preferably dimensioned such that a spinning nozzle assembly held on the nozzle holder 1 is substantially surrounded by the walls of the nozzle holder. The nozzle holder has a heating element (not shown here), so that the spinning nozzle assembly is heated in the nozzle receiving opening via the wall of the nozzle holder 1 . exist figure 1The nozzle receiving opening 36 is indicated by dotted lines in .

[0031] The melt connection 3 on the underside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com