Dynamic adjusting device and method for pre-tensioning force of main shaft bearing of machine tool

A technology of bearing preload and dynamic adjustment, applied in computer-aided design, metal processing mechanical parts, large fixed members, etc., to achieve the effect of improving rotation accuracy and life, sensitive electromagnetic induction response, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

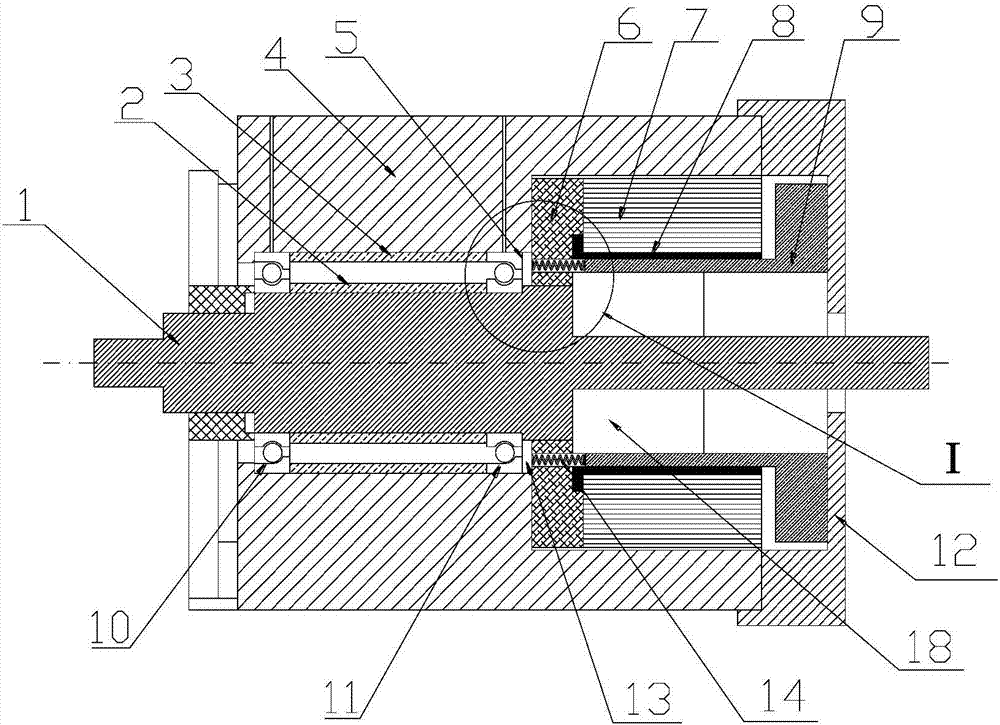

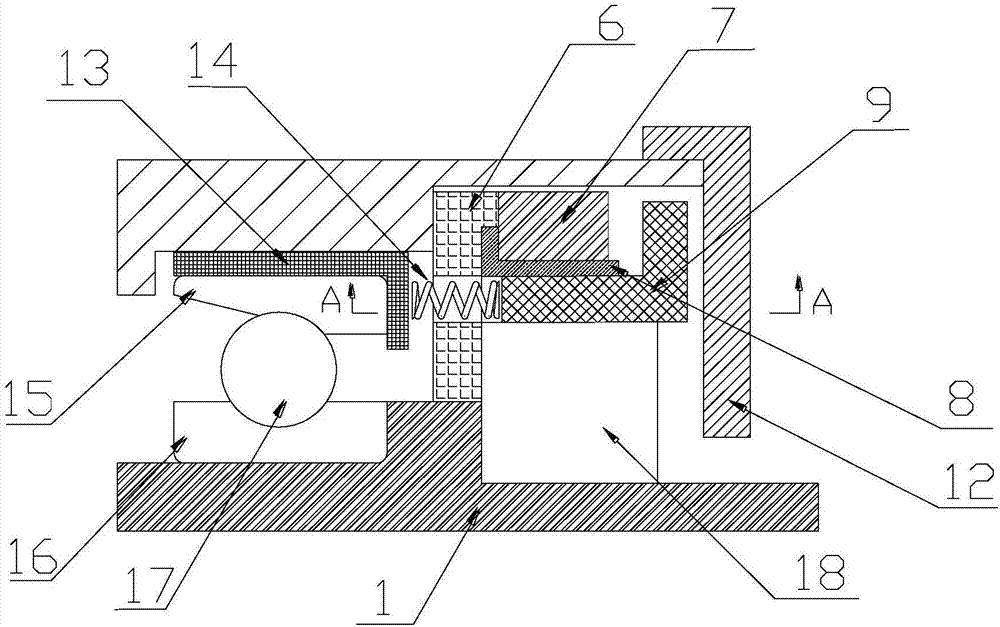

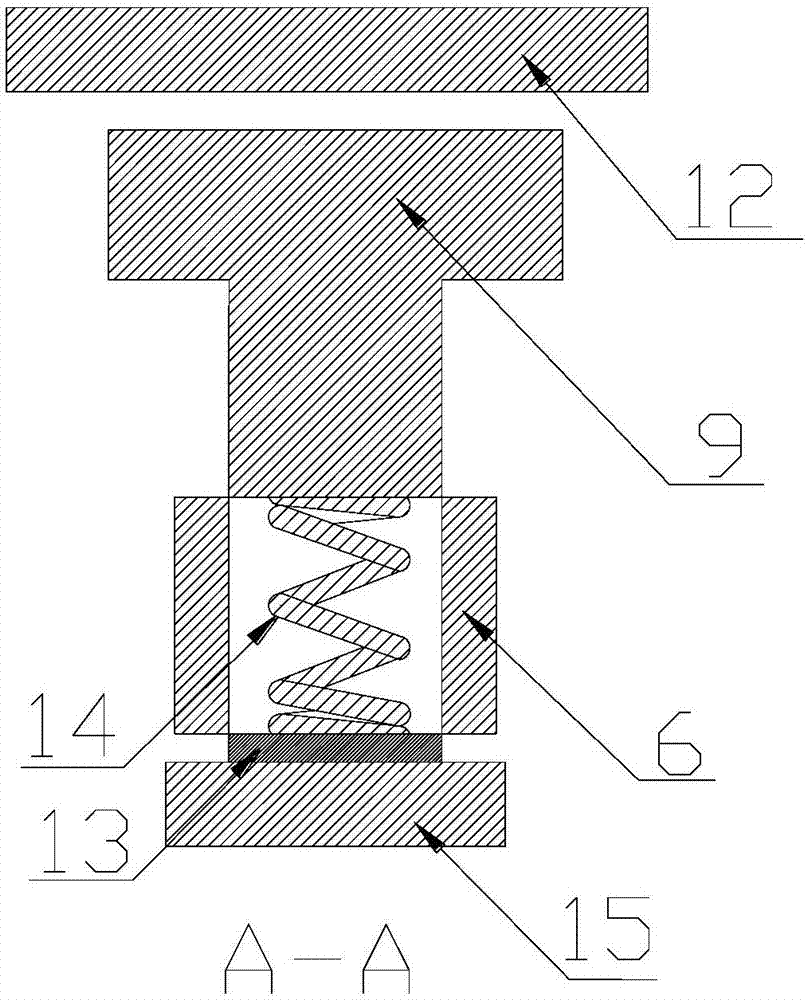

[0032] The invention provides a dynamic adjustment device for the pretightening force of the spindle bearing of a machine tool (see Figure 1-3 , referred to as the device), the spindle system includes a spindle 1, an inner sleeve 2, an outer sleeve 3, a housing 4, a front bearing 10 and a rear bearing 11; the front bearing 10 and the rear bearing 11 are a pair of angular contact ball bearings, Installed face to face in the middle of the main shaft 1 in the same direction, the inner sleeve 2 and the outer sleeve 3 are installed between the front bearing 10 and the rear bearing 11, the inner sleeve 2 is in contact with the inner rings of the front bearing 10 and the rear bearing 11 respectively, and the outer sleeve The cylinder 3 is in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com